Hatz BEAM E4 Advance User manual

WARNING!

(~~)

An RIC Helicopter is not a toy.

(RIC

~2.I~EH=

8ee.!-

~H::,f~OI

Of'8LICf.)

A radio controlled helicopter is a technical machine, operating at high RPM and

velocity.

(.~t!~l'H,!IJlc

:2",.

:2§J~5::§'.

6!§ofe

JIJjlgJLICf.)

It requires specialized skill and knowledge

in

its assembly, operations and

maintenance.

(~Ei,

6!§.

~:AI';C*~

~DHMe

~\i11E!

JI~J2I

:A1~OI

B:;:>~LICf.)

It

is

the user's responsibility to assemble, operate and maintain it

in

a safe manner,

without endangering the user or others.

Because the manufacturer has

no

control over its assembly, operation and

aintenance, the user assumes full responsibility for any and

all

claims, including

damages, bodily injury, death, or property damage, caused

by

the assembly,

operation and maintenance, whether negligence

is

present or otherwise.

(M*:AfLf

Cfe

MEi

011

Jil

~loHJf

JI:AI

eJ:2

2f~ofJiI

~JI~

~Ei,

6!§,

~:Zl.'r:*ofe

~g

fH~:Af~

:2igjgJLICf.

Ail~Me

~JI9-1

~Ei·.

6!§.

~:A1.'r:*0I1

2!()j~

*

:i'.!JI

[JI~OII

~JI~

~Ei,

6!§.

~:AI

';C*S'."f!Ei

\1i~ofe

~DH.

Mgj,

AHt!

ej]

§~

£~E!

(}iITiE!

~H~SO

Af*:Af~

-'!igjOlI

"'oVIl

~LlCf.)

By assembling, operating and maintaining the Beam

E4

Helicopter, the user

or person assembling, operating and maintaining the Beam

E4

Helicopter

indemnifies and agrees to hold harmless Beam

Inc.

and any of its employees,

distributors, dealers and agents from any and all claims asserted based on the

manufacturing, quality, assembly, operation and maintenance

of

the Beam E4

Helicopter. (Af*:AIJI

~

E4

~JI~

~Ei,

6!§.

~:AI.'r:*~

~Cfe

~g

~

Af~

J:!*2!,

*gJ~.

~c~.

::::OH~OI

gJ

E4

~JI~

Ail~.

~~.

~Ei.

6!§.

~:AI.'r:*'i'1

2!~i\H

(}i[iEl

~H~~:;:>~

;!igjSO

:AI:AI

PJ

1§

011

§~~~

9-IOI~LICI.)

Because of the potential for harm, the utmost care must be used

in

its assembly,

operation and maintenance, as one would with its full-scale counterpart.

It

is imperative that the user read these instructions carefully and understands

the associated danger of such occurrences as fire, bodily injury, death and

property damage.

woH9.J

~1~OI

£15::'='.S'.

fi<t!~§~JI~

~Ei.

6!§.

~:AI';C*OIle

~Ail

~JIOII

B:;:>£Ie

~:ilf

Of~Jf:Al§'.

e

"'?9-IJf

.2:;:>~LlCI.

Af*:Zfe

~~M~

Ail~of)1I

~:AIDHO~2fof[Jj

~JI'i'I

2!~DH

:2.IAH.

~DH.

Mg,>,

AW~9-1

e~:ilf

gg

~~Ol

'§j(}i'§t * £1Cfe

2j~

~~DHO~

gLlCfj

If for any reason you cannot agree or comply with the information contained

herein, return this product

in

saleable condition accompanied by a receipt within

1 year of purchase

to

the distributor below and your money, less and shipping

and handling fees will

be

refunded.

(Ol~~

LH*OII

§9.Jof:A1

§!'oft!Cfe! All§

:;:>OH

1~

OILHOII

2J*g:ilf

B>ml:;:>gJ

Ail§§

OIJH*

~EH

:::lOIS'.

OfcH

JIAH§

'1"gJx~OII

'2!~ofAIe!

~H§tll~

Ail'i'lE!

:;:>gJJf~~

§cl-,=cl1:l!i3L1Cf)

- 1 -

------

---

----

---

Table ofcontents

(~xf)

• Warning!

(~:L2)

.....•..............

1

~._---

• Table

of

contents

(~~f)

2

1.

Safety guidelines for the RIC helicopter (RIC

~2.1

§E1~

8:3!

JfOIEO) 3

1-1. Before a flight

(~I~m

3

1-2. During the flight

(~I~AI)

4

1-3. After the flight

(~I

~~)

4

2.

Tools needed & Additional items

(~~0I1

!!i£(~

'i:-T'2f

JIEf

§~)

5

3.

Assembly

(;;:;;~)

6

• Read before assembly

(;;:;;~:3!

;:;;~Af~)

6

3-1. Frame 7

3-2. Rotor

11

3-3. Gear 16

3-4. Tail 17

3-5. Etc.

21

4. Pitch and Throttle setting

(DHI2f

~£~

~~)

24

4-1. Pitch Range setting

(lIl~1

2(

~~) 24

4-2. Suggested RPM

of

the main rotor

(OII'2J£Ej~

~~

RPM)

24

4-3. Pitch curve setting

(1II~1

7l~

~~)

25

4-4. Pitch curve settings on the transmitter

($~JI~

lIl:!:1

3j'::'

~~

:J2H~)

25

4-5. Throttle curve settings

on

the transmitter

(~~JI~

::':£~

7i.'::'.

{g~

:J2H~)

26

5.

Movement

of

Transmitter Sticks and the Heli

($~JI

~~:ilI

~JI~

§~)

27

6.

Checkup points before flying

(~I~:3!

EM)

28

---"

-

-_

..

_---

7.

Data Sheet, 120· CCPM

(A11

~

[jl

01

En 28

8.

Tracking adjustment

(§ClI'bi~

~~) 29

9.

Selecting motor pinions

(2Ej2f

lIILI2!

JI()j~

~~)

29

10. Parts List

(¥§

~~)

30

10-1. Frame 30

10-2. Gear, Swashplate 32

10-3. Rotor 34

10-4. Tail 36

10-5. Etc. 39

11. Option Part

41

--_

..

_------_.

-

-_._-

-_.-

12. Flybarless System 42

-

2-

IT]

Safety Guidelines for the RIC Helicopter (RIC

~2.I~E~~

£f~

)fOI~)

1.

Beginners should get guidance and supervision from experienced flyers.

2.

Fly only at approved airfields.

Do

not fly at school, residential area or near roads, railways and

power lines.

(oD18

2!~OIIAl'2!

~I@~CI.

~:ll!.

?~,

C;::5".

~~.

@c:!C':!

2xiOilAle

~CIAI

aleCI.)

3.

Make sure there are

no

other pilots flying with the same radio frequency

as

yours.

Interference can

be

very dangerous to all.

(~~~

?IlI4'5"

~I@ole

Ala'OI

2x1011

~eJ.:l

'iCf.<=AI

~'2!~Cf.

4.

Keep the helicopter at least 5-1

Om

away from the flyer for safety.

('2!C:!)jcle

~~

5-10MOI~

~AloiDt

tll@E!CI.)

5.

Do

not fly the helicopter behind

the

flyer himself.

(lO§AI

§!E:!~£

~JI~

~1@oIAI

aleCl.)

6.

Never fly near or above other flyers, spectators or cars.

7.

In

case of emergency, priority should be given to the safety of other flyers and spectators.

1-1. Before a flight

(~I@C:I)

1.

Make sure batteries

in

the helicopter and the transmitter to

be

fully charged before flying.

(~I~C:I

~JI2I

@t.lJI~

~HEicIJI

'2!~c:!01

901~eAI

~'2!E!CI.)

2.

Do

a range check ofthe radio before the first flight. The radio should work at least 20 meters

away from the helicopter with the transmitter antenna collapsed.

(?!~1@0I1

~Al

@t.I~~)jcl~

~'2!E!CI

~t.lJI~1

'2!ElILI~

~g

~EHOIIAl

~JI£'i'-Ei

~~

20m

~OI~

)jcIOiIAlC;::

~;\il~OI

~JIJI

~50HOIE!CI.)

3.

Inspect the helicopter thoroughly so that there are no missing or loose bolts.

Important checking points: linkages, rotor blades, motor, gears.

(~1@0I1

~Al

~JI~

Zf

'i'-'i'l~

~'2!011

~§JI

~~CI)jLI

UHj~AI

algAl

~'2!~Cf

iSH

~'2!

'i'-'i'l: [33IAI,

5"E1~21101-'=,

2Ei,

JIOI)

4.

If there

is

too much slops or breakage

in

the linkages, replace

it

with a new one.

The linkages should not

be

too loose or too tight and they just fit snugly.

5.

Carefully check that the rotor blades are not damaged or cracked, especially around

the hole ofthe blade holder. Check that the rotor blade

is

safely fastened.

(5"Ei~

All

2J

<5IJlI

~AloHA1

~ol,

5Cl

?~0I1

;:;01

~)jLl2~01

~~'2'I ~-'=AI

AH

5"85"

:il!!ie!CI.)

6.

Make sure the motor is fastened securely

to

the mount as

it

produces high degree

ofvibration.

(28e

~ol

PJg

~~§

~{!!01~5"

2EiJi

@t

:J:!2)901

~eAI

~'2!~CI.)

7.

Check that the servos operate smoothly and properly. (21 Al';:!JI

'i'--'=~JlI

;\1101£

§~oleAI

~'2!E!CI.)

Their malfunctioning may cause a loss of control that will result dangerous situation.

8.

Be

sure to keep the following sequences to turn

on

or

off

the power:

(C:I~~

~

[He

CI~

~Al~

[leCl.)

CD

When you start flying, turn

on

the transmitter first and then the heli.

® After flying, turn

off

the heli first and then the transmitter.

- 3 -

1-2. During the flight

(tJl~AI)

1.

We strongly recommend you to spend time

in

practicing the helicopter simulation program

before you fly the real model.

(2~~]1~

tJl~ol]1

~Oll

~

~IJI

AI~ClIOIC'1

!!~.:J~~

~;l:j

e!ecr']I~

l'!~~c'.)

This will get you confidence and will significantly reduce the cost of repair.

(OIi'JlI

~~~}'\i

UleOiI

[IE

*2.ltJlg~

3JlI

~~

-*

£.!CI.)

Keep practicing the simulation program and that will accelerate your learning curve.

2.

If you face any problem during the flight, force the heli down straight away.

(tJl~~OII

~AiIJ'

!§,~Ofe!

~AI

~IJI~

2011

~~AI~CI.)

3.

If there

is

other helis

in

the airfield, you are advised not to fly at the same time.

But if you really want

to,

make sure

to

check the radio frequencies

to

prevent interfering.

4.

In

case there are people or animals

in

the airfield, a flyer should pay special attention

to

these objects coming to him or the helicopter

as

the flyer usually occupy himself

in

the

flying only.

(1:J1~~0I1

CIE

Af~OILi

§~Ol

£.!~

f,l£f

OI~OI

]ImOI

CI]I2~:A1

~!;11crl

'?~~

]1~OlOI~CI.

~§:AI~

~]IOII~

2iUOI

~~9

Ol~~

@!

!:i'!:A1

,)"ol]IIDI§"OICI.)

1-3. After the flight

(tJl~~)

1.

Conduct a through inspection

on

the helicopter

to

insure

no

parts have come loose

or become damaged during the flight.

2.

Check the temperature of motor and battery.

(2Ei'?l

~HEi2.l~

g'Z.~

~~~CI.)

If they are too hot

to

touch, something goes wrong.

(OI~OI

LW

~Ji"i'~

]1;\jIOlI

~]I

~AilJl

£.!§~

~DI~[f.)

In

this case, you should find the problem and fix

it

before the next flying.

3.

Disconnect the battery from the speed controller.

If you leave the battery connected overnight, this will seriously damage the battery.

(t'!~]I~!;2Ei

~HEi2.1

Z:I'=!jEi~

lO"2.I~[f

.

.:J(jj~

~f,l"i'

~HEi2.IOII

~2{e!

2~~

'?JlI§CI.)

4.

When the helicopter has crashed, inspect,

in

particular, main rotors, tail rotors, main mast,

tail shaft, the flybar. and the feathering shaft.

If any part

is

damaged, it must

be

replaced with a new part.

(2~§

~gg

\:O!~AI

All

~g>?5'.

:ll2;\~lelCl.)

Do

not try to repair damaged or broken parts with glue.

The parts

in

the helicopter are under high stress due

to

vibration.

If parts fail during the flight, this will lead

to

a loss of control that

is

highly dangerous.

-4-

[:IJ

Tools needed & Additional items

(~~0I1

~Qe!

~-=jJ-2f

JIEf

~!:?,)

Tools needed

Socket Driver

Hex

Wrench Screw Driver

4)

Ball

Link Plier

(Small, Large) (5.5mm 2pcs)

(1.5mm,2.5mm) 7

/)

-_.#

..

,

~.

.~

_7

r

(/~

.--'-

//

~

c/

Ball

Reamer Pitch Gauge Gimlet (for canopy)

Long Nose Plier

_.----:>-

0,

....

~

~··-···-··

...•....

I··

/

//"/

~

..........

I

~/

l / ,

/ /

'-'-("

J

'/

~/

~

-~

~

~

C.A Glue Cutting Knife

Thread Lock Scissor

(Cyano Adhesive)

~

/7

-:-:;/1

~

~

~/

I~~/

I I

\(

.//

~/

l

..

//

I

~

Additional items

Transmitter

Motor

Receiver

Electronic Speed

Controller

Servo

Li-Po Battery

Gyro

Battery Charger

-5-

---------

---------

---------

-------

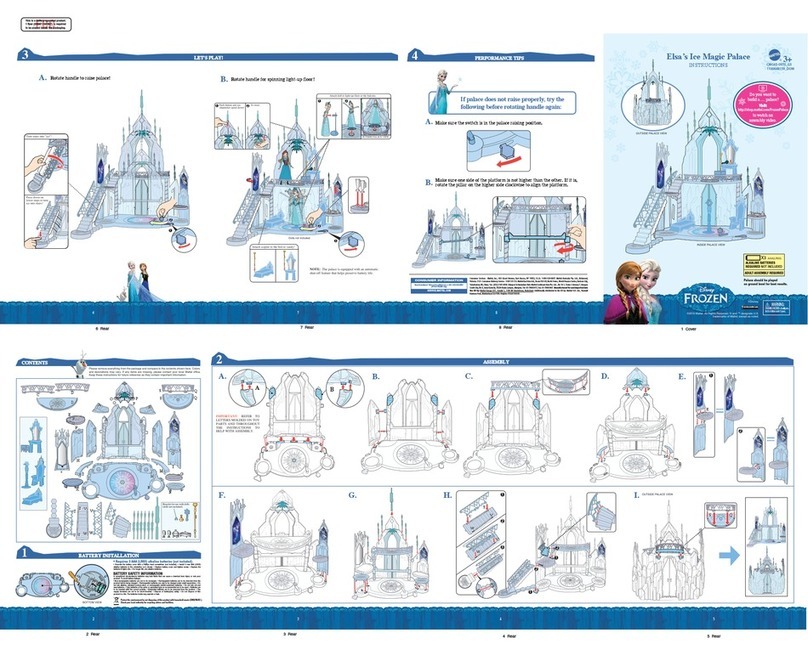

WAssembly

(~~)

• Read before assembly

(~iEJ~

-9-£IA~gj-)

1.

Before assembly, read the instruction manual thoroughly familiarizing yourself with

the model and assembly procedures.

2.

Check the contents of the box and make sure there is no missing part and all parts

are

in

good shape. After the packaging has been opened and parts have been used,

parts cannot be exchanged or returned.

(!;>{:'::2!~

LH~~~

~2!of:i}.

UUfl!

¥i§OI

~JiLf

3.

Tapping screws cut threads

in

the hole

of

the parts. When screws are difficult to tighten,

fasten the screw unit the parts

is

part

is

properly set. However, do not over-tighten

the screw to the point

of

stripping the threads or warping the part.

4.

Apply Locktite

(~EfOI§

Af~'iYtgj)

: Use Blue Locktite

(.:L1~JJI)

(Threadlock

on

all

screws)

~

:

Use

Red

Locktite

(~'?

.:L1~Jil)

~

: Use Cyano Adhesive glue (6:2f

~"um

5.

Check Rudder Servo Type

(em

Jd~

CI~)

~~---

l._

Micro

Rudder

Servo

(Nexus

DSW300

Series)

-r

I_".~~O

~

(Nexus

DSW600

Series)

\'"''''

R"dd"

s,~

I

I~?

~

..

~))(/

/~'

f:/

..

~

-

6-

I 3-1. Frame I

WJ

0

P""'9

P""'9

F_b::

::«-3

lTlTUlT

[flJ

~~~H

eeee

IT IT

IT

(UJ

@JJ

0== 0==

r=::Q:o:

) o

~~

-7-

~

Upper Bearing Block

@

[J:::::::::J

----- 2 pcs

Socket Head Bolt, 2x8mm

@

[J:::::J

------

2 pcs

Socket Head Bolt, 2x5mm

@0

.----

1 pc

Ball Bearing, #MR115zz

&.

Caution

@

IP

------ 2 pcs

Flat Head Bolt, 2x6mm

@

IP

-------- 2 pcs

Flat Head Bolt, 2x3mm

@ 0

---------

2 pcs

Ball Bearing, #MR52zz

Antirotation Plate

(1

pc)

Socket Head Bolt,

~

2x8mm

(2

pcs)

~

,.

~

:"'i'

"

~

...

/~

Socket Head Bolt,

Body Catch

-----------~,.

:

:/

.... 2x5mm

(2

pes)

(2

pcs)

,0

..

,~,Q

~

"~

Upper Bearing

------

~~~

:

Block

(1

pc) 0 :

((5)

Ball Bearing,

~

c::::r

#MR115zz

(1

pc)

[ill

Lower Bearing Block & Motor Mount

d Ball Bearing,

@0

-----

1 pc #MR115zz

(1

pc)

Ball Bearing, #MR115zz

~

Up

..L

IIaJaI

Up

..L

If?)

j;jl

&.

Caution

Mind the direction of

the Bearing Block.

Motor Mount

(1

pc)

Mind the direction of

the Bearing Block.

[ill

Belt Guide Pulley

~

~

n----

Flat Head Bolt, 2x6mm

(2

pes)

@,

Y®---Ball Bearing, #MR52zz

(2

pes)

H

--00--

Bot

Go;d,

Poll",

9.5

(2

Pc.)

+

~

Spacer, 3.5xO.7mm

(2

pes)

~

Crossmember, 30mm

(1

pc)

~"V

Pulley Support, 33mm

(1

pc)

~

Jr--

Flat Head Bolt, 2x3mm

(2

pes)

- 8 -

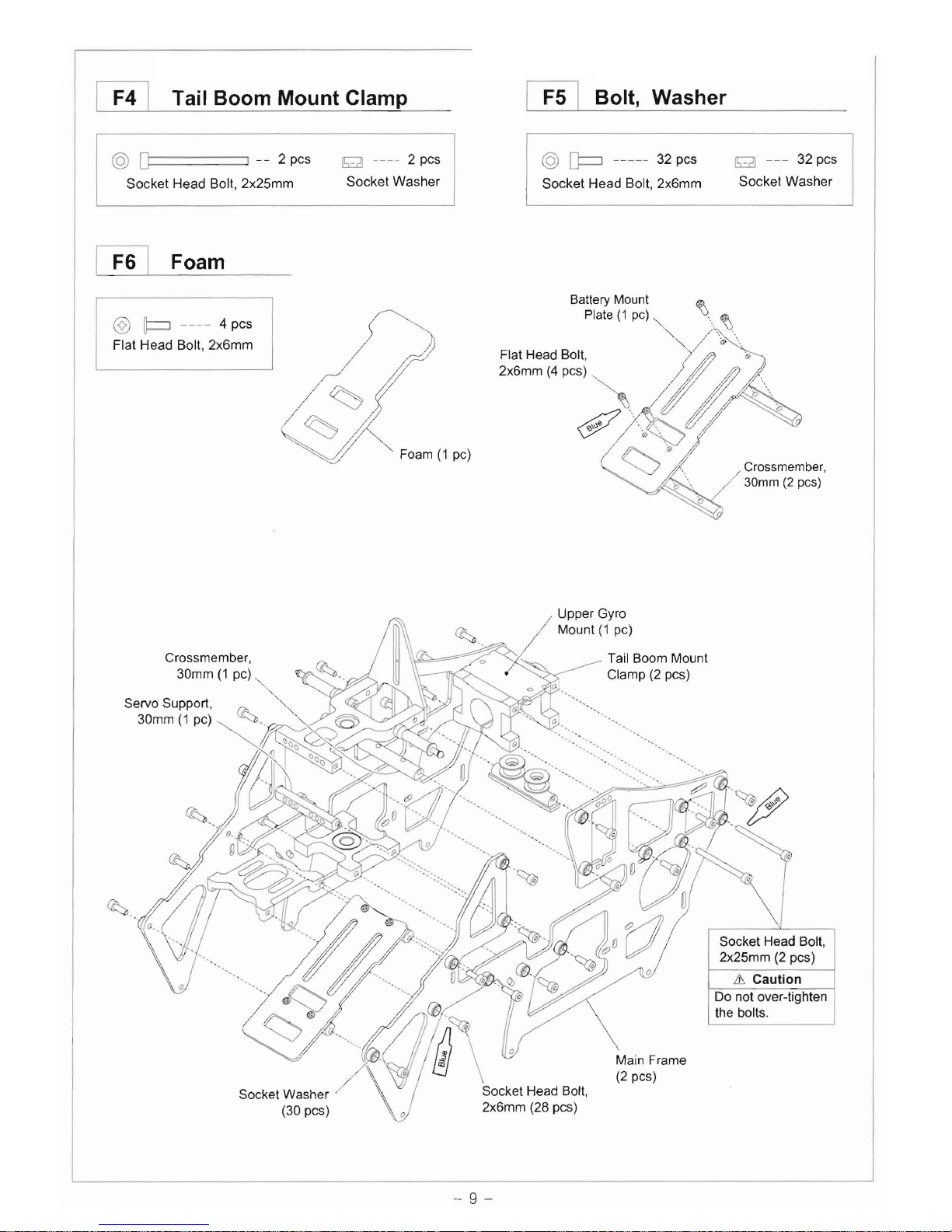

[£!J Tail Boom Mount Clamp

~

Bolt, Washer

@

[p

----- 32 pes g

---

32 pes

@ D i

--

2pes g

----

2pes

Socket Washer

Socket Head Bolt, 2x25mm Socket Washer Socket Head Bolt, 2x6mm

[£!] Foam

@ p ---- 4 pes

Flat Head Bolt, 2x6mm

Foam

(1

pc)

Battery Mount

Plate

(1

pc)

Crossmember,

30mm

(2

pes)

Upper Gyro

Crossmember,

30mm

(1

pc)

Servo Support,

rA

30mm

(1

pc)

~

~"

""-

~'

Socket Washer

(30 pes)

/ Mount

(1

pc)

\\a:,,==~::r-.<:-/

Tail Boom Mount

Clamp

(2

pes)

Socket Head Bolt,

2x25mm

(2

pes)

& Caution

Do

not over-tighten

the bolts.

Main Frame

(2

pes)

- 9 -

Self Tapping Screw,

2x7mm (4

pes)

Antenna Tube (L)

Landing Strut

(2

pes)

Socket Washer

(4

pes)

Socket Head Bolt,

2x8mm

(2

pes)

Socket Head Bolt,

I F7 -

Fal

Landing Skid & Main Frame Bottom Plate

@

~

------

4 pes @ p ------- 6 pes @

[p

------ 2 pes

SelfTapping

Screw, 2x7mm Flat Head Bolt, 2x6mm Socket

Head

Bolt,

2x8mm

Main Frame Bottom

Plate

(1

pc)

Antenna Tube (S)

Silicon Tube

$J

Landing Skid

(2

pes)

Landing Skid

~

P

Cap (4 pes)

'-0----

2x6mm

(4

pes)

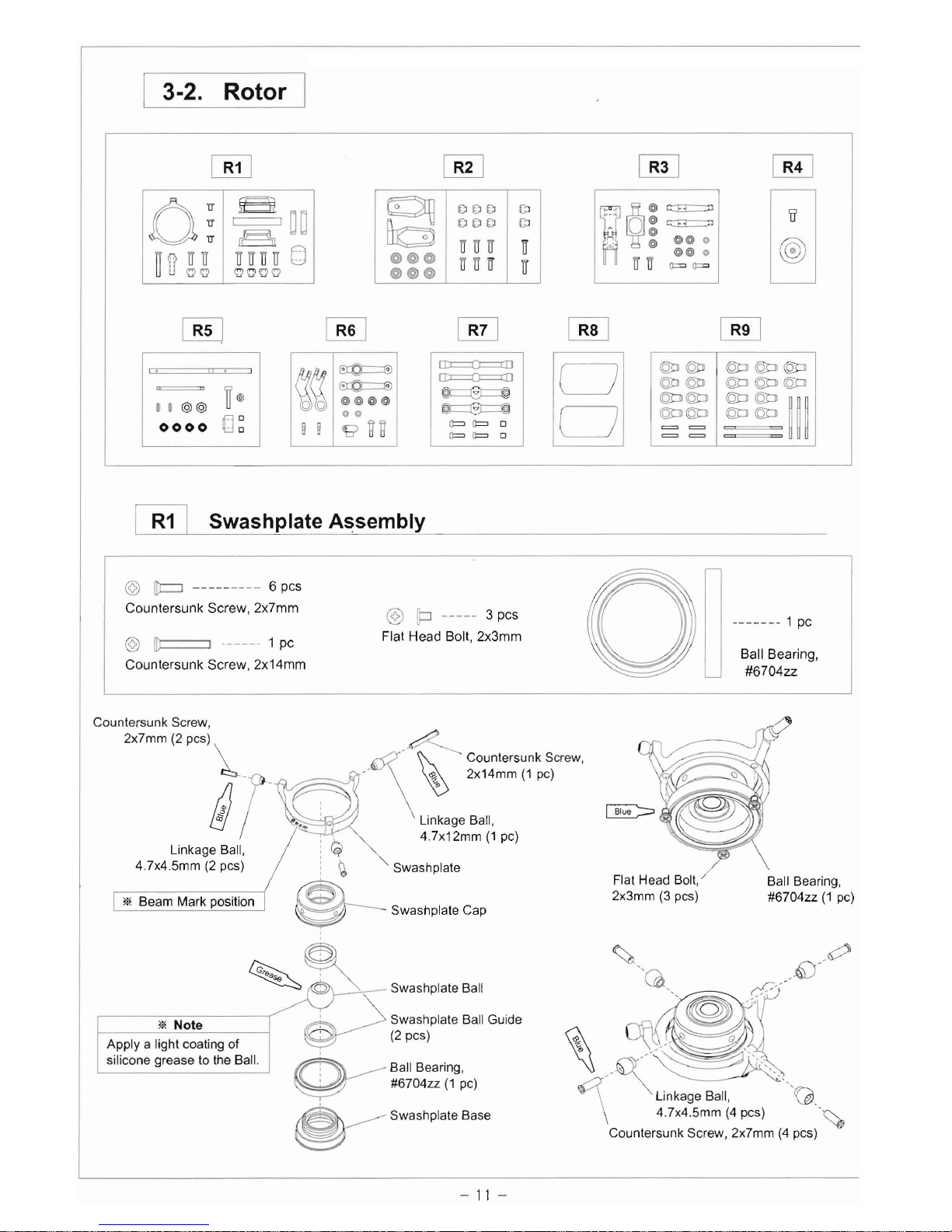

3-2. Rotor I

[ill

0:

g~~

r§

~

a

gg

UUUIT

[)

"''''''''''

~

i.

I

".

=

IT@

••

@@

00

0000

. 0

~

~~

ij ij

~

~

@@@@

00

~~

[B!J

~

~

~

DDD

GJ

0

DDD

GJ

UUIT

IT

@@@

@@@

ITITU

IT

"

O:~

'0' ;

@@

0

IRO

o =

@@

0

ITIT

==

~

[ill [ill

~

[D::::::::():::

[D::::::::():::

~

~

Q:= Q:=

0

Q:= Q:=

0 8

@:D @:D

@::li @::li @::li

@:D @:D

@::li @::li @::li

@::li@::li

@::li @::li

~~~

@::li@::li @::li @::li

==

==

[B!] Swashplate

A~sembly

@

[t=J

---------

6 pes

Countersunk Screw, 2x7mm @ [p

-----

3 pes

.------

1 pc

Flat Head Bolt, 2x3mm

@ [[t:::::=J .

--

-

-'

1 pc Ball Bearing,

Countersunk Screw, 2x14mm o #6704zz

Countersunk Screw,

2x7mm (2 pes)

~r

'~

~

~

Countersunk Screw,

~:2=:::::::;!v"

\

~

2x14mm

(1

pc)

~

. Linkage Ball,

4.

7x12mm

(1

pc)

Linkage Ball,

:~

4.7x4.5mm

(2

pes) !

~

Swashplate Flat Head Bolt, Ball Bearing,

2x3mm

(3

pes)

#6704zz

(1

pc)

* Beam Mark position

~

Swashplate Cap

Swashplate Ball

Swashplale Ball Guide

(2

pcs)

Apply a light coating of

~

silicone grease to the Ball.

0---

Ball Bearing,

~

~

#6704zz

(1

pc)

~

Linkage Ball,

'Vi>.

\ 4.7x4.5mm

(4

pes)

.~

~

Swashplate Base Countersunk Screw, 2x7mm

(4

pes)

* Note

-

11

-

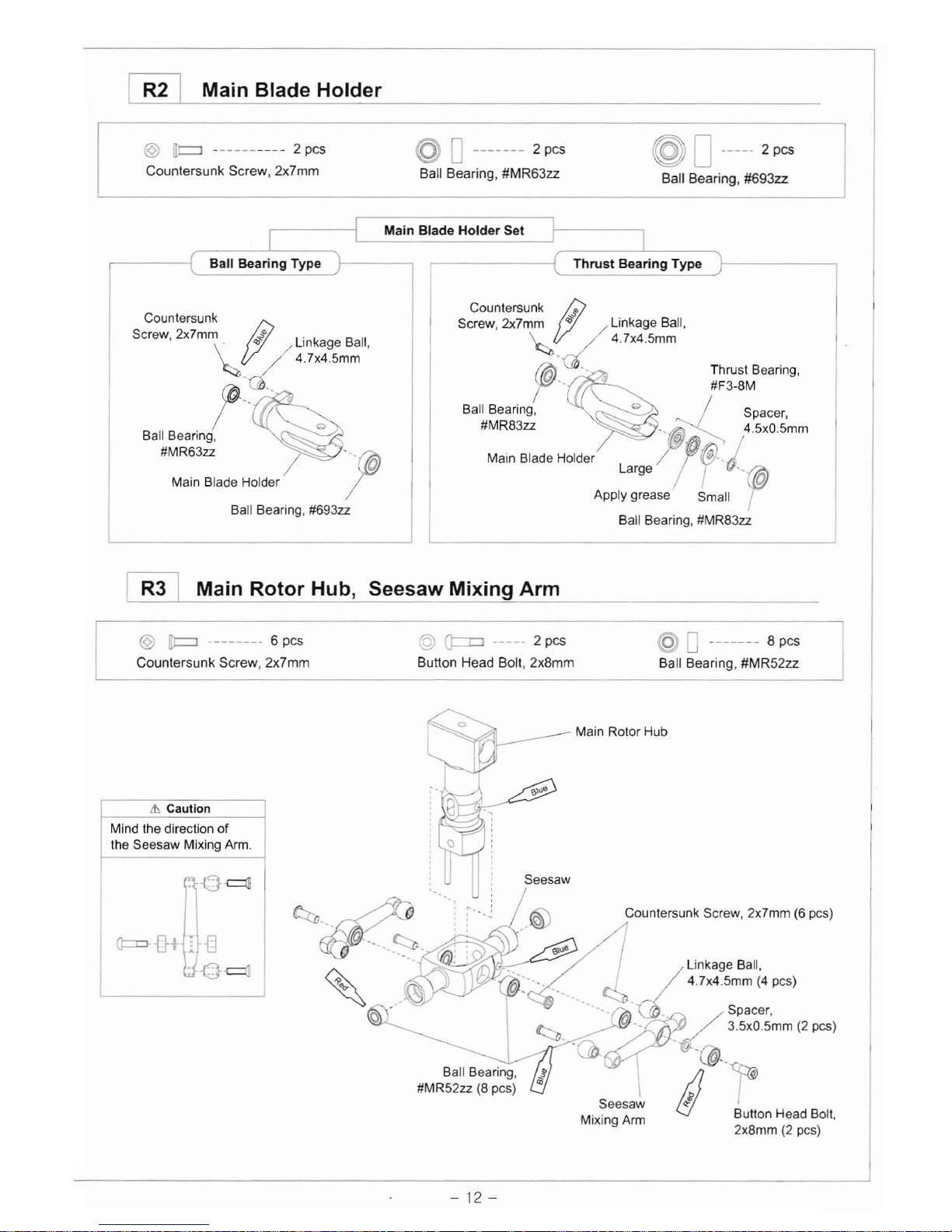

~

Main Blade Holder

@

IlJ::=J

---------- 2 pes © D

-------

2 pes @ 0

-----

2 pes

Countersunk Screw, 2x7mm Ball Bearing, #MR63zz Ball Bearing, #693zz

Main Blade Holder Set

[ill

Main Rotor Hub, Seesaw Mixing Arm

@

IP

-------- 6 pes @ Q::=o

-----

2 pes @ 0

-------

8 pes

Countersunk Screw, 2x7mm Button Head Bolt, 2x8mm Ball Bearing, #MR52zz

Main Rotor Hub

&. Caution

Mind the direction of

the Seesaw Mixing

Arm.

~D~

Q:=r::l-

-fi

t I

{]

.-o~

rt:::::tJ,

l:2

"

~,

3.5xO

5mm

(2

pes)

'a

11'(1"

Ball Bearing, !/

;fJ

#MR52zz

(8

pes)

as

Seesaw

,J

Bulton Head Bolt,

Mixing

Arm

2x8mm

(2

pcs)

Ball Bearing Type

Countersunk

SO",""

2><7m\~

;'~~~9;m"~"

t,,-'

Ball Bearing,

#MR63zz

Main Blade Holder

Ball Bearing, #693zz

Countersunk

I"

Screw,2x7mm

;3

/

~

d Linkage Ball,

47x45mm

{{6}"

r " Thrust Bearing,

#F3-8M

Ball Bearing, _ / Spacer,

#MR83ZZ',(@)~,

4

5xO

5mm

M,,"

61'd'

Hold"

/!~

j

APPI~a;~:ase

sm~1I

"rw

Ball Bearing, #MR83zz

-

12-

~

Head Button

~

Feathering Shaft, Main Shaft

@

[p

------ 1 pc @

O====J

-----

1pc @ ----- 1pc @

ldJ

-----

2 pcs

Socket Head Bolt, 2x4mm Socket Head Bolt, 2x11 mm

Nut,2mm

Nylon Nut, 3mm

Sockel Head

Bolt,

2x4mm

(1

pc)

~

/

";::1:':::

Sh,'

~

O-Ring -Soft

~

~--

~/~

o5x1.7mm -Ball Type

I

roo

-

J@L

"':p",,,

0

5,13mm

-

Th"'1

Typo

~---~

~

Soeket Head Bolt,

2x11

mm

(1

pe)

Nylon

Nut,

NUl,

2mm

(1

pe)

3mm

(2

pes)

Main Shaft

~

Washout Arm, Washout Base

@

/tC=l

------

2 pcs @

Q::::::o

----- 2

pes

@ 0

------

4 pcs

Counlersunk Screw, 2x8mm Button Head Boll, 2x8mm Ball Bearing, #MR52zz

@~

W

Sp",,,.

a2r~

C,",I,moo'

S,,~.

Washoul Link Boll,

1 7x7.5mm

(2

pes)

\

Washout Base

Washout

Arm

3.5xO.5mm

\ 2x8mm

(2

pes)

(2

pes)

!/%

Linkage Ball,

Bulton Head Boll, Ball Bearing, 4.7x5.5mm

(2

pes)

2x8mm

(2

pes)

#MR52zz

(4

pes)

-

13-

~

Flybar [B!] Flybar Paddle

@

(j:::::::::J

------

4 pes

Button Head Bolt, 2x7mm

---------------------

2 pes

@ 0

----------

2 pes

Washout

Arm

to Flybar Arm Spacer

Set Screw, 3x3mm (Linkage Rod 1.3x1Omm)

Set Screw,

3x3mm (2 pcs)

A

---

<-"

• -

__

--.----

~

~-

-.....:@/

~

~--~-

6:

./'

___

r\

--

Flybar

Control Arm

Flybar, 210mm

Button Head Bolt,

2x7mm

(4

pes)

Flybar Paddle,

(2

pes)

::'

-{I.L-

L1

Caution

[ill

Mintl the direction

of

the Flybar Arm Swashplate Assembly

Spacer to Flybar Control Arm.

~-

1

----'~

(p--

::'

-IT.'--I

_~

L1

Caution

Make sure both sides of

the Flybar are equal in length.

31\

80mm

Equal Distance

31\

80mm Equal Distance

+-

~

Linkage Rod, Ball Link

11.3 2.4

Washout Arm to Flybar Arm Spacer Seesaw Mixing Arm to Swashplate Cap

(Linkage Rod, 1.3x10mm) (Linkage Rod, 1.3x29mm)

13.4 21.2 13.4

13.4 2.6 13.4

----------

2 pes

29

48

---

2 pes

29.4

Main Blade Holder to Seesaw Mixing Arm Swashplate to Servo Arm

(Linkage Rod, 1.3x10mm) (Linkage Rod, 1.3x21mm)

--------

3 pes

-

------------

2

pes

Ball Link

(S),

11.3mm

(4

pes)

Ball Link

(L),

13.4mm

(14

pes)

'*

Note

Mind the direction of

the Ball Link

to

Linkage Ball.

~¢J-~

•

~

~T

Linkage Ball

Number mark Ball Link

& Caution

When the transmitter pitch stick

in

middle position.

Servo horn should

be

perpendicularity.

ll~1

~

-

15-

3-3. Gear

= @

ppp

[Q!] Main Drive Gear

@

[]::===:J

----~

1 pc <Nut, 2mm

(1

pc)

Socket

Head

Bolt,

2x11mm

©

~

----------

1

pc

Nut,2mm

@ p -------- 6

pcs

Lt

Caution

Do not over-tighten the bolt.

Socket Head Bolt

2x11mm

(1

pc) ,

Flat

Head

Bolt,

2x5mm

Main Drive

Pulley,51T

<0

0

-------~

2 pes Collar, 9.5x2mm

(1

pc)

Ball

Bearing,

#MR106zz

Flat Head Bolt,

2x5mm (6 pcs)

P

OD---1

C

Ball Bearing,

#HF0612zz

Main Drive Gear, 150T

lIE

Note

Apply a light coating

of

grease

to the One-way Bearing.

Lt

Caution

The word is in the bottom.

{OJ

Up

Lt

Caution

iJ:;;"'.

,I

Mind the direction

of

---'-

the Autorotation Case.

II

H,

"

"

III

"

'I

II,

I,

!i~:l---

Ball Bearing,

::~

#MR106zz

ii'::i:

, ,

c!>

'" , Autorotation Case

~

One-way Bearing,

#HF0612

(1

pc)

~

Collar, 10x1mm

(1

pc)

~

: Ball Bearing,

It #MR106zz

U----One-way Sleeve

I 3-4. Tail

WJ

[ill

[ill [ill [ill

III

c:J~

c:()

00

a::o

lTlT

@@

~

~

@o

c:::u

I=>

0 0

[~~I

0==

~

~

[p

EJl::::,

I=>

0

=11

[ill

@]

[ill [ill

[Iq@oQ=

0==

o _

Q=

LflJuu

8{]

@@~@

~

19j

la~gl

d

~

uU

F=F=

00

==

[!ill

II,.

31ml

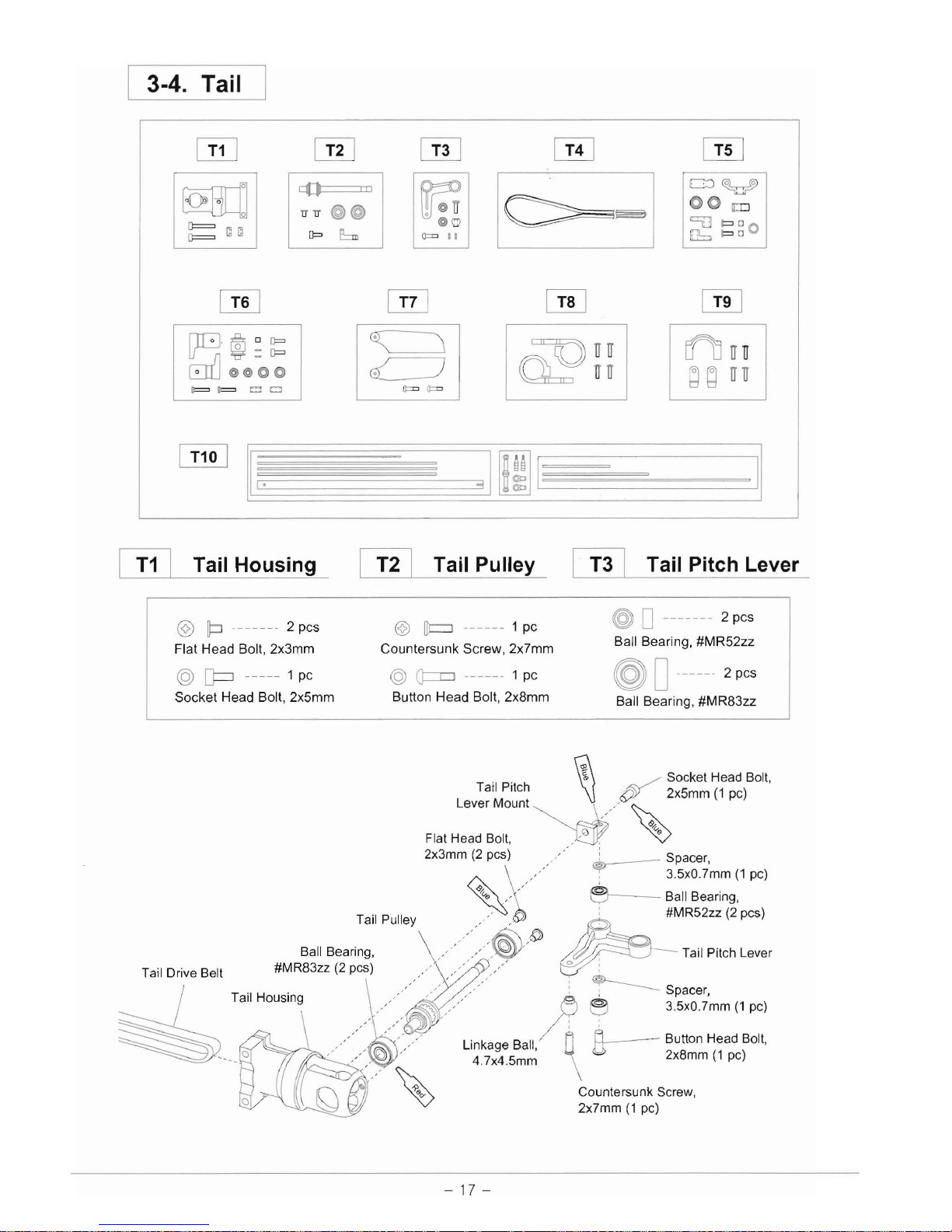

C!IJ

Tail Housing

~

Tail Pulley

~

Tail Pitch Lever

@ 0

.--.--.

2 pcs

@ p

------

2 pcs ©

[t::::J

-.----

1 pc Ball Bearing, #MR52zz

Flat Head Bolt, 2x3mm Countersunk Screw, 2x7mm

@

[J::=J

-----

1 pc @

Q=::o

------ 1 pc @ 0

------

2 pcs

Socket Head Bolt, 2x5mm Button Head Bolt, 2x8mm Ball Bearing, #MR83zz

m

~

Socket Head

Bolt,

Tail Pitch

\!

~

2x5mm

(1

pc)

Lever

Mount~,,-

~

~

~v.

Flat Head

Bolt,

,.0

, •

2x3mm

(2

pcs)

,":

Spacer,

,/

~

3.5xO.7mm(1

pc)

~,,-

e--

Tail Pulley

..

v~.':

: -

~~~~~~~~'

pes)

"~6i)

~

Ball Bearing,

,,-/

,

..

<~r

~

Tail Pitch Lever

83ZZ

(2

Pcs~)

\

A;----

~'s:~'imm

(1

po)

Tail

Drive Belt Tail

Ho::n:

/////

~

~

...

,,<'

.<,.",.

Linkage Ball,

0:

-

~

Button Head

Bolt,

~

--

__

()

,

,,-,~'

4

7x4

5mm

\ 2x8mm

(1

pc)

'-~

-.

Countersunk Screw,

2x7mm

(1

pc)

-

17-

II

~

Tail Pitch Plate, Tail Pitch Slider

@ p ---- 2 pcs

Flat

Head

Bolt,

2x6mm

~

0

------

2 pcs

Ball Bearing,

#MR74zz

& Caution

t:l

Apply just a little drop

of thread lock

to

the

I---

Tail Pitch

~

tip of the screw.

Make sure the Tail Plate ,,,"

",,"

)

~'

pitch link moves freely.

/,

T

'1

p't

hL' k

, ,

al

IC

In

Spacer Collar,

Spacer,

(ff;)~'

J)

fi

~

3x2.6mm

(2

pes)

6x0.4mm

(1

pc)

~

/~

~

Flat Head Bolt,

2x6mm

(2

pcs)

Ball Bearing,

~

""

#MR74zz

(2

pcs)

~

""

rA!1'

~

Tail Pitch Slider

~

""

~

Tail Slide Sleeve

[!!]

Tail Blade Holder

C!ZJ

Tail Rotor Blade

& Caution

Mind the direction

of the blade.

© [c::=J

-----

2 pcs

Countersunk

Screw,

2x10mm

@

[]:::::::J

------ 2 pcs

Socket

Head

Bolt,

2x6mm

@

Q=::r=J

------ 2 pcs

Bulton

Head

Bolt,

2x8mm

@ 0

----------

1 pc

Set

Screw,

3x3mm

@ 0

----------

2 pes

Ball Bearing,

#MR52zz

@ 0

---------

2 pcs

Ball Bearing,

#MR63zz

& Caution

Apply just a little drop

of thread lock to the

tip of the screw.

Make sure the Tail

pitch link moves freely.

Countersunk Screw,

-~

'R

2x10mm

(2

pes)

11

Spacer Collar,

,-----{j,

,

3,61mm(Z",,)

/M

o

'

v;

, /

~

Tail Rotor Blade

Socket Head Bolt,

2x6mm

(2

pes)

Ball Bearing,

#MR52zz

(2

pcs)

Button Head Bolt,

:

~

2x8mm

(2

pcs)

~

T,U

BI'd'

Hold"

-L

:

~

Ball Bearing,

~

#MR63zz

(2

pcs)

::

Tail Center Hub

3x3mm

(1

pc)

/'

Set Screw,

__

0

-

18-

~

Tail Servo Mount

~

Tail Fin Mount I T10 I Tail Boom

@

~

--------

8 pes @

[J:::::=J

------ 2 pes g

----

2 pes @

[J:::::=J

------ 2 pes

Self Tapping Screw, 2x7mm Socket Head Bolt, 2x13mm Socket Washer Socket Head Bolt, 2x8mm

2x7mm

(2

pes)

Tail Horizontal Fin \

Self Tapping Screw,

2,7mm

(4

p~)

\

~

~

--\

__

c?,~

Socket Head

Bolt,

2x13mm

(2

pes)

~

\

\i)

Self Tapping Screw,

2x7mm

(2

pes)

1 Tail Boom Brace,

Clockwise

\

Tail Boom,

Alumium

Caution

~

i,

<~~

Tail Fin Mount

Self Tapping Screw,

:~

, ,

~

i

Mind the direction

of the Tail Boom.

& Caution

Mind the direction

of the Tail Drive Belt.

Tail Brace Support

Tail Servo

Mount

Tail Drive Belt

Clockwise

3x263mm

K/~

/ •

0.,.

Micro, Mini servo type : 3x315mm

Tail Brace

Connector Standard servo type : 3x263mm

'*

CUlling

Tail Control

Rod

Socket Head Bolt,

2x8mm

(2

pes)

r--

--

Bali Link

(L),

\

13.5mm

(2

pes) Tail Control

Rod

End

-

19-

Table of contents

Popular Toy manuals by other brands

Topmodel CZ

Topmodel CZ MDM 1 FOX De-luxe quick guide

Accucraft

Accucraft Dora instruction manual

Babyhug

Babyhug Sporty Manual Ride-on user manual

Thames & Kosmos

Thames & Kosmos Ooze Labs 575004 Instructions for use

Multiplex

Multiplex FlightRecorder operating instructions

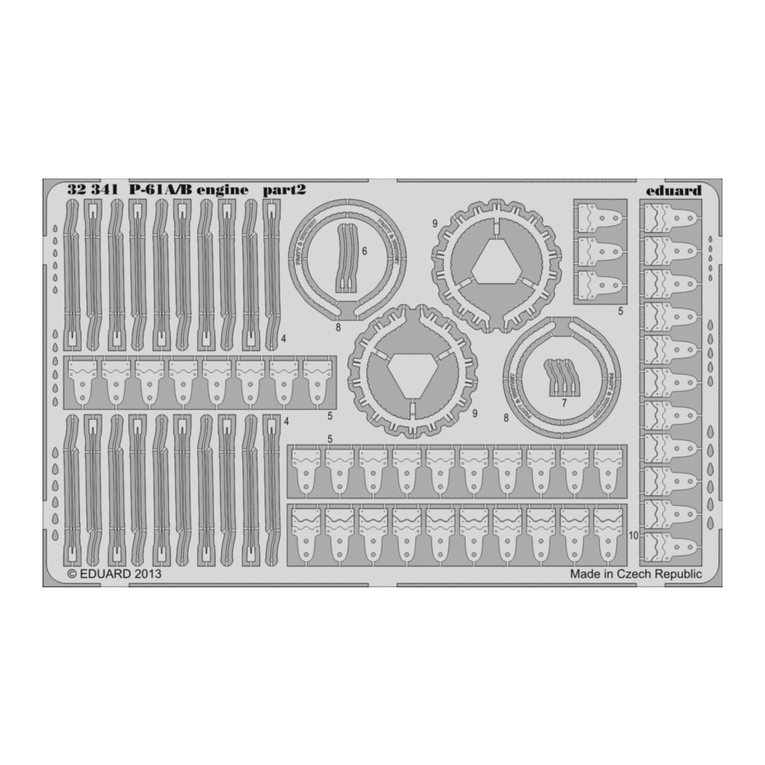

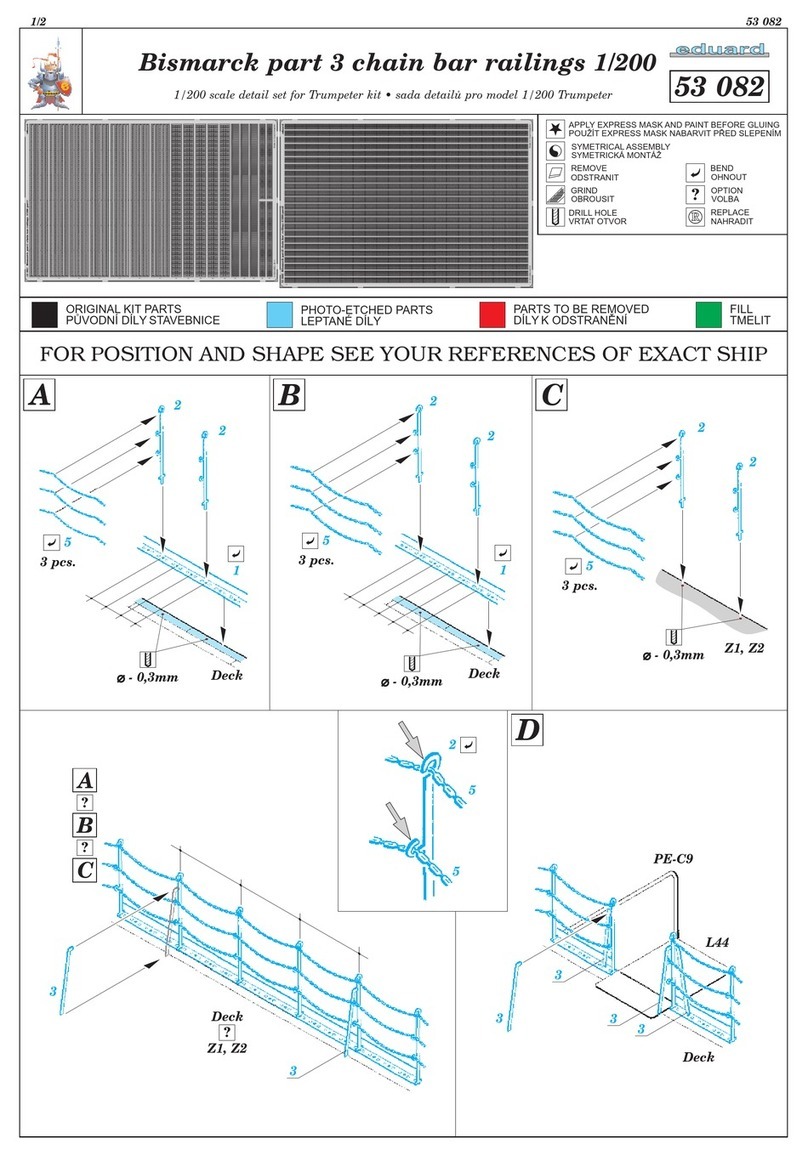

Eduard

Eduard Bismarck part 3 chain bar railings 1/200 quick start guide