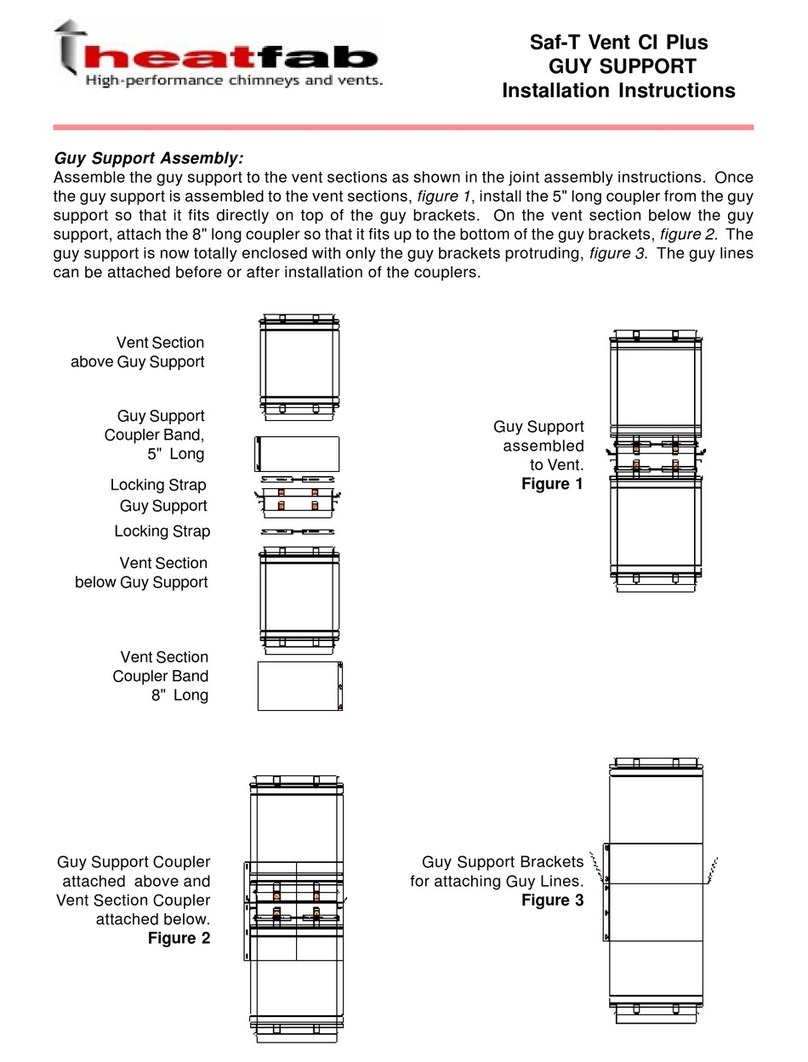

Heat-Fab Saf-T Vent User manual

INSTALLATIONINSTRUCTIONS

The Heat-Fab Saf-T VentTM isamasonrychimney liningand reliningsystem intended

for use with residential appliances burning liquefied petroleum (LP), natural gas,

home heating oil, and solid (wood or coal) fuels. Saf-T Vent is a high-quality,

extremely durable lining system constructed of a special alloy of stainless steel high

in both chromium and molybdenum. This alloy, plus Saf-T Vent's smooth-wall

design, give it a unique combination of corrosion resistance, high temperature

tolerance and desirable flow characteristics not found in any other chimney lining

system.

As with any venting system, its installation must be properly planned and executed in

order to ensure satisfactory results. Incorporation or substitution of parts or materials

not manufactured or supplied by Heat-Fab, or failure to follow these instructions, may

not provide a UL Listed system, and may result in appliance malfunction, fire or

endanger the health and safety of people.

Heat-Fab recommends that the installation be performed by an experienced

professional who works with venting systems for residential appliances on a regular

basis. Theseinstructionsare intendedasaguide toassistaprofessional installer. The

installation must conform to the requirements of the appliance manufacturers'

instructions, applicable National Fire Protection Association (NFPA) standards,

and local codes. Check your local codes and contact local building or fire officials to

obtain any required permits.

IMPORTANT: THESAF-TVENTSYSTEMMAYBEINSTALLEDIN

SEVERALDIFFERENTWAYS,USINGDIFFERENTPARTS,ACCORDINGTO

THE TYPE OF APPLIANCE(S) TO BE CONNECTED. TO ENSURE PROPER

INSTALLATION, FOLLOW THESE MAIN INSTRUCTIONS AND THE

SUPPLEMENTALINSTRUCTIONSINDICATEDBELOW.

For Solid Fuel or Oil Appliances: The liner must be insulated with Saf-T Wrap

Insulation. Follow these Main Instructions and the

Supplemental General

Residential Instructions (PI-WRAP) packed with the Saf-T Wrap Insulation.

Category I gas appliances may also be installed per these instructions if desired.

Page 12

Single-wall metal vent

connector may not pass

through an interior wall or

partition. It may pass

through a combustible

exterior wall if surrounded

at the point of passage by a

metal ventilated thimble at

least 4 inches larger in

diameter than the

connector, or by a wall

pass-through device Listed

for this purpose. The

thimble or wall pass-

through must not be located

directly behind the heating

appliance.

MAINTENANCE

INSTRUCTIONS

Cover Plate

Figure 7

Heat-Fab Inc. Saf-T VentTM

Stainless Steel Chimney Liner

For Venting Residential Type

Gas, Oil and Solid Fuel Appliances

Sizes: 3", 4", 5", 6", 7", 8" Diameters

Support

Clamp

Combina-

tion Tee

Saf-T Vent

Sections

Masonry

Rubble

Support

Legs

Vent Con-

nector slant

1/4 inch per

foot

Normal operation of a gas appliance does not result in deposits of combustible soot

or creosote in the venting system. However, a poorly adjusted or malfunctioning

appliance can deposit soot, and leaves or other debris can enter the flue. Just as with

all chimneys and vents the Saf-T Vent should be inspected annually forthe presence

of deposits or debris and cleaned if necessary. This should be done by a Certified

Chimney Sweep®or other qualified person.

To inspect the vent, pry up the locking tabs holding the rain cap to the top of the liner

and remove the cap. Replace the cap by inserting the locking tabs back under the ring

and bending them back into position. The system can also be inspected and cleaned

by removing the connector pipe from the liner tee or elbow.

PI-VINS R0900 TurnersFalls,Massachusetts01376

(800)772-0739

Page 2

Page 11

For Category I Gas Burning Appliances:Follow theseMain Instructions andthe

Supplemental Category I gas applianceinstructionson page9 ofthis booklet. Refer

to Heat-Fab's Saf-T Vent Planning & Preparation Manual for additional

considerations.

ForCategoryIII,IVGasBurningAppliances: Sectionsoffluegasconduitmustbe

sealed with a special sealant. Follow these Main Instructions, the Supplemental

CategoryIII andIVgasinstructions(PI-VSUP)packedwiththeSaf-TVentelbows

or tees, and the appliance manufacturer's instructions.

MAININSTRUCTIONS

PRE-INSTALLATIONINSPECTION

It is the installer's sole responsibility to inspect and verify the suitability of

the chimney and related construction for installation of this product.

Saf-T Vent is intended for installation in new or existing masonry chimneys which

comply with the requirements of Chimneys, Fireplaces, Vents and Solid Fuel

BurningAppliances (NFPA211). Thechimneymustbecomposedofsolidmasonry

units, such as bricks or concrete block, at least 4 inches (nominal) in thickness. The

chimney must extend at least 5 feet above the highest appliance draft hood or flue

collar, with a maximum height of 60 feet. The chimney must extend at least 3 feet

10 feet

2 feet

Figure 1

Connect the base assembly, assemble lengths of conduit, lower the liner down the

chimney, mount the liner to the appropriate support system, and install the termination

assembly as described in the Main Instructions in this document.

INSTALLTHEVENTCONNECTOR

IftheventconnectoristobesectionsofSaf-TVentfluegasconduitorgenericsingle-*

wall metal pipe, attach the conduit connector adapter, which has the female fitting on

each end, to the male tee or elbow take off. If the vent connector is to be sections of

TypeBorTypeLventpipe,attachaslipsectioninsteadoftheconnectoradapter. The

slip section can be trimmed to the necessary length. Regardless of connector type, it

must slope upward toward the chimney at least 1/4 inch per foot.

To close off the hole in the chimney, attach a cover plate. Slip the cover plate over the

connectoradapterorslipsectionandsecureittothefaceofthechimneywithTapcon®

screws, masonry anchors or other appropriate fasteners. The cover plate may be

trimmedto meet the chimney dimensions. However,the installationmust besuch that

the important safety label on the cover plate is not disturbed and is readily visible to

the homeowner. The cover plate and attached label are a mandatory part of the

installation.

If the vent connector is to be sections of Saf-T Vent conduit or other single-wall metal

connector pipe, attach the male end of the first section to the connector adapter and

continuewithstraight sections andelbowsbacktothe appliance. Whenusedasavent

connector the flue gas conduit is installed with the male ends up, pointing toward the

chimney. Connect the flue gas conduit to the appliance flue collar by cutting or

bendingthetabsoutoftheway,andsecuringitwithsheetmetalscrews. Theconnector

may be easily disconnected from the connector adapter for inspection of the flue.

If Type B, Type L or other double-wall construction vent pipe is used for the

connector,slidethepipeseveral inchesovertheslipconnectorandsecure itwithsheet

metal screws. Continue with pipe sections back to the appliance, following the vent

manufacturer's instructions.

Be sure that the connector has proper clearance to combustibles and conforms with

the requirements of the appliance manufacturer's instructions, NFPA 54, and local

codes. SinceSaf-TVentmay only beusedtoventapplianceswhich areListedforuse

with Type B vent, Saf-T Vent sections or other single-wall metal pipe used as a

connectormaybeinstalledwitha6-inchclearancetocombustibles. IfTypeBorType

L pipe is used as a connector, it may be installed at its Listed clearance. Clearances

may be reduced if the combustible material is protected in accordance with Table

6-5.1.2 ofNFPA 211 (1996) or Table 6.2.3(b) in NFPA54(1999).

Thoroughly clean the chimney of combustible deposits. Particular attention should

be given to deposits of tar glaze creosote, which may be resistant to normal cleaning

methods. Remove any mortar projections or snags from the interior wall of the

chimney. Heat-Fab strongly recommends that an internal inspection be done with

video inspection equipment such as a Chim-ScanTM.

There must be a 1-inch minimum airspace clearance from combustible material

surrounding the masonry chimney. However, under certain conditions Saf-T Vent

may be used in chimneys in which combustible material comes in contact with the

outer surface. See the appropriate supplemental instructions for optional minimum

clearances. Combustible material must not be embedded or otherwise penetrate the

above the point where it

penetrates the roof, and 2 feet

higher than any part of a structure

within 10 feet (Figure 1).

Inspectthe interiorof the chimney

for loose or missing mortar, holes,

and cracked, loose or missing

bricks or unused thimbles. Repair

any defects in the chimney.

3 feet

Page 3

Page 10

Insulation

Figure 2

Com-

bustible

Framing

Member

or Wall

2" min

4" nominal solid

masonry

Figure 3

1 Inch*

1 Inch*

chimney wall. All thermal insulation,

whether or not it is combustible or fire

retardant, must have a 2-inch clearance

from the chimney (Figure 2). If

necessary,constructabarriertoprevent

loose insulation from falling against the

chimney. Any resulting gaps between

the chimney and framing at floor or

ceiling levels must be closed with a

firestop.

If the chimney is currently lined with a

clay tile liner, dislodge any loose

sections, shards or flakes and remove

them. Makesurethatthefluespaceisat

least 2 inches* larger, at its smallest

point,thantheSaf-TVentfluediameter.

The existing tile liner may be removed

to provide the necessary space (Figure

3).

*See appropriate supplemental

instructions for variations to this

required clearance.

INSTALLATIONPROCEDURE

PersonalSafety

Wear eye protection and heavy gloves

throughout the installation. In addition

wear a dust and vapor respirator

wheneverincontactwithsoot,creosote,

mortarorinsulation. Usecautionwhenworkingonaroof. Properandsafescaffolding

and/or ladders should be used. All ladders should be secured to the building. Check

overheadforantennas,powerlinesorotherobstaclesbeforeerectingtheladders

orscaffoldingandwhileinstallingtheliner.

Make sure that all appliances connected to the chimney are turned off and any solid

fuel appliances are out during the installation. Plug the appliance flue collars to

prevent the entry of dust or debris.

Clear a safe working space around the bottom of the chimney and other work areas.

Lay down drop cloths to protect floors and furnishings. Use a chimney sweeping

vacuum, if necessary, to contain dust generated during installation.

outer surface. However, combustible material must not be embedded or otherwise

penetrate the chimney wall. All thermal insulation, whether or not it is combustible

or fire retardant, must be cleared from at least 2 inches around the chimney. If

necessary, construct a barrier to prevent loose insulation from falling against the

chimney. Any resulting gaps between the chimney and framing at floor or ceiling

levels must be closed with a firestop.

If the chimney is currently lined with a clay liner, dislodge any loose sections, shards

or flakes and remove them. Make sure that the flue space is at least 1 inch larger, at

its smallest point, than the Saf-T Vent diameter. Any existing tile liner may be

removed to provide the necessary space.

A Category I Saf-T Vent system should be insulated with Saf-T Wrap insulation in

the following situations:

•Very high efficiency Category I

appliances, or where previous

experience has shown a severe

condensation problem in the flue.

•Unusually tall exterior chimneys.

•Unusually long vent connector.

•Exterior chimneys in very cold climates.

•Chimneys in very cold climates with

significant exposed length above

the roof line.

•Very large chimneys, where the

liner would be surrounded by a very

large airspace.

It may be necessary to insulate only the portion of the vent exposed to the severest

conditions; e.g. the part above the roofline. In these cases, use a Saf-T Vent support

clamp to retain the insulation in place. Install the clamp, with the tabs pointing

upwards, under the lowest section of Saf-T Wrap and bend the tabs out to prevent the

insulation from sliding down. Although partial insulation is acceptable for use with

only Category I gas appliances; following the General Residential Supplemental

Instructions (PI-WRAP) will result in a less restrictive "all fuel" chimney liner

system. Use only Saf-T Wrap insulation provided by Heat-Fab, Inc. Do not

substitute other types or brands of insulation.

INSTALLATIONPROCEDURE

Consult the Main Instructions in this document for tools required, personal safety

considerations and a description of the system components. Proceed with the

installation as described in the Main Instructions.

Locate the hole for the appliance breeching as high as possible, considering clearance

to combustibles. (Consult the appliance manufacturer's instructions, section 7.10 of

NFPA54(1999)

, andTables 6-5.1.1and 6-5.1.2 ofNFPA 211 (1996)todetermine

clearance needed for the vent connector and thimble.)

Page 4

Page 9

Tools&MaterialsNeeded Masonry Tools

Cold Chisels Masonry Saw Masonry Drill Bits

Mortar Pan Trowel

Other Tools

Tin Snips Pliers Hammer

Screwdriver Measuring Tape

Materials&SafetyEquipment

Gloves Eye Protection Dust-Vapor Respirator

Drop Cloth(s) DuctTape Silicone Caulk

Ladders and/or Scaffolding Mortar or Mortar Mix

Sturdy rope, at least twice the length of the liner

Other tools may be needed for specific installations. All parts needed for joining

sectionsof Saf-T Vent conduit areattached toeach section. Donotdrillthroughthe

liner wall or attach sections with screws or pop rivets.

SystemComponents

All Saf-T Vent systems must include a base assembly, consisting of appliance tee

and/or elbow, support system and a cleanout access; vertical flue gas conduit,

consisting of Saf-T Vent liner sections; termination assembly, consisting of top

flashing, rain cap, slip section and storm collar; and a vent or chimney connector,

which may be sections of Saf-T Vent flue gas conduit or other approved material.

Other parts may be needed for the specific installation and appliance type -- consult

the appropriate supplemental instructions. Read the instructions thoroughly, plan the

installation, and make sure all necessary parts are on hand before commencing

installation. Do not substitute any parts not manufactured or supplied by

Heat-Fab, Inc.

A. Open The Chimney

Note:

Wear eye protection and respirator.

Anopening mustbemade inthechimney intheroom inwhichthe applianceislocated.

If the chimney already has a thimble hole, it will probably require expansion to

facilitate installation of the base assembly.

Locate the hole for the appliance breeching considering available headroom and

clearance to combustibles. (Consult the appliance manufacturer's instructions and

Tables6-5.1.1and6-5.1.2ofNFPA 211(1996)todetermineclearanceneededforthe

Supplemental Category I Instructions

These instructions apply when the Saf-T Vent system will be used only to vent one

or more Category I gas appliance(s). These Instructions are intended as a guide to

assist the professional installer. The installation must conform to the requirements of

theappliancemanufacturer's instructions,TheNationalFuelGasCode(NFPA54),

andlocal codes. Checkyour localcodes andcontact localbuilding and/or fireofficials

to obtain any required permits.

By following these instructions, Saf-T Vent may be used to vent Category I gas

burning furnaces, boilers, hot water heaters, space heaters and decorative appliances

with a maximum continuous flue gas outlet temperature not exceeding 480° F. The

appliance(s)mustbe testedbytheAmericanGasAssociation(AGA),Underwriters

Laboratories (UL),orotherrecognizedtestingagency,andListedforusewithaType

B venting system. Although most conventional Category I appliances include a draft

hood, certain newer mid-efficiency Category I appliances are fan assisted, without a

draft hood. They may be vented per these instructions so long as they are Listed for

use with Type B vents.

Consult the appliance manufacturer's instructions, NFPA 54, Heat-Fab's

Saf-TVent

Planning & Preparation Manualand local codes to determine the proper size liner

for the installation, and for information on common venting of more than one

appliance. The liner size must not be smaller than allowed by the appliance

manufacturer's instructions, regardless of flue collar size.

When installed according to these instructions, Saf-T Vent may not be used to vent

thefollowingtypesofappliances:GasappliancesListedforusewithTypeBWVent;

CategoryII,IIIorIVgasappliances,Unlistedgasappliances,oilfiredappliances,

multifuelappliances,solidfuelappliancesorappliancesthatmustbeventedbya

chimney. The Saf-T Vent system converts the chimney flue to a dedicated gas vent

designed to optimize the venting conditions for Category I gas appliances.

ChimneyInspectionandPreparation

Saf-T Vent is intended for installation in new or existing masonry chimneys which

complywiththerequirementsof

NFPA211,Chimneys,Fireplaces,VentsandSolid

Fuel Burning Appliances.It is the responsibility of the installer to inspect and

prepare the chimney prior to installation. Consult and follow the Main Instructions

in this document on inspection and preparation of the chimney.

When intended for use only with Category I gas appliances, the Saf-T Vent system

may be installed in chimneys which have combustible material in contact with the

Page 8

Page 5

insert the small end through the cover plate and guide it into the top liner section.

Continue sliding the slip section down until the storm collar rests on the cover plate

and supports the slip section on the expanded end. Tighten the storm collar clamp.

Finally, attach the rain cap to the slip section with the locking ring and locking tabs

(Figure 6).

I. Connect Appliance To The Chimney

Both the choice of connector material and the method of installation will differ

depending on the type of appliance to be connected. Follow the appropriate

supplemental instructions to choose the proper connector and attach it to the

Saf-T Vent system.

Figure 4

too far out, or they will

tendtosnagastheconduit

is lowered down the

chimney (Figure 4).

Attach the tee or elbow

(unless the elbow must be

attached from the bottom

opening) to a length of

flue gas conduit using the

locking ring and tabs (see

Preassemble Lengths,

below). Attach the tee

cover to the bottom of the

tee.

Support Clamp

ventor chimneyconnector.) An additionalopening maybe neededfor a cleanouttee.

The size of the hole will depend on the type of support system to be used with the

installation. See Heat-Fab'sPlanningandPreparationManualforSaf-TVentto

determine which support system, the support bracket or support legs, is most

appropriate for this installation. Use the instructions packaged with the support for

specifications on preparing the chimney and installing the support.

B. Connect the Tee or Elbow

When a tee is to be used for the appliance connection it may be preconnected to the

sections of vertical flue gas conduit and lowered down the chimney. Remove the

horizontal take-off from the tee by loosening the retractable bands.

When a 90°, 70°, or 45° elbow is to be used for the appliance connection, it may also

be possible to attach it to the liner and lower it down the chimney. The chimney flue

space must, however, be large enough to accommodate the horizontal take-off from

the elbow (which extends approximately 5 inches). If the flue space is not large

enough, the elbow will have to be attached to the bottom of the vertical conduit after

it is lowered down the chimney.

Attach the support clamp to the tee or elbow, just below the expanded portion at the

top of the fitting. The tabs on the support clamp should be facing down, and should

be oriented 90 degreesfrom the horizontal take-off of the tee or elbow. Tighten the

clampby turningthescrew clockwisewitha screwdriver. Tomakeconnection ofthe

support clamp to the support brackets or legs easier, it is useful to pry the tabs on the

support clamp out from the side of the conduit about 1/4 inch. Avoid bending them

Crown or

Flashing

Slip Section

Storm

Collar Rain

Cap

3 to 14

Inches

Saf-T Vent

Sections

Figure 6

SAF-TVENTLIMITEDWARRANTY

Heat-Fab,Inc.warrantstotheoriginalconsumerpurchaserthattheSaf-TVentwillbefreefromdefectsinmaterial

ormanufacturer'sworkmanship. Anydefectarisingfromtheimproperoperationormaintenanceofthissystemand

connectedappliance(s)isnotcoveredbythiswarranty.

Inordertoobtainwarrantyservice,theconsumermustgivepromptwrittennoticeofanydefecttoHeat-Fab,Inc.

withinten(10)yearsfromthedateofpurchase. ThesoleresponsibilityofHeat-Fab,Inc.shallbetoreplacethose

partsofSaf-TVentfoundtobedefectiveuponreturnF.O.BtoHeat-Fab,Inc. 130IndustrialBlvd.,TurnersFalls,MA

01376. Heat-Fab,Incshallnotberesponsibleforthecostofinspecting,removingorreinstallingthepartssubject

hereto,norshallitbeliableforanyspecial,incidentalorconsequentialdamagesorexpensesincurredbytheconsumer

oritscontractors. Thewarrantyonanyreplacementpartsshallbefortheunexpiredtermoftheoriginalwarranty.

Thiswarrantygivestheconsumerspecificlegalrights,inadditiontoanyotherrightswhichmaypertain,whichvary

fromstatetostate

ThisProductisListedby

UNDERWRITERS LABORATORIES INC.

andBears the Mark:

Page 6

Page 7

E. Lowering The Liner

Carefully lower the first length of conduit into the chimney, until the top is 6 to 12

inches above the chimney top. Secure the lowering rope or have a helper hold it fast.

Attach the next length of conduit (see Figure 5) and again lower the liner. Continue

lowering the liner and attaching lengths until the Tee, Elbow, or bottom section

approaches the opening near the bottom of the chimney.

Using a combination of 4 ft., 3 ft., 2 ft., 18 inch, 1 ft., or 6 inch sections, the conduit

should end at least 3 inches but no more than 14 inches below the top of the chimney.

This space is needed because the conduit expands as it is heated, and will be bridged

by the slip connector part of the termination assembly.

F. Attach Tee Take-Off or Elbow

When a tee is attached to the bottom of the liner, extend the retractable bands on the

teetake-offtothemaximumbyturningthescrewcounterclockwise. Donotscrewthe

end of the band completely out. Position the take-off for the tee in the opening in the

chimney. Lower the base assembly through the band until the hole in the tee is even

withthetake-off. Withalong-handledflatheadscrewdriver,turnthescrewclockwise

untilthetake-off ispulled tightly againstthetee.

Makesurethetake-offiscentered

over the hole, with the projecting lip around the tee hole inside the take-off at all

points. Do not overtighen the screw, or distortion of the tee body will result. Verify

by looking in through the take-off that the sides have not been squeezed inward.

When an elbow is to be attached to the bottom of the liner, hold it in the chimney

opening and guide the bottom of the liner into it. Secure it to the liner with the locking

ring and locking tabs per Figure 5.

G. Attach The Support System to the Tee or Elbow

Bend the tabs on the support clamp out about 1/2 to 3/4 inch away from the side of the

tee or elbow. Raise or lower the liner until the tabs engage the edges of the support

bracketorlegs. Letthe liner restonthesupportsystemand removetheloweringrope.

H. Install The Termination Assembly

Trim the cover plate so that the hole is centered over the flue space. If a clay tile liner

projects from the top of the chimney, trim the cover plate 2 to 4 inches larger than the

outer dimensions of the tile. Cut a rectangular notch out of each corner and fold each

side of the plate down 90 degrees, so that the top surface is slightly larger than the tile.

Run a bead of silicone caulk on top of the tile and press the plate down into it. If there

is no projecting tile, run a bead of caulk around the chimney top and press the cover

plate flat on top of the chimney. Slip the storm collar, with the rounded surface facing

up, onto the slip section up to the expanded end. Reaching in through the slip section,

Make sure that the sections are tightly joined and form a straight, continuous flue gas

conduit. To eliminate snagging of the locking tabs as the liner is lowered down the

chimney, you may wish to tape the ends flat against the conduit with foil tape.

D. Attach Lowering Rope

The lowering rope will allow the liner to be safely and smoothly fed down the

chimney, and held in position while additional lengths are attached. Attach the rope

to the tee, elbow or lowest section of conduit by looping it around the outside of the

section and securing it to the sides of the conduit with duct tape. Locate the tape so

that it can be reached for easy removal from the bottom of the chimney. Never feed

the rope up the inside of the conduit - it will be impossible to attach additional sections!

C. Preassemble Lengths of Conduit

Note: All parts needed for secure joining of conduit sections are attached to

each section. Neverdrillthroughtheconduitwallorattempttojoinsectionsusing

screwsorpoprivets.

Several sections of Saf-T Vent conduit may be preassembled to manageable lengths

on the ground, to minimize trips up and down the ladder. Generally, lengths of 8 to

10 feet can be safely carried up the ladder and manipulated on the roof. Be sure to

check for overhead power lines and other obstacles, and provide safe and stable

footing, before working with long lengths of conduit.

To join sections of conduit, fit the smaller, male end into the flared female end (with

theprojecting lockingtabs)of thesectionbelow, makingsurethat thelocking tabs stay

on the outside (Figure 5-A). Push the loose locking ring upward on the conduit using

the fingers of both hands, press the ends of the locking tabs against the conduit. Let

the locking ring fall over the tabs (Figure 5-B). Push the locking ring downward as

far as it will go. Bend the locking tabs tightly down over the locking ring and tap the

ends against the conduit with a hammer and block of wood (Figure 5-C).

AB C

Figure 5

Table of contents

Other Heat-Fab Fan manuals