heatco HE SERIES User manual

OEM INSTALLATION INSTRUCTIONS

HE SERIES

DUCT FURNACE

HE Series Duct Furnaces are a Recognized Furnace Component

by Intertek Testing Services (ITS / ETL)

For Indoor or Outdoor Installation

For Installation Downstream of Refrigeration Systems

This Product is intended for installation by Original Equipment Manufacturers

of Listed Heating Equipment in Duct or Cabinet mounted Applications on

Positive Pressure side of the Circulating Air Blower

The duct furnace modules covered by these instructions become a component of a

“Listed” product, subject to the guidelines of application provided in these instructions

and as designated by the Certifying Agency in the Manufacturer’s Listing Procedure

Manufactured by

Heatco Inc

50 Heatco Court

Cartersville, Ga. 30120

HE-OEM-MAN-E-2016-2

Improper installation, adjustment or alteration

can cause injury or death. Read installation,

operating and maintenance instructions

thoroughly before installing or adjusting furnace.

WARNING !

2

Table Contents

Rating Information (Rating Plate) 3

Conditions of Application 3

Duct Furnace Installation 4

Condensate Drains 4

Cabinet / Air Tunnel 5

Vestibule Enclosure 5

Combustion Air 6

Gas Supply and Piping 7, 8

Electrical Requirements 8

Venting 9

Outdoor 9

Indoor 9-12

Airflow / Turndown 13

Burner Operation, Wiring Diagrams 13

Instructions & Labels 14

Annual Inspection & Maintenance 14

HE Series Ratings 15

3

Duct Furnace Ratings

A Rating Plate is attached to the front shroud of the duct furnace to identify the model and serial number of this

product. This plate must be left attached when the furnace is installed in the product for identification purposes. The

Rating Plate contains information including gas type, maximum and minimum input rating for this furnace assembly

and application, manifold pressure to provide rated Btuh input, maximum and minimum inlet supply gas pressure,

maximum and minimum airflow requirements, output capacity and electrical ratings for this specific module.

A Nameplate / Rating Plate is also attached to the power burner housing by the burner manufacturer, indicating the

input range, gas manifold pressure and electrical ratings for the power burner. The power burners used in these duct

furnaces typically have a wide range of input settings allowing a specific burner model to be used on more than one

size duct furnace. The burner has been orificed to provide the maximum input for this duct furnace at the manifold

pressure marked on the Furnace Rating Plate attached to the front shroud. Never adjust burner for inputs

exceeding the marked furnace maximum input.

Conditions of Application

This duct furnace must be applied in accordance with the requirements of its listing as follows:

Maximum input ratings, duct and cabinet clearances to heat transfer surfaces, maximum and minimum

temperature rise and maximum and minimum airflow.

Installed on the positive side of the circulating air blower only.

Installed in a Non-Combustible Duct or Cabinet and is not designed to have any portion of the heat

exchanger exposed outside the duct or cabinet in which it is housed. The furnace heat exchanger should be

sheathed to direct airflow over the heat exchanger surfaces (See Pg.4)

Have adequate airflow within the duct or cabinet, sufficiently well distributed to limit the maximum

temperature above inlet air temperature on heat exchanger surfaces as follows:

o409 Stainless Steel 1080 oF 304 Stainless Steel 1380 oF

Specify Vent pipe the same diameter or cross-sectional area equal to flue collar or integral vent connector.

In constant volume airflow or modulating applications, burner turndown is limited to maintain the required

minimum 20 oF rise across the heat exchanger. For applications using 50% or more outside air, other

restrictions may apply. Refer to section “Airflow Consideration and Burner Turndown.

May be installed in series, provided the discharge air temperature does not exceed an average of 160 oF

above Room Temperature.

Clearances to combustibles as appropriate for the design, but in no case less than the following unless

determined by test as part of the manufacturer’s listing:

6 in. – Sides and back 2 in. – Bottom 36 in. – Top 24 in. – Front 2 in.- Vent

The equipment manufacturer shall provide adequate Installation and Operating Instructions for the completed air

handling unit to which the duct furnace is applied. The Installer/User Instructions, Gas Burner Instructions and Flame

Safeguard Instructions as well as wiring and piping diagrams provided in the information package shipped with this

duct furnace must be included with the finished product at the time of shipment. In addition, see labelling

requirements on Page 14.

WARNING

Never adjust burner for an input rate exceeding the maximum input marked on the DUCT FURNACE

rating plate located on front shroud. Damage to the furnace and hazardous operation can result.

4

Duct Furnace Installation

Figure 1 -Typical Installation

Locate circulating blower at least 24 inches from closest heater surface. Locate downstream filters (if used) at least

36 inches from closest heater surface.

An automatic reset High Limit Switch is provided in accordance with the listing standard to shut-off of the gas

supply to the main burners if the outlet air exceeds the allowable maximum. The switch is set at 180 oF. Do Not Set

switch to a higher temperature.

An airflow proving switch is provided to insure circulating airflow over the heat exchanger prior to burner ignition

and operation. Uncoil tubing from circulating airflow switch provided, and position open end of tube in representative

location facing the airflow.

An auxiliary manual reset temperature limit must be installed in the duct furnace module application. A manual

reset auxiliary limit prevents overheating of the furnace module in the event of a circulating air fan failure or

reverse air flow. Under these conditions the integral primary high limit would cycle the heater resulting in possible

heat build-up and damage to the heating unit.

Duct furnaces may be installed downstream of cooling systems.

Condensate drain lines must be connected if heating unit is equipped with modulating controls or if it is located

downstream of cooling section or is equipped with modulating gas controls. ½ ” NPT condensate drain fittings are

provided in each collector box. Condensate drain lines should be corrosion resistant. If Metal tubing is used, it must

have corrosion resistance at least equal to that of 304 SS. Copper tubing is not suitable for flue gas condensate.

Attach drain lines with proper pitch (1/4” per 12”) to provide positive drainage of any condensate. Free flow of any

condensate that may be present is critical to life of the heat exchanger.

Provide proper rigging to support furnace during installation into cabinet. Do not lift module by tubes or burner

housing, as damage could result.

Expansion and contraction occur during heating and cooling cycles and heat exchanger mounting employs

elongated slots for mounting bolts. Nuts and washers are used to secure heat exchanger elements to the frame in a

manner that will allow for expansion of the heat exchanger assembly within the frame. NEVER tighten nuts to

supports. Heat exchanger damage can occur.

5

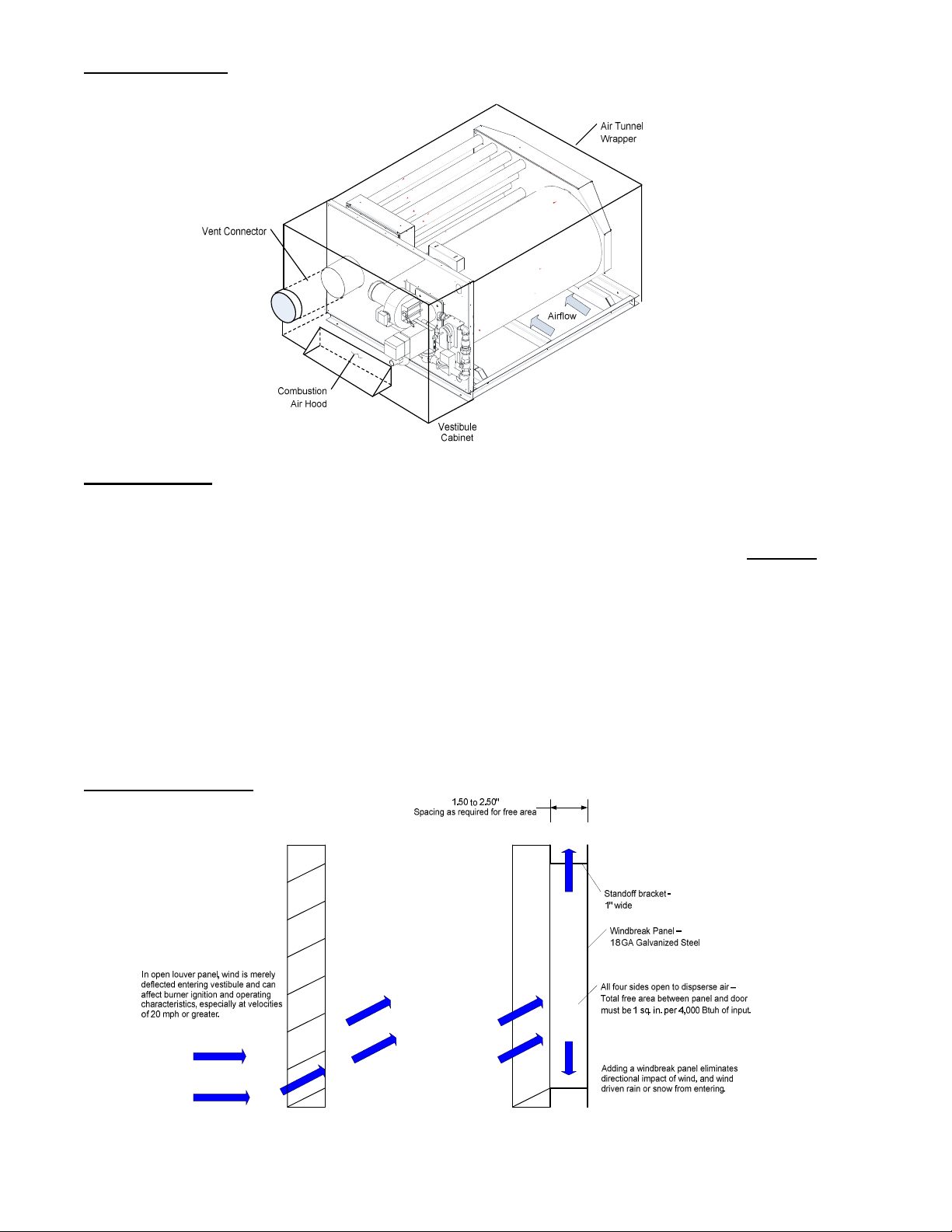

Cabinet / Air Tunnel Size

Sheeting must be added to HE modules to direct airflow over the heat exchanger. See diagram below for proper

sheeting guidelines.

If the AHU cabinet is larger than the sheeted heat exchanger assembly, block off panels must be installed to prevent

circulating air from bypassing the heat exchanger.

Provide removable access panels on both upstream and downstream sides of ductwork. These openings

need to be large enough to inspect heat exchanger for leaks (i.e.. smoke or light test) and observe heat exchanger

for hot spots indicating poor air distribution.

Vestibule Enclosure

Provide an enclosed vestibule area (See Figure 2) to house and protect gas controls, burner assemblies,

combustion air fans and electrical controls. For outdoor applications this enclosure must be weathertight.

Provide access door or panels for access to burners and components. Access panels or doors to the vestibule

area should be sized and located to provide easy access for adjustment, servicing and maintenance of gas and

electrical controls.

Provide a vent connector the same size as the flue collar for attachment of vent pipe on the installed unit. All joints

in the vent connectors inside the vestibule must be sealed to prevent leakage of flue gases in the vestibule area and

into the combustion air supplied to the burners.

Permanent connection of the line voltage supply shall be made into the vestibule area on part of the assembly that

does not require movement during normal servicing and adjustment. Means shall be provided for connection of

metal clad cable or conduit housing the line-voltage supply circuit to the appliance enclosure.

Using the top of the insulated front

shroud as a guide, sheet horizontally

back to join the vertical sheeting

For optimum performance

sheet vertically from the end

of the base rail

This right to left airflow heat

exchanger is now in place in the

AHU air tunnel

Note: Insulation used for sheeting

adjacent to heat exchanger should be

rated for 850 oF. Otherwise a heat

shield with a minimum gap of 1in. must

be used for vertical sheeting

6

Figure 2 - Vestibule

Combustion Air

Air required for combustion is drawn in through the inlet of the burner fan assembly. The vestibule in which burner is

installed must have an ample supply of combustion air. Opening(s) in a panel or door (except separated

combustion systems) must be provided in the enclosure and should be sized at 1 square inch of open area per

4,000 Btuh of input.

Openings should be located to avoid recirculation of flue gases from the vent discharge into the combustion air

supply. Consideration should be given to location of air openings so that flow of air is not impeded by other features

of unit design and also to prevent blockage from snow build-up for outdoor installations.

Louvered openings may restrict free area up to 50%. If louvers are employed be sure the overall opening size is

sufficient. Additionally, for outdoor installations with louvered panels, a windbreak should be provided to prevent

accumulation of wind driven rain or snow on components. See Figure 3.

Figure 3 - Windbreak

7

Gas Supply and Piping

Installation of gas piping must conform with ANSI Z223.1 (NFPA 54) National Fuel Gas Code. In Canada,

installation must be in accordance with CAN/CGA –B149.1 for Natural gas and B149.2 for propane units.

Use a pipe sealant resistant to LP gases on gas supply connections to heater.

Properly support gas valve with back-up wrench, during installation to prevent loosening valves or damage to

burner assembly or manifold.

Supply piping must be the same size or larger than piping supplied on the burner assembly

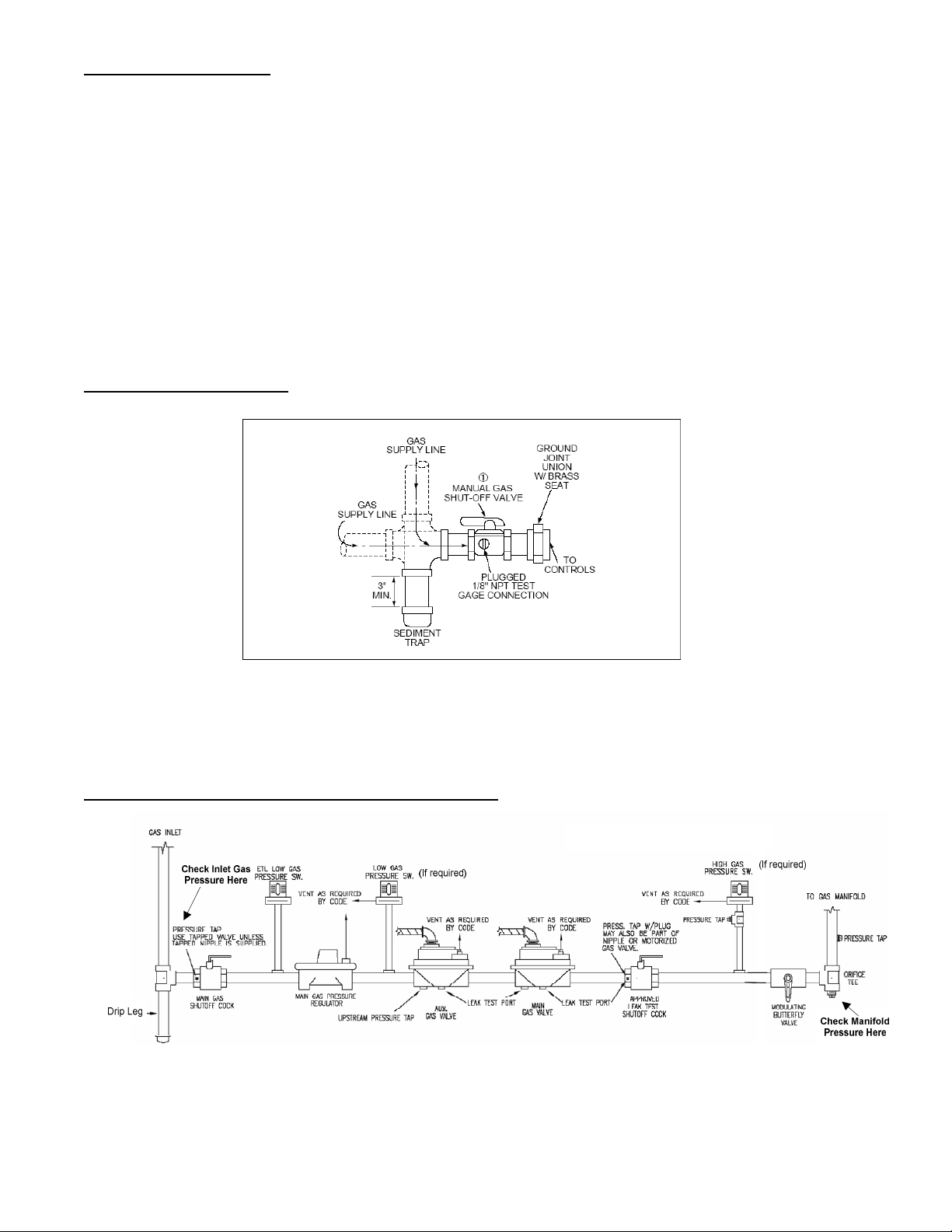

The manufacturer’s instructions must specify the use of drip leg (sediment trap) and a manual shut off valve

immediately upstream of the gas control on the heating unit. To facilitate servicing of unit, installation of a union is

recommended. (See Figure 4)

Figure 4 – Sediment Trap

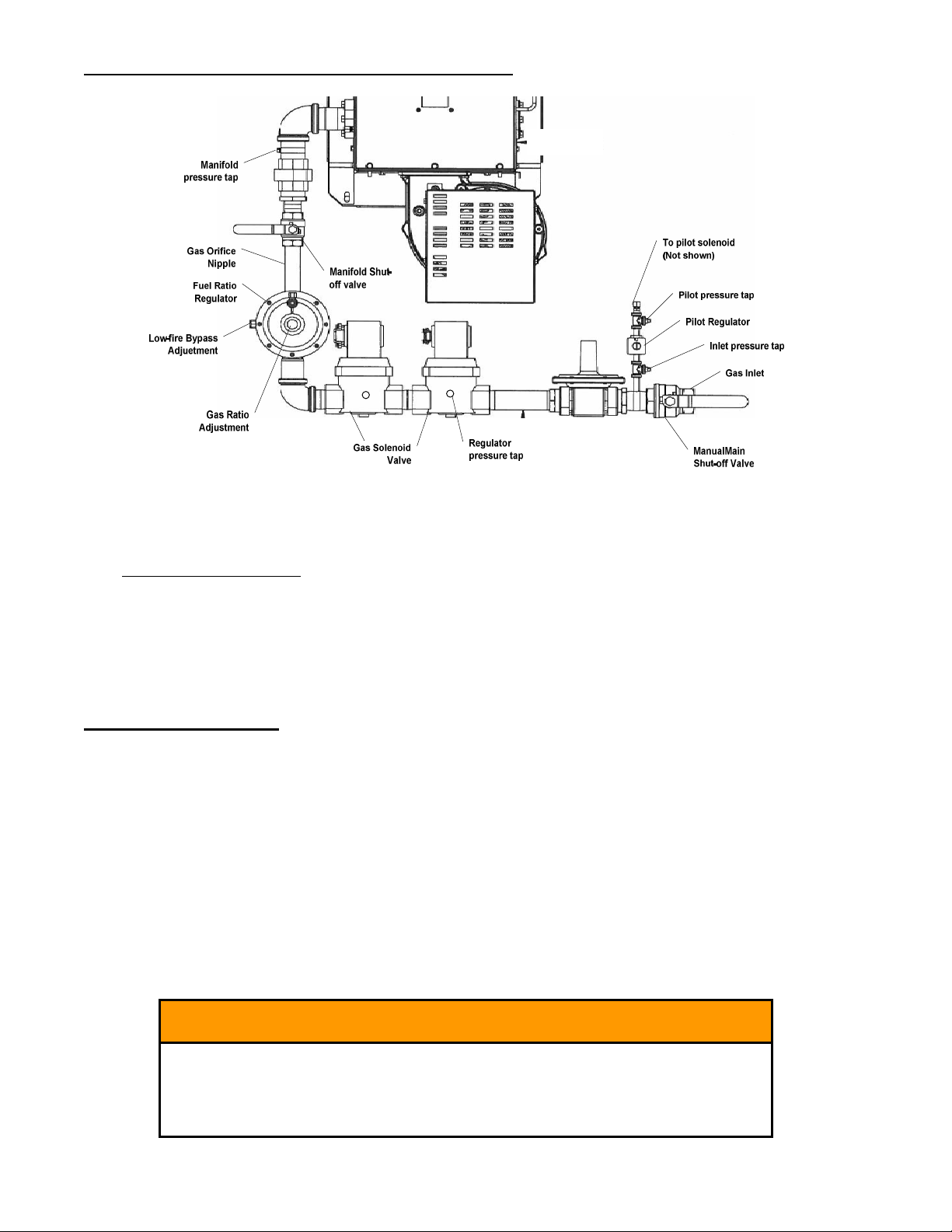

Gas burners are Listed to UL Standard 295 and have valve trains that meet UL and FM requirements. Valve train

configuration depends on the burner utilized. See Figures 5 and 6 for typical gas piping and valve trains.

Figure 5- Typical Gas Piping – Power Flame Burners

Verify setting of ETL Low gas pressure switch (Power Flame burners only) is 5.0” w.c.

8

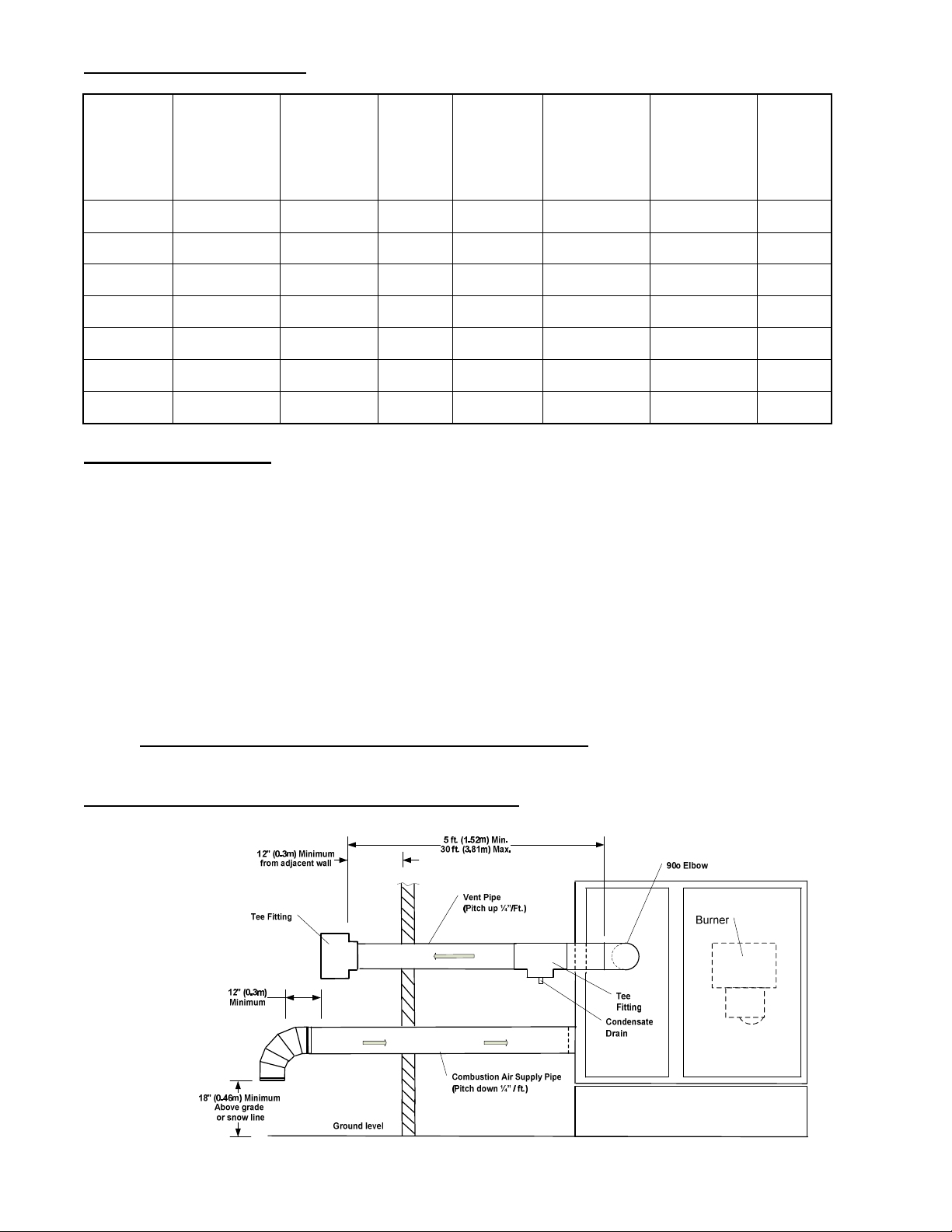

Figure 6- Typical Gas Piping – Midco V Series Burners

Prior to shipment check both the supply lines and factory piping for leaks. Apply a soap and water solution to all

joints and watch for bubbles indicating a leak. NEVER test for gas leaks with an open flame.

The duct furnace requires a minimum inlet gas pressure of 7.0 “w.c. and a maximum inlet gas pressure of 13.5”

w.c., with the furnace operating.

Instructions are provided with the power gas burner installed on furnace covering proper set-up and adjustment,

including minimum rate adjustment. These instructions must be included with the fully assembled product.

If gas pressure switches are provided, they are listed, vent limited switches and do not require vent piping to the

building exterior.

Electrical Requirements

All electrical equipment must be grounded and wired be in accordance with the National Electric Code (ANSI/NFPA

70) in the United States, and the Canadian Electric Code (CSA C22.1), in Canada. The installer / equipment

manufacturer is responsible for final compliance with these requirements.

Permanent connection of the line voltage supply shall be made in the vestibule area on part of the assembly that

does not require movement during normal servicing and adjustment. Means shall be provided for connection of

metal clad cable or conduit housing the line-voltage supply circuit to the appliance enclosure. Line voltage and

safety circuit wiring which is external to the appliance enclosure must be protected by metal clad cable or conduit.

The furnace control system requires both line voltage and low voltage circuits with correct polarity, and clean neutral

and ground. Line voltage readings between L1 and Neutral as well as L1 and Ground should be within +/- 3 volts.

Refer to the furnace rating / nameplate for electrical ratings.

WARNING !

Wiring must be in accordance with wiring diagram provided. Altering

the wiring could result in a hazard to persons and property.

If any original factory wiring must be replaced, replacement wiring

material must have a temperature rating of at least 105 oC.

9

Venting

Installation of venting system in U.S. must conform to local building codes and / or the National Fuel Gas

Code (ANSI Z223.1) or in Canada the Canadian Installation Code (CAN/CGA-B149) and the manufacturer’s

installation instructions. If venting requirements exceed these guidelines, a custom vent design may be required.

Proper venting of the heating section is important to safe and efficient operation of the duct furnace. Vent

materials are provided by others and must be of a suitable type for the Category

Outdoor Installation

1. The vent piping must be the same diameter as the integral vent connector.

2. See Figure 7 below for preferred outdoor venting configuration. The vent termination or cap must extend a

minimum of 18 inches feet above the AHU cabinet. Transition from horizontal to vertical should be made in

a “T” fitting. Provide a drain opening in the bottom of the “T” to drain condensate that may form in vent stack

during heater operation.

3. Use of B Vent is acceptable and helps reduce condensation in outdoor vent pipe runs.

Figure 7 – Outdoor Vent Installation

Indoor Installations

All duct furnaces installed indoors must be connected to a venting system to convey flue gases outside of

the heated space. Standard indoor installations use building air for combustion air supply and vent the products of

combustion outdoors through a single wall or roof penetration.

Vent pressures are positive and therefore are classified as Category III venting systems in accordance with ANSI

standards. All vent pipe joints must be sealed to prevent leakage of flue gases into the heated space. Specify use

of Category III vent materials listed to UL1738 / ULC S636 for vent pipe and fittings only. Provide a minimum

of 12 inches of straight vent pipe after the discharge connection before tee fittings or elbows.

Proper venting of the heating units is the responsibility of the installer. Vent piping is supplied by others.

EACH DUCT FURNACE MUST HAVE ITS OWN INDIVIDUAL VENT PIPE AND TERMINAL. Do not connect vent pipe to

other vent systems or a chimney. Down turned sections are not permitted in vent piping runs.

Indoor Installations require a blocked vent safety switch to shut-off burner in the event of a blockage in the vent

pipe. Specify unit for indoor installation or request switch kit.

10

Figure 8 - Standard Horizontal and Vertical Indoor Venting Arrangements

Horizontal Venting

Vertical Venting

WARN

ING

!

Indoor furnaces are equipped with a blocked vent safety switch to shut-

off gas supply to the main burner in the event that a blockage occurs in

the venting system downstream of the heater. Do not disable or bypass

this switch. Disabling switch may result in hazardous operation.

11

Table 1 – Vent Connector Size

Model

Size

Maximum

Input (Btuh)

Flue

Exhaust

Max.

Eq.

Vent

Length

(ft.)

Model

Size

Maximum

Input (Btuh)

Flue Exhaust

Max.

Eq.

Vent

Length

(ft.)

Diameter

(inch)

Diameter

(inch)

HE0250 325,000 6 60 HE1500 1,875,000 12 60

HE0320 400,000 6 60 HE1750 2,250,000 12 60

HE0400 550,000 6 60 HE2000 2,500,000 12 60

HE0500 625,000 8 60 HE2500 3,000,000 14 60

HE0750 950,000 10 60 HE3000 3,750,000 14 60

HE1000 1,250,000 10 60 HE4000 5,000,000 14 60

HE1250 1,550,000 10 60

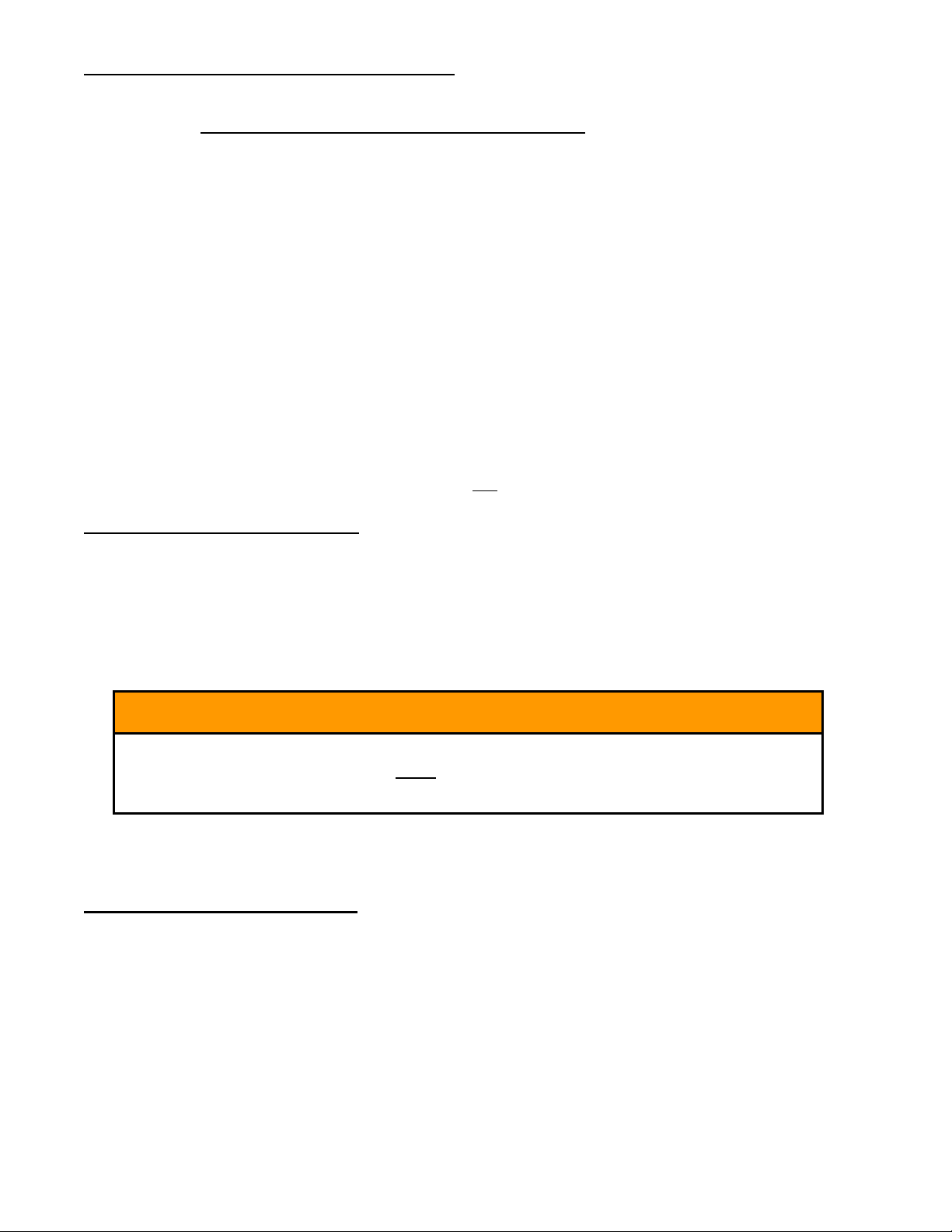

Separated Combustion

In indoor applications where combustion air must be brought from outdoors, a two-pipe separated combustion

system may be used.

The duct furnace must be mounted with the burner section in a reasonably airtight vestibule compartment. No air

openings are to be provided in the vestibule access door or panel communicating with the heated space and sealing

grommets or gaskets must be provided for doors or access panels, gas and electrical entry points into the vestibule

to maintain a reasonably airtight seal.

Provide the following information in the Installation and Operating Instruction Manual:

1. Vent pipe must be Category III vent materials listed to UL1738 / ULC S636. Air piping may be single

wall 24-gauge galvanized pipe with joints sealed with silicone caulking or metal tape.

2. Category III vent materials must be from the same vent manufacturer. Do Not intermix vent system parts

from different vent manufacturers.

3. Separated combustion systems may not be common vented. Each heater must have its own

individual air supply and flue gas exhaust vent.

Figure 9 – Separated Combustion – Horizontal Venting

12

Alternate Vent Terminations

Vent Pipe

18" (.45m) Minimum

Combustion Air

Inlet Pipe

6 ft. (1.8m) Min.

to Adjacent Wall

or Buidliung

24" (0.6m) Min.

From adjacent

Wall or building

90o Elbow

Vent Pipe

(Pitch up ¼”/Ft.)

Condensate

Drain

Tee

Fitting

Combustion Air Supply Pipe

(Pitch down ¼” / ft.)

Listed Vent Cap

Ground level

Burner

Gas Burner

18" (0.45m) Minimum

Above grade

or snow line

12" (0.3m) Minimum

from adjacent wall

12" (0.3m)

Minimum

18" (.45m)

Minimum

5 ft. (1.52m) Min.

30 ft. (3.81m) Max.

Figure 10 – Separated Combustion – Horizontal Venting

Table 2 – Vent and Air Pipe Size

Model

Size

Maximum

Input

(Btuh)

Flue

Exhaust Air Intake

Max.

Eq.

Vent

Length

(ft.)

Model

Size

Maximum

Input

(Btuh)

Flue

Exhaust Air Intake

Max.

Eq.

Vent

Length

(ft.)

Diameter

(inch)

Diameter

(inch)

Diameter

(inch)

Diameter

(inch)

HE0250 325,000 6 6 30 HE1500 1,875,000 12 12 30

HE0320 400,000 6 6 30 HE1750 2,250,000 12 12 30

HE0400 550,000 6 6 30 HE2000 2,500,000 12 12 30

HE0500 625,000 8 8 30 HE2500 3,000,000 14 14 30

HE0750 950,000 10 10 30 HE3000 3,750,000 14 14 30

HE1000 1,250,000 10 10 30 HE4000 5,000,000 14 14 30

HE1250 1,550,000 10 10 30

13

Airflow Considerations and Burner Turndown

The HE duct furnace is a Category III appliance for non-condensing operation with a positive vent pressure.

Operating under continuous condensing conditions must be avoided.

The likelihood of condensing operation increases with:

a.) Colder return air across the heat exchanger as on units supplying a large % of return air as outside air

b.) Lower heat flow through heat exchanger, as with modulating burners operating at reduced input

c.) Higher airflow across the heat exchanger as with low temperature rise applications or constant volume

airflow while modulating burner input.

d.) Applications where heat exchanger is over-sized for actual heat requirements and unit typically runs at 50%

input rating or less.

These conditions can result in reduced heat exchanger temperatures, especially on the secondary tubes. If the tube

surfaces fall below the dew point of the flue gases passing through them, condensation of the water vapor present in

the flue gas can occur inside the tubes. This condensate is mildly corrosive and can damage heat exchanger.

If any of these conditions is expected, a bypass duct or section should be included so that proper airflow can be

maintained over the heat exchanger to provide sufficient temperature rise and avoid operating conditions where

continuous condensation occurs. Bypass duct should be sized to reduce airflow to provide at least a 20 oF rise

across the furnace, or higher as practical, to provide the desired supply air temperature and maintain flue gas

temperatures at furnace outlet of 200 oF or higher under any operating condition.

Burner Adjustment and Operation

Manufacturer’s instructions for proper set-up, adjustment and operation of the power burner installed are provided

with this furnace. Each duct furnace is test-fired at the factory to verify proper component operation. A copy of the

Test and Inspection sheet is also included.

Final adjustment must be made with duct furnace connected to the venting system. Refer to burner manufacturer

instructions provided for proper burner set-up.

A Start-up Information sheet is provided with these instructions and the Installer/User Instruction package provided.

This form must be completed at the time of start-up and adjustment and returned to validate warranty coverage.

Wiring Diagrams and Instructions

Each duct furnace is shipped with its own wiring diagram, sequence of operation and control diagnostic information

for the control system provided on the furnace as part of this OEM information package. These documents should

be retained by the air handling unit manufacturer for future reference

A separate Operating and Maintenance Instruction package is provided with each duct furnace including these

documents. This package should be included with the manufacturer’s instructions sent with the appliance.

WARNING !

The power burner provided with this furnace requires a Qualified Burner Technician

for start-up. A flue gas analyzer must be used when making adjustments to insure

proper combustion. Improper set-up may result in hazardous operation.

14

Label Requirements

The following labels are provided with the OEM package and must be affixed to the exterior of the appliance.

A Lighting and Operating label is also provided in the instruction package. This label must be attached to

the appliance in a conspicuous place preferably near the appliance control panel.

Annual Inspection and Maintenance

Provide instructions for proper maintenance and inspection of the heating system including the following:

Gas Supply

Remove the drip leg and clean any debris or liquid that may have accumulated. Re-attach drip leg and plug.

Turn off electrical supply to unit. Verify that there is no leakage from combination gas valve (no manifold

pressure) with the system at normal inlet pressure and no power to gas valve.

Burners

Burner should be inspected to verify that all components are free from damage and cleaned of any debris in

accordance with the burner manufacturer’s instructions provided.

Condensate Drains

Inspect periodically. Verify proper flow of any condensate present.

Be sure that condensate drain lines are not obstructed. Clean any debris or blockage from the line.

Ensure that freeze protection is functioning properly if provided.

Heat Exchanger / Flue Collector

The heat exchanger and collector box should be checked annually for deterioration and cracks. If any areas

are detected where leakage of flue gases could occur, the heat exchanger or collector should be replaced

before putting the unit back into operation.

Inspect condensate drain lines to insure they are not corroded or blocked. Clean or replace as necessary

Flue gas passageways should be inspected and cleared of any debris or loose foreign matter.

WARNING!

Improper installation, adjustment, alteration,

service or maintenance can cause injury or

death. Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing this equipment.

Une installation, un réglage, une

modification, une réparation ou un

entretien non conforme aux normes peut

entraiiner des dommages matériels, des

blessures ou la mort. Lisez attentivement

les instructions d’installation, de

fonctionnement et d’entretien avant de faire

l’instal

l

ation ou l’entr

e

t

ien cet equipment.

AVERTISSEMENT

15

Electrical Wiring

Check wiring for loose connections or deterioration. Tighten connections and replace any wiring that is

deteriorated. Wiring materials must be replaced with wire suitable for at least 105 oC.

HE Series Ratings

Model

No.

Input

Rate Output Temp Rise Air Flow @ Min.

Duct Opening

Min. Max Min. Max.

Btuh Btuh oF oF cfm cfm

W W oC oC m3/s m3/s

HE0250 325,000 260,000 20 100 2407 12037

95,248 76198 11 56 1.14 5.68

HE320 400,000 320,000 20 100 2963 14815

117,228 93782 11 56 1.40 6.99

HE0400 550,000 440,000 20 100 4074 20370

161,189 128951 11 56 1.92 9.62

HE0500 625,000 500,000 20 100 4630 23148

183,169 146535 11 56 2.19 10.93

HE0750 950,000 760,000 20 100 7037 35185

278,417 222733 11 56 3.32 16.61

HE1000 1,250,000 1,000,000 20 100 9259 46296

366,338 293070 11 56 4.37 21.85

HE1250 1,550,000 1,240,000 20 100 11481 57407

454,259 363407 11 56 5.42 27.10

HE1500 1,875,000 1,500,000 20 100 13889 69444

549,506 439605 11 56 6.56 32.78

HE1750 2,250,000 1,800,000 20 100 16667 83333

659,408 527526 11 56 7.87 39.33

HE2000 2,500,000 2,000,000 20 100 18519 92593

732,675 586140 11 56 8.74 43.71

HE2500 3,000,000 2,400,000 20 100 22222 111111

879,210 703368 11 56 10.49 52.45

HE3000 3,750,000 3,000,000 20 100 27778 138889

1,099,013 879210 11 56 13.11 65.56

HE4000 5,000,000 4,000,000 20 100 37037 185185

1,465,350 1172280 11 56 17.48 87.41

16

(Page Left Blank)

Heatco Inc.

Cartersville, GA. 30120

Other manuals for HE SERIES

1

This manual suits for next models

13

Table of contents

Other heatco Furnace manuals

Popular Furnace manuals by other brands

Lennox

Lennox G50UH Series installation instructions

Nordyne

Nordyne SC Series installation instructions

Empire Heating Systems

Empire Heating Systems GWT-25-3 Installation instructions and owner's manual

Coleman

Coleman UGAA075BUJ installation manual

Lennox

Lennox ML195UH User's information manual

Payne

Payne PG95XAT Product data