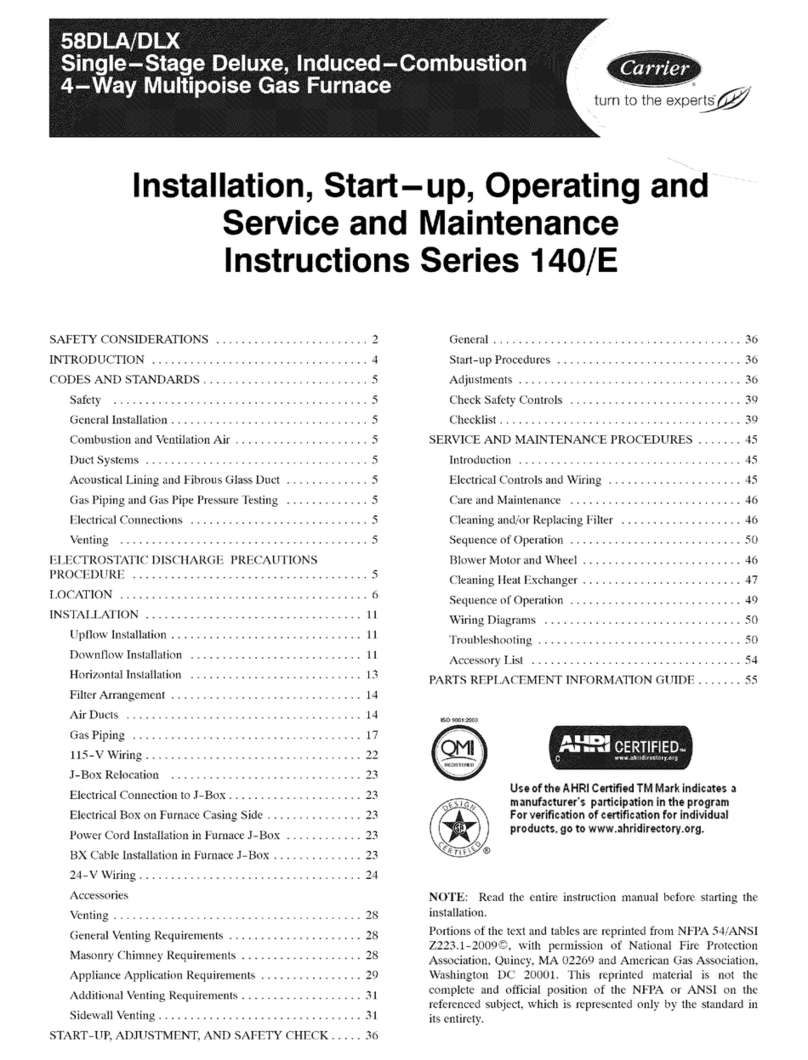

9. Use a manometer to check the pilot pressure at the tap provided.

a) Pilot gas pressure should be 3.2” to 3.5” W.C

10. Open the Manifold gas shut-off valve. With an analog input of 2.0 VDC burner will run at low fire.

11. Using the observation window on the burner back plate look at the low fire condition. If light is visible

through all the holes in the burner plate, low fire is set within range. If flame is not visible through all holes,

then low fire setting is too low.

12. Locate the low fire bypass adjustment on the side of the Fuel Ratio Regulator.

13. Increase gas flow (turn adjusting screw counter-clockwise) until flame is visible through all holes.

14. Using a combustion analyzer, sample the flue gases at the vent discharge of the furnace. Verify that

readings range as follows:

Natural Gas Propane Gas

CO2…….. 1.5 to 2.8% 2.0 to 3.2%

O2…….. 16.0 to 18.5% 16.0 to 18.0%

CO …….. <100 ppm <100 ppm

Flue Gas Temp …….. < 100oF < 100oF

15. Modulate the burner to high fire by applying a 10 VDC analog input signal.

16. Verify the main regulator gas pressure setting as follows and adjust regulator if necessary:

a. Natural Gas – Regulator outlet pressure 6.0” W.C.

b. Propane Gas – Regulator outlet pressure 9.0” W.C.

17. Verify that the manifold pressure is the same as marked on the Furnace rating plate.

Note: Burners are not always set-up to their maximum capacity. The manifold pressure marked on

furnace rating plate or in the “Firing Rate” portion of the burner rating label, provides the correct fuel

input rating for the appliance.

18. Using a combustion analyzer, sample the flue gases at the vent discharge of the furnace. Verify that

readings range as follows:

Natural Gas Propane Gas

CO2…….. 8.5 to 10.0% 9.0 to 11.0%

O2…….. 3.0 to 5.0% 4.0 to 6.0%

CO …….. <100 ppm <100 ppm

Flue Gas Temp …….. < 150oF < 150oF

19. A Start-Up Data sheet is included with these instructions. Please complete this sheet and return the top

half to address shown. Keep bottom portion with instructions for future service reference.

20. Refer to the Burner Manufacturer’s instructions provided with this information package if any adjustments

need to be made to obtain correct manifold pressure or combustion characteristics.

Commissioning / Final Preparation

1. Remove call for heat (Open heat enable contact)

2. Close main manual shut-off gas valve.

3. Turn off main power disconnect and burner control panel switch

4. Remove pressure tap fittings and gauges used for pressure measurements. Replace pipe plugs.

5. Open main manual shut-off valve and check for leaks where pipe plugs were replaced.

6. Close main manual shut-off gas valve.

7. Reinstall caps to the pilot regulator, main regulator, low-fire bypass and ratio regulator that may have been

removed during start-up.

Never adjust burner for an input rate exceeding the maximum input marked on the

FURNACE rating plate. Damage to the furnace and hazardous operation can result.