Heatex B Operating and safety instructions

heatex.com

MODEL B

INSTALLATION & MAINTENANCE MANUAL

heatex.com

Table of contents

ORIGINAL

GENERAL

BY DELIVERY

TRANSPORT

STORAGE

INSTALLATION

ADJUSTMENTS

MAINTENANCE

MATRIX

HYBRID/ADSORPTION MATERIAL

BRUSH SEALANTS

CONTROLLER

APPLICATION LIMITS

TROUBLESHOOTING

CONDITIONS TO FULFILLING THE HYGIENE CERTIFICATION REQUIREMENTS

SUPPORT

heatex.com

Declaration of Incorporation

Heatex AB

Bronsyxegatan 13

SE-213 75

Malmö

Sweden

Description and identification of the partly completed machinery:

Rotary heat exchanger model B with casing and with a drive unit.

The following essential requirements of EC Machinery Directive 2006/42/EC have been applied and

fulfilled:

1.1.2, 1.2.1, 1.2.3, 1.2.4.1, 1.2.4.2, 1.2.4.3, 1.2.6, 1.3.1, 1.3.2, 1.3.4, 1.3.7, 1.3.8, 1.3.8.1, 1.3.8.2, 1.4.1,

1.4.2.1, 1.4.2.2, 1.4.2.3, 1.4.3, 1.5.1, 1.5.2, 1.5.4, 1.5.5, 1.5.6, 1.6.1, 1.6.3, 1.7.1, 1.7.3, 1.7.4, 1.7.4.1,

1.7.4.2, 1.7.4.3

The relevant technical documentation has been compiled in accordance with Annex VII, Part B of EC

Machinery Directive 2006/42/EC. We undertake, in response to a reasoned request, to supply it in

electronic form to the market surveillance authorities within a reasonable period.

The party authorized to compile the technical documentation is:

Ola Prahl, Product Manager Ventilation

The partly completed machinery must not be put into service until the final machinery into which it is

to be incorporated has been declared in conformity with the provisions of the Machinery Directive.

Malmö, 2014-07-01

heatex.com

General

A rotary heat exchanger with casing and

drive is “partly completed machinery” as

defined in Directive 2006/42/EC. This

product is delivered in compliance with the

Directive 2006/42/EC but when installed in

the complete machinery it is up to the

installer to make sure that the final product

complies with the directive.

Special attention should be paid to sharp

edges (risk of cuts) and that when the

wheel is rotating the rotating parts may

cause injuries.

The surfaces of the drive motor and gear

can be hot and attention should be paid to

the risk of burn injuries.

The sound level from the heat exchanger is

less than 70 dB (A).

By delivery

Before installation, the following should be

checked:

• Check if there are any signs of

transport damage before accepting

the goods.

• Has the right exchanger been

delivered? Check type, design, size

and options.

• How is the exchanger to be

positioned?

• In case of any damage, please

report this in writing by fax or

email as soon as possible.

Transport

• The weight of the unit can be found

on the product label attached to the

unit.

• Always transport the exchanger

vertically.

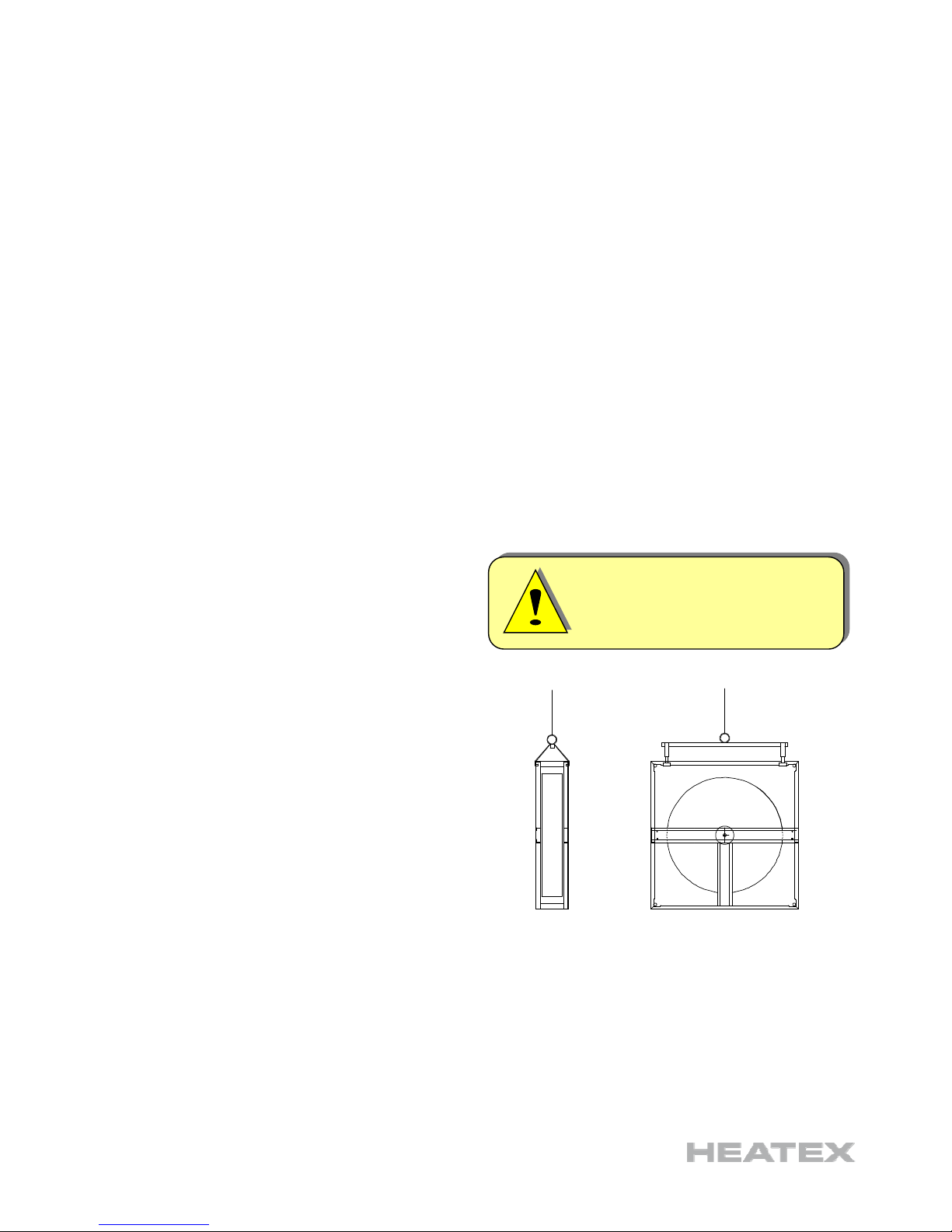

• Lift the exchanger in the upper two

aluminum rods alternatively the

gables according to picture 1.

• It is important that all transport is

carried out by qualified staff.

Picture 1. Lift the casing in the gables.

Alltransportandhandle

shallbecarriedoutby

q

ualifiedstaf

f

.

heatex.com

Storage

There are no other requirements for storage

than a horizontal even surface and out of

weather. Please note that an uneven surface

can wrap the cassette and affect the factory

adjustments.

Always make sure that the heat exchanger

is supported and secured during transport,

handling, storage and installation so it can

not fall over and cause damage or injuries.

Please observe that there may be sharp

edges and a risk for cuts so we recommend

that gloves be used when the heat

exchanger is handled.

Installation

• When designing the air handling

unit and or duct system, the system

designer needs to make sure it is

possible to remove/pull out the heat

exchanger for inspection,

maintenance, service, cleaning and

disinfection. Furthermore, the

system designer needs to consider

enough space inside and outside of

the system to make sure that it is

possible to remove/pull out the heat

exchanger.

For bigger heat exchanger units it is

required to add doors or hatches on

all sides in the air-handling unit

and/or duct system making it

possible to access the heat

exchanger for inspection,

maintenance, service, cleaning and

disinfection.

• In case condensate is present, it is

required by the designer of the air

handling unit and/or duct system, to

design and install a condensation

tray according to the norm VDI

6022, chapter 4.3.16

• The casing is self-supporting but

cannot take up extra load e. g.

ducts.

• Place the rotor on a horizontal

surface since an uneven surface can

wrap the casing and affect the

factory adjustments.

• Make sure that the front- and back

plates of the casing are installed

perpendicular to the horizontal

bottom surface. If not the casing

may interfere with the movement of

the rotor wheel

• In case of horizontal rotors, support

is needed for the frame and center

girder. Also, check that rotor is

ordered and manufactured as a

horizontal rotor. Rotor may only be

Usegloveswhenhandling

theheatexchanger.

Heatexchangermayfallover

ifnotsecured.

heatex.com

installed either in a vertical or a

horizontal position according to

design, not at an angle.

• Avoid diagonal flow since this can

affect the rotation and drive of the

wheel. Heatex AB recommends the

airflow to be perpendicular to the

rotor.

• The rotor is designed for counter

flow only; co-current flow will

decrease efficiency and reduce the

rotors self-cleaning.

• Prior to initial operation, please

make sure no objects are blocking

the rotors free movement. The rotor

should move evenly and smoothly

around its shaft.

• Drive motor if delivered with

controller is pre-wired and 230V

should just be wired to the

controller. Constant speed motors

are without wiring. It is important

that all electrical work is carried

out by qualified staff. Please see

enclosed documentation and/or

wiring Picture 2.

• If the unit is delivered with a

variable speed drive, read the

corresponding controller

documentation.

Adjustments

• If necessary, adjust the brush

sealants to minimize leakage.

• If the belt slides adjust belt tension.

• The round belt should have a

tension of 4-6% and Powerbelt

should have a tension of 1-2% (i.e.

belt should be 1-2% shorter than

the length it travels). For Powerbelt

remove one link per meter belt to

get correct tension.

Picture 2. Wiring diagram constant drive Δ/Y

220/380V.

IMPORTANT!

Allelectricalworkmustbe

carriedoutbyqualifiedstaff.

Placingtheunitonan

unevensurfacemaywrap

thecasing.

heatex.com

Maintenance

Matrix

To secure the function and performance,

the face of the rotor has to be inspected

regularly for dust and dirt. In most cases,

the self-cleaning due to counter flow and

rotation of the matrix makes manual

cleaning unneeded. If the self-cleaning is

insufficient dirt or/and dust can appear in

the matrix. Depending on the degree of

soiling it is recommended to use following

cleaning:

1. For only a small amount of easily

removable dirt, Heatex

recommends to use a vacuum

cleaner.

2. For heavier dirt it is also possible to

use compressed air but with

caution.

3. Firmly attached dirt in the rotor is

easiest removed by using hot water

and a mild detergent.

The mild detergent may be

removed with high-pressure water

cleaner with the nozzle placed 50-

100 mm from the matrix.

4. If required, Heatex recommends

disinfection with the substance

known as LIV +45.

Hybrid/Adsorption material

The adsorption material is aluminum

coated with a silica gel based coating.

There is a small amount of surplus material

that might leave the matrix during the first

time of usage. This will NOT affect the

hygroscopic properties. The excess powder

is harmless and easy to remove using a

vacuum cleaner.

The hybrid wheel properties are obtained

by a combination of a flat strip of

adsorption material consisting of silica gel

coated aluminum and a corrugated

aluminum strip, which result in a moisture

transfer capacity in between that of an

aluminum matrix and an adsorption matrix.

Just as for the adsorption wheel, a small

amount of surplus material may leave the

matrix during the first time of usage.

Powerbelt

The Powerbelt is subject to natural

stretching which may require shortening of

the belt. Tension of the belt must be

checked after the first 24-48 hours in

operation to secure the rotational function

of the wheel.

The belt is made of links that can easily be

added or removed without any tools. By

just twisting the belt, it is possible to open

it and remove links to shorten the belt until

correct length and belt tension is obtained.

Belt tension should be 1-2% (i.e. belt

length 1-2% shorter than travelled length).

For Powerbelt remove one link per meter

belt to get correct tension.

Round belt

In addition, the round belt may need

adjustment. When delivered from factory

the belt is welded together. If adjustment is

needed the belt must be cut, shortened and

joined together again with a special joining

pin. Belt tension should be 6-8%.

Brush sealants

Tightness between brush sealants and

casing has to be checked during inspection.

The brush sealants are easily adjusted by

unscrewing the screws and moving the

brush sealant into the right position.

heatex.com

Controller

For further information regarding rotary

heat exchanger equipped with controller,

please see corresponding controller

instructions.

Application limits

Recommended temperature limits for

rotary heat exchanger:

It is however important not to exceed the

temperature limits on mounted

components:

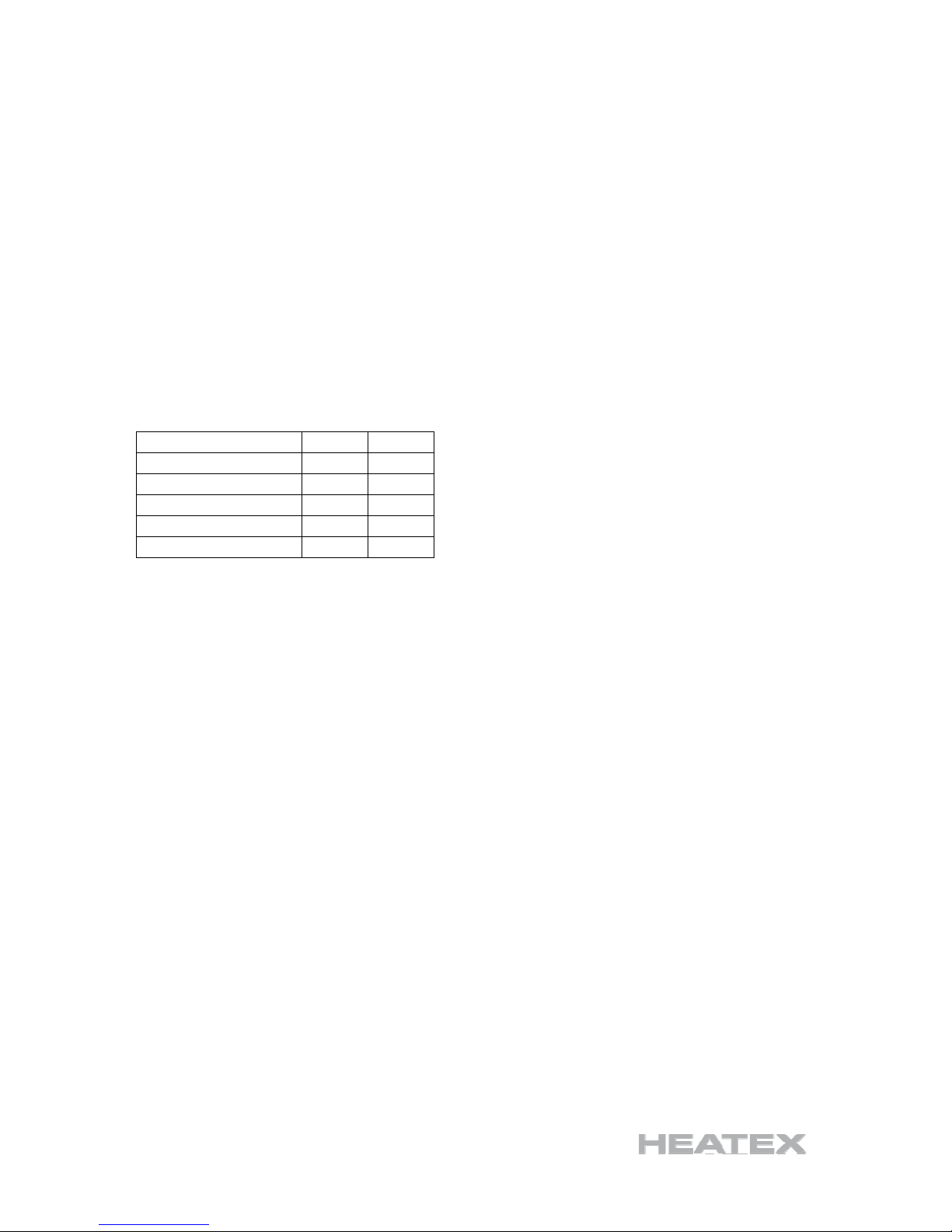

Component Min Max

Bearing temp. -40°C 110°C

Belt temp.* -40°C 66°C

Motor temp.** -20°C 40°C

Emotron Controller -30°C 40°C

Standard Controller 0°C 45°C

* Powerbelt max 110°C

**Thermo contacts release at 150°C inner temp.

Temperature inside casing is

approximately the mean temperature of

supply and exhaust air temperatures.

Recommended pressure drop and

differential pressure for rotary heat

exchanger:

• Pressure drop max 300 Pa

• Recommended P drop 100-200 Pa

• Differential pressure max 600 Pa.

Troubleshooting

If the rotary heat exchanger does not rotate

properly, please follow these steps to

solve/locate the problem.

1. If the motor runs properly, please

jump to step 5.

2. If there is a controller installed

please check controller technical

specifications, chapter

troubleshooting.

3. If there is a constant drive installed:

Please check that the drive is

correctly connected. Note that all

electrical maintenance and

installation must be performed by

qualified personal.

4. Disconnect the belt, is the motor

running correctly?

5. If the belt is sliding, please tighten

the belt according to maintenance

instruction.

6. Rotate the wheel by hand (belt

disconnected from the motor). Is it

possible to smoothly rotate the

wheel or does the wheel interacts

with the casing? If there is

mechanical friction, please locate

the position.

7. Make sure the connected ducts do

not press on the casing making it

squeeze against the wheel. Make

sure the diagonal measures of the

casing side where the motor is

positioned are equal.

heatex.com

Conditions to fulfilling the hygiene certification requirements

• Purge sector is required in order to

make sure that less carry-over than

3% is reached.

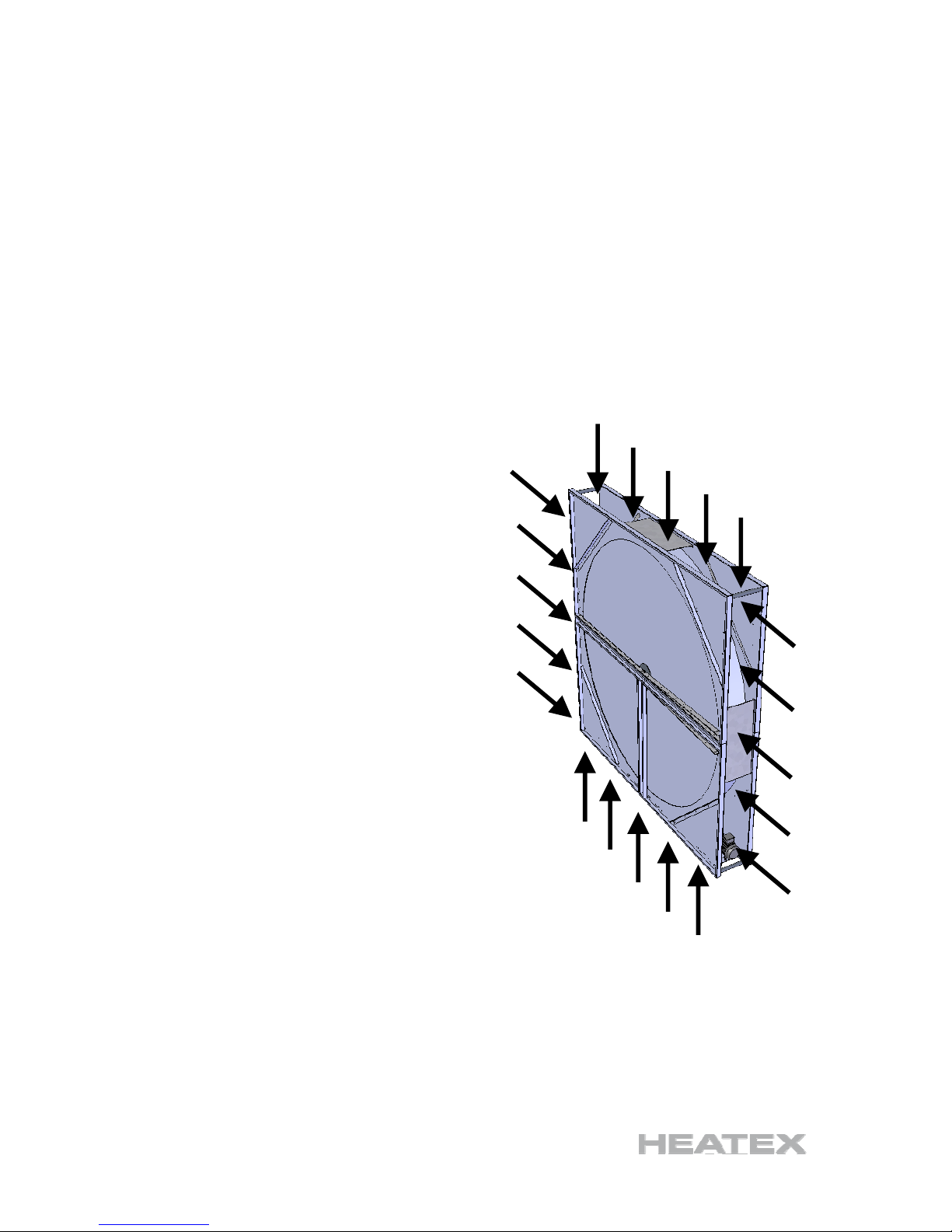

• The AHU needs to be designed

with hatches or openings towards

all 4 open sides of the rotary heat

exchanger. The heat exchanger

itself has all 4 sides open according

to the picture 3.

• All surfaces inside and outside of

the rotor casing, especially the

bottom surface and around the

motor should be reachable for

maintenance, cleaning and

disinfection. Meaning that the

openings or hatches mentioned in

the item above need to be of

sufficient size to fulfilling the

cleaning and disinfection

requirements.

• The AHU needs to be designed in

such a way that the rotary heat

exchanger is possible to slide out

for cleaning and disinfection.

• Cleaning and disinfection of the

heat exchanger should be done in

accordance with Heatex cleaning

and disinfection instructions with

the cleaning and disinfection

substances prescribed by Heatex.

• When condensation is present, the

AHU installer needs to make sure

that condensation trays are installed

beneath the heat exchanger. These

trays need regular inspection,

cleaning and disinfection.

• The trays should be designed and

installed with sufficient drainage in

accordance with the hygiene

standard VDI 6022, chapter 4.3.16.

• The heat exchangers are not

certified for installation in

exhausted classes ETA 3 and ETA

4 according to EN 13779

(09/2007).

(Picture 3, all 4 sides are open on the heat

exchanger. The AHU designer and installer

need to have openings or hatches on all of

these 4 sides in the AHU for easy access

during maintenance, cleaning and

disinfection of the heat exchanger)

heatex.com

Support

For questions or other requirements

regarding this product, please state order

number, product name and message.

Heatex is available for support during

office hours: 0800am – 0430pm (GMT +1)

on weekdays.

Please contact us:

Heatex AB

Bronsyxegatan 13

SE-213 75 Malmö, Sweden

Telephone +46 410 710 500

E-mail [email protected]

www.heatex.com

Owing to continued product development, Heatex AB reserves the right to

introduce alternations both in design and prices without prior notice.

Version: I&M M 2014 07

Other manuals for B

1

Table of contents

Popular Heat Pump manuals by other brands

Nulite

Nulite New Energy BKDX30-95I/1/S manual

Carrier

Carrier 50KQ006-019 Installation, Start-Up and Service Instructions

Mitsubishi Electric

Mitsubishi Electric PUHZ-SW160YKA-BS Service manual

C.P.A.

C.P.A. CLIMEXEL Series manual

Vaillant

Vaillant VWL 57/5 IS Operating, installation and maintenance instructions

Nortek

Nortek 1RP24K Series installation instructions