Heatrae Sadia Handy 3 NT User manual

Handy No Touch Electric Handwash

Fitting Instructions

Important

Please read & understand all these instructions

before commencing installation.

Please leave this manual with the customer for future

reference

This product can be used by children aged from 8 years and above and

persons with reduced physical sensory or mental capabilities or lack

of experience and knowledge if they have been given supervision or

instruction concerning use of the product in a safe way and understand

the hazards involved. Children shall not play with the product.

Cleaning and user maintenance shall not be made by children without

supervision. Children must be supervised to ensure they do not play

with the product.

Contents

1. Introduction...............................................................................................3

1.1 General ...............................................................................................3

1.2 Symbols used......................................................................................3

1.3 Abbreviations.......................................................................................3

1.4 Liabilities .............................................................................................3

2. Safety.........................................................................................................4

2.1 General safety warnings .....................................................................4

2.2 Recommendations ..............................................................................4

2.3 Specic safety instructions..................................................................4

3. Technical specications ..........................................................................5

3.1 Technical data .....................................................................................5

3.2 Dimensions and connections ..............................................................5

3.3 Electrical diagram(s) ...........................................................................6

4. Description of the product.......................................................................7

4.1 General description .............................................................................7

4.2 Operation principle ..............................................................................7

4.3 Standard delivery ................................................................................7

4.4 Main components................................................................................7

5. Before installation ...................................................................................8

5.1 Installation regulations ........................................................................8

5.2 Installation requirements .....................................................................8

5.3 Choice of location................................................................................9

6. Fitting Instructions ...................................................................................10

6.1 General ...............................................................................................10

6.2 Water connections...............................................................................10

6.3 Electrical connections .........................................................................11

7. Commissioning.........................................................................................12

7.1 General ...............................................................................................12

7.2 Checklist before commissioning..........................................................12

7.3 Commissioning procedure ..................................................................12

8. Operation...................................................................................................12

8.1 General ...............................................................................................12

9. Maintenance..............................................................................................13

9.1 General ...............................................................................................13

10. Troubleshooting.....................................................................................14

10.1 Decommissioning procedure.............................................................14

11. Spare parts .............................................................................................15

Warranty ........................................................................................................15

3

1. Introduction

1.1 General

The following instructions are offered as a guide to

the user and installer.

The installation must be carried out by a competent

plumbing and electrical installer in accordance

with Building Regulation G3 (England and Wales),

Technical Standard P3 (Scotland) or Building

Regulation P5 (Northern Ireland) and the Water

Fitting Regulations (England and Wales) or Water

Byelaws (Scotland).

1.2 Symbols used

In these instructions, various risk levels are employed

to draw the user’s attention to particular information.

In doing so we wish to safeguard the user, avoid

hazards and guarantee the correct operation of the

product.

WARNING

Risk of dangerous situation causing slight

physical injury.

CAUTION

Risk of material damage.

Signals important information.

1.3 Abbreviations

`PRD – Pressure relief device

`RCD – Residual current device

`MCB – Miniature circuit breaker

1.4 Liabilities

Manufacturers liability

Our products are manufactured in compliance with

the requirements of the various applicable European

Directives.

This product complies with the requirements of the

CE marking directive.

In the interest of UK customers, we are continuously

endeavouring to make improvements in product

quality. All the specications stated in this document

are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked

in the following cases:

`Failure to abide by the instructions on using the

product.

`Faulty or insufcient maintenance of the

product.

`Failure to abide by the instructions on installing

the product.

Installer's liability

The installer is responsible for the installation and

the commissioning of the product. The installer must

respect the following instructions:

`Read and follow the instructions given in the

manuals provided with the product.

`Carry out installation in compliance with the

prevailing legislation and standards.

`Perform the initial start up and carry out any

checks necessary.

`Complete the commissioning checklist.

`Explain the installation to the user.

`If maintenance is necessary, warn the user of

the obligation to check the product and maintain

it in good working order.

`Give the instruction manual to the user.

Users liability

To guarantee optimum operation of the product, the

user must respect the following instructions:

`Read and follow the instructions given in the

manuals provided with the product.

`Call on qualied professionals to carry out

installation and initial start-up.

`Get your installer to explain your installation to you.

`Have your required checks and services done.

`Keep the instruction manuals in good condition

and close to the product.

4

2.2 Recommendations

WARNING

The plumbing installation must comply

with Water Regulations.

The supply pipe must be ushed to clear

debris before connecting to the product.

DO NOT solder pipes or ttings within

300mm once the pipework is located

in the product, as heat transfer can

damage components.

DO NOT t any form of outlet ow control

as the outlet acts as a vent for the heater

can.

DO NOT use excessive force when tting

the spout xing nut, nger tightness is

sufcient.

All plumbing connections must be

completed and checked for leaks before

making the electrical connections.

2.3 Specic safety instructions

WARNING

Before tting the product, ensure that

the consumer unit and any switches

are suitable for the additional load. If in

doubt contact your electricity supplier or

a qualied electrician.

The installation must comply with

BS 7671 ‘Requirements for electrical

installations’ (IEE Wiring Regulations).

2. Safety

2.1 General safety warnings

WARNING

ISOLATE the electrical and water

supplies before removing the cover.

ISOLATE the electrical and water

supplies BEFORE proceeding with

installation or servicing.

DO NOT operate the product if:

`It is frozen or suspected of being

frozen. See fault nding table on

page 14.

`Water ceases to ow during use.

`Water has entered inside the

product because of an incorrectly

tted cover.

`The product is damaged.

CAUTION

`DO NOT tile up to the product

after xing to the wall.

`The sprayplate must be cleaned

when any of its holes become

blocked, otherwise restriction to

the ow from the outlet spout will

result in higher temperatures and

could also cause the pressure

relief device in the appliance to

operate - see 9.1 p13.

`The product is NOT SUITABLE

for mounting into steam rooms or

steam cubicles.

5

3. Technical specications

3.1 Technical data

Model numbers

3.1kW - Handwash - 95 020 115

3.2 Dimensions and connections

151

74

235

19.5

Dimensions in mm

196.5

Inlet water

connection

Terminal

block

29

86

Cable

clamp Rear entry access

area for electricity and

inlet water supply

Supplier’s name or trade mark Heatrae Sadia

Supplier’s model identier Handy 3 NT

The declared load prole XXS

The water heating energy efciency class of the model A

The water heating energy efciency in % 38.6

The annual electricity consumption in kWh 478

Daily fuel consumption in kWh 2.200

Specic precautions that shall be taken when the water heater is assembled, installed or

maintained and disposed of at end of life

See Section 3

to 11

Figure 1

Table: Technical parameters in accordance with European Commision regulations 814/2013

and 812/2013

6

Nominal Power Rating

Model 240V 230V Minimum

cable size

3.1kW 3.1kW

12.9 amp

2.9kW

12.4 amp

1.5mm2

Materials

Backplate and cover assembly - ABS

Element(s) - Copper sheathed rod type.

Dimensions

Height - 235mm

Width - 151mm

Depth - 85mm

Standards and approvals

Complies with the requirement of EN 60335-2-35.

Complies with European Community Directives

(CE). kiwa approved.

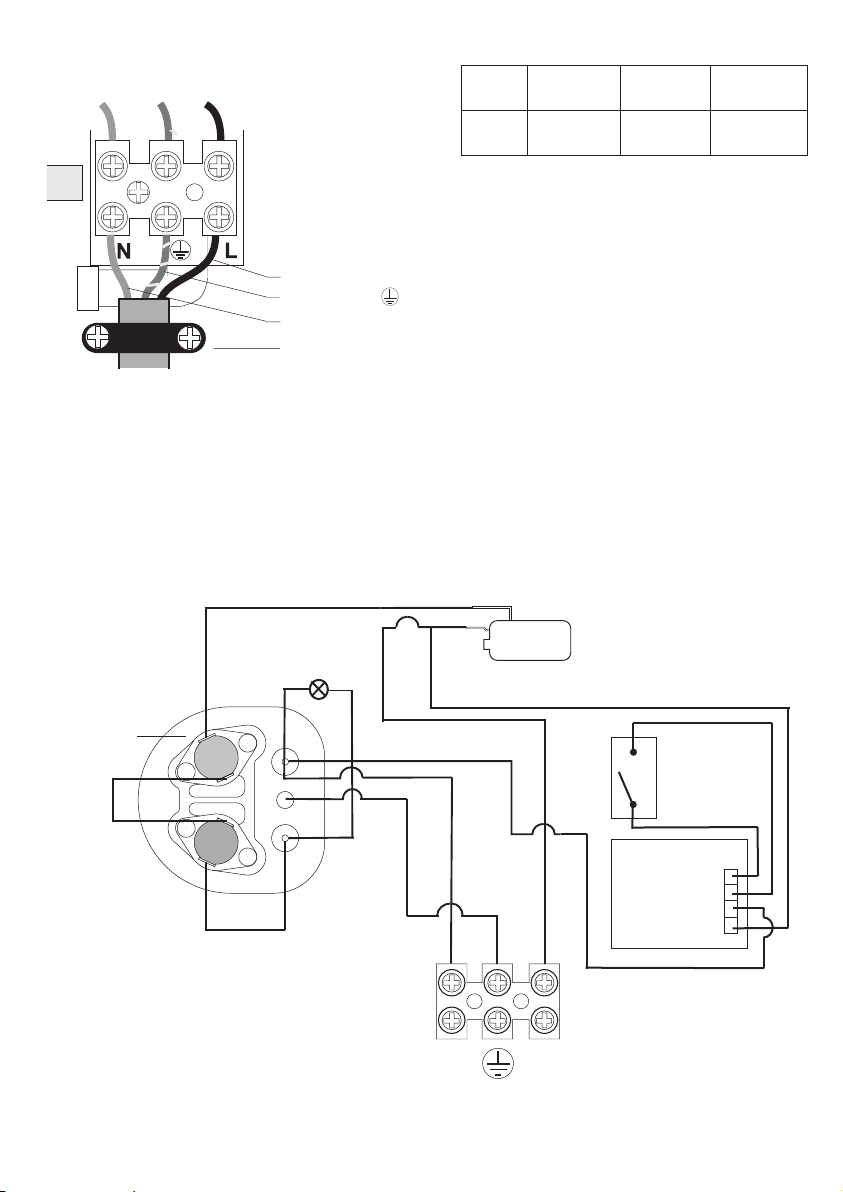

3.3 Electrical diagram(s)

Red or brown to 'L'

Green & yellow to

Blue or black to 'N'

Cable clamp

Figure 2 – Electrical connection

Figure 3 – Wiring diagram

Neon

Inner

container

Red

Red

Red

Cut

Out

Terminal

block

N L

Red

Red

Red

Pressure

switch

3.1kW

Black

Black

Black

Black

Green/Yellow

Solenoid

valve

PCB Infra-red

L

L

N

N

{

{

Solenoid

PCB

7

4.2 Operation principle

The product is used to provide the user with hot

water for hand washing.

By activating the sensor the water ows through the

product which then switches the element on to heat

the water.

4.3 Standard delivery

Pack contents

`Heater

`Spout assembly

`Fixing screws and plugs

`Installation and user Instructions

4.4 Main components

See Figure 4

4. Description of the product

4.1 General description

This product is manufactured to British and

European Standard. These products are safe and

without risk provided they are installed, used and

maintained in good working order in accordance with

our instructions and recommendations.

Please read and understand these instructions

before starting work and retain them for later use.

This product is a purpose designed handwash

heater. The unit has a cooper sheath element

contained in a high grade plastic canister, this with

the ow control valve is assembled into high quality

ABS plastic backplate and front cover.

Sprayplate

Oultlet spout

Spout fixing nut

Pressure relief device (PRD)

Cable clamp

Terminal block

Flow control valve

Pressure switch

Inner

container

Front

cover

Thermal

cut-out

Thermostat

Rating label

Solenoid valve

Figure 4 – Internal components

8

If the product is operated outside of the stated

pressure parameters it may not be possible to

achieve optimum performance from the product

throughout the year.

WARNING

`The product must be earthed

`IMPORTANT - INSTALLATION

TO BE CARRIED OUT BY A

COMPETENT INSTALLER

Electrical requirements

The installation supply cable and circuit protection

must conform to BS 7671.

Before making any sort of electrical connection,

ensure that no terminal within the circuit is live. If in

any doubt SWITCH OFF the whole installation at the

consumer unit.

The product must only be connected to a 230-240V

ac supply.

The earthing and protective conductor arrangement

within the property, in particular the supplementary

bonding in the room containing the product, must

comply with BS 7671.

Ensure that the supply cable and fuse are sufcient

for the rated input of your unit. Please refer to the

rating label within the product.

A minimum heat resistance cable size of 1.5mm²

should be used.

The product can be connected in two different ways:

`Via a fused and switched connection unit taken

as a spur from a 13amp ring main.

`As a separate circuit taken directly from a spare

way in a consumer unit.

In each case a double pole isolating switch having a

contact separation of at least 3mm in each pole, and

a minimum rating of 13amp must be incorporated in

the wiring of the appliance.

5. Before installation

5.1 Installation regulations

WARNING

Installation of the product must be

carried out by a qualied engineer in

accordance with prevailing and national

regulations as listed below.

`Building Regulations

`The Building Standards

(Scotland)

`The Building Regulations

(Northern Ireland)

`I.E.E Electrical Regs

`UK Water Regulations

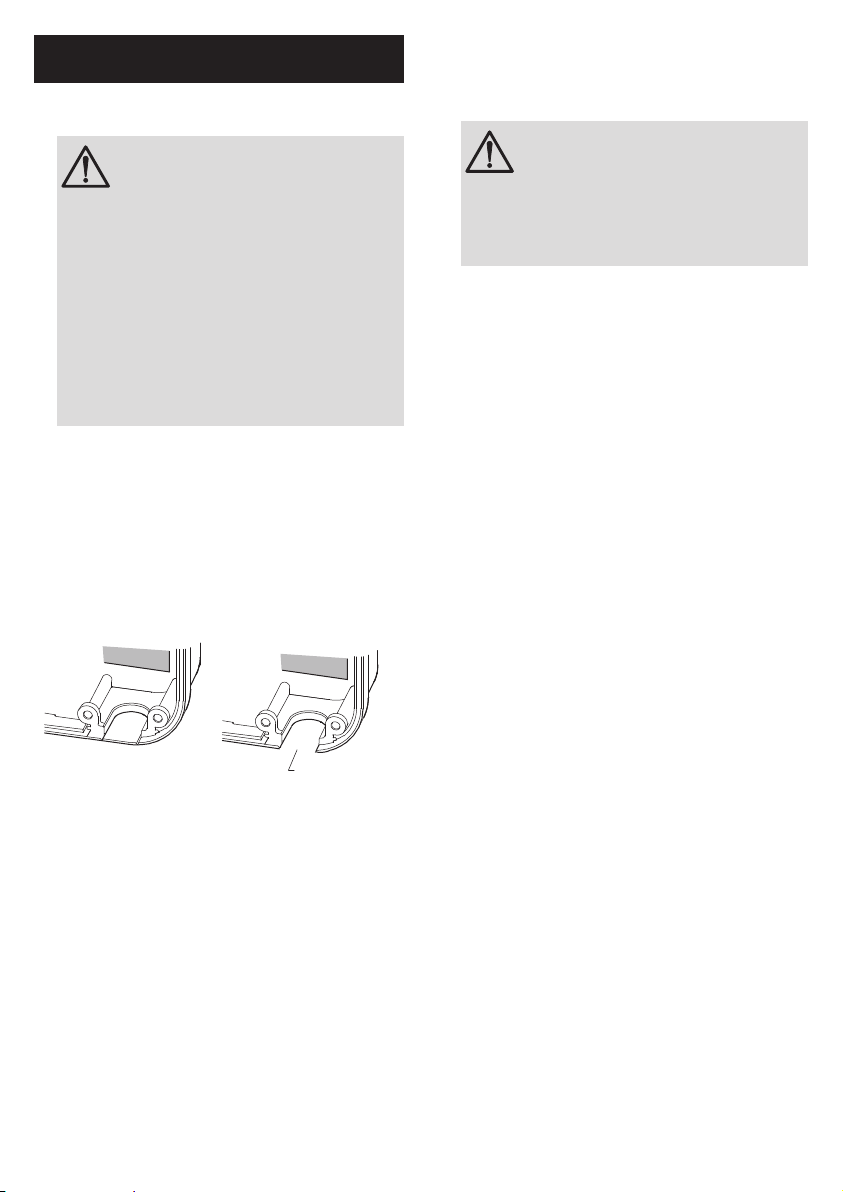

5.2 Installation requirements

Pipe entry

Plumbing entry can be from the rear (preferred) or

from the bottom. The backplate has a cut out position

to suit 15mm pipe. When opting for bottom entry

make the cut out before tting the backplate to the

wall - see gure 5 below.

Make cut-out

using sharp knife

Figure 5 – Plumbing cut-out

Water requirements

The installation must be in accordance with Water

Regulations. To ensure activation of the heating

elements, the handwash must be connected to a

mains water supply with a minimum running pressure

of 0.1 MPa (1 bar) and a maximum static pressure

of 0.7 MPa (7 bar). If static pressure exceeds 0.7

MPa (7 bar) t a pressure reducing valve to avoid

damaging the product. If in doubt, the pressure

should be checked taking account of other services

from the same water supply which could cause

the pressure to fall below the minimum. The water

supply can also be taken from a cold water storage

cistern provided there is a minimum head of 10m

above the product.

9

5.3 Choice of location

The product must be mounted on a at surface,

which covers the full width and length of the

backplate. It is important that the wall surface is at

otherwise difculty may be encountered when tting

the cover.

Ensure that the product is positioned over the basin,

if the PRD operates, water will eject from the bottom

of the product.

The outlet of the product acts as a vent and MUST

NOT be connected to any form of outlet ow control,

or any other tting not recommended by the

manufacturer.

WARNING

DO NOT t the product to the wall and

tile up to the case. It must be tted on to

a nished at and even wall surface. This

allows removal for servicing.

Position the product above the basin so that the

spray will be contained within the basin and at a

convenient height for hand washing see gure 7

below.

Main water supply

(Use rear entry when

it is possible)

130

200

PRD

outlet

Typical arrangement

Isolating stop valve

All dimensions in mm

Figure 7 – Handwash position over basin (or sink)

Multipoint Instantaneous unit

(use rear entry when it is

possible)

80A or 100A main switch

Meter

Meter ‘tails’

Consumer

unit

RCD (can be part of

the consumer unit)

Double pole isolating switch:

pull cord or wall mounted in accordance

with IEE regulations

Figure 6 – schematic of typical electrical layout

Fuses do not give personal protection against electric

shock. To enhance electrical safety a 30mA residual

current device (RCD) should be installed in all electric

handwash circuits. This may be part of the consumer

unit, or a separate unit.

Ensure that all terminal block connections are

sufciently tight.

Switch off the product immediately and isolate if

water ceases to ow during use.

Other electrical equipment e.g. extractor fans, must

not be connected to the product or its supply circuit.

To obtain full advantage of the power provided by the

product, use the shortest cable route possible from

the consumer unit to the product.

If your consumer unit has a rating below 80A, or if

there is no spare fuse way, then the installation will not

be straightforward and may require a new consumer

unit. A qualied electrician should install the new

consumer unit. It may be necessary to contact your

electrical supplier to upgrade your supply.

CAUTION

To enhance electrical safety a 30mA

residual current device (RCD) should be

installed in all electric handwash circuits.

This may be part of the consumer

unit or a separate unit. DO NOT use a

rewireable fuse, instead use a suitably

rated miniature circuit breaker (MCB)

or cartridge fuse. The handwash must

be connected to its own independent

electrical circuit.

10

'O' rings

Plastic nut

(finger tight only)

Outlet pipe

Figure 10 – Fitting outlet spout

After choosing the correct site for the product, use

the backplate as a template and mark the two xing

holes.

WARNING

BEWARE OF CABLES AND PIPES

WHICH MAY BE BURIED IN THE WALL.

Drill holes using a 6.5mm diameter masonry drill.

Use plugs to suit the wall and use the xing screws

supplied.

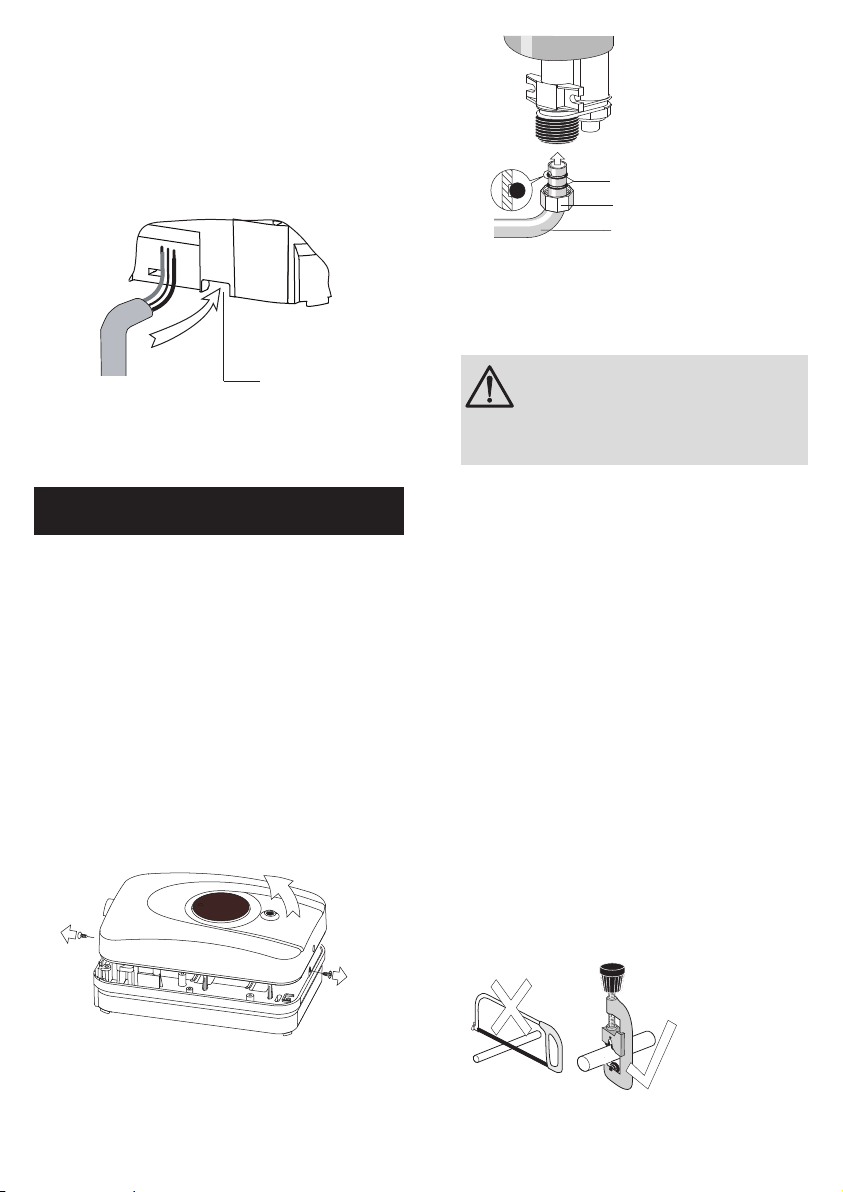

6.2 Water connections

The outlet spout can be removed to ease installation.

The product has been designed for a 15mm water

pipe using the pusht connection - see gure 13.

Decide where to connect the cold water mains feed

to the product. Ensure the pipe you have selected

is not a gas pipe or a hot water pipe. Chrome and

stainless steel pipe is not recommended.

An isolating stop valve MUST be incorporated to the

main water supply to comply with Water Regulations

- see gure 7.

Cut all necessary pipework to length with a pipecutter

and not a hacksaw. This will minimise the swarf and

prevent damage to the sealing o-ring in the pusht

tting - see gure 11 below.

Figure 11 – Cutting pipes

A clearance of at least 130mm above and below the

product should be allowed for access to the cover

screws.

Cable entry can be from the rear (preferred) or from

the bottom. The backplate has cut-out positions to

suit the size of the cable. When opting for bottom

entry make the cut- out to suit the cable before tting

the backplate to the wall - see gure 8 below.

Make cut-out

using sharp

knife

Figure 8 – Bottom entry cable cut-out

6. Fitting Instructions

6.1 General

After reading the previous sections in this booklet

and choosing a good location for the product please

install, paying attention to the following plumbing,

electrical and commissioning sections.

TURN OFF the water and electrical supply.

The product is designed for bottom and rear entries

of water and electric cable. It is advisable to use the

rear entry (when it is possible), in order to obtain a

neater installation.

Unscrew the retaining screws and lift the cover from

the back plate - see gure 9 below.

Figure 7 Removing Cover

Figure 9 – Removing cover

Fit the outlet spout - DO NOT over tighten, nger

tight will be sufcient - see gure 10.

11

close

Figure 14 – Gear control valve

Turn the isolating stop valve on slowly and check for

leaks in all the pipework, rectify as necessary.

Turn off the isolating stop valve.

6.3 Electrical connections

WARNING

This product must be earthed.

CAUTION

When working on electrical components

ensure they are NOT LIVE. If in any

doubt, SWITCH OFF THE ELECTRICITY

SUPPLY.

A double-pole isolating switch having a contact

separation of 3mm in each pole MUST be

incorporated to the circuit - see paragraphs 5.2 p8.

The cable entry should have been decided before

tting the backplate - see 5.3 p9.

Remove the screws and clamping bar from the cable

clamp - see gure 2 p6.

Feed the cable in the backplate (unscrew backplate

for easy feeding if necessary).

Strip the outer sheath of the cable to a point about

5mm above the clamp, thus ensuring that the cable

is clamped across its outer sheath.

Strip the insulation from the cores and make

connections - see gure 2 p6.

Make sure that all the terminal block screws are

sufciently tight.

Ret the clamp bar.

Assemble the installation before making any

soldered joints to ensure that the pipe is the correct

length. DO NOT use jointing compounds on any pipe

ttings for the installation.

CAUTION

Remove the product before soldering the

connections.

It is essential to ush the pipe in order to clear debris,

particles of solder and swarf - see gure 12 below.

Figure 12 – Flushing the pipework

Turn the water off after ushing using the isolating

stop valve.

Connect the cold water supply pipe to the inlet of the

product, this is a push t - see gure 13 below.

35mm

Bottom entry Rear entry Copper compression

fitting shown - push fit stem

elbow can be used

Figure 13 – Pipe connection

Fit top and bottom screws and secure the backplate

to the wall ensuring that it is level. See gure 1 for

securing positions.

Close the product ow control valve by turning the

gear fully anti-clockwise.

12

6.4 Fitting cover

Fit outlet spout if required - see gure 10 p10.

Check that the ow control valve is fully closed by

turning the gear fully anti-clockwise.

Place the cover onto the back plate.

Secure the cover to the back plate using the screws

provided.

WARNING

This product must be earthed.

7. Commissioning

7.1 General

NOTE: The rst operation of the product is intended

to ensure the heater unit contains water before the

product is switched on.

7.2 Checklist before commissioning

Before turning on the electricity and mains water to

the hand wash ensure the torx adjusting screw is

turned fully anticlockwise – see gure 15 below.

7.3 Commissioning procedure

`Turn on the electrical supply and main water

supply at the isolating stop valve.

`Place hand in front of appliance sensor to

activate solenoid.

`When water ows constantly from spout turn

torx adjusting screw to an acceptable level of

ow, appliance will then start to heat water. (You

may have to place your hand in front of sensor to

keep water owing) adjust further for acceptable

heat.

`Leave torx adjusting key with customer.

8. Operation

8.1 General

Place hand in front of appliance sensor. After

approximately 15 seconds the water will start to heat.

Shut off the product by moving your hand away from

the sensor. The product is now ready to use.

The neon light will illuminate when the water is

heating.

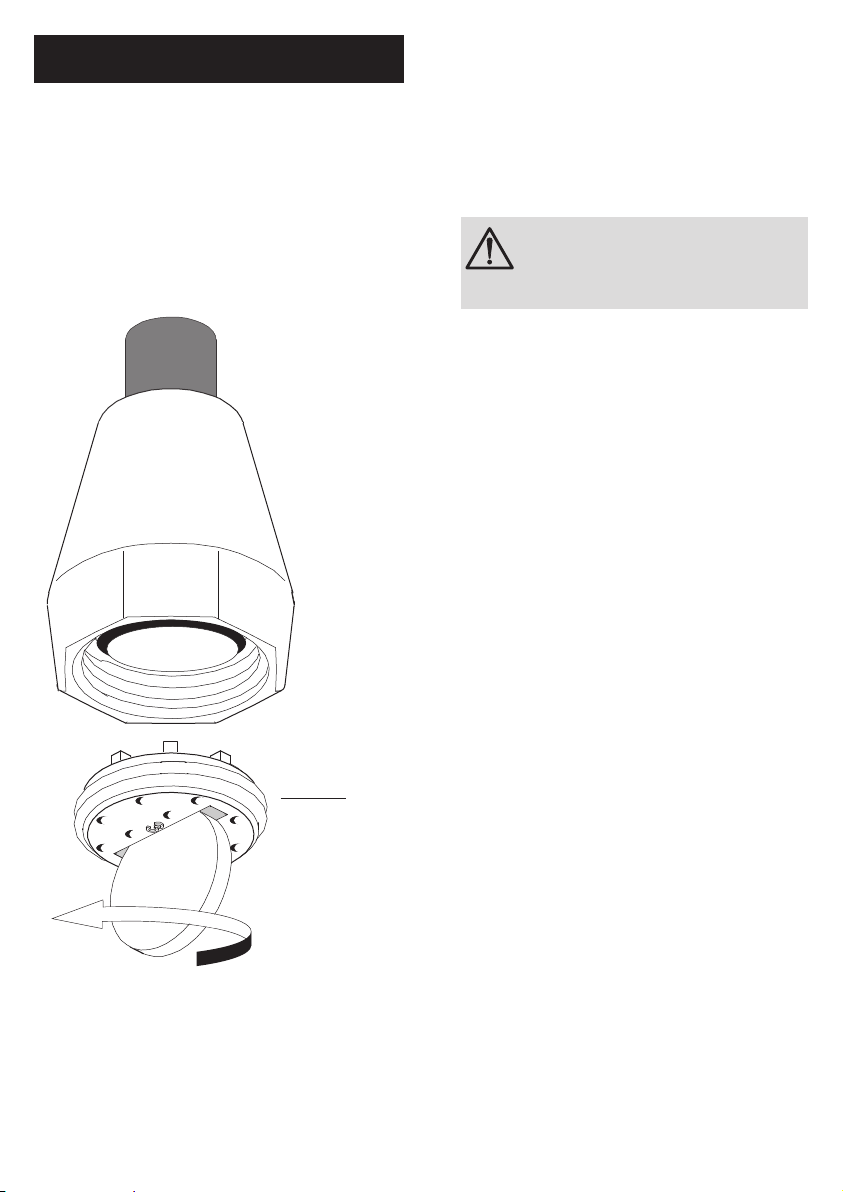

Sprayplate

To remove sprayplate

unscrew anticlockwise

using a coin.

Ensure all holes in

sprayplate are clear.

It is recomended to soak

the sprayplate overnight

in suitable descalant.

DO NOT OVERTIGHTEN

when refitting sprayplate.

Figure 15

13

9. Maintenance

9.1 General

It is recommended that the product casing be

cleaned using a soft cloth and that the use of abrasive

or solvent cleaning uids be avoided. It is advisable

that before cleaning, the isolating switch is turned off,

thus avoiding accidental operation of the product.

IT IS MOST IMPORTANT TO KEEP

THE SPRAYPLATE CLEAN IN ORDER

TO MAINTAIN THE PERFORMANCE

OF THE HANDWASH. The hardness

of the water will determine the

frequency of cleaning.

WARNING

This product must be earthed.

Sprayplate

To remove sprayplate

unscrew anticlockwise

using a coin.

Ensure all holes in

sprayplate are clear.

It is recomended to soak

the sprayplate overnight

in suitable descalant.

DO NOT OVERTIGHTEN

when refitting sprayplate.

Sprayplate

To remove sprayplate

unscrew anticlockwise

using a coin.

Ensure all holes in

sprayplate are clear.

It is recomended to soak

the sprayplate overnight

in suitable descalant.

DO NOT OVERTIGHTEN

when refitting sprayplate.

Figure 16 – Sprayplate

14

10. Troubleshooting

In the unlikely event of a problem, consult the trouble-

shooting chart below.

If you are unable to remedy the problem, contact

your installer in the rst instance.

Do not attempt any electrical or plumbing

work unless you are competent to do so.

If you still cannot solve the problem,

please contact the manufacturer.

Inspection

It is advisable that, in the interests of safety, the

product and its electrical installation is checked by a

competent electrician at least every two years.

10.1 Decommissioning procedure

`Isolate electrical supplies and make safe

`Isolate the water supply

`Drain the product

`Remove the product

`Cap pipework

Environmental information

Handwash products are manufactured from many

recyclable materials.

WEEE Declaration

Disposal of Waste Equipment by Users in Private

Households in the European Union.

This symbol on the product indicates that this product

must not be disposed of with your other household

waste. Instead, it is your responsibility to dispose

of your waste equipment by handing it over to a

designated collection point for the recycling of waste

electrical equipment. The separate collection and

recycling of your waste equipment at the time of

disposal will help to conserve natural resources and

ensure that it is recycled in a manner that protects

human health and the environment. For more

information about where you can drop off your waste

equipment for recycling, please contact your local city

ofce, your household waste disposal service or the

company where this product was purchased.

Symptom Possible cause Remedy

1. No water ows

with valve open

A. Water supply turned off Turn on water supply

B. Unit frozen Turn OFF ELECTRICITY at isolating switch

and contact installer. DO NOT USE THE

HANDWASH.

C. Spout blocked Clean sprayplate - see 9.1 p13

D. Filter blocked Clean lter

2. Water too cold A. Water control at wrong setting Adjust as per commissioning notes

B. Water ow too high Adjust as per commissioning notes

C. Electricity off Turn on electricity at isolating switch

D. Poor ow Check inlet pressure

3. Water too hot A. Temperature control at wrong

setting

Adjust as per commissioning notes

B. Spout partially blocked Clean sprayplate - see see 9.1 p13

C. Isolating valve not fully open Open isolating valve

D. Filter blocked Clean lter

4. Water runs from

pressure relief

device

A. Spout blocked Clean sprayplate - see see 9.1 p13, push

plastic plunger up and back in place

B. Spout not blocked Call a service engineer as there may be a

problem with internal parts

15

11. Spare parts

The following comprehensive list of spare parts is

available for your product. Please refer to the rating

label on the side of your product before ordering to

ensure the correct spare part is obtained.

DO NOT REPLACE WITH PARTS NOT

RECOMMENDED AS THIS WILL INVALIDATE

YOUR WARRANTY AND MAY RENDER THE

INSTALLATION DANGEROUS.

Warranty

Warranty & Service Policy

This product is covered against faulty materials and

manufacture for a period of two years from the date

of purchase provided that:

`The product has been installed by a competent

person in accordance with the Installation, User

instructions, all relevant Codes of Practice,

Regulations in force at the time of installation

and that all necessary controls and safety valves

have been tted correctly.

`Any valves and controls are of the Heatrae

Sadia recommended type and specication.

`The product has not been modied or tampered

with in any way, and has been regularly

maintained as detailed in the Installation and

User Instructions.

`The product has been used only for heating

potable water.

The product is not covered against damage by frost,

and the inner container with integral heating element

is not covered against excessive scale build-up.

This warranty in no way affects the statutory rights

of the consumer.

The policy of Heatrae Sadia is one of continuous

product development and, as such, we reserve the

right to change specications without notice.

Description Code No

1 Heat Exchanger Assembly 3.1kW 95 608 003

2 Spout-3.1kW 95 604 002

3 Cut-out - 3.1kW 95 612 029

4 Cut-out - 3.1kW (one shot) 95 612 031

5Valve/Pressure Switch Assembly

- 3.1kW

95 605 052

6Cover Assembly 95 614 092

7Neon Assembly 95 615 056

8 Micro switch 95 613 003

9 Filter 95 607 107

10 Pressure Relief Device 95 607 108

11 PCB 95 615 024

12 Solenoid Valve 95 605 058

13 Torx Adjustor 95 607 037

6

2

10

11

13

912

5

4

3

8

7

1

Please follow us online:

Electric Water Heating Co.

2 Horsecroft Place

Pinnacles

Harlow

Essex CM19 5BT

Tel: 0845 055 3811

E-Mail: [email protected]

SPD

Special Product Division

Units 9 & 10

Hexagon Business Centre

Springeld Road

Hayes

Middlesex UB4 0TY

Tel: 020 8606 3567

Parts Center

Tel: 0344 292 7057

www.partscenter.co.uk

Newey & Eyre

Unit 3-5 Wassage Way

Hampton Lovett Ind. Estate

Droitwich, Worcestershire

WR9 0NX

Tel: 01905 791500

Fax: 01905 791501

UK Spares Ltd

Unit 1155

Aztec West

Almondsbury

Bristol BS32 4TF

Tel: 01454 620500

Alternatively contact your

local supplying merchant

or wholesale branch or use

our online stockist nder at

www.interpartspares.co.uk

PRODUCT RANGE

Full specication details on all our products are available to download from our website.

To support our corporate responsibility and sustainability charters and reduce our

printed material we encourage you to download product brochures from our website.

In designing these les we have taken into account the need to access data on screen.

If you would like to receive a printed copy of our full product catalogue please call

our literature hotline on 01603 420127.

Heatrae Sadia may introduce modications to their products from time

to time. Consequently, the details given in this brochure are subject to alteration

without notice.

OUR NATIONWIDE NETWORK OF CUSTOMER SUPPORT ENGINEERS

Heatrae Sadia has its very own dedicated nationwide network of highly trained

customer support engineers so you can have peace of mind that we’re always

here to help.

2

2 YEAR

WARRANTY

SPECIFICATION ADVICE HOTLINE

t| 01603 420220 e | speci[email protected]

AFTER SALES SERVICE

t| 0344 871 1535 e| customer[email protected]

w | heatraesadia.com

16

PN 36 00 6009 Issue 5

©Heatrae Sadia 2015

Table of contents

Other Heatrae Sadia Dryer manuals

Popular Dryer manuals by other brands

Samung

Samung DVG50R5400 Series user manual

Samsung

Samsung DV9 M82 Series user manual

Indesit

Indesit G74V Use and care & installation instructions

Alliance Laundry Systems

Alliance Laundry Systems DV6000WG Installation & operation

montpellier

montpellier MSD2800W Installation and operating instructions

LG

LG DVH5-08W owner's manual