Hedman HF100 Instruction and safety manual

Printed in U.S.A.

Form No. 198557HF

HEDMAN

®

Form No. 198557HF

HF100 FOLDER

OPERATING & SERVICE MANUAL

THE HEDMAN COMPANY

189 Gordon St.

Elk Grove Village, IL 60007

800-872-2788

The HEDMAN Company • 189 Gordon St. • Elk Grove Village, IL 60007 • 800-872-2788

NOTICE

Proprietary Information - this material is not to be reproduced by

any means or disclosed in any way without prior written approval by

THE HEDMAN COMPANY.

Disclaimer - this material is subject to change without notice and

should not be construed as a commitment by THE HEDMAN

COMPANY.Neitherexpressnorimpliedwarrantyismaderegarding

the procedures herein, their merchantability, or fitness for any

specific application.

These procedures are provided solely on an "as-is" basis, and the

customer agrees to assume any costs arising from use or misuse of

the material, including all correction and damages consequential or

incidental.

THE HEDMAN COMPANY - ALL RIGHTS RESERVED.

©2001 The Hedman Company

2

TABLE OF CONTENTS

Page

4 SPECIFICATIONS

5 COMPONENTS & CONTROLS

6 AUTOMATIC FOLDING

7 MANUAL FOLDING

8-10 MAINTENANCE

8 Removing Cartridge

9 Cleaning Feed Roller

10 Adjusting Separator

11-12 SERVICE

11 Replacing Separator

12 Replacing Feed Roller

13-19 PARTS DRAWINGS & PARTS LISTS

13 Fold Plates

14-15 Drive Assemblies

16-17 Covers & Knobs

18 Feed Tray

19 TROUBLESHOOTING

19

TROUBLESHOOTING

1. FOLD QUALITY

A. Documents skew - crooked folds

1. As folder runs, adjust PAPER GUIDES slightly to correct the skew.

2. Re-position paper in HOPPER. Hold HOPPER LEVER open and load

paper squarely and centered. Slowly release HOPPER LEVER.

3. Too much paper in folder. Stop folding and remove some paper.

Maximum paper stack is 5/8" (16 mm).

4. Remove and clean CARTRIDGE.

WARNING: Turn POWER SWITCH off and unplug POWER CORD

before removing CARTRIDGE.

5. Clean FEED ROLLER.

B. Fold dimensions are incorrect

Remove CARTRIDGE.

WARNING: Turn POWER SWITCH off and unplug POWER CORD

before removing CARTRIDGE.

NOTE:

Use compressed air to blow obstructions out of FOLD PLATES.

2. CLEARING PAPER JAMS

A. Remove CARTRIDGE and clean (refer to instructions on page 8).

B. Clean FOLD PLATES using compressed air.

3. DOUBLE FEEDING

A. Clean FEED ROLLER using alcohol.

B. Adjust SEPARATOR (refer to instructions on page 10).

C. Replace FEED ROLLER and SEPARATOR (refer to instructions on pages

11 and 12).

4. NOT FEEDING - IRREGULAR FEED

A. Change paper if possible. Some types of paper do not feed well.

B. Clean FEED ROLLER using alcohol.

C. Replace SEPARATOR and check FEED ROLLER (refer to instructions on

page 11).

D. MOTORS run, FEED ROLLER does not drive, but rotates freely.

1. Replace "O" RING, page 15, #19.

3

18

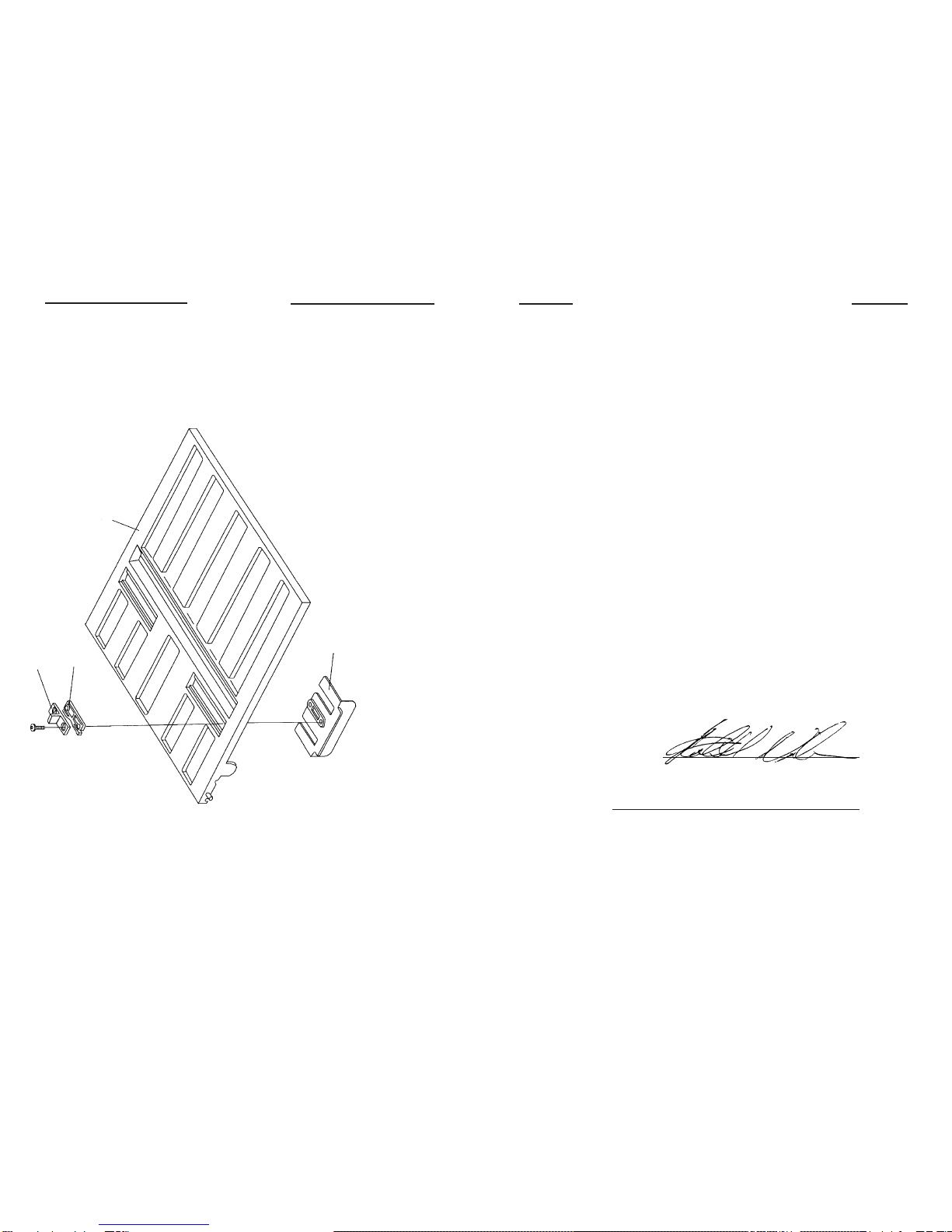

DECLARATION OF CONFORMITY

(Manufacturer's Declaration according to EC Machinery Directive

89/392/EEC, Annex II A)

Applicant: The Hedman Company

189 Gordon St.

Elk Grove Village, IL 60007

Manufacturer: AUTOMECHA Mfg.

Route 12

Oxford, NY 13815

The manufacturer declares that the following described machine complies with the

appropriatebasicsafety and health requirementsofthe EC Machinery Directive89/

392/EEC, based on its design and type. In case of alteration of the machine, not

agreed to by the manufacturer, this declaration will lose its validity.

Equipment Type: Paper Folding Machine

Model Designation: HF100-IN, HF100-UK.

Description: Rated Voltage - 15 VDC (Output of stand-alone power supply)

Rated Input Power - 1.4A

Applicable EC Directives: EC Machinery Directive (89/392/EEC)

EC Low Voltage Directive (72/23/EEC)

EC Electromagnetic Compatibility (89/336/EEC)

Applicable Standards: EN 292, EN294, EN 60950, EN 55014

(C.I.S.P.R. 14). EN 50082-1. IEC 801

Date/Authorized Signature: 20 April, 2001

Title of Signatory: Agent

FEED TRAY

ITEM # PART # DESCRIPTION

1 6F1582 COVER, TOP SCREENED

1 6F 1582IN COVER, TOP SCREENED (FOR A-4 PAPER)

2 3F1544 PAPER GUIDE

3 3F1522 GUIDE SPRING

4 3F1521 GUIDE RETAINER

4

3

1

2

SPECIFICATIONS

POWER: 15V, D.C.(14.8)/1.4 amp/external; wall mountable;

power pack with internal circuit breaker

UL, CSA & FCC approved

120/220/240 V.A.C., 50/60 HZ

International approvals TUV, GS, CE

WEIGHT: 20 lbs. (9.0 kg) / 26 lbs. shipping (11.8 kg)

SPEED: up to 200 sheets per minute

PAPER SIZE: 8.5" x 11" (or A4 European)

PAPER

WEIGHT: 16 to 24 lb. bond/up to 60 lb. offset (50 to 180 GSM)

HOPPER

CAPACITY: up to 150 sheets

MANUAL

FEED

CAPACITY: 3 sheets stapled or loose

FOOTPRINT: 12" (30.4 cm) long x

13" (33 cm) wide x

8.75" (22.2 cm) high

417

COVERS & KNOBS

ITEM # PART # DESCRIPTION

1 3F1618 INDICATOR, DIAL

2 6F1549-02 COVER ASSEMBLY

3 3F1609 LEVER

4 7F1596 SEPARATOR SHAFT ASSEMBLY

5 3P1911 RUBBER FOOT

6 3F1553 POWER SUPPLY (120V)

6 3F1643 EUROPE POWER SUPPLY (220V)

6 3F1642 UNITED KINGDOM POWER SUPPLY (220V)

7 3F1549-01 COVER, NON-OPERATOR SIDE

8 7F1656 ON/OFF/JOG SWITCH AND HARNESS

9 7F1571 POWER JACK ASSEMBLY - NOT SHOWN

10 3F1657 LABEL, SWITCH - NOT SHOWN

11 3F1619 SHIPPING CARTON, MACHINE - NOT SHOWN

12 3F1607 CORK PATCH

13 3F1592 SPRING WINDER

(Not shown - only on machines with Serial # 300D1471 and lower)

14 3F1591 SPRING

(Not shown - only on machines with Serial # 300D1471 and lower)

15 3F1653 SPRING, FEED DOOR

(Only on machines with Serial # 300D1471 and higher)

16 3F1541 BASE

17 3F1599 PAPER DEFLECTOR

18 3F1586 FEED DOOR

19 3F1539 FRONT BAFFLE

20 6F1545 LARGE END

21 3F1546 INNER COVER

22 3F1585 PAPER END STOP

23 3F1506 PAPER DEFLECTOR EXTRUSION

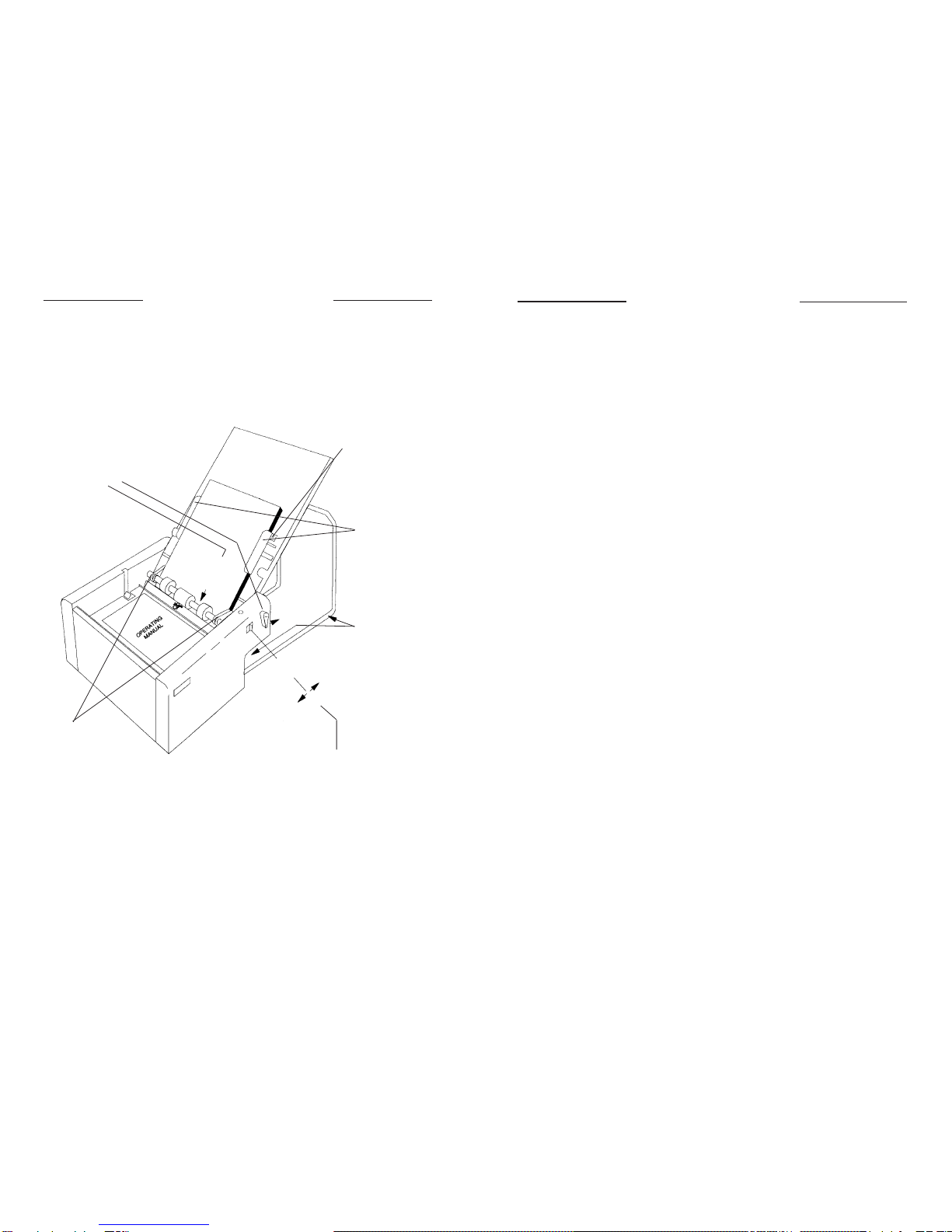

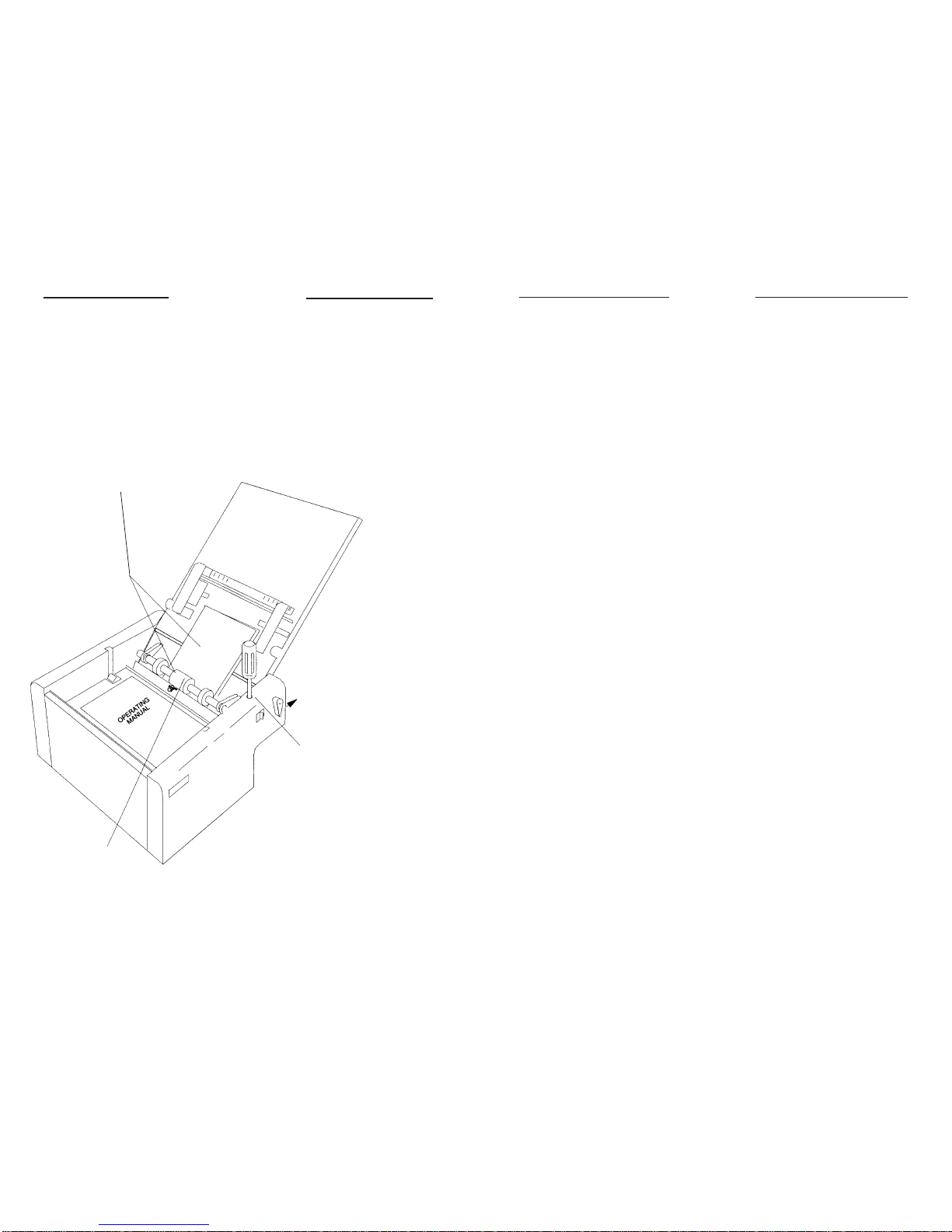

COMPONENTS & CONTROLS

5

POWER CORD

SEPARATOR

ADJUSTMENT

HOLE

POWER

SWITCH

GUIDE

ROLLERS

OPERATING

MANUAL

GUIDE FINGERS

FEED ROLLER

PAPER GUIDES

HOPPER

LEVER

RECEIVING

RACK

PAPER WIDTH

SCALE

FEED

TABLE

HOPPER

WARNING

The outlet socket is the

main power. It must be

located near the

equipment and easily

accessible.

16

COVERS & KNOBS

18

19

16

20

21

17

23

22

5

6

3

82

1

12

4

15

7

AUTOMATIC FOLDING

(Stack of sheets up to 5/8" (16 mm) high)

6

3. Slide PAPER

GUIDES snugly

against stack.

2. Center paper on

FEED TABLE and

release HOPPER

LEVER.

1. Hold HOPPER LEVER

open (right) and load

neatly stacked and

squared paper into

HOPPER.

4. Position

RECEIVING

RACK by placing

a folded sheet

against the folder

and sliding the

rack 1" to 2" from

the sheet.

6. Turn POWER SWITCH on.

Turn POWER SWITCH off

when you are finished

folding.

5. Slide

GUIDE

FINGERS

snugly

against

stack.

HOPPER

POWER

SWITCH

ON JOG

OFF

15

DRIVE ASSEMBLIES

ITEM # PART # DESCRIPTION

1 3F1559 GEAR (24T 20PA 24P)

2 7F1525 FEED ROLL ASSEMBLY

3 3F1536 PULLEY, FEED ROLL

4 3F1601 GUIDE, FRONT

5 3F1581 SPRING, CLUTCH

6 3F1602 BUSHING, SPLIT

7 3F1608 ROLLER, GUIDE

8 3F1525 ROLLER, FEED

9 7F1519 GEAR ASSEMBLY

10 3P1916 MICRO SWITCH

11 3F1556 MOTOR

12 3F1511-02 PRESSURE LEVER (OPERATOR SIDE)

13 3F1511-01 PRESSURE LEVER (NON-OPERATOR SIDE)

14 3F1514-01 SPRING, PRESSURE LEVER (NON-OPERATOR SIDE)

15 3F1514-02 SPRING, PRESSURE LEVER (OPERATOR SIDE)

16 7F1551 CARTRIDGE ASSEMBLY

17 3F1594 HOLDER, SQUARE SHAFT

18 3F1510 BEARING RETAINER SHORT

19 3F1637 “O” RING

20 3F1603 PULLEY, SMALL FEED

21 3F1557 BELT, 1/5 PITCH (134XL037)

22 3F1555 PULLEY, DRIVE 26T

23 7F1526 2 STEP PULLEY ASSEMBLY

24 3F1558 BELT, 1/5 PITCH (148XL037)

25 3F1554 PULLEY, MOTOR 10T

26 3F1552 BEARI NG

27 3F1543 RECEIVING RACK

28 05-0795-00 CAM SWITCH

29 02-1598-02 RUBBER "O" RINGS

7

SLOT

MANUAL FOLDING

(1 to 3 sheets stapled or loose)

1. Close FEED TABLE

onto top of folder.

2. Slide PAPER

GUIDES as far

apart as possible. 3. Insert sheet(s)

squarely into

SLOT and let

them rest on your

finger as shown.

Do not hold

sheet(s).

4. Turn POWER

SWITCH to JOG

until paper is folded.

14

DRIVE ASSEMBLIES

19

NON-OPERATOR

SIDE

OPERATOR

SIDE

20

21

22

18

23

14

26

3

17

27

24

29

25

11

13

12

47

857

6

4

17

28

10

9

16 1

18

813

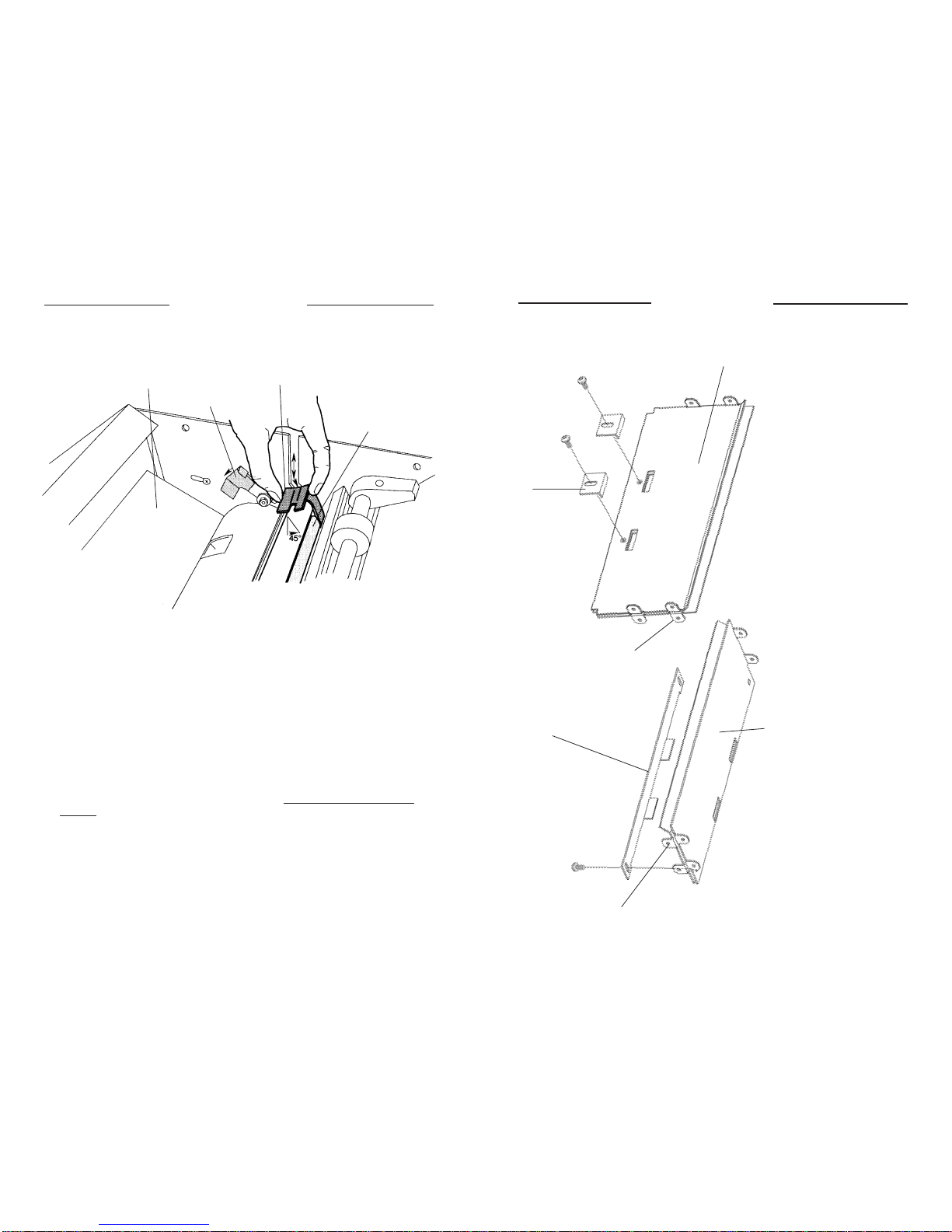

MAINTENANCE

Removing CARTRIDGE

WARNING: Turn POWER SWITCH off and unplug POWER CORD before

removing CARTRIDGE.

To Remove CARTRIDGE:

1. Open TOP and INNER COVERS.

2. Pull back RED PRESSURE LEVERS.

3. Remove CARTRIDGE by sliding it up and out of the folder in the slot.

When installing CARTRIDGE, the RUBBER ROLLER must be held at a 45°

angle toward the feed end of folder (refer to illustration above).

4. Once in place, push the CARTRIDGE down to make sure it is in place and

leveled.

5. Close RED PRESSURE LEVERS.

6. Close TOP and INNER COVERS. Important: INNER COVER must be closed

or folder will not run.

NOTE:

If CARTRIDGE has wear marks, cuts, etc., it must be replaced.

(Part # 7F1551).

INNER

COVER RED

PRESSURE

LEVER

CARTRIDGE

RUBBER

ROLLER

ITEM # PART # DESCRIPTION

1 04-0364-00 "A" OUTER FOLD PLATE

2 04-0365-00 "A" INNER FOLD PLATE

3 04-0313-00 "A" STOP

4 04-0427-00 "B" OUTER FOLD PLATE

5 04-0426-00 "B" INNER FOLD PLATE

6 04-0314-00 "B" STOP

FOLD PLATES

2

1

3

4

5

6

9

12

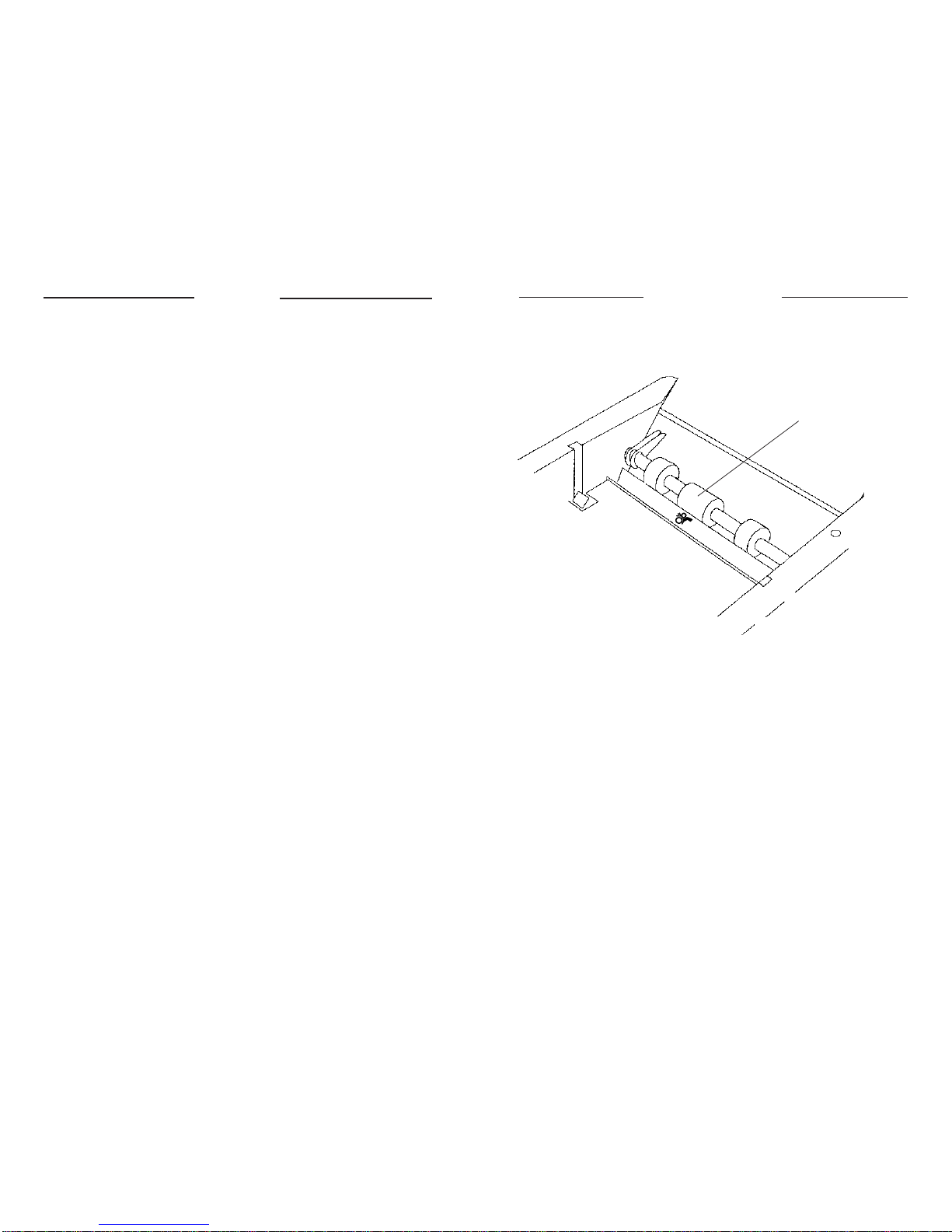

MAINTENANCE

Cleaning FEED ROLLER

To clean FEED ROLLER:

1. Turn POWER SWITCH off.

2. Using a cloth and alcohol, clean entire FEED ROLLER.

3. Allow FEED ROLLER to dry completely before folding.

FEED ROLLER

SERVICE

Replacing FEED ROLLER

If the FEED ROLLER is visibly worn or is chunking apart, it must be replaced. When

changing the SEPARATOR, replace the FEED ROLLER as well.

To change the FEED ROLLER:

1. Turn POWER SWITCH off and unplug POWER CORD.

2. Remove SIDE COVERS.

3. Remove DRIVE BELT and PULLEY.

4. Removethe"E"RINGSontheinsideof frames nexttotheOILITEBUSHINGS.

NOTE:

OILITE BUSHINGS are pressed in and removal is not necessary.

5. LoosenGUIDE ROLLERS and slidetheshaft 3 to 4inches to the operator side

so GUIDE FINGER, BUSHING and GUIDE ROLLER can be removed.

6. Remove the "E" RING located next to the FEED ROLLER. Slide the FEED

ROLLER off as well as the CLUTCH SPRING. Inspect inside of CLUTCH

SPRINGfor wear. Ifa"flat"wearareahasappearedinstead of normal rounded

coils, replace the CLUTCH SPRING (part# 3F1581).

7. Cleantheshaftandlightlylubricatewithalightmachineoil,theareaontheshaft

where the CLUTCH and FEED ROLLER are mounted. Reassemble theFEED

SHAFT.

8. TheFEEDROLLERshouldspineasilyinonedirectionand"lock-up"whenspun

intheoppositedirection.NOTE:

Iftherollerdoesnot"lock-up",thereistoomuch

lubrication between CLUTCH SPRING and FEED SHAFT.

9. Re-assemble shaft into frame.

10. Lightly oil the OILITE BEARINGS for the FEED SHAFT and make sure the

FEED SHAFT spins freely in the side frames.

11

10

The SEPARATOR must be set to feed one sheet of paper at a time.

WARNING: Turn POWER SWITCH off and unplug POWER CORD before

making adjustment.

To adjust SEPARATOR:

1. Clean FEED ROLLER before adjusting SEPARATOR. (Refer to page 9.)

2. Fold a strip of standard (20# bond) paper in half. Hold HOPPER door open.

Turning the FEED ROLLER by hand, feed the sheet under the roller.

3. Hold the FEED ROLLER so it cannot turn. Pull the strip out. It should pull out

with some difficulty.

5. To adjust FEED ROLLER

separation, insert #1 Phillips

screwdriver into SEPARATOR

ADJUSTMENT HOLE. Turn

screwdriver

clockwise

to increase

pressure and

counterclockwise

to de-

crease pressure. Adjust FEED ROLLER to

satisfy Steps 1 thru 3. If the pressure setting is

correct, folder will run quietly and easily. If these

adjustments do not correct the condition, the FEED

ROLLER and/or SEPARATOR must be replaced.

Refer to Pages 11 and 12.

FEED ROLLER

Hold

Open

MAINTENANCE

Adjusting SEPARATOR

4. Repeat Steps 1

and 2 using a

sheet of paper

folded in thirds.

With three

thicknesses of

paper you must

pull hard enough

to almost tear the

paper.

SERVICE

Replacing SEPARATOR

TheSEPARATOR(locatedbelowtheFEEDROLLER) isavery important partofthe

automaticfeedingsystem.KeepingtheSEPARATORadjustedasitwears(seePage

10)will insure proper operation.Ifthe adjustment screws runout of travel and canno

longerbeadjusted,theSEPARATORHOLDERASSEMBLY(part#7F1596)mustbe

replaced. It is also recommended that the FEED ROLLER (part # 3F1525) and

CLUTCH SPRING (part # 3F1581) be replaced.

To change the SEPARATOR:

1. Turn POWER SWITCH off and unplug POWER CORD.

2. RemovebothSIDE COVERS. NOTE:

The folddialsmustberemoved.

Observe

the alignmentof dialsand tightnessof ACORNNUT for dialtension. Remember

to reconnect the POWER SWITCH.

3. Removethe PAPERDEFLECTOR(withstatic brushattached)atthe outputend

of folder by removing the screws in the side frame.

4. Remove theplastic FEED SHAFTPULLEY on the non-operatorside and remove

thesquareSHAFTHOLDERonbothsidesaswellastheSEPARATORADJUST-

ING SCREW and SPRING.

5. Remove the loose SEPARATOR SQUARE SHAFT ASSEMBLY through the

outputend of thefolder.Turntheshaft so thepinonthe non-operator sideclears

the keyhole.

6. Install the new SEPARATOR SHAFT ASSEMBLY the same way old assembly

was removed.

7. Assemble the SQUARE SHAFT HOLDER on non-operator side first. NOTE:

Make sure the SEPARATOR PATCH is positioned to fit through the hole under

the FEED ROLLER. The SQUARE SHAFT should slide through the slots with

little or no interference.

8. Re-assemble SEPARATOR ADJUSTMENT ASSEMBLY and re-adjust the

SEPARATOR using instructions on Page 10.

Table of contents

Other Hedman Paper Folding Machine manuals