1General .......................................................3

1.1 Information on the operating manual...........3

1.2 Explanation of symbols................................3

1.3 Liability disclaimer .......................................4

1.4 Copyright protection ....................................5

1.5 Warranty regulations ...................................5

1.6 After-sales service.......................................5

2Safety..........................................................6

2.1 Owner’s responsibility..................................6

2.2 Operating personnel....................................7

2.2.1 Requirements ..............................................7

2.2.2 Unauthorized persons .................................8

2.3 Intended purpose of the equipment.............8

2.4 Personal protective gear..............................9

2.5 Special dangers.........................................10

2.6 Securing against unauthorized switching

use 10

2.7 Response in case of danger or accident...11

3Transport, packaging and storage ........12

3.1 Safety instructions for transport.................12

3.2 Transport inspection..................................12

3.3 Packaging..................................................12

3.4 Storage conditions.....................................13

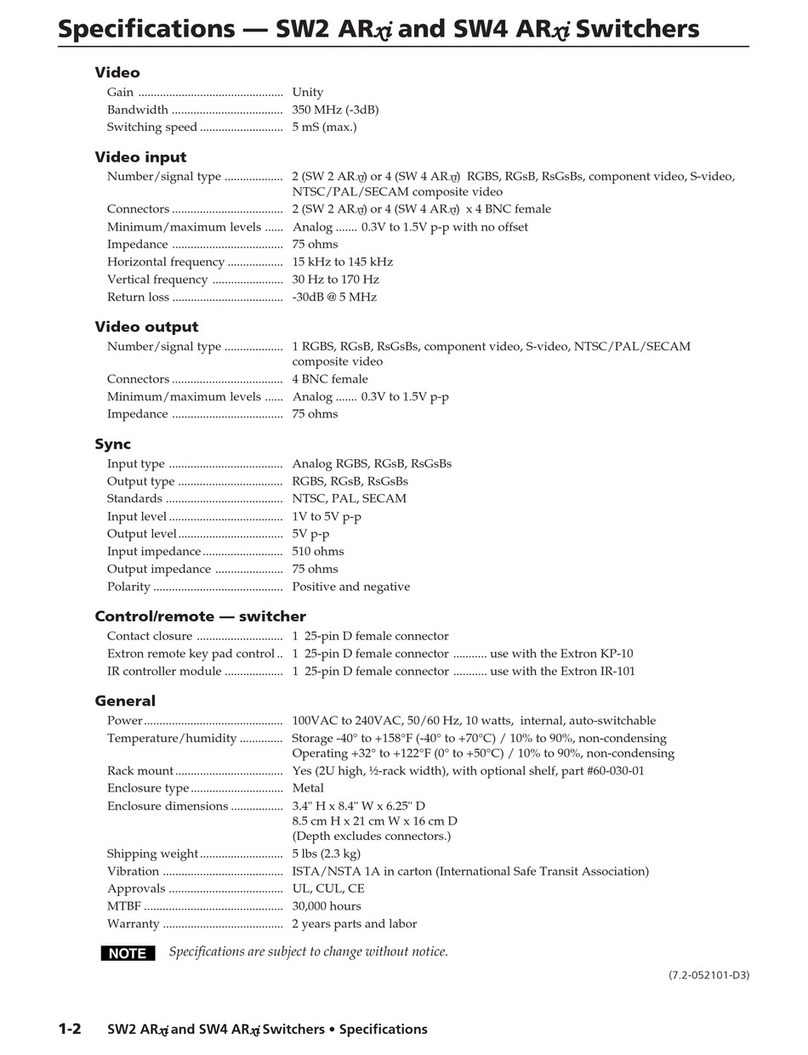

4Specifications ..........................................14

4.1 Type designation with type key .................14

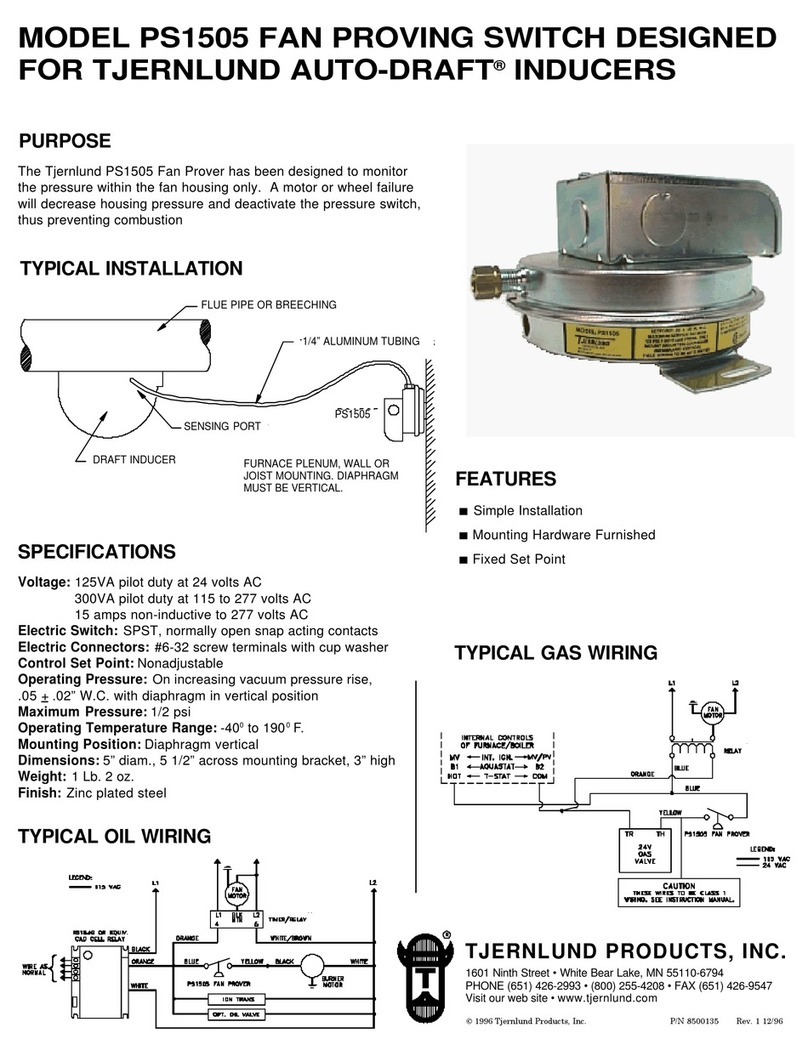

4.2 Pressure switch .........................................15

4.3 Dimensional drawing.................................16

4.4 Rating plate ...............................................16

4.5 Service life.................................................17

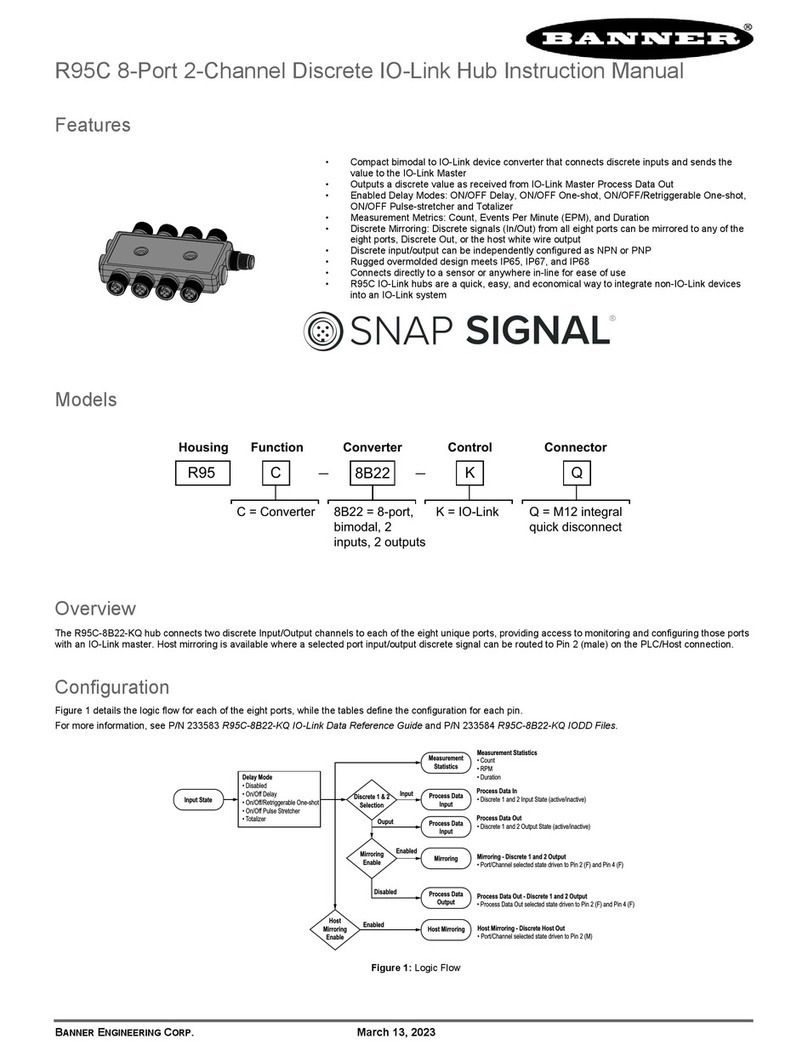

5Functional characteristics and

structure ...................................................18

5.1 Functional characteristics ..........................18

5.2 Structure ....................................................18

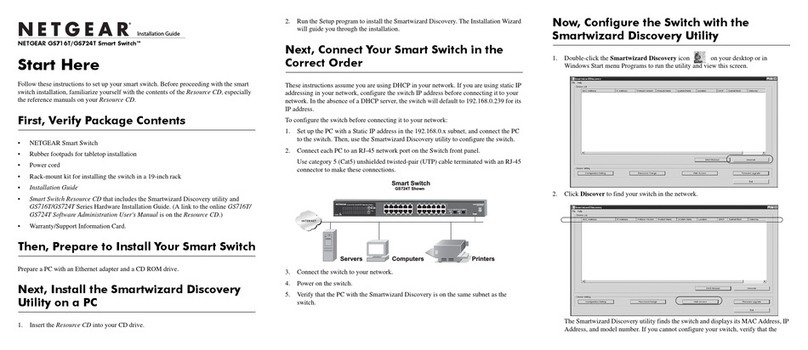

6Installation and initial commissioning...20

6.1 Safety.........................................................20

6.2 Installation..................................................20

6.3 Electrical connection..................................22

6.3.1 Cable inlets through cable glands Pg

13,5............................................................22

6.3.2 Special design with plug and socket

connection FD.../0B0000 ...........................23

6.3.3 Setting the switch-on point acc. the

switching pressure.....................................24

6.3.4 Control the switch-on point acc. the

switching pressure.....................................25

7Maintenance.............................................26

7.1 Safety.........................................................26

7.2 Conditions for maintenance work ..............26

7.3 Maintenance, general ................................27

8Troubleshooting.......................................28

8.1 Safety.........................................................28

8.2 Troubleshooting table ................................29

9Dismantling / Disposal ............................30

9.1 Safety.........................................................30

9.2 Dismantling................................................30

9.3 Disposal .....................................................31

10 Annex........................................................32

10.1 EC type examination certificate.................32

10.2 EU Declaration of conformity.....................34