Hengstler tico 735 User manual

2 735 021, Rev. 030798 Operating Instructions tico 735 - Position Indicator page 1/11

Operating Instructions tico 735 - Position Indicator

Introduction

Your Hengstler tico 735 Position Indicator is one model in a family of 1/8 DIN units which offers

breakthrough display technology as well as easy-to-program single-line parameters.

Designed to provide instant visual feedback regarding an application’s key input value, the tico 735 not

only has a 18 mm high LED display, but also the ability to change display colour based on process status

(programmable parameter in Operation Mode). Easy programming is made possible via a help function

and a secondary legend display.

This manual will guide you through the installation and wiring of your tico 735 unit with information on

proper panel mounting and rear terminal layout and wiring instructions. In addition, the instrument’s

operation and programming modes are thoroughly explained. The operation mode provides day to day

operation and allows editing of preset values. The Program Mode enables the configuration of various

parameters prior to initial operation. These parameters include

those for basic configuration as well as other settable features

which will enhance the functionality and usability of the device.

This manual also provides information on the tico 735 Position

Indicator’s product specifications and ordering information.

Features

•Awesome 18 mm high digit LED display

•Programmable colour change display based on an event

•Programmable help function and secondary legend display

•High and low alarm outputs

•Optional linear output relative to position

•Filter speed settable 20 Hz, 200 Hz, or 10 kHz

•Standard outputs: 2 NPN transistors & 1 relay (optional 2nd relay)

•Front panel reset enable and preset/alarm lockout

•Optional RS-485 plug in card

Index

Safety Instructions...........................................................................................................................2

Installation........................................................................................................................................3

Panel mounting.........................................................................................................................3

Wiring........................................................................................................................................4

Operation.........................................................................................................................................5

Front Panel...............................................................................................................................5

Operation Mode........................................................................................................................6

Program Mode.................................................................................................................................7

Entering Program Mode and basic operation............................................................................7

Program Parameter Sequence .................................................................................................7

Technical Data...............................................................................................................................10

Ordering Information...............................................................................................................11

2 735 021, Rev. 030798 Operating Instructions tico 735 - Position Indicator page 2/11

Safety Instructions

This symbol indicates passages in the text which you have to pay special

attention to so as to guarantee proper use and preclude any risk.

•The range of applications for this product are industrial processes and controls, where the

overvoltages applied to the product at the connection terminals are limited to values of the

overvoltage category II.

•This device is made and tested according to the valid standards of technics and has left the

factory in a perfect safety state. To keep this state and secure operation without danger, the user

has to observe the saftety and warning hints, contained in this operation manual.

•Assembling and mounting of electrical divices are restricted to be done by skilled electricians!

Skilled electrician is, who can judge the tasks deputed to him and foresee possible dangers, due

to his special education, knowledge and experience and consciousness of the pertinent

standards.

•Mount devices are only allowed to be operated when mounted.

•Finger protection at connection part of mount devices is to be secured when mounting!

•While mounting the device, it must be secured that the requirements, which are asked for the

device in the pertaining standards for safety, are not affected in a negative way, so reducing the

safety of this mount device.

•Mounting and assembling of device needs observation of the specifications of the local Energy

Suppliers.

•Before switching on, make sure that the power and control voltages are not exceeding the values

in accordance with the technical data.

•If it is to be assumed that operation without danger is not further possible, the device must be put

out of operation and secured from unintentional operation! It must be assumed that an operation

without danger is not further possible,

if the device shows damage

if the device stops functioning

after a longer stocking period under unfavourable conditions

after heavy strain during transportation.

•If by a failure or a malfunction of the device, endangering of men or animals or damaging of

facilities are possible, this must be avoided by additional safety measures (end switches,

protection devices and etc.).

•Before opening any cover, the device must be switched voltagefree.

•Hengstler Counters are intended for industrial applications.

•The mounting environment and nearby cabling have an important influence on the EMC (noise

radiation and noise immunity) of the counter. When putting into operation, the EMC of the whole

installation (unit) has to be secured. In particular, the relay outputs are to be protected from high

noise radiation by suitable wiring.

2 735 021, Rev. 030798 Operating Instructions tico 735 - Position Indicator page 3/11

Installation

Panel mounting

The instrument can be mounted in a panel with a thickness of up to 12 mm. The cutout should be made based

on the recommended panel opening illustrated in the drawing below.

10096

48

tico 735

PGM RST

92

+ 0.5

45

+ 0.5

Panel Cutout

Insert the unit in the panel through the cutout. Ensure that the panel gasket is not distorted and the instrument is

positioned squarely against the panel. Slide the mounting clamp into place on the instrument and push it

forward until it is firmly in contact with the rear face of the mounting panel and the tabs on the bracket arm are

seated in the mounting grooves on the side of the unit.

The electronic components of the instrument can be removed from the housing after installation without

disconnecting the wiring. To remove the components, grip the side edges of the panel and pull the instrument

forward. Take note of orientation of the unit for subsequent replacement in the housing.

2 735 021, Rev. 030798 Operating Instructions tico 735 - Position Indicator page 4/11

Wiring

Rear Terminal

Connections

0 V

CTRL 1

CTRL 2

0 V

Input A

Input B

NC

Linear

Output

+

-

NC Relay

OUT2

OUT1

NPN

OUT2

NPN

Aux.

Power

28 73

13 14 15 16 17 18 19 20 21

22

23

24

1

654

9

10

11

12

B - A +

(+) RS 485

Power Supply 0V

(-)

~~Relay OUT1

Danger! Hazardeous

voltage!

Count Inputs

Terminal #2 is the connection for Input A, which is

used for channel A of an encoder input. Terminal #1 is

the connection for Inut B which is used for channel B of

an encoder input. The common connection for both

input A and input B is terminal #3.

Control/Digital Inputs

A contact closure or NPN signal can be used to

activate preconfigured functionality. Terminal #5 is

used for a remote reset function, while terminal #6 is a

security function, that when active, will prohibit entry

into Program Mode. Terminal #8 serves as the

common for both of these inputs.

Auxiliary Power Output

A 9-15 VDC for powering external sensors and

encoders up to 125 mA can be accessed by

connecting the positive supply side of the sensor to

Terminal #4 and the negative side to Terminal #8.

Linear Output

An option board may be installed that provides a 10 bit

linear output signal relative to the Position Value.

Terminal #12 is the positive side of the connection, and

Terminal #10 is the negative side. The default range of

the input is 4-20mA but can be changed via the front

panel to 0-20 mA, 0-10 VDC, 2-10 VDC, 0-5 VDC, or

1-5 VDC.

Power Supply Input

For an AC powered unit, Terminal #13 serves as the line

or hot side connection for AC powered units and as the

positive side for DC powered units. The neutral side for

AC powered units and the negative side for DC powered

units are connected to terminal #14.

Transistor Outputs

Your unit comes standard with 2 NPN outputs which are

activated by each of the alarms. Transistor Output 1,

which is tied to the High Alarm Value, is on Terminal #7.

Transistor Output 2, which is tied to the Low Alarm

Value, is on Terminal #9. Terminal #8 serves as the

common connection for both transistor outputs.

Relay Outputs

Your unit comes standard with a relay output which is

tied to the High Alarm Value. Terminal #19 is NC,

Terminal #20 is common, and Terminal #21 is NO. A

second relay output tied to the Low Alarm Value can be

added as an option at the time of order or later installed

in the field. Terminal #22 is NC, Terminal #23 is common

and Terminal #24 is NO.

Serial Communication

An RS-485 communication board, utilizing ASCII

protocol, can be installed as an option. Terminals #16

and #17 serve as the B and A connections respectively,

while terminal #18 is connected as the common.

Terminals 11 & 15 are not used and must not

be connected!

2 735 021, Rev. 030798 Operating Instructions tico 735 - Position Indicator page 5/11

Operation

Front Panel

Output

Indicators

Primary

Display

Secondary

Display

Down Scroll Program Reset

Key functions

Key

Function

Down

In

Operation Mode:

Used in Edit Operation

to decrement the digit highlighted by the

Scroll Key.

In

Program Mode:

Used in Edit Operation

to decrement the digit highlighted by the

Scroll Key, if the setting is a numerical

value, or present the next in the series of

choices for that parameter.

Scroll

In

All Modes:

Moves the unit into Edit

Operation, which is indicated by the left

most digit flashing. Successive presses of

the key are used to move to the digit to be

edited. Wrap around will occur from least

significant digit to most significant digit.

Program

In

Operation Mode:

Used to move between

the position display & the alarms and to

enter an edited alarm value. Holding the

key down for 3 seconds will cause the unit

to enter Program Mode.

In

Program Mode:

Used to move from one

parameter to the next and enter the edited

parameter values. Holding the key down for

3 seconds will cause the unit to return to

Operation Mode.

Reset

In

Operation Mode:

Resets the position

display to zero (under Reset Value in

Program Mode). This button can be

disabled via the „Front Panel Reset Enable“

parameter in Program Mode.

In

Program Mode:

No function

Down &

Scroll

In

All Modes:

Will abort an Edit Operation

and return the preset/parameter to its

previous value.

Display functions

Display

Function

Primary

In

Operation Mode:

Default display is the

position. Can be scrolled using the

program key to display the alarm values.

If the „Help“ function is enabled, this

display will first show the parameter

description for 3 seconds ( see page 5 for

example).

In

Program Mode:

Displays the value or

selection for the current parameter. If the

„Help“ function is enabled, this display will

first show the parameter description for 3

seconds ( see page 6 for example).

Secondary

In

Operation Mode:

Indicates

alphabetically if one of the alarms is

being viewed on the primary display. This

display is blank when Position is being

shown.

In

Program Mode:

Provides a 1 digit

alpha or numeric character to indicate

which parameter value is being shown on

the primary display.

Output

indicators

illuminates when the High Alarm Value

is reached (OUT1)

illuminates when the Low Alarm Value

is reached (OUT2)

2 735 021, Rev. 030798 Operating Instructions tico 735 - Position Indicator page 6/11

Operation Mode

Changing a Preset value (example)

Default display is the position

value.

),C

Pressing the Program Key will

cause the display description to

appear on the main display.* If

there is no key activity for 3

seconds, the primary display will

switch back to the count value.

$ '

Continued pressing of the

Program Key will scroll to the

Alarms. (see parameter

sequence below.) The full

parameter description will appear

on the main display.*

O

$

To change the Alarm value,

press the Scroll Key. If there was

no key activity for 3 seconds, the

Alarm value will appear (one digit

description shown on secondary

display); however, press the

Scroll Key in order to edit. The

unit will now be in Edit Operation

as signified by the most

significant digit flashing.**

P

$

Use the Scroll Key to move from

left to right and highlight the digit

that needs to be changed. Wrap

around will occur from the least

significant to the most significant

digit.

O

$

Use the Down Key to decrement

the digit until the desired value

appears. The display will wrap

around from 0 to 9.

$ '

After the desired digits have been

changed, press the Program Key

to enter the new value. The new

value will appear on the main

display without any flashing

digits. Press the Program Key

again and the parameter

description will appear on the

main display.

* Parameter descriptions will not appear on the

primary display if the „Help“ function has been

disabled

** Edit Operation cannot be accessed if the Preset

Lock has been enabled in Program Mode

Display Parameter Sequence

),C

Position

Function

: Displays the position

value.

Display Range:

-19999 to 99999

' '

'

Low Alarm Value

Function

: Defines the position

value at or below which Alarm 2

will activate.

Adjustm. Range

:-19999 to 99999

Default Value

: 10

$ '

$

High Alarm Value

Function

: Defines the position

value at or above which Alarm 1

will activate.

Adjustm. Range

: -19999 to 99999

Default Value

: 1000

2 735 021, Rev. 030798 Operating Instructions tico 735 - Position Indicator page 7/11

Program Mode

Entering Program Mode and basic operation

The Program Mode can be

accessed from the Operation

Mode by holding the Program

Key for 3 seconds.

⇑⇓

for 3 secs.

The Program Mode can be exited by holding the Program

Key for 3 seconds or remove power from the unit and

repower it.

After 90 seconds of key inactivity the unit returns to

Operation Mode automatically.

The name of the first parameter

will appear on the primary

display.*

Successive presses of the

Program Key will scroll the

display through the remaining

parameters in the Program

Mode. To exit Program Mode,

hold the Program Key for 3

seconds.

* Parameter names will not

appear on the main display if

the „Help“ function has been

disabled in Program Mode

3'

= N )

3 secs. or

⇒

⇐

Edit Operation

Q

R

Pressing the Scroll Key or no key activity

for 3 seconds will display the value for that

parameter. The secondary display will

indicate the one digit identifier for the

parameter. The digit in the secondary

display will flash to indicate the unit is in

Program Mode. If the Scroll Key was

pressed (instead of waiting 3 seconds), the

unit is in Edit Operation, as indicated by the

MSD flashing. If there had been no key

activity for 3 seconds, press the scroll key

to enter Edit Operation (MSD flashing). Use

the scroll and edit keys to change the value

as in Operation Mode, described on page 5.

Press the Program Key to enter any

changes.

Program Parameter Sequence

3'

N

Calibration Factor

Function

: Scales the input into engineering units by multiplying this value by the number of pulses

received.

Adjustment Range

: 0.0001 to 9.9999

Default Value

: 1.0000

= N )

=

Decimal Position

Function

: Set the decimal point position for the position and alarm displays

Adjustment Range

: 0 (no dp) to 0.0000

Default Value

: 0 (no dp)

*!,!/

Reset Value

Function:

Defines a home position by selecting a value other than zero or another value

within the displayed range of the device to which the counter can reset

Adjustment Range:

-19999 to 99999

Default Value:

0

2 735 021, Rev. 030798 Operating Instructions tico 735 - Position Indicator page 8/11

-) =

"

Filter Speed

Function

: Enables the debounce filter of the counter to properly match the application.

Note: the sum of both input frequencies should not exceed 10 kHz, i.e. you can apply up to 5kHz

channel frequency.

Adjustment Range:

T

20: The unit will accept

up to 20 pulses per

second. Generally

used with contact

inputs to eliminate

false counts caused by

contact bounce

T

200: The unit will accept

up to 200 pulses per

second. Generally used

for higher speed contact

inputs or to filter noise

on electronic signals in

low speed applications

T

10,000: The unit will

accept up to 10,000

pulses per second.

Generally used with

high speed electronic

inputs and encoders

Default Value

: 10000

+- C

+

Front Panel Reset Enable

Function

: Determines whether the Front Panel Reset key can be used to reset the

position value.

Adjustment Range:

C

C

+

Enable: The position

value can be reset

while being viewed in

Operation Mode by

pressing the Front

Panel Reset Key

=-

+

Disabled: The Front

Panel Reset Key is

disabled and the

position value can only

be reset through the

Remote Reset Input

Default Value

: Enable

+/ C

/

Retransmission Enable/Select

Function

: Determines whether a voltage/current is an output, and if so, which range. A

jumper on the output module determines whether it outputs current or voltage.

Adjustment Range:

CC!

CC!

/

None

Default Value:

None

1

/

1

/

0-5 or 1-5 Volts

1

/

1

/

0-10 or 2-10 Volts

/

/

0-20 mA, 4-20mA

+/ '

'

Retransmission Scale Minimum(Appears only if a current/voltage is selected)

Function

: Defines the lower end of the linear scale for the retransmission output by

defining the value equated to the minimum output signal.

Adjustment Range:

-19999 to 99999

Default Value:

0

+/ $

$

Retransmission Scale Maximum (Appears only if a current/voltage is selected)

Function

: Defines the upperer end of the linear scale for the retransmission output by

defining the value equated to the maximum output signal.

Adjustment Range:

-19999 to 99999

Default Value:

100

2 735 021, Rev. 030798 Operating Instructions tico 735 - Position Indicator page 9/11

3DE,

N

Serial Communication enabled (Appears only if communication board is installed and

activated

Function

: Activates the RS-485 communication option board.

Adjustment Range

CC

N

None: no communica-

tion board installed

"/

N

Fitted: A communica-

tion board is installed in

the unit

Default Value

: If ordered from the factory

with the RS-485 board, the default will be

„Fitted“. If the board is installed in the field,

this parameter will need to be changed

fromt its default of „none“.

==+

Communication Address

(Appears only if communication board is installed and activated)

Function

: Defines the unique communication address of the unit

Adjustment Range

: 1 to 99

Default Value

: 1

1=

Baud Rate

(Appears only if communication board is installed and activated)

Function

: Selects the serial communication speed

Adjustment Range:

1200 BPS

2400 BPS

Default

: 4800 BPS

9600 BPS

37+

Display Colour Change

Function

: Defines the colour of the display

Adjustment Range:

*!=

Red: The display will

always be red

Default Value

:

Green to red

#+!!C

Green: The display

will always be green

#C:+=

#C:+=

Green to Red: The

display will be green

prior to the Alarm value

being reached. It will

turn red after the Alarm

has been reached

+=:#C

Red to Green: The

display will be red prior

to the Alarm value

being reached. It will

turn green after the

Alarm has been

reached

'N

Preset Lock

Function

: Determins whether the Alarm Values changes via the front panel are locked out.

Adjustment Range

:

C

Locking Enable. Alarm

values are read only.

=-

=-

Locking Disabled.

Alarm values can be

viewed and changed.

Default Value

:

Locking Disable

$ ')

?

Help Prompt

Function

: Determines whether the multi-character parameter name will appear on the main display

for 3 seconds prior to the paramter value appearing.

Adjustment Range

:

$

') 4

$') 4

?

Help-Yes: Multi character parameter

descriptions will appear on the primary

display. The value associated with that

parameter will appear by pressing the

scroll key or waiting for 3 seconds

$') (

?

Help-No: Only the parameter values

will appear on the primary display. The

parameter can be identified by a single

digit in the secondary display

Default

Value

:

Help Yes

2 735 021, Rev. 030798 Operating Instructions tico 735 - Position Indicator page 10/11

Technical Data

Display

Primary Display Red/Green, 7 segment LED, 5 digits, height 18.5 mm

and Keyboard

Secondary Display Red/Green, single digit 7 segment LED, height 7 mm

Annunciators 2 red LEDs for OUT1 and OUT2

Keyboard 4 rubber keys for programming and manual reset

Physical

Dimensions DIN 48 mm x 96 mm, 110 mm total depth

Mounting Front panel mounting (mounting bracket supplied)

Panel Cutout

45+0.5 mm x 92+0.5 mm, panel thickness max 12 mm

Construction Front carrier with circuit boards can be pulled out

Terminals Screw Type - combination head

Environmental

Power Supply

90 - 264 VAC 50/60 Hz (electrically separated from all inputs and outputs) or

20 to 50 VAC / 22 to 55 VDC

Power Consumption 4 Watts

Temperature Operation: 0°C to +55°C (32°F to 131°F)

Storage: -20°C to +80°C (-4°F to 176°F)

Relative Humidity 20 % to 90 %, non-condensing

Approvals

Ratings Frontpanel IP 66

EMC Susceptibility Complies with EN 50082-1/92-95

EMC Emissions Complies with EN 50081-1/92, -2/94

Safety DIN EN 61010 part 1; according to protection class II

General

Overvoltage category II, Contamination level 2

UL, CUL

Count Inputs

Phase Discriminator capable of TTL; 30 VDC max; counts up when A leading B

A and B

Levels High

≥

3.0 V, Low < 2.0 V or open; 10 kOhm to 0V

Count Frequency 20 Hz, 200 Hz or 10 kHz programmable (5 kHz per channel)

Control Inputs

CTRL1

(Reset) NPN; High

≥

3.0 V or open, Low < 2.0 V; 4,7 kOhm to V+

edge sensitive; 25 ms min., max 30 VDC

CTRL2

(Security Lockout) NPN; High

≥

3.0 V or open, Low < 2.0 V; 4,7 kOhm to V+

level sensitive; 25 ms min.; max 30 VDC

Outputs

OUT1 NPN,

OUT2 NPN Open Collector; 30 VDC max; 100 mA max;

response time < 75 µs at<2µscyclical accuracy

OUT1 Relay,

OUT2 Relay

Changeover (Form C); 240 VAC / 3A or 115 VAC / 5A;

pull-in time approx. 8 ms

Sensor Power Supply 12 (unregulated VDC), 125 mA max; ripple < 0.5 V

Linear Output

Isolation

Optically isolated; 250 VAC / 400 VDC against all other inputs and outputs.

Option

Output Range 0-20 mA, 4-20 mA, 0-5 V, 1-5 V, 0-10 V, 2-10 V

Accuracy

±

0.25 % (mA at 250 Ohm, V at 2kOhm); Linear Deviation

±

0.5%

Resolution 8 Bit after 250 ms (10 Bit after 1000 ms typically)

Updating approx. 4 updates per second

RS-485 Option

Type

RS485, serial asynchronous, Open ASCII, Master-Slave, up to 99 zones

Parameters

9600...1200 Bd, 1 start, 7 data, 1 stop, even parity

2 735 021, Rev. 030798 Operating Instructions tico 735 - Position Indicator page 11/11

Ordering Information

Relay 2

0 none Communications

1 with Relay 2 0 none

(only with function 4,5,8,9) 5w

i

t

h

RS

48

5

0 735 P

Function Power Supply

1 Totaliser 0 90...264V AC

2 Position Indicator 2 20...50V~ or

4 Tacho/Rate Meter 22...55V=

5 Rate & Totaliser

6 Time Counter Linear Output

7 1 Preset Counter 0 none

8 2 Preset Counter 3 with 4-20 mA

9 Batch Counter (only with function 2,4,5)

© 1998 HENGSTLER GmbH

This documentation may not be changed, amended, or copied without prior written consent of HENGSTLER GmbH, and may not be used in

contradiction to this companys rightful interests.

Hengstler GmbH

Postfach 11 51

D-78550 Aldingen

Germany

Tel. +49-7424-89 539

Fax +49-7424-89 470

Member of the U.S.A

Other manuals for tico 735

1

This manual suits for next models

1

Table of contents

Popular Touch Panel manuals by other brands

AXIOMTEK

AXIOMTEK GOT321W-502-PCT/FR user manual

AMX

AMX Modero Viewpoint MVP-5200i Operation/reference guide

Digital Touch Systems

Digital Touch Systems TILTED TABLE KIT Assembly instructions

Advantech

Advantech PPC-A84/A120-X5X user manual

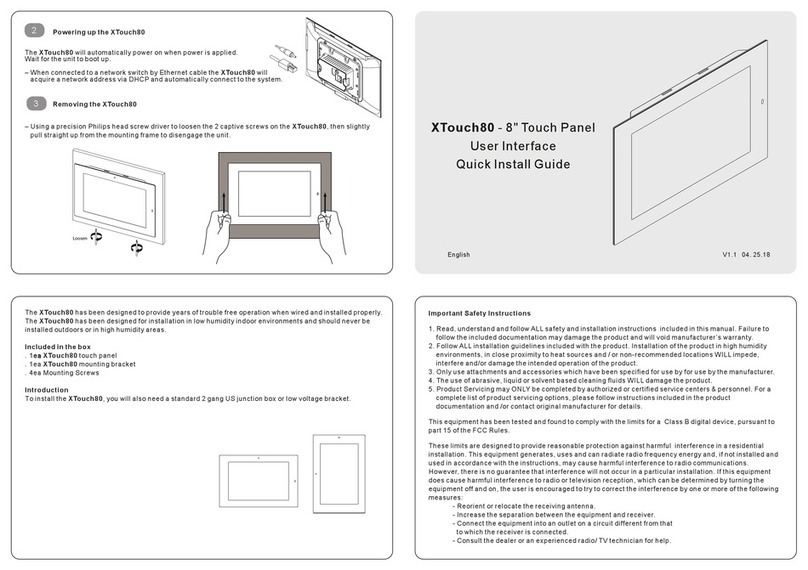

Xilica Audio Design

Xilica Audio Design XTouch80 Quick install guide

Avalue Technology

Avalue Technology SID-10WR1 Quick reference guide