8.2 Operation and handling

................................

................................

................................

................................

8.6 Date and time selection

................................

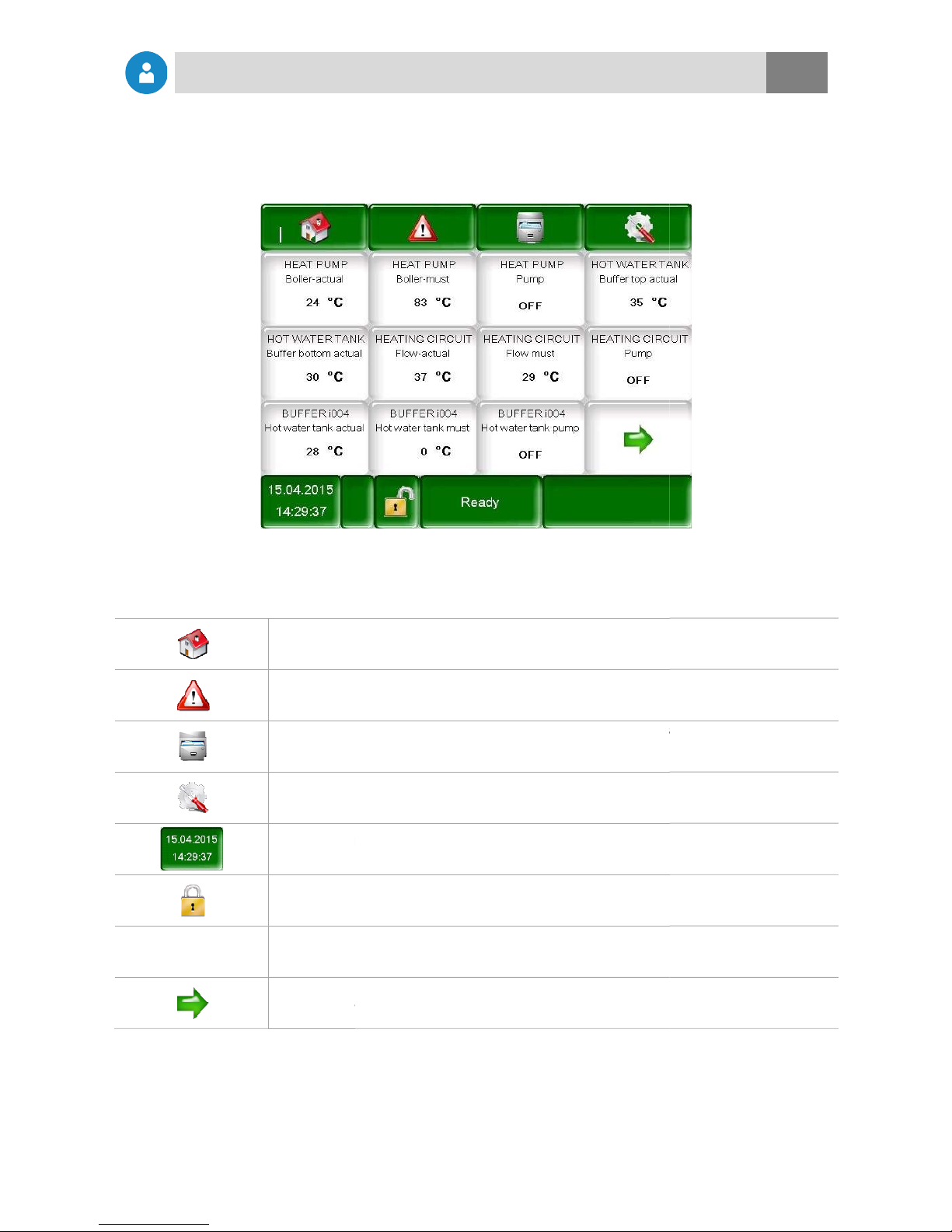

Determining main menu values

Adding main menu display values

Fault messages and warnings

................................

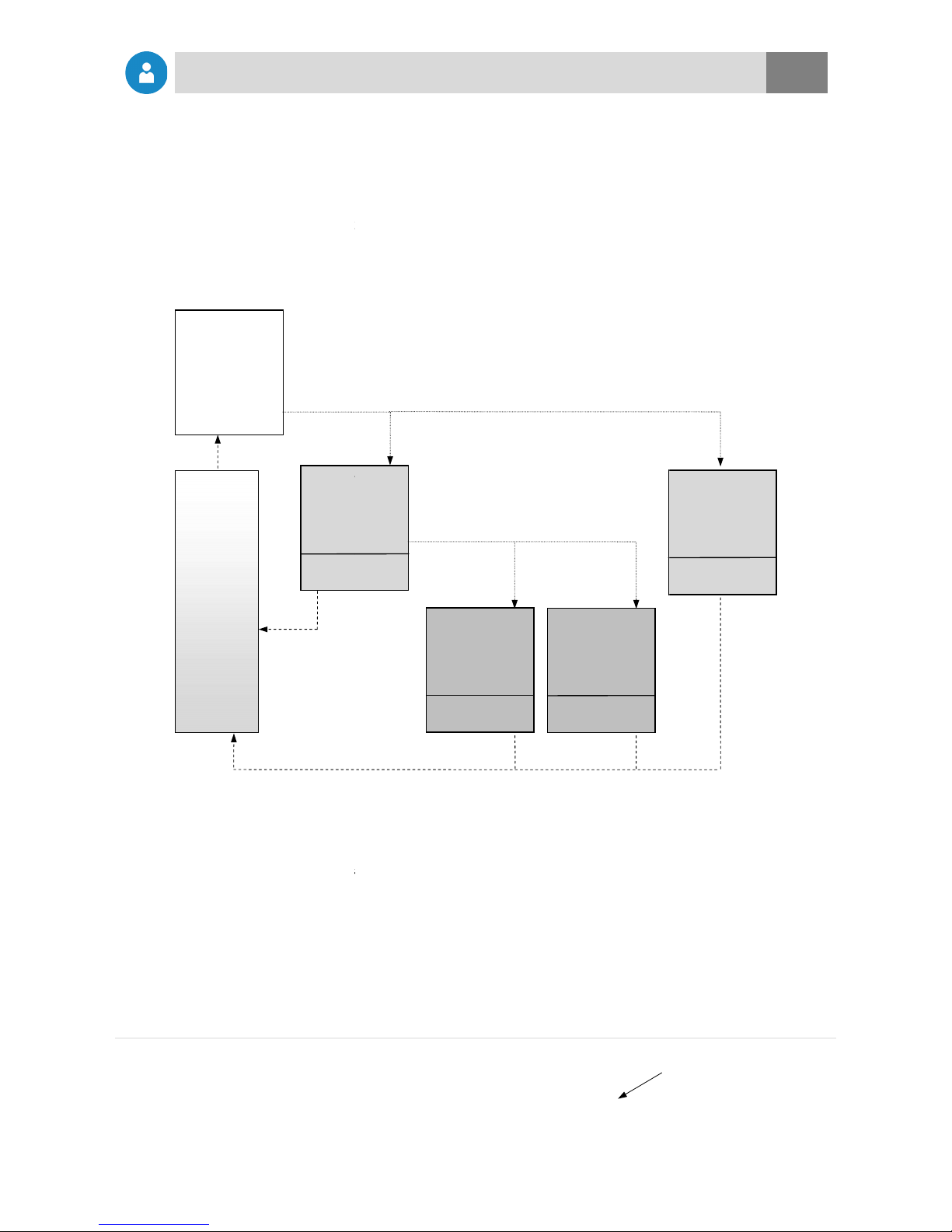

Module structure and navigation to the most important settings

................................

Switching on the heat pump

Switching off the heat pump

8.10.2 Hot water tank module

................................

................................

8.10.4 Heating circuit module

................................

................................

................................

8.10.7 Hydraulic compensator

................................

................................

................................

External requirement module

External additional boiler module

................................

8.11.1 Network configuration

................................

................................

................................

8.11.4 Information overview

................................

................................

8.11.6 E-Mail status report

................................

................................

................................

................................

................................

................................

................................

................................................................

................................

................................

................................

................................

................................

................................................................

................................

................................

................................

................................

Determining main menu values

................................................................

................................

Adding main menu display values

................................................................

................................

................................

................................

Fault messages and warnings

................................................................

................................

................................

................................

................................

Module structure and navigation to the most important settings

................................

................................

................................

................................

Switching on the heat pump

................................

................................

Switching off the heat pump

................................

................................

................................................................

................................

................................

................................

................................

................................

................................................................

................................

................................

................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................

................................

................................

................................................................

................................

................................

................................................................

................................

External requirement module

................................................................

................................

External additional boiler module

................................................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

.............................

................................

................................

................................

..............................

................................

................................

................................

................................

................................

................................

................................

................................

.................................. 24

................................

................................

............................ 26

................................

................................

........................... 28

................................

................................ 28

................................

................................ 29

................................

................................

................................

................................

...................... 40

................................

................................

................................

................................

................................

................................

................................

................................

................................. 60

................................

....................... 61

................................

............................ 62

................................

................................

........................ 63

................................

............................... 64

................................

.......................... 66

................................

................................. 67

.............................

................................

..............................