Herz BW/WW User manual

Operating instructions

commotherm heat pump

for Brine- and water operation (BW, WW)

Introduction

2 Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2

INTRODUCTION

Dear Customer!

Your heating system is powered by a HERZ commotherm heat pump and we are pleased to be able to count

you as one of our many satisfied owners of a HERZ system. The HERZ commotherm heat pump is the result

of years of experience and continuous improvement. Please remember that in order to be able to work

properly, a well-designed product also needs to be operated and maintained correctly. We definitely

recommend that you should read this documentation carefully while paying particular attention to the safety

instructions. Compliance with operating procedures is required for any claims made under the

manufacturer’s warranty. In the event of any faults or defects, please contact your heating specialist or the

HERZ Customer Service department.

Yours sincerely

HERZ – Energietechnik

Warranty / Guarantee (general information)

For Herz heat pumps we give a 3-year guarantee on the closed cooling circuit. The guarantee can also be

optionally extended to 5 years or a maximum of 15,000 operating hours, in each case via an appropriate

agreement. Storage tanks and HERZ solar collectors come with a 5-year warranty. We generally guarantee

freedom from defects of mobile objects purchased for a period of 2 years, to a maximum of 6,000 hours of

operation. For non-moving purchased items, the guarantee is generally for a period of 3 years to a maximum

for 9,000 hours of operation. Parts subject to wear are excluded from the warranty/guarantee. Furthermore,

claims under warranty will not be applicable if commissioning1 is not carried out by specialist personnel

authorised by HERZ or if hydraulic diagrams2, not recommended by HERZ are used.

Any claim to warranty services requires maintenance to be carried out on an annual basis by

specialist personnel authorised by HERZ.

The general warranty period will not be extended if work is carried out under warranty. In the event of a

warranty claim, the due dates for payments owed to us will not be deferred. We will only provide a guarantee

if all the payments owed to us for the product supplied have been made.

The warranty will be carried out at our discretion by repairing the item purchased or replacing any defective

parts, by exchanging the item or by reducing the price. Parts or goods replaced are to be returned to us at

our request free of charge. Wages and costs paid out in connection with installation and removal are to be

paid for by the purchaser. The same applies to all warranty services.

The Supplier shall under no circumstances be liable to the Customer, for any direct, indirect or consequential

costs incurred by the Customer for works carried out on HERZ equipment.

This document is the translation from the German original. The reproduction or copying, even of extracts,

may only be undertaken with the permission of the company HERZ©.

Subject to technical modifications,

Version 04/2015

1 Maintenance by the manufacturer

2 Recommended hydraulic diagrams can be found in the installation manual while hydraulic balancing will be carried out by the heating

contractor

Furthermore, the quality of the heating water must be in accordance with ÖNORM H 5195 (current version) or VDI 2035

Table of content

Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2 3

TABLE OF CONTENT

page

1 Documentation notes ........................................................................................................ 5

1.1 General notes ...................................................................................................................................... 5

1.2 Symbols ............................................................................................................................................... 5

2 Safety notes ....................................................................................................................... 6

2.1 Warning notes ..................................................................................................................................... 6

2.2 Installation ........................................................................................................................................... 6

2.3 Operation and maintenance ............................................................................................................... 6

2.3.1 Operation ............................................................................................................................................... 7

2.3.2 Maintenance .......................................................................................................................................... 7

3 Information about the product ......................................................................................... 8

3.1 Intended use ........................................................................................................................................ 8

3.2 Type label ............................................................................................................................................. 8

3.3 Care and cleaning ............................................................................................................................... 9

3.4 Maintenance ......................................................................................................................................... 9

4 Plant overview ................................................................................................................... 10

5 Equipment functioning ..................................................................................................... 11

5.1 Refrigerant ........................................................................................................................................... 12

5.1.1 Characteristics of the refrigerant ........................................................................................................... 12

5.1.2 Measures when refrigerant escapes ..................................................................................................... 12

5.1.3 First Aid measures for contact with refrigerant ..................................................................................... 13

5.2 Safety devices ..................................................................................................................................... 13

5.2.1 Low pressure switch .............................................................................................................................. 13

5.2.2 High pressure switch ............................................................................................................................. 13

5.3 Operating conditions to be maintained ............................................................................................ 14

5.3.1 Permissible temperatures ..................................................................................................................... 15

5.3.2 Flow rate ................................................................................................................................................ 15

6 Operating conditions ........................................................................................................ 17

7 Temperature manager ....................................................................................................... 18

8 T-Control ............................................................................................................................ 19

8.1 Starting the system ............................................................................................................................. 19

8.2 Operation and handling ...................................................................................................................... 19

8.3 Main menu ............................................................................................................................................ 20

8.4 Symbols explanation .......................................................................................................................... 21

8.5 Code – entry ......................................................................................................................................... 22

8.6 Date and time ....................................................................................................................................... 23

1 Documentation notes

4 Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2

page

8.7 Main menu values ............................................................................................................................... 24

8.7.1 Adding values ........................................................................................................................................ 24

8.7.2 Delete values ......................................................................................................................................... 25

8.8 Fault messages and warnings ........................................................................................................... 26

8.9 Modules overview ............................................................................................................................... 27

8.10 Module configuration .......................................................................................................................... 28

8.10.1 Heat pump ............................................................................................................................................. 29

8.10.2 Buffer ..................................................................................................................................................... 32

8.10.3 Hot water tank ....................................................................................................................................... 34

8.10.4 Heating circuit ........................................................................................................................................ 36

8.10.5 Time mode ............................................................................................................................................ 41

8.10.6 Solar ...................................................................................................................................................... 42

8.10.7 Hydraulic compensator module ............................................................................................................. 44

8.10.8 Net pump ............................................................................................................................................... 45

8.10.9 Zone valve ............................................................................................................................................. 46

8.10.10 External requirement ............................................................................................................................. 47

8.11 Menu settings ...................................................................................................................................... 49

8.11.1 Network configuration............................................................................................................................ 50

8.11.2 Modbus – settings ................................................................................................................................. 51

8.11.3 Screensaver .......................................................................................................................................... 52

8.11.4 Information overview ............................................................................................................................. 52

8.11.5 Mail sending .......................................................................................................................................... 53

8.11.6 Mail – status report ................................................................................................................................ 55

8.11.7 Server – settings ................................................................................................................................... 56

9 Fault reports and their corrections .................................................................................. 57

10 EC Declaration of conformity ........................................................................................... 62

11 Index................................................................................................................................... 63

Documentation notes

1

Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2 5

1 DOCUMENTATION NOTES

1.1 General notes

Before commissioning, please read the documentation carefully and pay attention to the safety

instructions given in particular (see chapter 2). Please consult this manual if anything is unclear.

Make sure that you understand the instructions contained in this manual and that you are sufficiently

informed regarding the way in which the heat pump works. Should you have any queries at any time,

please do not hesitate to contact HERZ.

For safety reasons, the owner of the system must not make any changes to the construction or the state

of the system without consulting the manufacturer or his authorised representative.

All connections are to be checked before the commissioning of the system in order to make sure that

they are leak-tight.

A portable fire-extinguisher of the prescribed size is to be kept by the boiler room. (Please heed the

relevant national regulations).

Carry out maintenance regularly or use our Customer Service department. The maintenance jobs are

listed in chapter 3.4.

When carrying out maintenance on the system or opening the control unit, the power supply is to be

disconnected and the generally valid safety regulations are to be heeded.

It is also not permitted for objects which are not required for the purpose of operating or carrying out

maintenance on the system to be kept in the boiler room.

Should you have any queries, please call us on +43 / 3357 / 42840-840.

Initial commissioning must be carried out by the HERZ Customer Service department or an authorised

specialist (otherwise any warranty claim will not be applicable).

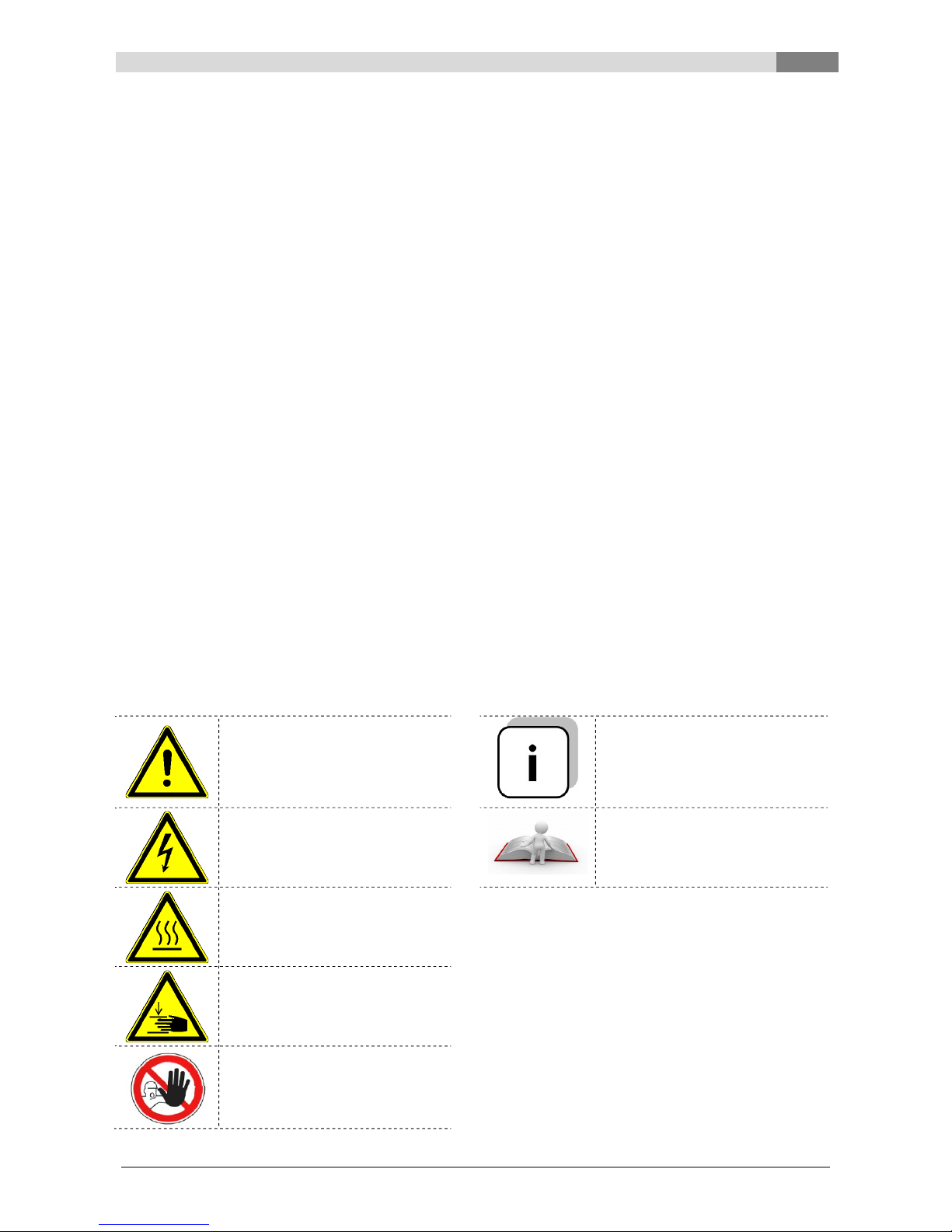

1.2 Symbols

The symbols which are fixed on the heat pump or which are listed in this documentation have the following

meaning:

Warning!

Information!

Dangerous electric tension!

Reference to other

documentation!

Hot surface!

Warning of hand injury!

Off limits to unauthorised

personnel!!

2 Safety notes

6 Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2

2 SAFETY NOTES

2.1 Warning notes

Risk of injury and damage to property due to improper handling of the system.

However, adherence to guidelines for transportation, installation, operation and maintenance notices as well

as technical data (in the operating instructions, product documentation and on the equipment itself) which

are not specifically highlighted, is also vital to avoid breakdowns which may directly or indirectly cause major

personal or material damage.

General note

For reasons of clarity and possible permutations, this documentation does not contain all detailed information

and cannot take account of every conceivable operating or maintenance scenario. Should you require further

information or encounter specific problems, which are not handled in detail in the documentation supplied,

you can obtain the required information from your specialist dealer or direct from HERZ.

People (including children) who, because of their physical, sensory or mental capabilities or because of their

lack of experience or knowledge, are unable to use the equipment safely must not use this equipment unless

they are supervised or instructed by a responsible person.

Basic safety information

Due to its functionally limited electrical and mechanical characteristics with regard to usage,

operation and maintenance, if the equipment is not able to work according to its appropriate

use or improper interference occurs, it may cause serious health and material damage. It is

therefore conditional that the planning and implementation of all installations, transportation,

operation and maintenance will be carried out and supervised by responsible, qualified

persons.

When operating electrical systems, certain parts of those systems will always carry a

hazardous electrical voltage or be exposed to a mechanical load. Only appropriately

qualified personnel may carry out work on the system. They must be thoroughly familiar with

the content of this and all other manuals. In order for this system to function safely and

without any problems, transportation, storage, operation and maintenance must be carried

out properly and carefully. Instructions and information on the systems must also be

heeded.

2.2 Installation

In order to ensure that the system will function properly, the relevant standards and the manufacturer’s

installation instructions are to be heeded during the installation of the system!

Documents from the manufacturer relating to the heating devices and components used are available from

HERZ on request.

2.3 Operation and maintenance

In order for the system to be operated and maintained safely, it must be operated and

maintained properly by qualified personnel while heeding the warnings in this documentation

and the instructions on the systems.

Safety notes

2

Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2 7

2.3.1 Operation

Covers which prevent contact with hot or rotating parts or which are required in order to

direct the flow of air correctly and thus ensure the effective functioning of the system must

not be opened during operation.

In the event of a fault or unusual operating conditions the system is to be switched off

immediately. Notify the HERZ Customer Service department immediately.

The generated system noise during operation does not present any danger to the operator´s

health.

2.3.2 Maintenance

Before starting to carry out any work on the system, but especially before opening covers

protecting live parts, the system is to be properly disconnected from the power supply.

Besides the main circuits, attention is also to be paid to any existing additional or auxiliary

circuits in the process.

The normal safety rules according to ÖNORM are:

Disconnect all poles and all sides!

Ensure that the system cannot be switched on again!

Check to ensure that no voltage is connected!

Earth and short-circuit!

Cover adjacent live parts and locate hazardous areas

These above-mentioned measures must not be reversed until the system has been fully

installed and maintenance has been completed.

In order to prevent any maintenance errors, if maintenance is not carried out properly, it is recommended to

be carried out regularly by authorised personnel or by the HERZ Customer Service department.

Spare parts must be obtained directly from the manufacturer or a distribution partner. The customer will not

be exposed to any health risks as a result of the noise generated by the machine.

3 Information about the product

8 Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2

3 INFORMATION ABOUT THE PRODUCT

3.1 Intended use

The commotherm heat pump may be used only for

heating,

cooling and

hot water heating.

Any other use is considered improper.

In addition, the device may only be used within its technical application area! The

technical application is listed in the assembly instruction!

The intended use of the device includes also the attention of the following documents:

Operating, Installation and electrical documentation

Other applicable documents

Care and maintenance conditions

3.2 Type label

The type label is located on the back side of the heat pump. On the type label item number, production

number, heating power, application area are listed (see figure 3.1).

figure 3.1: Type label

Information about the product

3

Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2 9

3.3 Care and cleaning

The care of the cover parts of the heat pump can be performed with a damp cloth and commercially-

available cleaning agents.

Do not use cleaning products that contain abrasives, acids and/or chlorine. These products could

destroy the surface of the cover parts and it is possible that damages can occur on the heat pump.

3.4 Maintenance

The refrigerant circuit of the heat pump requires no regular maintenance.

4 Plant overview

10 Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2

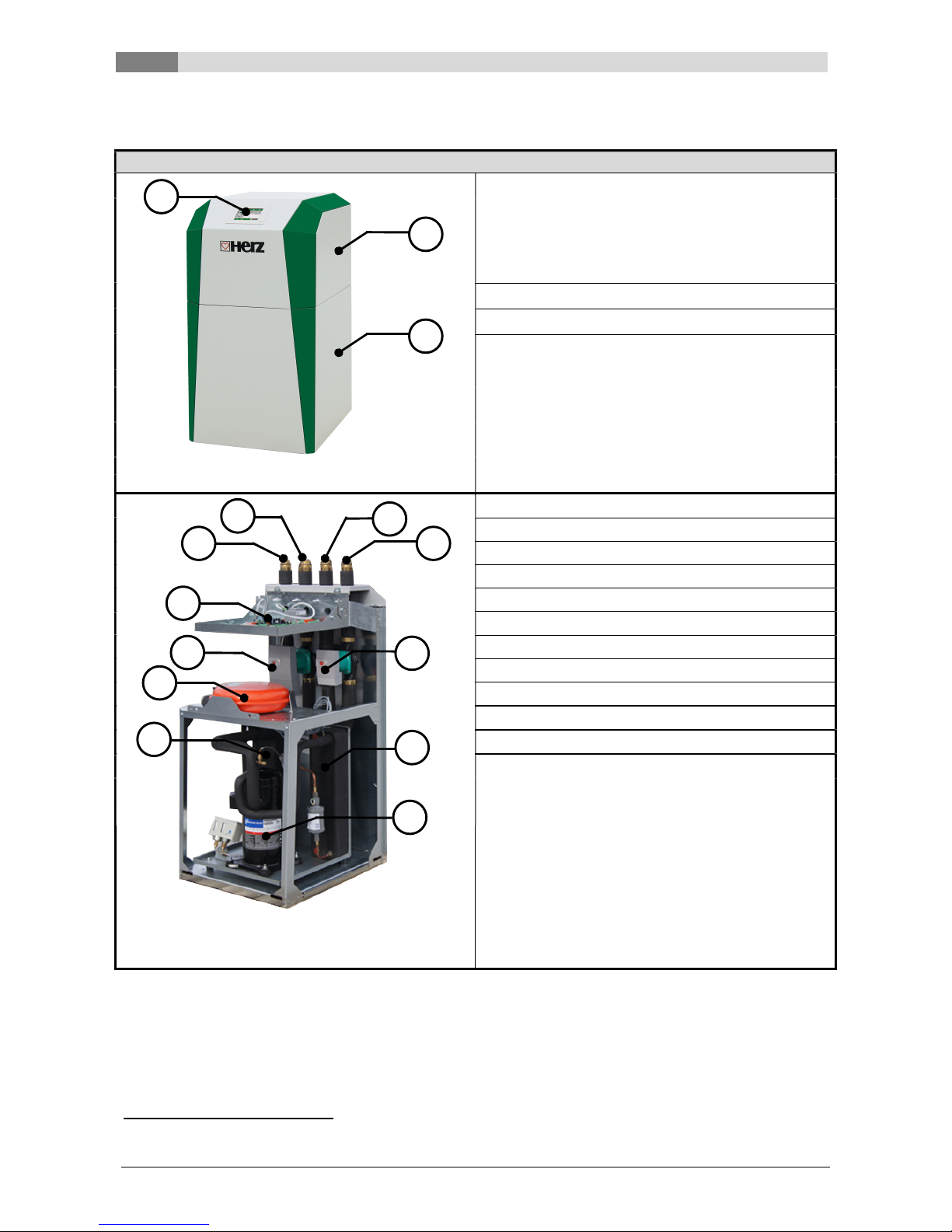

4 PLANT OVERVIEW

commotherm 5 – 15 BW/WW

3

1

Integrated control

The commotherm heat pump is equipped

with a user-friendly touch – display, which

can be used to control and operate the

system centrally. (The menu navigation for

the control can be seen in chapter 8).

2 Upper part of the casing

3 Lower part of the casing

1 Input source

2 Output source

3 Heating back flow

4 Heating flow

5 Operating part

6 Source pump

7 Brine side expansion vessel

8 Condensator pump (supply pump)

9 Compressor

10 Condensator

11 Evaporator

3 BW/WW Brine-Water/Water-Water

1

2

3

figure 4.2: System overview without casing

1

2

4

3

5

7

8

6

9

10

11

figure 4.1: System overview with casing

Equipment functioning

5

Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2 11

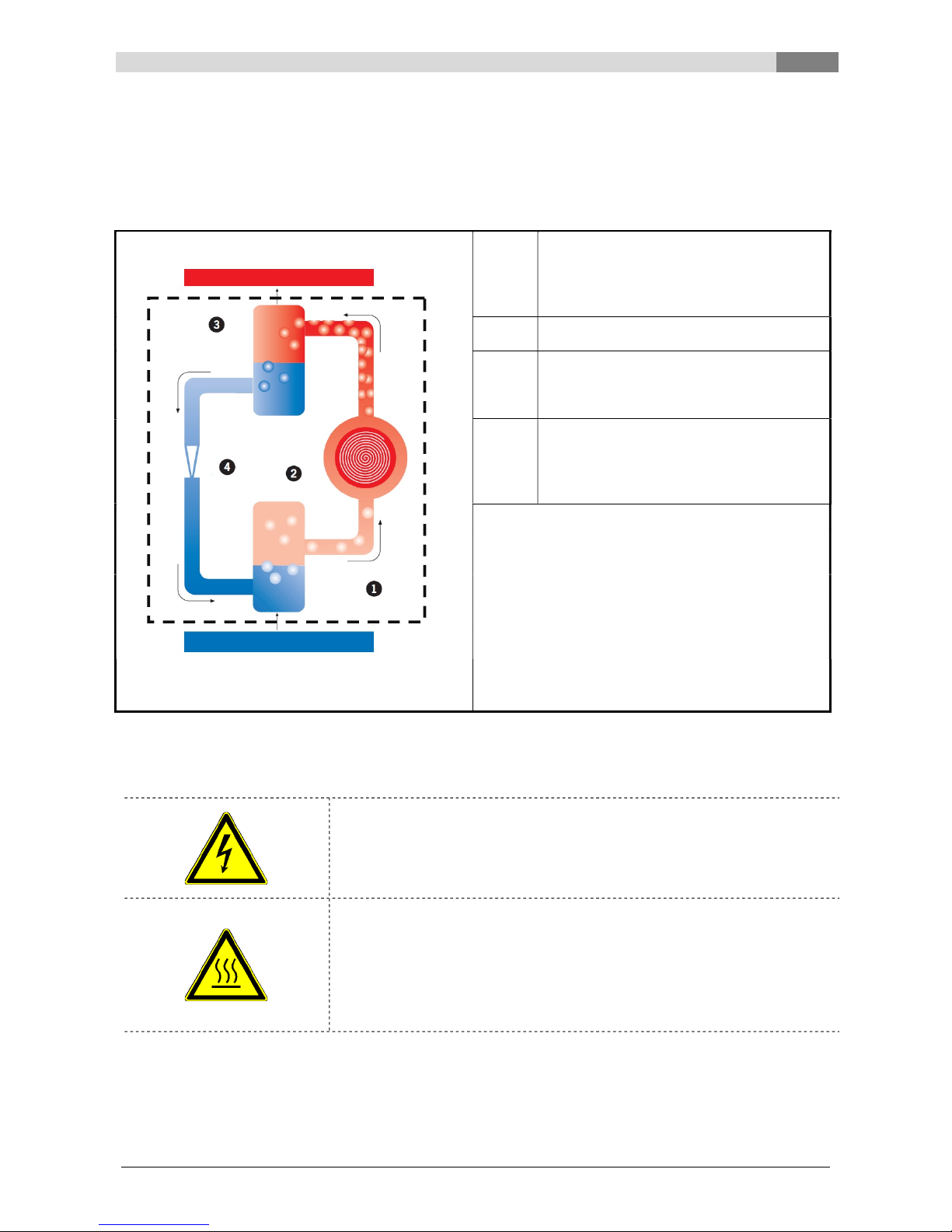

5 EQUIPMENT FUNCTIONING

The core part of your HERZ heat pump is the cooling circuit. The main components are the evaporator (1),

compressor (2), condenser (3), expansion valve (4) and the refrigerant. At this point we should mention that

the handling of the refrigerant is described in chapter 5.1.

figure 5.1 shows the functioning of the heat pump. The refrigerant runs through 4 stages:

1

The fluid refrigerant is evaporated at low

pressure in the evaporator. This also takes

place at temperatures below 0° C. The

ground area, water or air serves as a

source of heat.

2 The compressor increases the pressure

and therefore raises the temperature.

3

The higher temperature is now used for

room heating or hot water preparation in

the condenser, and the hot refrigerant

gives off heat and becomes fluid again.

4

The high pressure is relieved in the

expansion valve and the coolant is

therefore released. The refrigerant can

once again take in heat from the ground

area, water or air.

The circuit is now closed and begins again

from the start.

The HERZ BW/WW heat pump is an “electrically-driven compression heat pump with the coolant, R407C”.

An electrically driven compressor compresses and feeds coolant through a pipe circuit consisting of copper

pipes, whereby pressure up to 30 bar may arise.

The device is under voltage. Removing the device casing as well as working

on the equipment parts may lead to serious physical harm.

The refrigerant supplied can affect surfaces of the equipment parts (pipes

and compressor) at temperatures of more than 100° C ( risk of burning).

Therefore:

work on equipment parts as well as electrical cabling may only be carried

out by qualified specialists.

HEATING CIRCUIT

HEAT SOURCE

Compressor

Evaporator

Condensator

Room heating / Hot water

Earth area / Water / Air

Expansion valve

cooling circuit

figure 5.1: functioning of the HERZ heat pump

5 Equipment functioning

12 Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2

5.1 Refrigerant

Generally, what is understood by a refrigerant is a working material for heat pumps or cooling machines. The

refrigerant circulates in a closed system and is also subject to various changes in condition (see figure 5.1).

The HERZ heat pump works with the refrigerant, R407C, which consists of the following components:

1,1,1,2-tetrafluoroethan (R134a)

50% - pentafluoroethane (R125)

50% - difluoromethane (R32)

5.1.1 Characteristics of the refrigerant

According to ÖNORM EN378-1 refrigerants are divided up into groups with regard to health and safety:

Classification according to flammability

Classification according to toxicity

Group 1: No flame propagation Group A: Lower toxicity

Group 2: Lower flammability Group B: Higher toxicity

Group 3: Greater flammability

Table 5.1 shows the position of the refrigerant, R410A, used in safety group A1.

Table 5.1: safety group for the coolant, R410A, used

Safety group

Greater flammability A3 B3

Lower flammability A2 B2

No flame propagation A1 B1

Lower toxicity Higher toxicity

Other characteristics are:

Ozone reduction potential: 0

Boiling temperature: - 48,5 °C

Temperature operating range: -25°C to 32°C

5.1.2 Measures when refrigerant escapes

If refrigerant escapes, fast evaporation of the fluid may cause frostbite. Steam is also heavier than air, which

may lead to suffocation due to displacement of oxygen in the air. If an escape of refrigerant is noticed (it is

heard to escape, icing over of the exit point), the following measures should be taken:

Ensure there is adequate ventilation.

Close and seal the door to the room where the equipment is located.

Notify HERZ service or customer service.

People must leave the room where the equipment is located straight away.

Consult the doctor or veterinarian if people or animals were exposed to an increased dose for a long

period.

Switch off the power immediately.

In the event of fire, any type of fire extinguisher may be used.

There is no risk of the R410A refrigerant escaping if the HERZ heat pump is

used correctly. If there is an escape of refrigerant due to improper use, there

is a risk of suffocation (air displacement) and frostbite (exit points may

become extremely cold). In chapter 5.1.3 First Aid measures are also

described for contact with coolants.

Equipment functioning

5

Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2 13

5.1.3 First Aid measures for contact with refrigerant

General Tips

In the event of unconsciousness, place carefully on the side and seek medical

advice

Never allow an unconscious person to take in anything by mouth

With irregular breathing or if breathing stops, try artificial respiration. If complaints

persist, seek medical advice

Inhalation

Take the person out of the contaminated area

Respiration with breathing apparatus or oxygen supply

In the event of difficulties with breathing or nerve problems, seek medical advice

Go into the fresh air

Contact with the

Open the eyelids wide to vaporise the agent

eyes

Rinse the eyes out with flowing water for a few minutes, opening the eyelids wide

In the event of continuing sore eyes, seek medical advice

Contact with the

Vaporise the agent

skin

Rinse with lukewarm water

If soreness continues or the skin is red, seek medical advice

Remove soiled or soaked clothing immediately

Never remove refrigerant, let it escape or add additional refrigerant yourself.

This is a risk to humans, animals, the environment and the device itself.

5.2 Safety devices

The pressures in the commotherm heat pump should remain within a define range. To ensure this, so-called

pressure switches are built in. These serve on the one hand as a safety device, and on the other hand to

ensure that the heat pump works in the defined range. The pressure switches are designed as chamber

pressure switches, i.e. the set, adjusted pressures cannot be reset by unauthorised persons. The pressure

switches are also used as low or high pressure switches. These devices are briefly described below.

5.2.1 Low pressure switch

The low pressure switch turns off the compressor at an operating pressure of < 1 bar and therefore protects

this at low pressure (low pressure may be caused by a lack of refrigerant, for example).

5.2.2 High pressure switch

High pressure switches also serve to switch off the compressor in an emergency. In contrast with low

pressure switches, however, this turns off the compressor at a higher pressure. In the event of the BW/WW

heat pump this occurs at pressures of > 28 bar.

5 Equipment functioning

14 Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2

5.3 Operating conditions to be maintained

Some important operating conditions are described below, which must be adhered to.

Equipment functioning

5

Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2 15

Table 5.2 also gives a summary on avoiding faults, if these conditions are not adhered to.

5.3.1 Permissible temperatures

Flow temperature

The heat pump should be operated with a maximum flow temperature of 58° C. If a flow temperature of more

than 58° C is selected, the heat pump works inefficiently. The compressor is also very greatly overloaded

and the equipment will keep malfunctioning.

In general, the flow temperature should actually be adapted to the actual operating temperatures and be set

as low as possible.

Brine temperature

The brine temperature should not be lesser than -6°C. If the temperature is lesser, the device works

inefficient and there is danger of freezing of the device.

5.3.2 Flow rate

No flow rate for heating equipment

If there is no flow rate in the heating equipment, the system will be extremely overloaded until release of the

safety device, in this case the high pressure switch. The water flow rate and system pressure should

therefore be checked.

No flow rate in the brine system

If there is no brine side flow rate, again the system will be extremely overloaded until release of the low

pressure switch. A freezing of the system and the heat exchanger inside the device may also occur until the

heat exchanger bursts and then there is a leak of refrigerant. In the worst case, the device is damaged and

will have to be replaced. The solution here again, is to check the water flow rate and the system pressure as

well as checking the frost safety (at least -15° C).

No ground water flow rate (only at W/W-devices)

Analogous to the missing flow rate in the brine system the device will be extremely overloaded until release

of the low pressure switch. Moreover, a freezing of the system and the external heat exchanger is possible

again. A compensation takes place by a control of the water flow, of the system pressure and the

groundwater conveyor system, a cleaning of the filters and an annual maintenance of the under water pump.

5 Equipment functioning

16 Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2

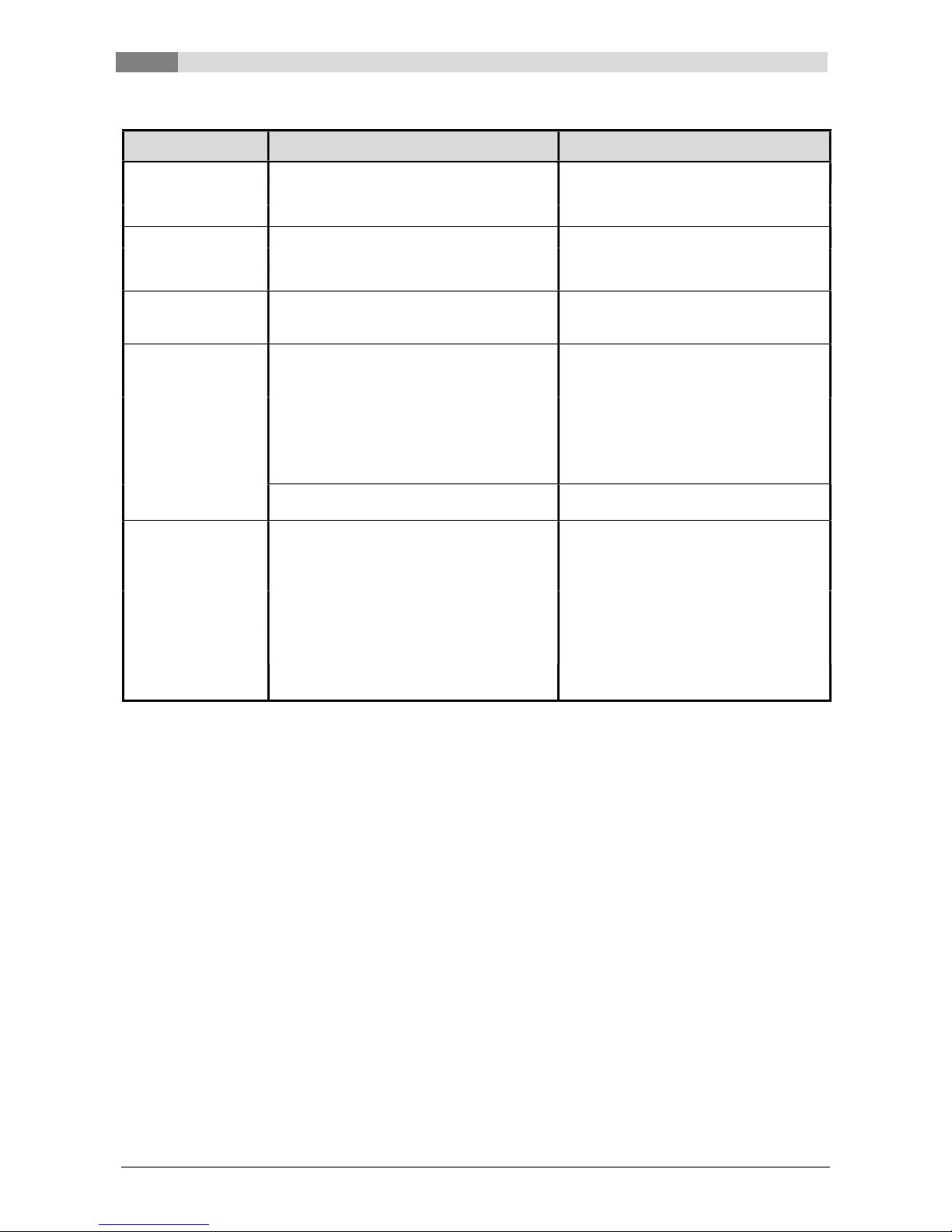

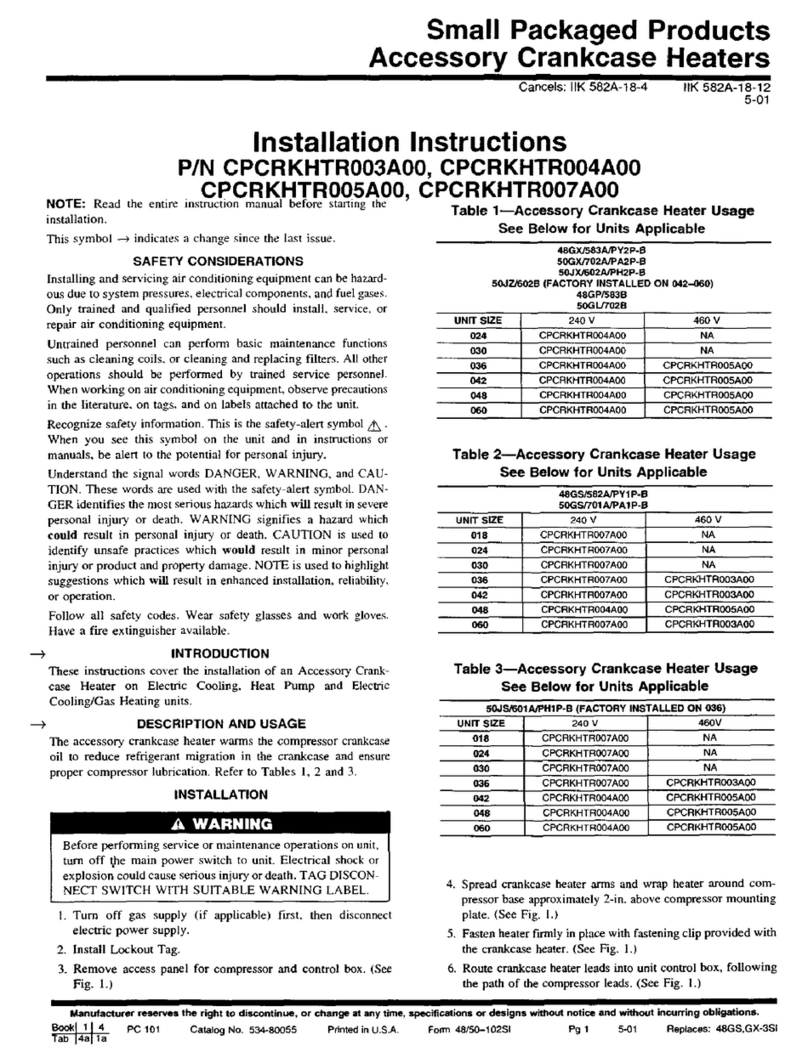

Table 5.2: Summary of the operating conditions to be maintained

Fault source Possible consequences Measures to avoid faults

Flow temperature

> 58°C

Device works inefficiently

Adapt operating temperatures to

the actual requirements and set as

low as possible

Device is constantly malfunctioning

Compressor is heavily overloaded

Brine temperature

< -6°C

Device works inefficiently

Control the brine flow

Danger of freezing of the device

Possibly air in the system

System pressure too low

No flow rate for

heating equipment

The system will be extremely

overloaded until the safety device is

released (high pressure switch)

With new systems, daily checking

of the water flow rate is required

(thereafter annually).

No flow rate for

brine equipment

The system will be extremely

overloaded until the safety device is

released (low pressure switch)

With new systems, daily checking

of the water flow rate is required

(thereafter annually).

Freezing of the system and the heat

exchanger inside the device may

also occur until the heat exchanger

bursts and then there is a leak of

coolant.

Annual check of frost safety (at

least -15

℃

)

The system is damaged and will

have to be replaced.

No ground water

flow rate (only at

W/W-devices)

The system will be extremely

overloaded until the safety device is

released (low pressure switch)

At new installation the flow and

system pressure should be

controlled every day (thereafter

annually)

Freezing of the device and the

external heat exchanger

Cleaning of the filters

Control of the groundwater

conveyor system

Annual maintenance of the under

water pump

Operating conditions

6

Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2 17

6 OPERATING

CONDITIONS

Ready

There are essentially two versions to be

differentiated here, for which the heat pump may

be in the operating condition "ready”:

In the “OFF” mode the heat pump does not

work and is ready to start.

If the heat pump is in “heating operation” or

“cooling operation” mode but there is no

request from the user, the operating condition

"ready" also appears

Wait

This condition serves as compression protection.

If the compressor is switched off and switched on

again straight afterwards, the compressor only

starts after minimal downtime, which may be, for

example, 10 minutes. The “wait” condition is then

displayed.

The compressor may also only be started 6 times

per hour. If the compressor is started more

frequently, it also remains in “wait” operating

condition.

Pump flow

In this condition, the source and condenser pump

start up and run for a pre-set time. This serves to

build up circulation in both circuits.

Compressor

In this condition, the heat pump run and heat or

cooling consumer sends a request to the heat

pump.

Stop

In this condition, the heat pump is switched off but

the source and condenser pump are still running

in so-called pump stoppage to transport any

residual heat / cold to the heat consumer. The

pump stoppage continues according to the fixed

set pump stopping time.

Error

A serious fault has occurred. The heat pump and

all outputs are switched off too.

Cooling mode

This condition indicates that the heat pump is

cooling, i.e. the process is reversed and the

system is taking in heat and diverts this to the

source, for example.

Min. temp.

The heat pump changes in this condition as soon

as the source has reached a minimum

temperature. The source pump is also switched

on which brings about circulation and a

regeneration of the equipment in the brine circuit.

Max. temp. Residual heat

This condition is achieved if the flow temperature

of the heat pump is greater than the set maximum

temperature (usually 58° C). To lower the flow

temperature the circulation pump is switched on.

This runs as long as the maximum temperature is

not reached.

Residual heat

The compressor is switched off here and residual

heat is supplied to heat consumers.

Ext. Stop

The input “external stop” has responded and the

heat pump is switched off. The heat pump only

starts up again if the input “external stop” is no

longer responding. This input can respond, for

example, through phase limit switching by the

energy supply company.

7 Temperature manager

18 Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2

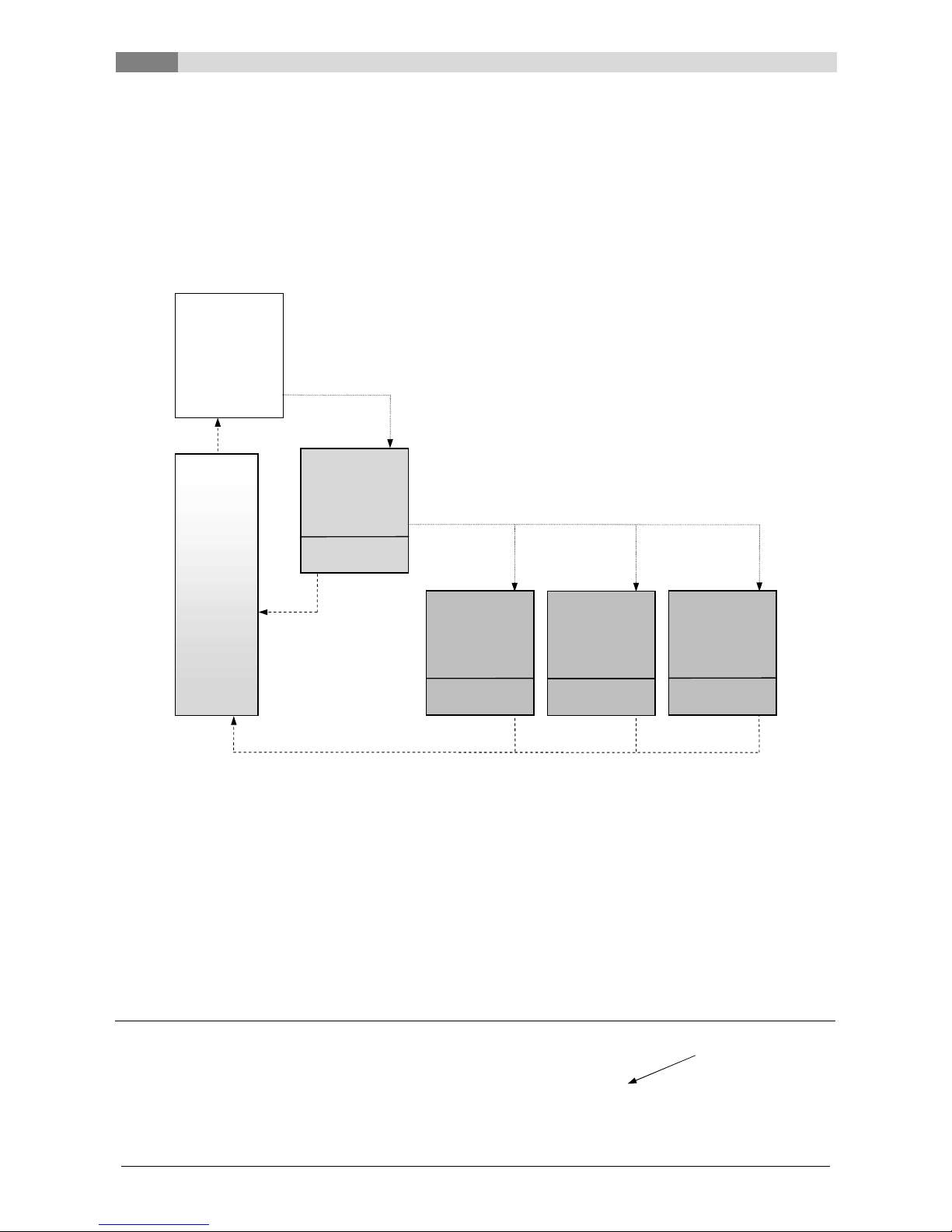

7 TEMPERATURE MANAGER

The heat demand of the individual modules (boiler, hot water tank, heating circuit, solar, etc.) is controlled by

the temperature manager. The below-mentioned scheme (see figure 7.1) explains the functionality of the

temperature manager. A module contains of an in- and output. Every module sends a required demand

temperature to the temperature manager. The sent required demand temperature is a sum of an internal

calculated temperature demand + set up increase. The heat supplier (= heat generator respectively heat

pump/hot water tank), which receives the different module demand temperatures from the temperature

manager, must supply the required temperature demand to the different modules. The temperature manager

calculates the maximum demand temperature of all modules.

Example:

Heat supplier = heat pump

Module 1 & 2 = heating circuit 1 & 2

Module 3 = hot water tank

Module 4 = buffer

Heating circuit 1 Heating circuit 2 Hot water tank Buffer

Calculated required temperature [°C]

40 30 55 48

Temperature increase [°C]

5 3 0 2

Required temperature of the

modules [°C]

45 33 55 50

Maximum temperature requirement

55

HEAT PUMP

(Heat supplier)

B

UFFER

(Module 4)

HEATING

CIRCUIT 1

(Module 1)

HEATING

CIRCUIT 2

(Module 2)

HOT WATER

TANK

(Module 3)

Temp. requirement

+ increase

Temp. requirement

+ increase

Temp. requirement

+ increase

Temp. requirement

+ increase

TEMPERATUR

E

MANAGER

figure 7.1: Temperature manager (simplified scheama – example)

T-Control

8

Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2 19

8 T-CONTROL

The handling and menu navigation are described in this chapter. Every single T-CONTROL parameter is

explained in chapter 8.10 (page 28).

8.1 Starting the system

To switch on the display, the following condition must be fulfilled:

The heat pump must be connected to the power supply

If this condition is fulfilled, the starting process of the display, which takes 1-2 minutes, starts (see figure 8.1).

figure 8.1: Starting process of the display

8.2 Operation and handling

The touch panel is a touch-sensitive screen and control unit. By touching the screen you can change

released values or move to other pages. The screen navigation and input can be done with finger, pen,

pencil, etc.

figure 8.2: Screen navigation with finger or pen

8 T-Control

20 Betriebsanleitung_commotherm_5_15_SW_WW_Touch_Englisch_V1.2

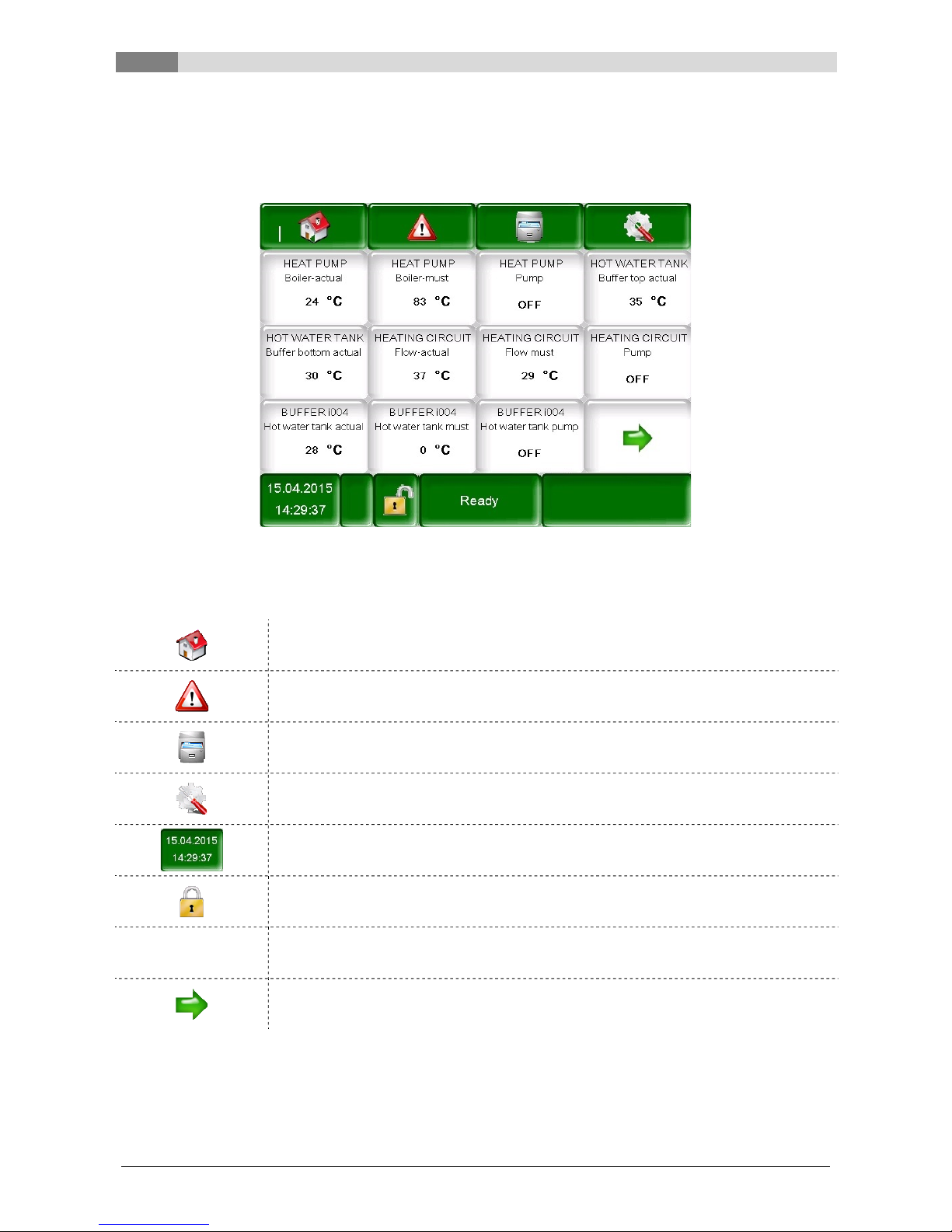

8.3 Main menu

After start up figure 8.3 will appear. In the centre of the screen important values according the boiler, buffer,

hot water tank, heating circuit and so on are shown. The shown values can be adapted individually (see

chapter 8.7.1).

figure 8.3: Main menu

If the following symbol is pressed

the main menu will be displayed.

(see figure 8.3)

fault messages (warnings & alarms) will be displayed.

(see figure 8.14)

the individual modules (heat pump, hot water tank, buffer, heating circuit, solar) will

be displayed.

(see figure 8.15)

the menu settings (network configuration, E-Mail, screen saver) will be displayed.

(see figure 8.19, visible only with code!)

the date & time can be set up.

(see figure 8.6, visible only with code!)

the code input screen will be shown.

(see figure 8.4)

Ready in general the field is used to display the operating conditions (see chapter 6).

more important values will be shown on the second page.

Table of contents

Other Herz Heat Pump manuals

Popular Heat Pump manuals by other brands

BWT

BWT SHP2.5 ON/OFF Installation and operating instructions

Emerson

Emerson Copeland EazyCool ZX Series manual

ClimateMaster

ClimateMaster TRM Series Installation, operation & maintenance instructions

Hitachi

Hitachi YUTAKI S COMBI Series instruction manual

Atlantic

Atlantic alfea extensa + Installation and operating manual

Heatmaster

Heatmaster R-22 Series owner's manual

Daikin

Daikin Altherma ERYQ005ABV3 installation manual

Igloo

Igloo MultiTherma mobile user manual

Carrier

Carrier CPCRKHTR003A00 installation instructions

Eubank

Eubank TH Series Installation & operation manual

Gree

Gree GWH09MA-A3DNA3A Installation, service & troubleshooting

Dimplex

Dimplex SI 5MER Installation and operating instructions