HEUTE Neptun SC1 User manual

Operating Manual EN

Neptun SC1

2

IMPORTANT – READ FIRST

Only put the machine into operation once you have read and

understood the operating manual. We shall be happy to answer

any questions you may have.

HEUTE® sole cleaning machine Neptun SC1 cleans and disinfects

dirty soles of working and safety shoes and boots. By means of an

integrated hand brush bootlegs and plastic trousers can be

cleaned effective.

HEUTE® sole cleaning machines are built and tested in accordance

with the latest safety regulations. The faultless functionality

and operational assurance of the device can only be guaranteed

if the generally applicable safety precautions and device-specic

safety information in this operating manual are observed during use.

The guarantee is not valid in relation to damages caused by a failure

to observe this operating manual. The manufacturer assumes no lia-

bility for personal injury or damage to property arising as a result of

this. In the event of problems please contact our service department

immediately.

Intended use

HEUTE® sole cleaning machine Neptun SC1 is used to clean closed

shoes and boots outside by means of an electrical driven brush and

hand brush as well.

Other use is not permitted! Only use the spare parts approved for

use with the machines by the manufactuer. Operation is only permis-

sible in closed rooms whilst observing the specications mentioned

in the "Safety instructions" section.

Use in potentially explosive environment is not permitted.

Foreseeable misuse

The sole cleaning machine is not suitable for use as follows:

- Cleaning and care of human body parts and objects that are not

parts of a shoe.

- Use as a tool for working on surface nishes

- Use with the addition of corrosive uids

Safety instructions

Read this operating manual carefully and follow our

advices for starting and for use.

The machine must not be changed or modied

because this can lead to risks such as a short circuit,

electric shock, re. Maintenance and repairs must

be carried out exclusively by authorised persons with

the use of original parts.

The use of non-original spare parts or the implemen-

tation of unauthorised modications to the machine

will result in cancellation of the declaration of

conformity issued by the manufacturer/distributor

and sign as well.

Use the machine only in closed rooms.

Operation is only permissible at ambient

temperatures between 0° C and 40° C.

The machine is not suitable for permanent operation.

It is essential to consider the time of duration (KB)

mentioned under section technical data - see page 14.

Do not continue to use the machine if the cleaning

brushes are worn. This can result in damaging the

shoes. The brushes must be replaced by a qualied

person.

The design complies with protection class IP55. The

voltage supply is 3-phase 400 V + grounding, power

0,18 kW. Observe the specic data provided on the

manufacturer's type plate!

During use, the motor can heat up to temperatures of

up to 90° C. Do not touch the motor without safety

gloves.

Use by children, in particular when unattended, must

be excluded.

Ensure that any contact between (household) animals

and the machine is excluded.

For safety reasons please pay attention that during

use of the rolling brush no laces and straps will touch

the ground.

These can be catched by the rolling brush, which

could cause injuries and damage of the shoes/boots.

Always disconnect the mains plug prior to cleaning,

service and repair work. Do not continue to use the

machine if the machine or the control cabinet with

cabling, the water pipe and water drain are damaged.

Ensure that the installation is at ground level.

Enter and use the machine only with closed shoes/

boots appropriate for wet cleaning.

Slip danger - pay attention to slippery ground in front

of and besides the machine caused by splashing

water.

Do not touch rotating brush.

Never drink the water out off the machine or the

detergent liquid out of the container (option).

Excessive application pressure during use of the

brush can lead to damage of shoes/boots!

Stop using the machine in case that brush stops

and potential foreign objects cause malfunction.

The operator is responsible for all personal injury and

damage to property that arises due to unintended

use, faulty machine connections and/or operating

errors.

When in commercial facilities observe the safety

ordinance applicable on site as well as the acci-

dent prevention regulations issued by the union of

professional associations for electrical systems and

equipment.

3

Welcome

Dear Customer, we would like to thank you for purchasing one of

our HEUTE industrial sole cleaning machines. You have purchased

a quality product, which – if used correctly – will provide many years

of satisfaction.

This operating manual is a constituent of the machine. It contains

important information on commissioning, operation and mainte-

nance. Please store this operating manual for future reference!

Scope of delivery

Sole cleaning machine with integrated hand brush, control cabinet,

operating manual.

Declaration of conformity

The manufacturer herewith conrms that the following machine

of type Neptun SC1 complies with the directives listed below:

- EC Machinery Directive (2006/42/EC)

- EC EMV Directive (2004/108/EC)

Technical specications

- DIN EN 60335-1 (DIN VDE 0700-1):2014-11

- DIN EN 60335-2-82 (DIN VDE 0700-82):2009-02

- DIN EN 55014-1 (DIN VDE 0875-14-1):2012-05

- DIN EN 55014-2 (DIN VDE 0875-14-2):2009-06

- DIN EN 61000-3-2 (DIN VDE 0838-2):2015-03

- DIN 61000-3-3 (DIN VDE 0838-3):2014-03

- DIN 61000-6-2 (DIN VDE 0839-6-2):2011-06

- DIN 61000-6-3 (DIN VDE 0839-6-3):2012-11

Authorized representative Steffen Moersch,

contact details (see address of manufacturer)

Christian Löwe, Managing director

Maschinenfabrik HEUTE GmbH & Co. KG

Environmental protection

Disposal of transport packaging

The packaging materials in which your machine is supplied are

environmentally friendly and recyclable. Please help by disposing of

the packaging in an environmentally friendly manner. The packaging

must not be given to children to play with. There is a risk of

suffocation due to the folding box and plastic lm.

Disposal of the product

Old devices that are no longer in use are not worthless waste.

Valuable raw materials can be recovered through environmentally

friendly disposal. Please inform yourself of the current disposal

methods by contacting the person responsible within your company

or your local authority

Table on contents

Important – read rst 2

Intended use 2

Foreseeable misuse 2

Safety instructions 2

Welcome 3

Scope of supply 3

Declaration of Conformity 3

Environmental protection 3

Overview 4

Installation and commissioning 6

General information 6

Transport and assembly 6

Water connection 6

Waste water connection 6

Electrical connection 6

Precaution while commissioning 6

Operation 7

How to clean 7

Adjustment of water quantity - access 7

Adjustment of water quantity 7

Use of sole cleaning function 7

Use of hand brush 8

Non-usage for longer time 8

Service and maintenance 8

Control 8

Cleaning 8

Maintenance 8

Recommended service intervals 9

Cleaning of surfaces 9

Cleaning and access to heavy waste-strainer 9

Cleaning of roller brush 9

Change of roller brush 9

Disassembling of brush axle 10

Access to gear motor 10

Dosing system - access 11

Dosing system 11

Dosing system - activation 12

Dosing system - rinsing 12

Trouble shooting 13

Technical data 14

Wiring diagrams 15

Parts drawing 17

EN

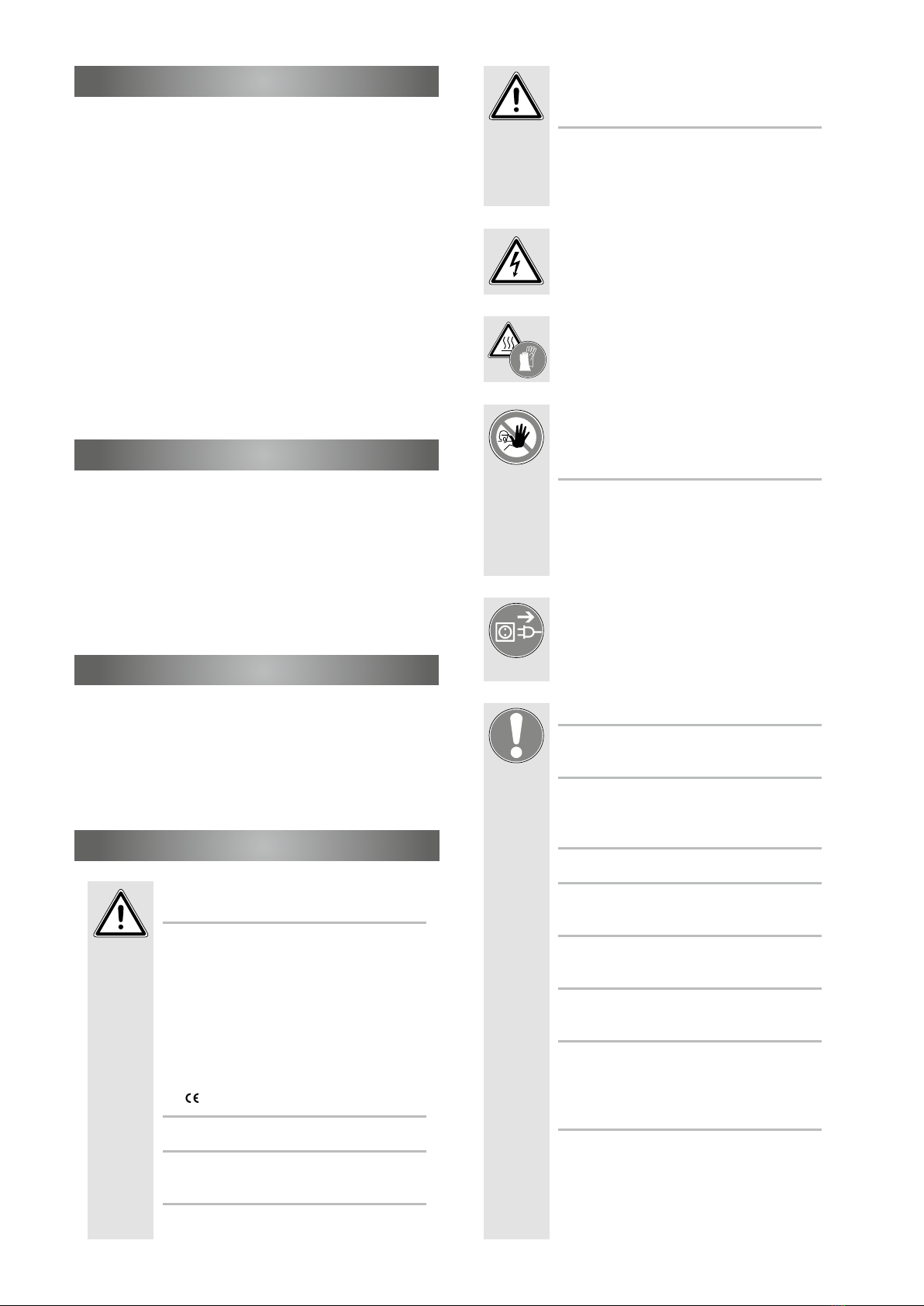

4

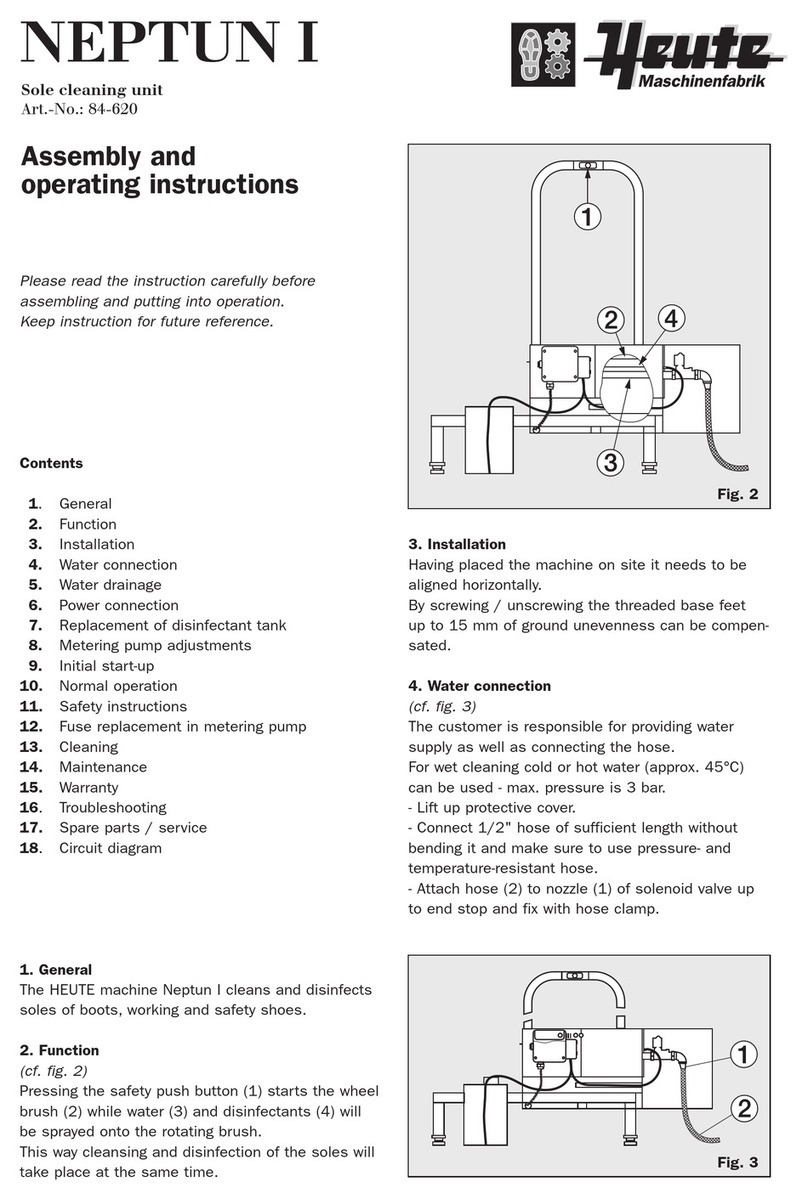

633 mm

300 ± 15 mm

Control cabinet

Dimension: 250 x300 x 150 mm

Power supply 400 V,

3-phase + grounding

50Hz P=0,18kW

Water outlet with siphon

ø 38 mm with heavy waste strainer

and opening for inspection

Hand brush with exible PVC hose

and ball valve 1/2"

hand brush with exible PVC hose

and ball valve 1/2"

Detergent canister

(not belonging to the machine)

Push button

Brush ø 150 mm, can be easily

removed without any tool for cleaning

PVC hose to protect

electrical cables

(length 2 m)

Access to dosing

system of detergent /

disinfectant

Adjustable feet ABS

Opening for cleaning of shoe/

boot tip and heels

Overview

5

EN

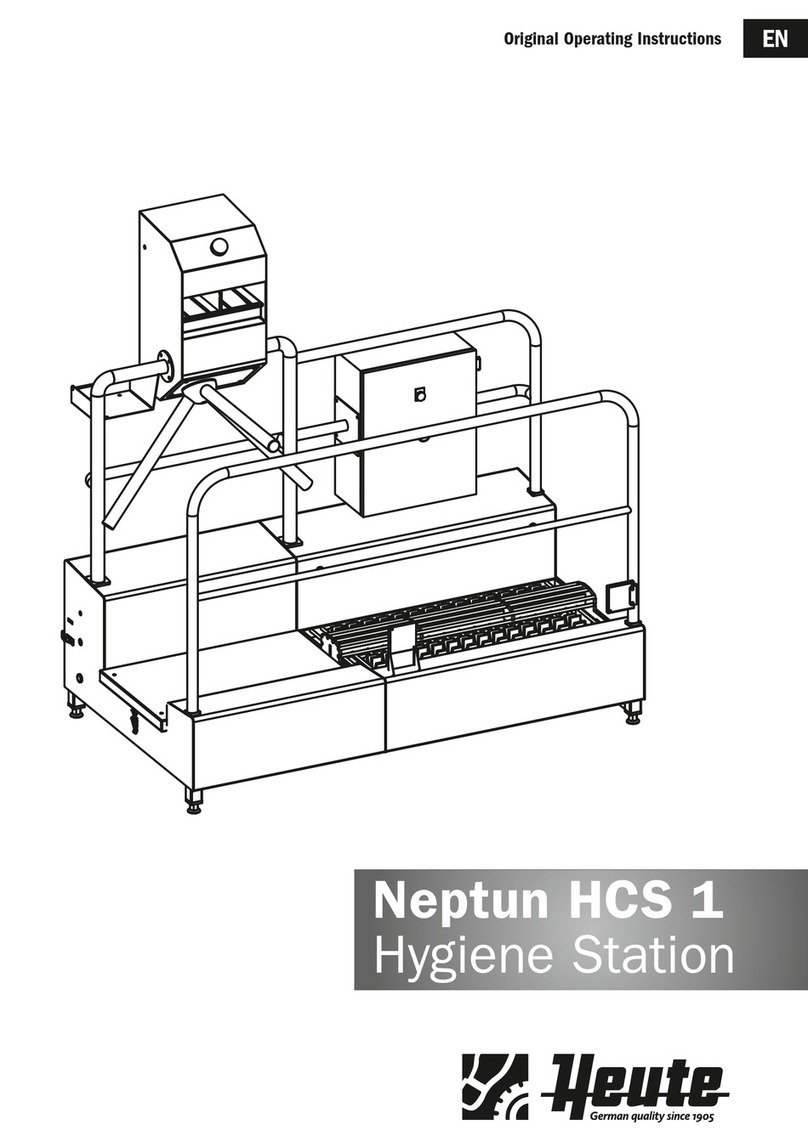

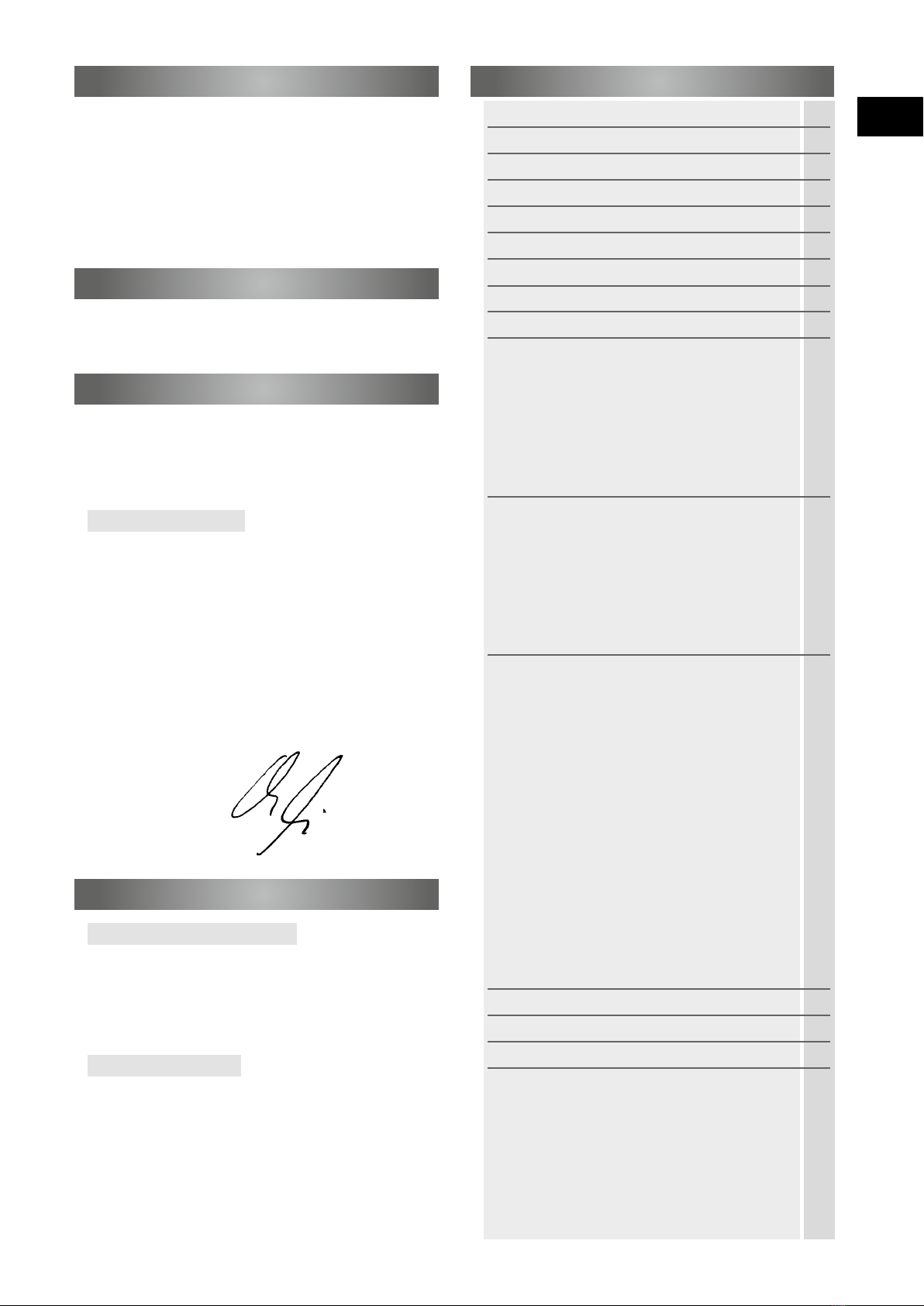

229 mm

755 mm

100 mm

92 ± 15 mm

1215 ± 15 mm

245 ± 15 mm

Water inlet 1/2" male,

dosing system

Inlet for transparent

silicone hose / dosing system

platform to store

detergent canister

grid, when closed lockable

by bracket clamping

nylon roller brush

ø 150 mm, length 330 mm

Inlet for PVC hose

(to protect electrical cables)

Water connection for hand brush

6

Installation and commissioning

General information

Please follow below mentioned advices to protect the stainless

steel housing of the sole cleaning machine during storing, before

installation, commissioning and use.

- Protect the machine against environmental inuences like rain,

sunshine and frost. Use the machine only in closed rooms.

- To avoid contact corrosion (e.g. steel spanes, tools used for steel

treatment) the surface of the machine must not be in touch with

other kind of steels

Transport and assembly

Weight of the machine is abt. 50 kg. Due to the heaviness transpor-

tation and unpacking should be done by 2 workers using suitable

means of transport.

Only use the machine in closed rooms. When choosing the place of

installation please consider the necessary space 755 x 640 mm,

availability of waterinlet and -outlet, as well as power supply (more

details see section Installation and commissioning). Control cabi-

net has to be xed at suitable place on the wall. The ground must be

level and slip protected. To ensure stability level out any uneven oor

areas by adjusting the feet under help of a spirit level.

Water connection

- Inlet dia. 1/2"

- Advised operating pressure: 3 bar

- Maximum operating pressure: 6 bar

- Operating temperature between 30 °C and 50 °C

(water temperatur more than 60 °C will damage the brush)

- Water ow rate: abt. 4 l/min with 3 bar

(adjustable valve at the machine)

The machine is not equipped with an upstreamed return valve

and water ltre. If necessary return valve and water ltre have to

be installed before the unit. The requested water quantity can be

indiviually adjusted – see sector Operation > adjustment of water

quantity.

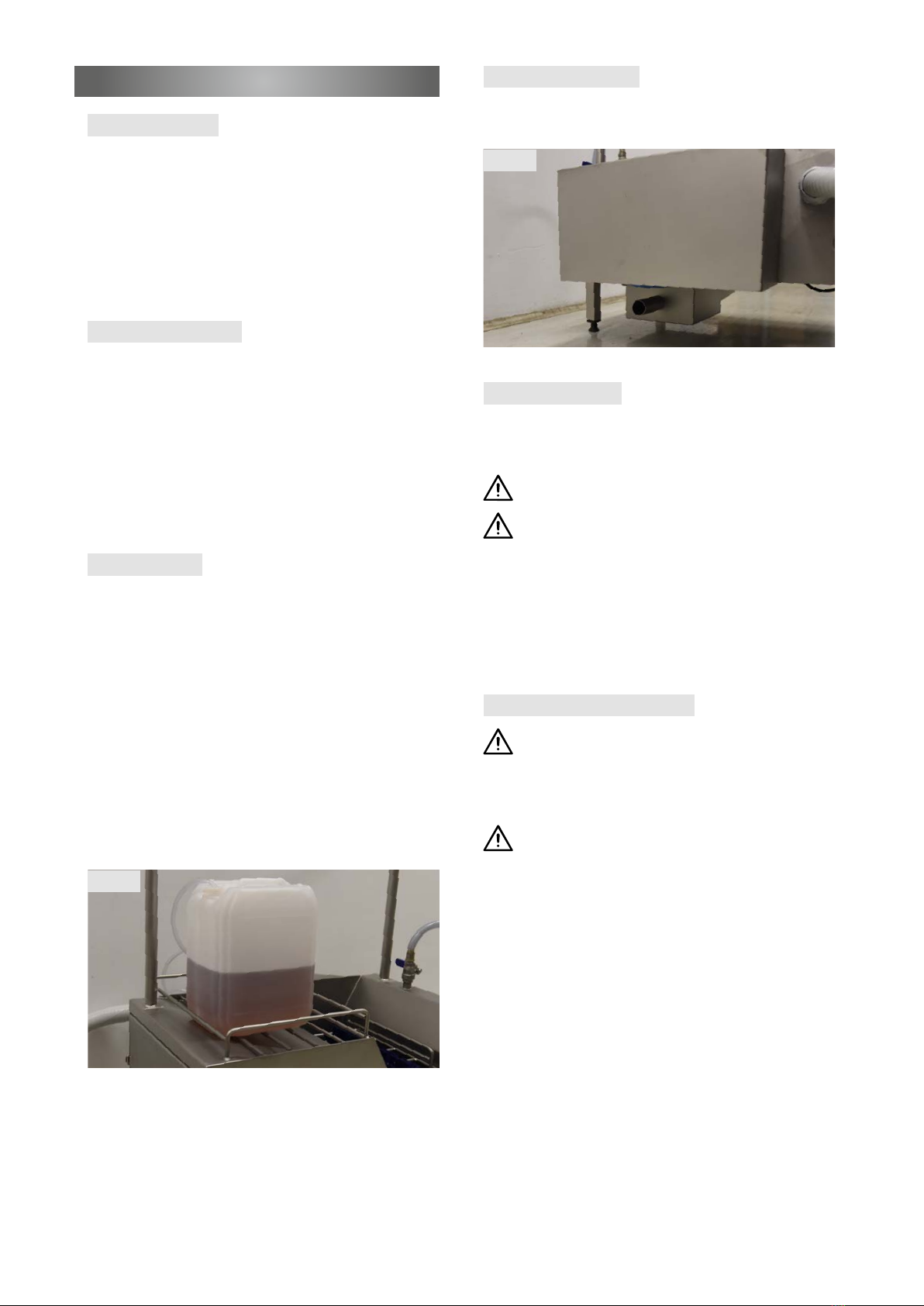

Put the detergent canister (not belonging to the machine) at suitable

place (Fig. 1).

Electrical connection

- 3-phase 400 V + grounding, power 0,18 kW

- Connection to the clamps in the control cabinet

(see sector "Technical data" > conguration of clamps

Take care that available voltage in your country is

corresponding to machine's voltage!

Machine's power supply must be electrically protected

against indirect contacts!

- High sensitive difference power protection device max. 30 mA.

- This protection must be provided by the house installation and

is not supplied with the machine.

- The control cabinet should be mounted approx. 1,2 m above oor

level.

- Turn-on and check rotating direction of the brush.

Precaution while commissioning

Never remove or block the contact switches on the housing,

which are active when the grid is closed/down. When open-

ing the grid during operation these will automatically turn off

the water and power supply and will stop rotation

of the brush.

The installation works for the water supply could cause

soiling which can block the pipes, nozzles, dosing device

and could damage the solenoid valve. It is important that

the machine is free of metal and plastic parts, before it is

connected to the electric circuit.

Fig. 2

Fig. 1

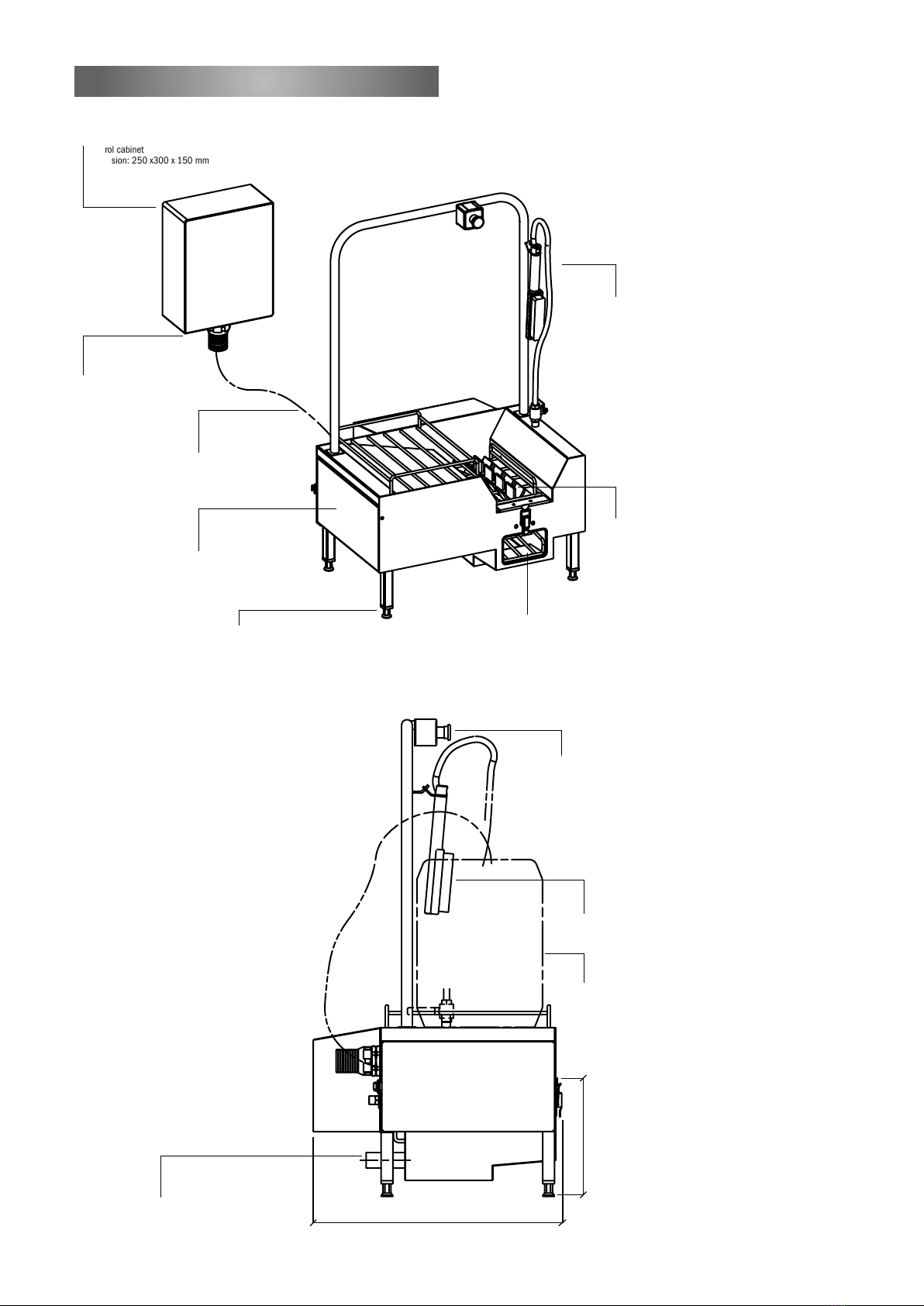

Waste water connection

- Outlet ø 38 mm (Fig .2)

- Provided with an access ap at the piping

7

Operation

How to clean

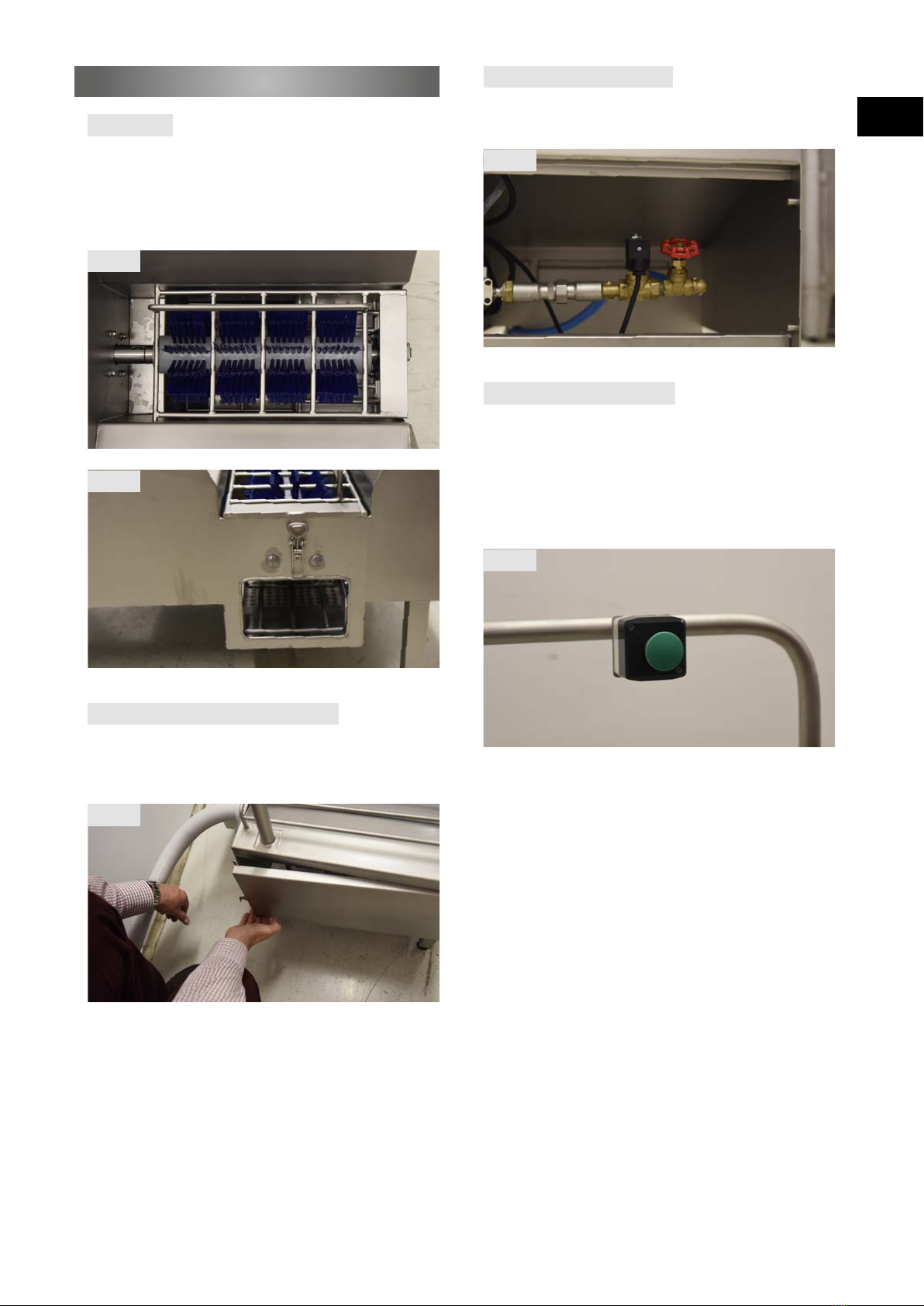

- Cleaning of shoes/boots with horizontal roller brush (Fig. 3)

- Cleaning of shoe tip by means of separate cleaning opening

underneath of horizontal roller brush – EasyClean function (Fig. 4)

- Supply of water and detergents, dosage by mixture in the dosing

system

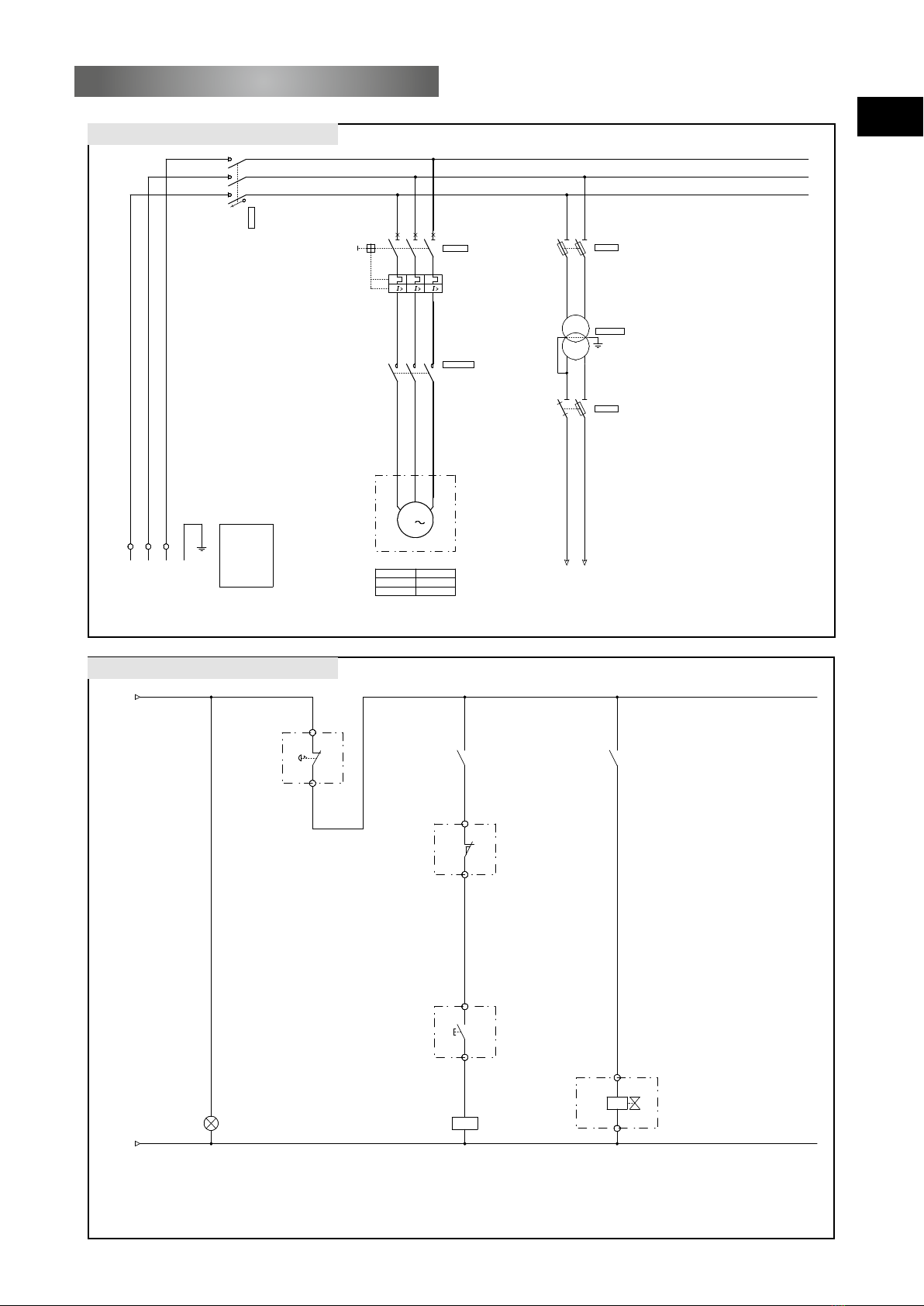

Use of sole cleaning function

Start the sole cleaning function by pressing the push button (Fig. 7)

causing:

- Rotation of roller brush will start.

- Solenoid valve of the dosing system opens and starts spraying

water and detergents on the rotating roller brush.

- Release push button to stop the sole cleaning process.

EN

Fig. 3

Fig. 4

Fig. 7

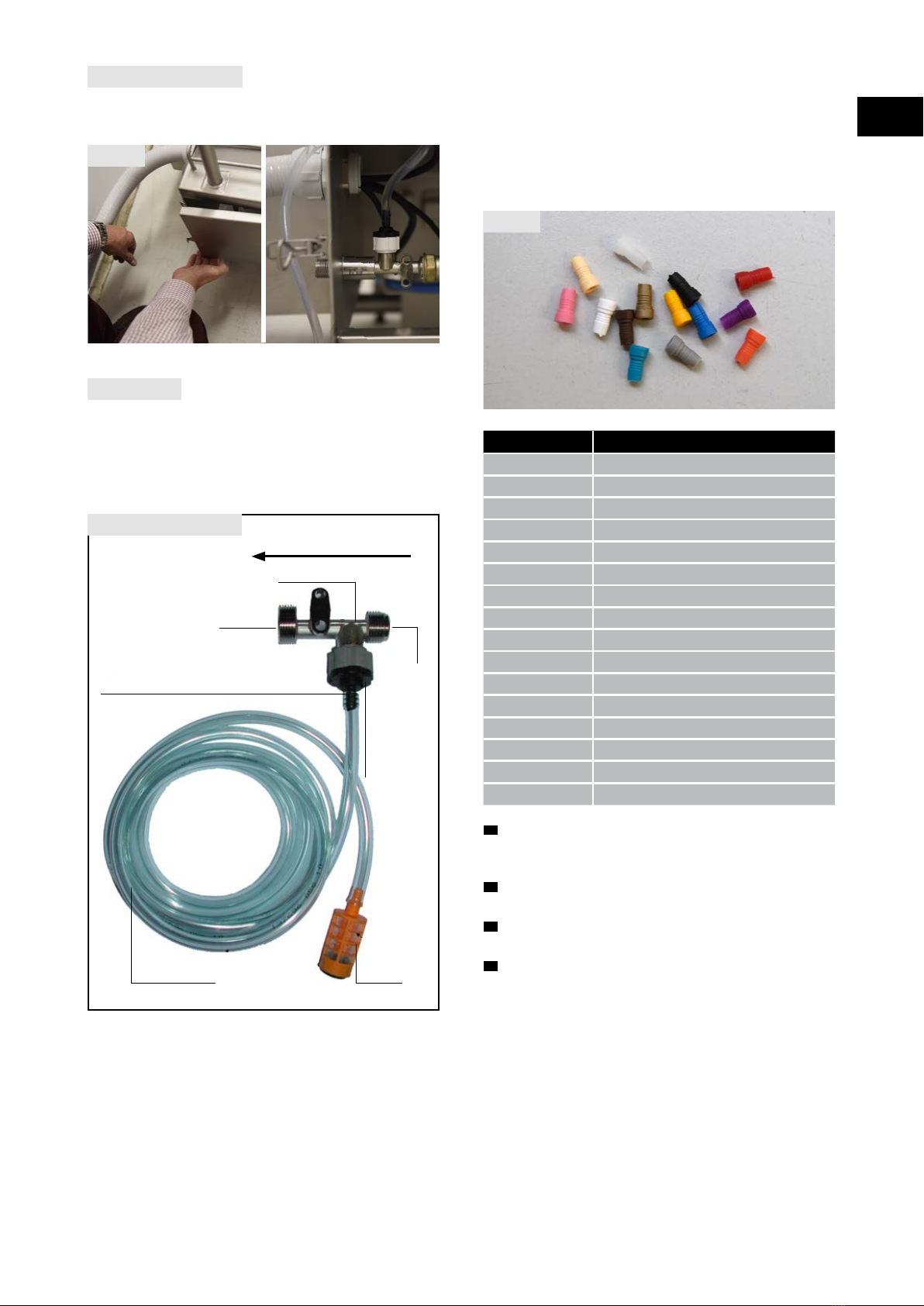

Adjustment of water quantity – access

The handwheel (valve) for adjusting the water quantity is located on

the side. Remove the cover by opening the bracket clamping – no

tools needed (Fig. 5)

Adjustment of water quantity

The requested water quantity is adjustable by the valve (Fig. 6).

The medium position allows a water ow of about 4 litres/minute.

Fig. 6

Fig. 5

8

Use of hand brush

Bootlegs and plastic pans can be easily and effectively cleaned with

the hand brush installed at right hand side (Fig. 8). Move the handle

of the valve to adjust water quantity (Fig. 9). Medium opening allows

a water ow of abt. 6 litres/minute.

Non usage for longer time

If you know that the machine will not be used for longer time (e.g.

annual holidays), we advise to rinse the dosing system through in

advance to avoid blockage of dosing system.

Fig. 8

Fig. 9

Service and maintenance

Service and maintenance should be carried out only by customer

service technicians. To secure optimal functioning of the sole clean-

ing machine, it should be contolled in regularly intervalls. HEUTE sole

cleaning machines are service reduced and reliable. However, there

are some components which will wear after long period of time and/

or reduce the cleaning result.

Unplug the power supply at the control cabinet prior to all

repairs.

Before any action stop water supply.

Drain the transparent silicone hose of the dosing system.

Rinse through the dosing system to remove residues.

In case of unintended opening of the grid the roller brush

stops automatically and the solenoid valve will close the

water supply.

Control

The machine should be controlled regularly. Take care if components

are damaged or worn and if the machine achieves the necessary

cleaning result. Foreign objects may not be nearby the roller brush.

Cleaning

The intervals of cleaning depends on local circumstances. The more

dirt occurs the shorter should be the cleaning intervals. Don't forget

to clean the dosing system regularly.

The mixture of used disinfectant and detergent should correspond

with local regulations of hygiene and cleanness.

Maintenance

Neptun SC1 sole cleaning machine is service reduced and reliable.

However, there are some components which will wear after long

period of time and/or reduce the cleaning result, e.g. roller brushes.

Overused roller brushes are visible by bent down and too softy

bristles.

Suitable spare parts are available from your local dealer or from

manufacturer.

Advices to change spare parts please read more in section "Service

and maintenance".

9

EN

Recommended service intervals

Below mentioned intervals are based on our experience. However,

any single case could vary from each other. That is the reason why

you have to adapt the intervals according to your own experience.

Change of roller brush

1. Lift up the grid to have access to the roller brush. It can be

removed without any special tool (Fig. 10).

2. Roller brush: Pull it at the front side. The gear of roller brush

happens by a pin located at the motor side (Fig. 11).

3. When insert the roller brush pay attention that the pin is in

the right position and the brush ts properly.

Fig. 11

Fig. 10

Service

Interval

Control once a week

Cleaning of surfaces once a week

Cleaning of

heavy waste strainer once a week

Cleaning of brushes once a month

Cleaning of dosing system once a month, strictly when

changing the medium

Change of roller brush every 5-7 years,

earlier when worn

Cleaning surfaces

The surface is made of stainless steel type 304.

Cleaning should be done with intensive water rinsing.

Avoid following:

- contact with carbon steel

- use of steel sponge, grinding powder

- use of chlorine products and bleaching agent

Cleaning and access to heavy waste strainer

Remove roller brush rst - see section "Service and maintenance"

> Change of roller brush.

Lift up the heavy waste strainer to remove (Fig. 12). Insertion in

reversed order.

Cleaning of roller brush

Cleaning of roller brush should be done by intensive water rinsing

or by soaking in suitable detergent. Never use chlorine products and

bleaching agent. Use of high pressure cleaner is strictly forbidden.

Overused roller brushes are visible by bent down and too softy

bristles.

Fig. 12

10

Disassembling of brush axle

1. Remove roller brush (see section "Service and maintenance" >

Change of roller brush)

2. Remove inbus screw placed at the long side in front of the brush

with suitable tool (Fig. 13)

3. Remove snap ring located at front side of the brush with suitable

tool and pull off the distance washer (Fig. 14)

4. Now the brush can be pulled off the axle (Fig. 15)

5. When assembling put the pin in the center position of the brush,

x the inbus srew, insert distance washer (ø 30 mm) and snap

ring.

Fig. 15

Fig. 16

Fig. 14

Access to the gear motor

The cover at the rear is not xed.

Just remove the cover vertical up. No tools are required (Fig. 16).

Fig. 13

11

Dosing system – access

Remove the cover by opening the bracket clamping – no tools

required (Fig. 17).

The dosage of detergent/disinfectant is done by nozzles in different

sizes – supplied with the machine (Fig. 18). To achieve the desired

concentration choose the corresponding nozzle (see below scheme).

The indications should be treated as guideline to nd the requested

concentration. Achieving optimal dosing results, tests should be

made.

The transparent nozzle is a stopper.

1. Have a look at the structure of dosing system – see section

"Service and maintenance" > Dosage > Structure of dosing

system.

2. Loose the transparent silicone hose by turning from the return

valve.

3. Plug the chosen nozzle with the narrow side on to the return

valve.

4. Plug transparent silicone hose on to the return valve.

Take care that the hose is wholly plugged and is not bended.

Dosing system

The dosing system prepares the mixture of water and detergent/

disinfectant in a certain proportion. This proportion will be deter-

mined by the installed nozzle.

To achieve optimal function use products having the same viscosity

than water. Don't use crystallised detergent/disinfectant.

Colour of nozzle

Admixture of detergent/disinfectant

without 22,00 %

grey 21,20 %

black 21,00 %

beige 17,00 %

red 12,20 %

white 9,00 %

blue 7,60 %

light brown 5,20 %

green 4,10 %

orange 3,10 %

dark brown 2,50 %

yellow 1,90 %

turquoise 1,10 %

purple 0,94 %

pink 0,35 %

transparent 0,00 % (used as stopper)

Fig. 18

Structure of dosing system

ow direction of water

G3/4”

connection

outlet

nozzle for dosage of detergent/disinfectant

chosen according following scheme

Transparent

silicone hose, 2 m Filter

G1/2”

connection

inlet

dosing system unit

Return valve

integrated

to the

dosing system

Fig. 17

EN

12

Dosing system – activation

Activation of detergent/disinfectant happens by water rinse of

the system

1. During initial operation put the lter device located at the

end of the transparent silicone hose into the detergent canister

(Fig. 19) – not belonging to the machine.

Detergent/disinfectant should not contain chlorine bleaching

ingredients because it could damage the surface, brushes and

other components.

2. Turn on the machine by pressing the push button until the dosing

medium has reached the level of the mixing tap (Fig. 20). To

achieve optimal function and mixture use products having the

same viscosity than water (water = viscosity of 1). Media having

higher viscosity (semiuid) could cause problems.

Dosing system – rinsing

We recommend to rinse the system for the detergent /disinfectant

regularly. However, basically when changing the detergent /disinfec-

tant canister or during maintenance work cleaning should be done.

Put the transparent silicone hose with lter device into a canister

with clear water and start the machine for 20-30 seconds.

Sediments and foreign objects could cause damage to the machine.

If the machine has not been used for a longer time we advise to

check that transparent silicone hose and lter device are free of

sediments. Just in case rinse the dosing system with clear water.

Fig. 19

Fig. 20

13

EN

Machine does not work

Canister is empty

Liquid is semiuid

No water ows after

starting the machine

Power supply interrupted or malfunction of components.

Contact qualied personnel

Take a full one

Try to absorb clear

water. If the machine

runs properly, dilute

the liquid before the

canister and/or take a

different nozzle

Is there a valve installed

before in machine?

Check that the valve is

not completely open

(*) Remove the trans-

parent silicone hose

from the return valve of

the dosing system. Put

your nger on the valve

to check if you feel a

suction effect

Yes - open this valve

No - the solenoid valve

does not open

To check it, close the

valve completely and

nd out if the liquid will

be absorbed

Suction effect visible

Suction effect not visible

Qualied personnel

should replace it

If the detergent is not

absorbed, turn to (*)

Ensure that the hose

or lter device is not

blocked by soilings

Ensure that the hose is

not damaged

Ensure that the nozzle is

not blocked

Remove the return valve. Check the 2 O-rings, the cone

and the spring (if necessary replace the dosing system

ap completely)

Clean thoroughly or re-

place the components.

Don't forget to install

the lter device on the

hose

If it is damaged replace

it. Don't forget to install

the lter device on the

hose

If the nozzle is blocked,

remove the blockage or

replace the nozzle

Trouble-shooting only by qualied personnel

Remove the nozzle and

clean it. Sediments could

block the system

14

Technical data:

Dimensions: 76 cm x 63,5 cm x 121,5 cm

(width x depth x height)

Weight: 50 kg

Connection load: 3-phase 400 V + grounding

Power: 0,18 kW

Protection category: IP55

Short term operation time (KB): 8 min

Noise emission: less than 80 dB(A)

Trouble-shooting only by qualied personnel

Machine operates without water

Water supply is closed or interrupted

Check water supply

Machine does not drain off waste water

Water outlet is blocked

Check water outlet - if necessary remove blockage

Motor stops or runs unproperly

Foreign objects inside

Unplug immediately the machine from power

supply. Search and remove foreign objects

(turn roller brush by hand)

Machine makes much noise during operation

Foreign objects inside

Unplug immediately the machine from power

supply. Search and remove foreign objects

(turn roller brush by hand)

or

Check correct installation of roller brush

15

EN

Wiring diagrams Neptun SC1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Motor for brush

Power connection

24V AC

push button

Motor

Power

Current rating

0.18KW

.....A

L3

1

L2

0

L3

119

7

L1

10

M

3

L1

-XP

L2

-XP

L3

-XP

-CF

NSYPLM3025

SCHNEIDER ELECTRIC

1

2

3

4

5

6

-IG

VCDN20

20A

-M1

U V W

1

2

3

4

5

6

-Q1

NO/03-9

- -

GV2ME04

8A

0,4-0,63A

-KM1

1

2

3

4

5

6

LC1K0610B7

03-9

0V AC

03-1

2gG

N 1

2

-F2

56015005

10x38

32A

P1 P2

S1 S2

-T1

ABL6TS04B

40VA

230+400V

24V

0.5aM

1

2

3

4

-F1

56010020

10x38

32A

24V AC

03-1

Wiring diagram I

Wiring diagram II

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Control (brush)

Solenoid valve

(water supply)

345

2

7

1

7

6

8

0V AC

02-13

24V AC

02-13

X1

X2

-H1

24V

-XB

1

-XB

2

21

22

-AU

Emergency

push button

-Q1

13

14

02-8

A1

A2

-KM1

24V

j

j

j

a

02-81 2

02-83 4

02-85 6

03-1213 14

-XB

3

-XB

4

-FDC

1

2

Safety switch

(grid)

-XB

5

-XB

6

13

14

Push button

(brush)

-BP

24V

1

2

-EV

-XB

8

-XB

7

13

14

-KM1

03-9

Power control lamp

16

123456789 10 11 12 13 14 15 16 17 18 19 20

-XP

Conductor 4

L3

Conductor 3

02-2

IG:5 L2

Conductor 2

02-2

IG:3 L1

Conductor 1

02-1

IG:1

-ALIM

Power supply

Conguration clamping strip I

123456789 10 11 12 13 14 15 16 17 18 19 20

-XB

Conductor 3

3

3

3Conductor 1

03-9

FDC:1

4

545

4Conductor 2

03-9

Conductor 3

2

2

2Conductor 2

03-5

1

1

1Conductor 1

03-5

AU:21

6

6

6Conductor 2

03-9

KM1:A1

Conductor 3

8

8

8Conductor 2

03-12

EV:1

5

54

54 Conductor 1

03-9

BP:13

Conductor 3

7

7

7Conductor 1

03-12

-EV ARM

Solenoid valve (grid)

-BP ARM

Push button (brush)

-FDC ARM

Safety switch (grid)

-AU ARM

Emergency push button

Conguration clamping strip II

17

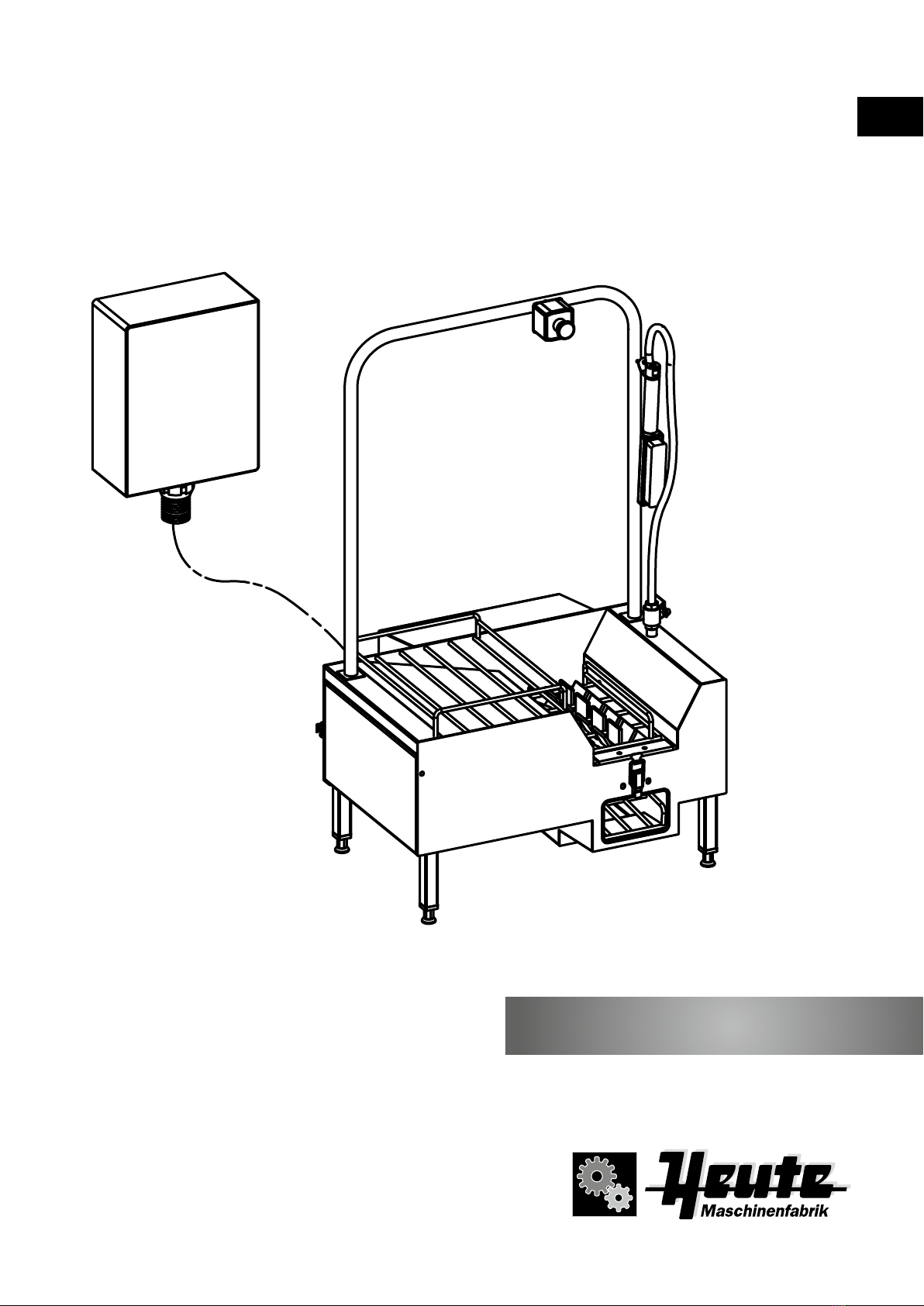

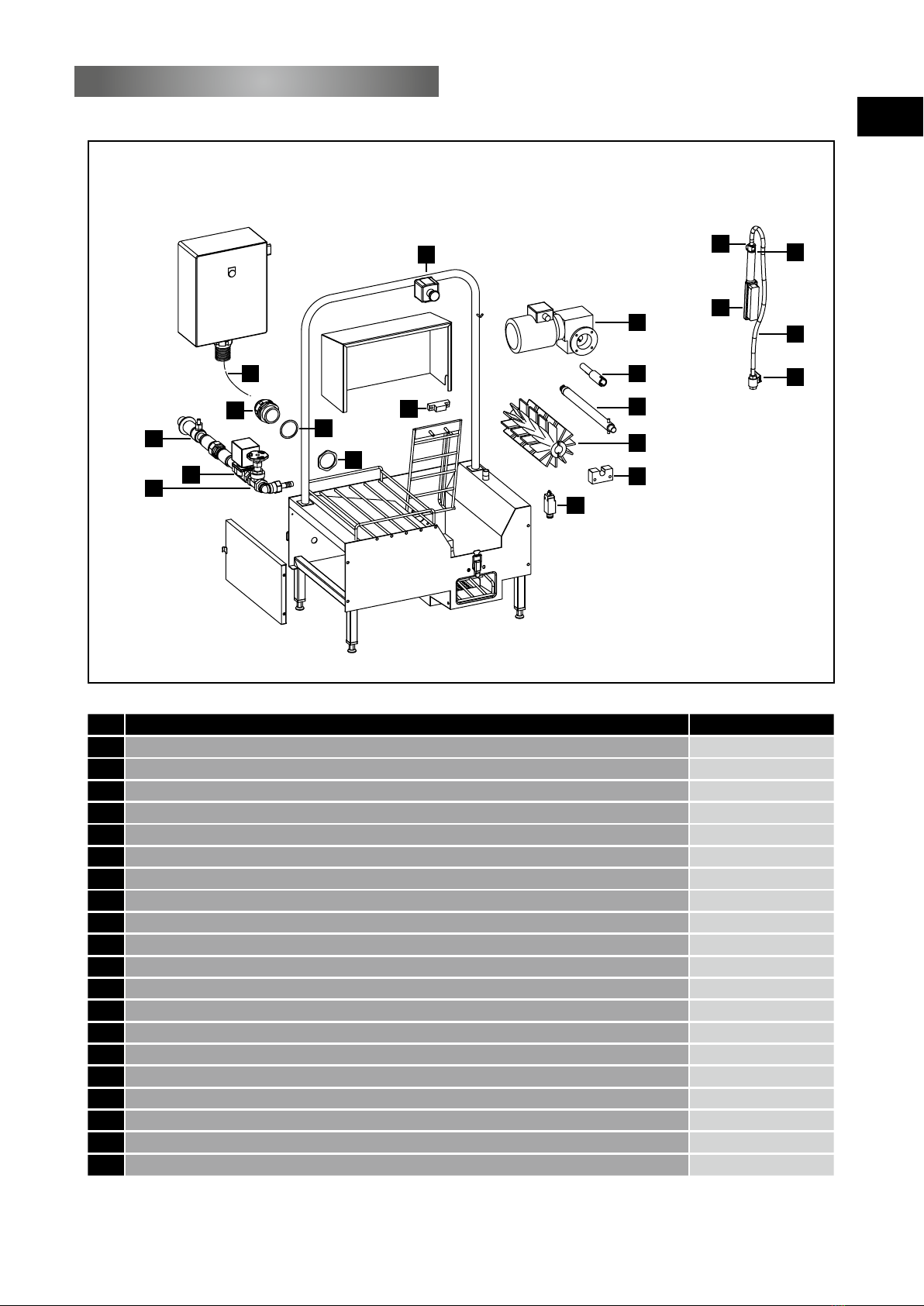

Part drawings Neptun SC1

11

7

2

3

119

6

10

12

13

14

9

8

4

5

16 17

15

18

Item Article Article No.

1 Coupling stainless steel + spring, 6 x 6 x 30 mm 06800101

2 Axle for brush, ø 150 x 330 mm, stainless steel 304 06800102

3 Brush blue, ø 150 mm, length 330 mm PBT 06800103

4 Stop Nylatron GSE 06800104

5 Position switch XCKP102 06800105

6 Gear motor MB2101 M50C LS63 p=0,18kW 06800106

7 Bearing Nylatron GSE 06800107

8 Nut Perfect CEPFV36 06800108

9 Gasket for connection piece PG36 06800109

10 Connection piece, grey, PG36 06800110

11 PVC hose GP, 40 x 46 - 2 lg = length 2 m 06800111

12 Dosing device chromed brass, ø 2,6 mm 06800112

13 Solenoid valve 24V-50Hz-NF-1/2", ø 11,5 mm 06800113

14 Valve to adjust water quantity, brass, 1/2" 06800114

15 Hand brush 06800115

16 Coupling for hand brush, stainless steel 304 06800116

17 Fixing piece for hand brush, stainless steel 304 06800117

18 Flexible PVC hose, length 1500 mm 06800118

19 Ball valve, stainless steel 1/2" 06800119

20 Push button 06800120

20

EN

Address: Weinsbergtalstraße 2-4 · 42657 Solingen · Germany

Postal address: P.O. Box 100507 · 42605 Solingen · Germany

Phone: +49(0)212-380 310 · Fax: +49(0)212-380 31-39

E-mail: info@heute-gmbh.de · Internet: www.heute-gmbh.de

EN

01-2016

This operating manual contains descriptions of our products, but it does not give any warranties for

specific properties or operational results. Authoritative is, unless otherwise specified, only the technical

base, at the time of delivery of the goods in combination with this manual, by Maschinenfabrik HEUTE

GmbH & Co. KG. The products and their design are subject to constant changes / improvements. We

reserve the right to apply technical changes, anytime.

This manual is protected by copyrights. All rights reserved. This manual shall not be copied, translated,

or otherwise modified, unless explicitly accepted, in writing, by the manufacturer (Maschinenfabrik

HEUTE GmbH & Co. KG).

Askims Skytteväg 4A · SE-436 51 Hovås · Sweden

Tel: +46(0)31 28 50 90 · Fax: +46(0)31 28 50 90

Table of contents

Other HEUTE Washer manuals