HEUTE NEPTUN I User manual

NEPTUN I

Sole cleaning unit

Art.-No.: 84-620

Please read the instruction carefully before

assembling and putting into operation.

Keep instruction for future reference.

Contents

1. General

2. Function

3. Installation

4. Water connection

5. Water drainage

6. Power connection

7. Replacement of disinfectant tank

8. Metering pump adjustments

9. Initial start-up

10. Normal operation

11. Safety instructions

12. Fuse replacement in metering pump

13. Cleaning

14. Maintenance

15. Warranty

16. Troubleshooting

17. Spare parts / service

18. Circuit diagram

1. General

The HEUTE machine Neptun I cleans and disinfects

soles of boots, working and safety shoes.

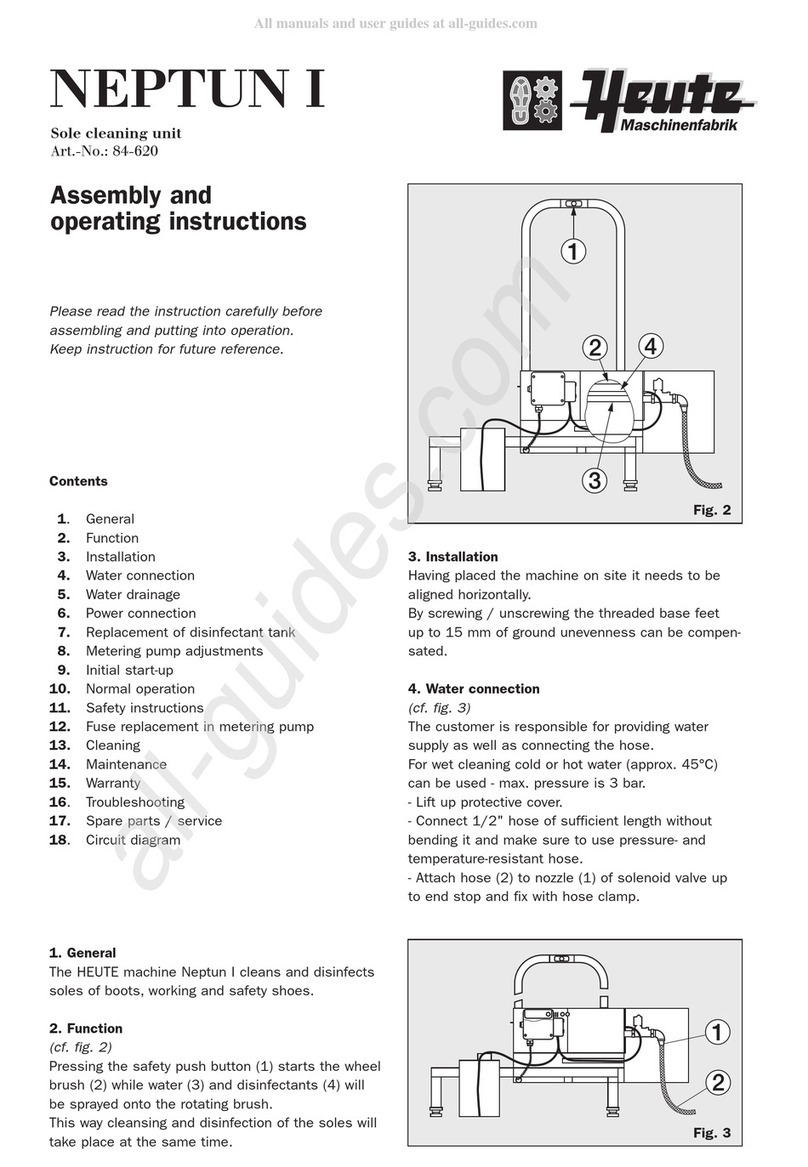

2. Function

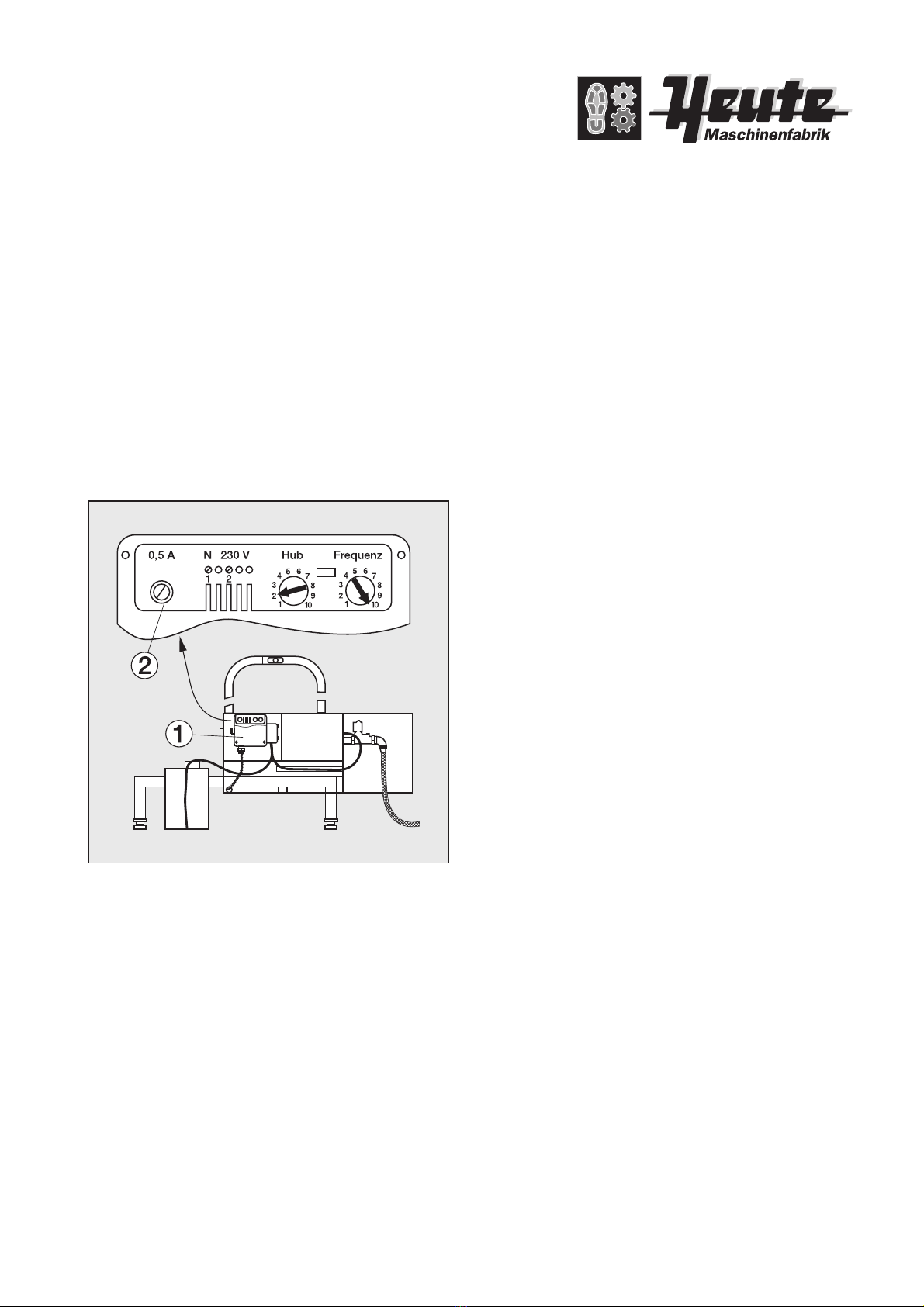

(cf. fig. 2)

Pressing the safety push button (1) starts the wheel

brush (2) while water (3) and disinfectants (4) will

be sprayed onto the rotating brush.

This way cleansing and disinfection of the soles will

take place at the same time.

3. Installation

Having placed the machine on site it needs to be

aligned horizontally.

By screwing / unscrewing the threaded base feet

up to 15 mm of ground unevenness can be compen-

sated.

4. Water connection

(cf. fig. 3)

The customer is responsible for providing water

supply as well as connecting the hose.

For wet cleaning cold or hot water (approx. 45°C)

can be used - max. pressure is 3 bar.

- Lift up protective cover.

- Connect 1/2" hose of sufficient length without

bending it and make sure to use pressure- and

temperature-resistant hose.

- Attach hose (2) to nozzle (1) of solenoid valve up

to end stop and fix with hose clamp.

Assembly and

operating instructions

Fig. 2

Fig. 3

NEPTUN I

Sole cleaning unit

Art.-No.: 84-620

5. Water drainage

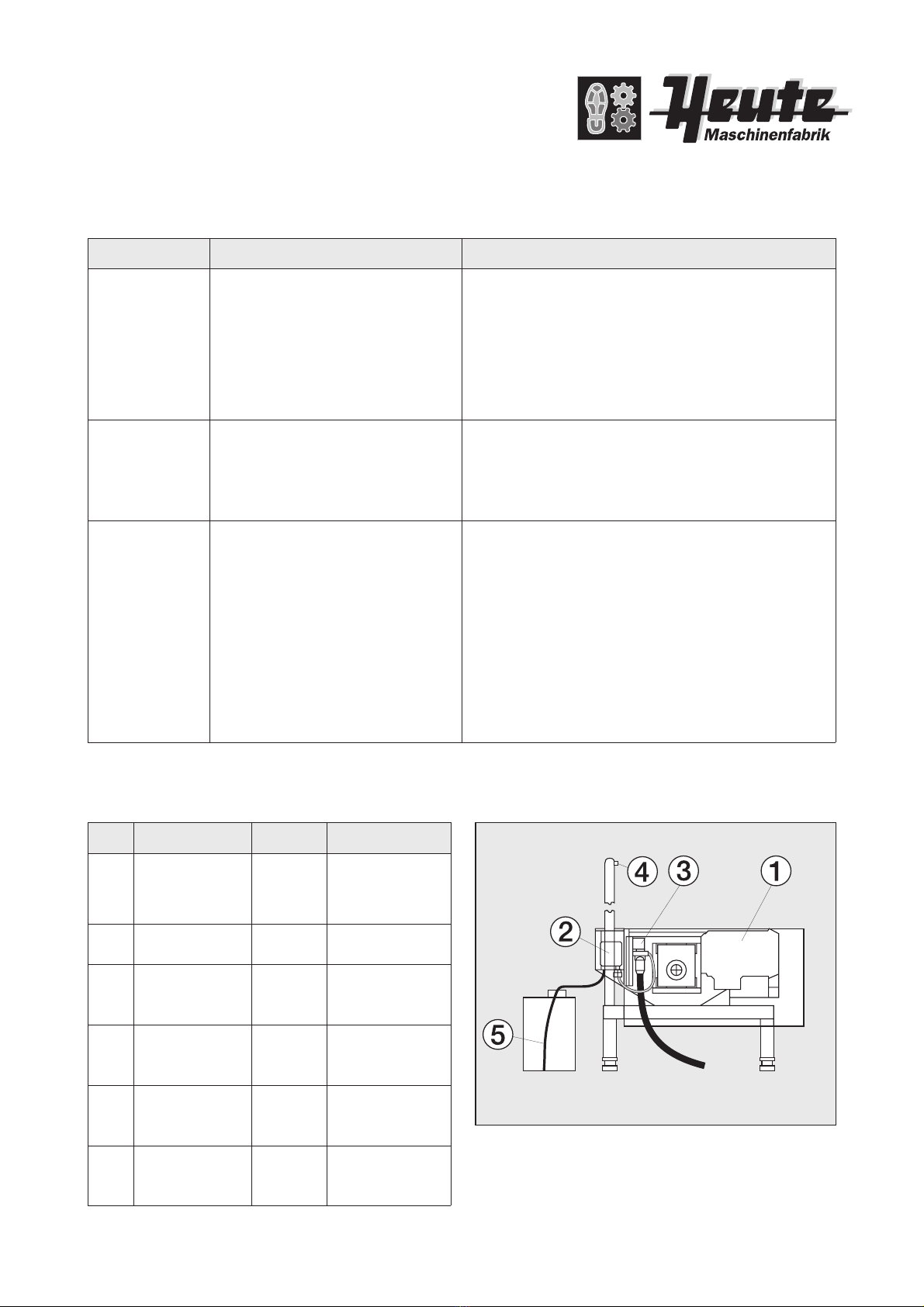

(cf. fig. 4)

Dirty water is drained off through the pipe socket (1)

to the floor.

Pipe socket diameter outside 70 mm, inside 66

mm, length 58 mm.

6. Power connection

The machine comes with a cord of approx. 4m

length, fitted with a 5-pole CEE connector (16 A).

The customer must provide an appropriate CEE

socket installed (400 VAC/16 A).

Motor / wheel brush rotates clockwise.

7. Replacement of disinfectant tank

(cf. fig. 5)

- Place tank (1) with disinfectant next to the machine.

- Insert hose (2) into the tank down to base level;

avoid kinks and bends.

- Press and continue to hold down the safety push

button (3) and high-speed push button (4) on

metering pump (5) until disinfectant flows out

of the spray tube (6) without forming bubbles;

afterwards release (3) and (4).

8. Metering pump adjustments

- Opening of the metering pump may only be carried

out by qualified electrician.

- Caution! Components carry live voltage

- Volumetric displacement 0,01 - 0,5 l/min

- Follow disinfectant manufacturer's instructions

for dosage and take samples

8.1 Increase dosage

(cf. fig. 6)

- Loosen cover screws and take off cover (1) of

metering pump

-

Turn “Hub” adjuster (2) clockwise with a screwdriver

- Remove pressure hose (3)

- Press safety push button (4) and place measuring

cup (5) underneath the pressure nozzle (6)

- Adjust “Hub” (2) according to measurement results

- Re-assemble in reverse order

8.2 Decrease dosage

(cf. fig. 7)

- Loosen cover screws and take off cover (1) of

metering pump

- Turn the “Hub” adjuster (2) counter-clockwise with

a screwdriver

- Remove pressure hose (3)

- Press safety push button (4) and place measuring

cup (5) underneath the pressure nozzle (6)

- Adjust “Hub” (2) according to measurement results

- In case the dosage is still too high when using

setting "Hub=1" adjust "Frequenz" (7) counter-

clockwise

- Re-assemble in reverse order

Fig. 4

Fig. 5

NEPTUN I

Sole cleaning unit

Art.-No.: 84-620

9. Initial start-up

After power and liquid connections have been made

follow these steps:

- Hook the protective cover into carriers

- Insert gratings into carriers

- Turn on water tap

- Plug in main power supply

- Carry out test run

- Place machine on platform

- Firmly grasp retaining bracket

- Step on grating in the cleaning area with one foot

at a time

- Press safety push button and release button after

a short runtime

10. Normal Operation

- Enter platform

- Firmly grasp retaining bracket

- Step on grating in the cleaning area with one foot

at a time

- Press safety push button and release the button

after cleaning process

11. Safety Instructions

- Operation not permitted without protective cover

in proper position

- Do not start a cleaning process without grating in

its proper place

- Do NOT touch rotating brushes either with bare

hands or wearing gloves

- The machine must only be used for cleaning the

soles of boots, working and safety shoes

- Disconnect mains plug prior to carrying out any

maintenance or repair work

Fig. 6 Fig. 7

NEPTUN I

Sole cleaning unit

Art.-No.: 84-620

12. Fuse replacement in metering pump

(cf. fig. 8)

- Opening the metering pump may only be carried

out by a qualified electrician

- Caution! Components carry live voltage

- Loosen cover screws and take off cover (1) of

metering pump

- Loosen protective cap (2) with slide catch by

pressing down and turning slightly counter-clock-

wise

- Remove defective fuse and insert new fuse of

identical rating (M 0,5A /250 V/C)

- Re-assemble in reverse order

13. Cleaning

- The machine must only be cleaned when turned

off and not running

- Cleaning intervals depend on individual usage and

requirements

- In case the machine is heavily soiled it should be

cleaned inside and outside

14. Maintenance

- The machine must only be maintained when turned

off and not running

- Check hoses and make sure they fit tightly and

are leak-proof otherwiser replace them

- Check metering pump on casing for possible

leakage

- Make sure the safety push button runs smoothly

- Replace brush if worn with use

15. Warranty

We guarantee our products are free of manufactur-

ing and material faults. Warranty extends to

6 months on electrical components and to one year

on metal components commencing on the day

of dispatch from the supplier’s premises or depot.

Changes or modifications made by customers to our

products without our prior consent thereto given in

writing will void the guarantee.

Not following the operating instructions will also

void the warranty.

Fig. 8

NEPTUN I

Sole cleaning unit

Art.-No.: 84-620

Quantity

1

1

1

1

3 m

1

Pos.

1

2

3

4

5

6

Art. Nr.

MG.03.201

SB.10.022

EM.01.005

ES.09.424

KG.01.021

80.05.001.053

Description

Three-phase

a.c. motor

Metering pump

Solenoid valve,

G1/2“-24VAC

Safety push

button

Hose,

Di 6 x 1,5 mm

Disk brush,

D 180 mm

Error

- Brush does

not rotate

- No Water

- No

disinfectant

Cause

- Mains plug not plugged in

- Safety push button defective

- Transformer fuse has triggered

- Motor too hot, thermostat has

triggered

- Gate valve closed

- Hose removed from nozzle

- Hose defective

- Solenoid valve fails to open

- Storage tank empty

- Suction hose not inserted down

to base

- Metering pump fails to run

- Metering pump runs but no

delivery

Solution

- Plug in main power supply

- Have button checked by qualified electrician;

replace if necessary

- Have it checked by qualified electrician

- Have it checked by qualified electrician

- Open gate valve (max. pressure 3 bar)

- Make sure hose is fixed tightly to nozzle

- Replace hose

- Replace solenoid valve /notify HEUTE-Service

- Fill up storage tank or replace (refer to

7. Replacement of tank with disinfectant)

- Insert suction hose down to base (refer to

7. Replacement of tank with disinfectant)

- Refer to 12. Fuse replacement in metering pump

- Pump hose defective, replace / notify HEUTE-

Service

16. Troubleshooting

17. Spare parts

(cf. fig. 9)

Fig. 9

Product specifications and design

subject to change without notice.

NEPTUN I

Sole cleaning unit

Art.-No.: 84-620

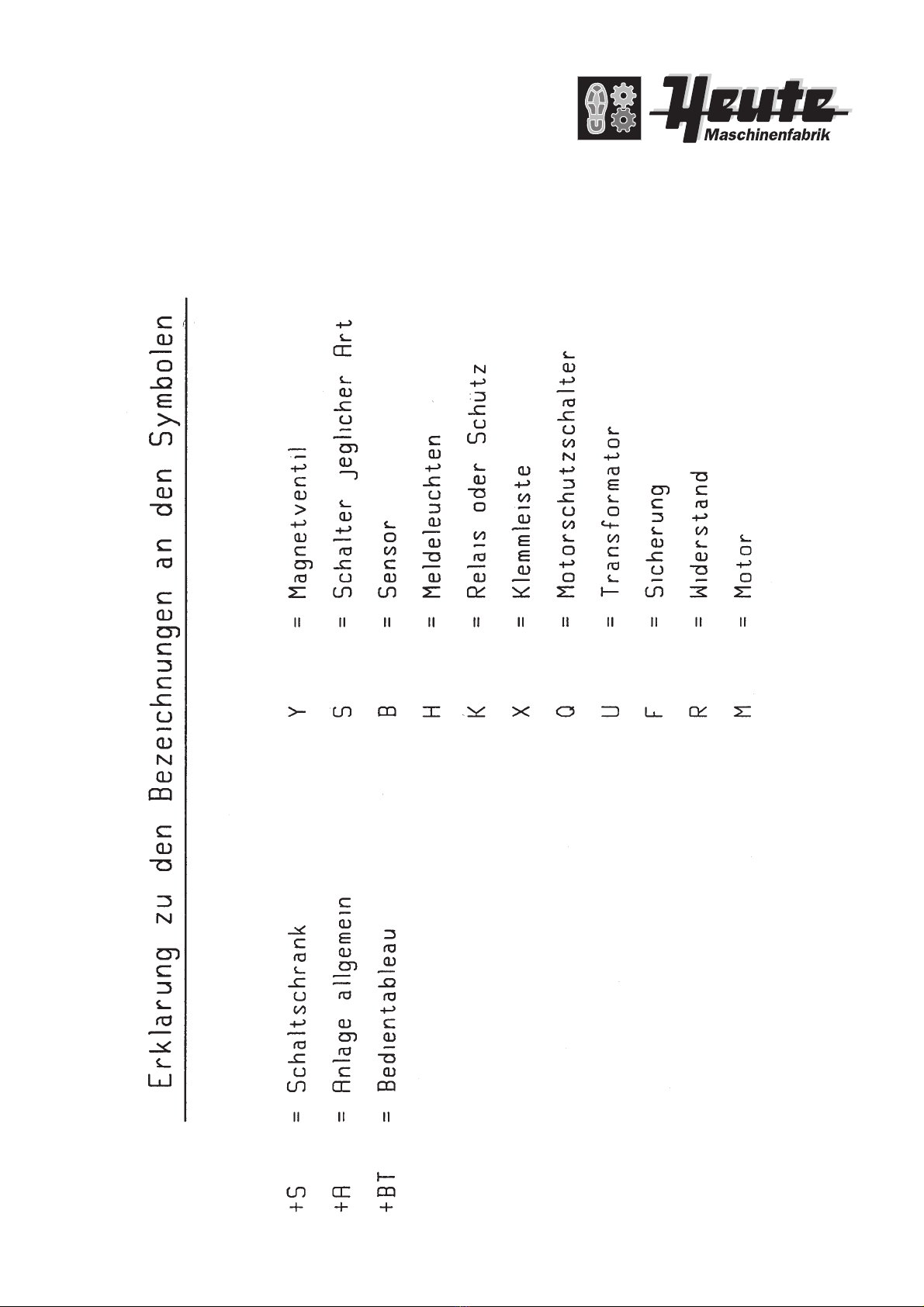

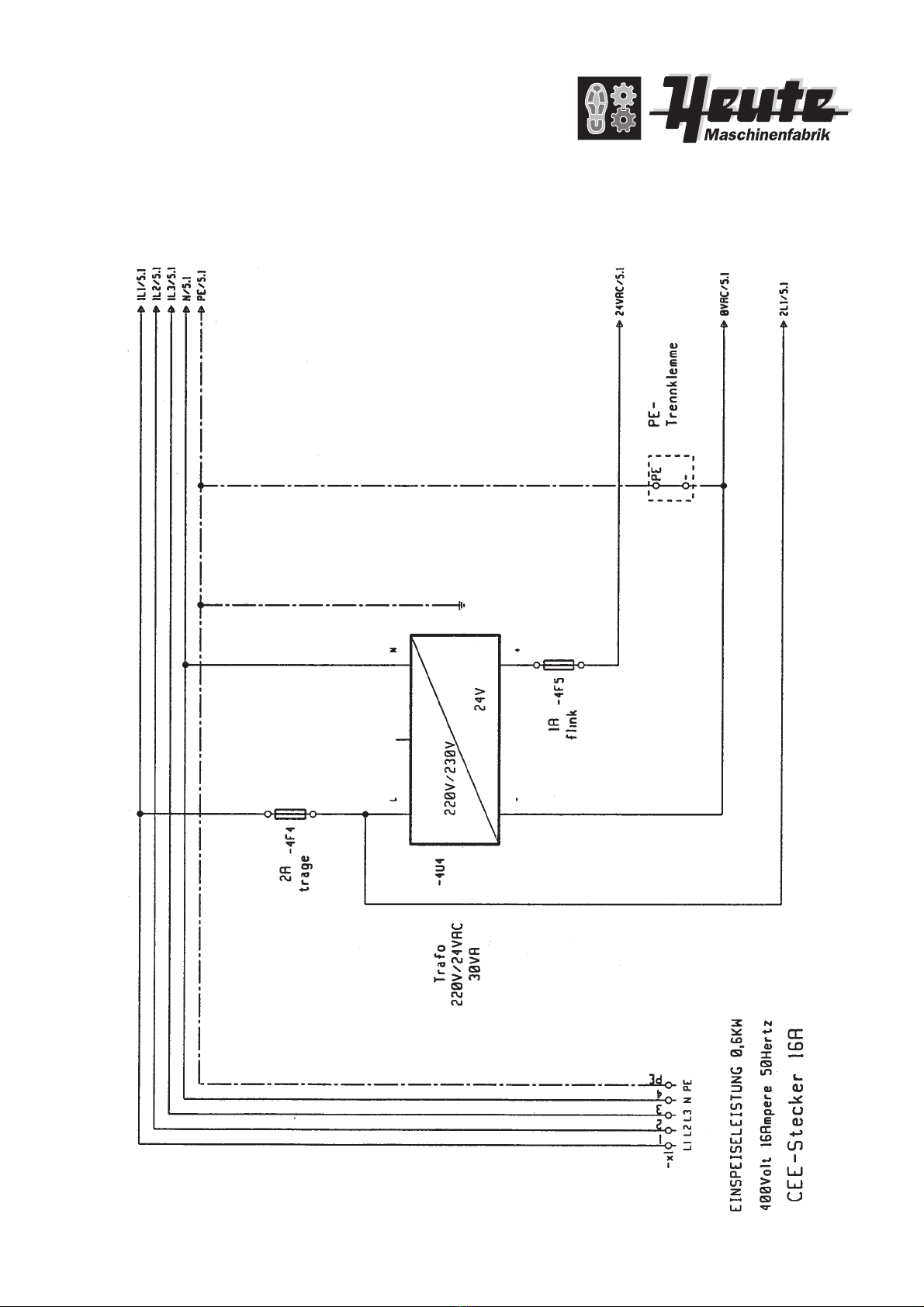

18. Circuit diagram

NEPTUN I

Sole cleaning unit

Art.-No.: 84-620

18. Circuit diagram

NEPTUN I

Sole cleaning unit

Art.-No.: 84-620

18. Elektro-Schaltplan

Maschinenfabrik

Heute GmbH & Co. KG

Germany

Postal address:

P.O.Box 10 05 07

42605 Solingen · Germany

Address:

Weinsbergtalstrasse 2-6

42657 Solingen · Germany

Phone:

+49 (0)212-3 80 31-13/14

Fax:

+49 (0)212-81 80 85

E-mail:

expor[email protected]

Internet:

www.heute-gmbh.de

Contact us for service, spare parts

and additional information:

Other manuals for NEPTUN I

1

Table of contents

Other HEUTE Washer manuals

Popular Washer manuals by other brands

Bosch

Bosch WAU28PBHSN User manual and installation instructions

Amana

Amana NTW4516FW quick start guide

Tricity Bendix

Tricity Bendix BA 450 Operating and installation instructions

Siemens

Siemens Washing machine installation instructions

Bosch

Bosch Vision 300 Operating Operating, care and installation instructions

Asko

Asko W4086.P.T.AU Instructions for use