Hexagon LS-R-4.8 User manual

LANGUAGE

DESCRIPTION

PAGE

DE

BETRIEBSANLEITUNG

3

Manual Version V01.00-REV01.00

Release Date 2021-03-19

LS-R-4.8 Table of Contents

3

Table of Contents

1Description.......................................................................................................................................................... 5

1.1 General....................................................................................................................................................... 5

1.1.1 Preface .......................................................................................................................................... 5

1.1.2 Safety Instructions ......................................................................................................................... 5

1.1.3 Validity........................................................................................................................................... 7

1.2 Purpose ...................................................................................................................................................... 7

1.3 Declarations and Approvals........................................................................................................................ 8

1.3.1Europe and UK (EU an UKCA Declarations of Conformity) ........................................................... 8

1.3.2 USA (FCC Declaration) ................................................................................................................. 8

1.3.3 Canada (IC /RSS Declaration) ....................................................................................................... 8

1.3.4 China ............................................................................................................................................. 8

1.3.5 Japan............................................................................................................................................. 8

1.4 System Components .................................................................................................................................. 9

1.5 Technical Data.......................................................................................................................................... 10

1.5.1 Laser scanner technical data ....................................................................................................... 10

1.5.2 Calibration sphere technical data................................................................................................. 10

1.6 Dimensions............................................................................................................................................... 11

1.7 Markings................................................................................................................................................... 12

1.8 Function parameters................................................................................................................................. 14

1.8.1 Measuring Range ........................................................................................................................ 14

1.8.2 Sensitivity and gain factor (Laser Sensor Gain) ........................................................................... 15

1.8.3 Quality filter.................................................................................................................................. 15

1.9 Transmission and Reception Area ............................................................................................................ 16

1.10 Delivery Contents, Accessories and Spares ............................................................................................. 17

1.10.1 Delivery Contents ........................................................................................................................ 17

1.10.2 Accessories, General................................................................................................................... 17

1.10.3 Shanks ........................................................................................................................................ 17

1.10.4 Spares ......................................................................................................................................... 18

2Operation .......................................................................................................................................................... 19

2.1 Tools, Measurement and Test Equipment ................................................................................................ 19

2.2 Consumables for maintenance ................................................................................................................. 19

2.3 Commissioning and Setup of the Scanner................................................................................................ 20

2.3.1 Mounting/dismounting the shank ................................................................................................. 20

2.3.2 Inserting/Replacing the Battery.................................................................................................... 21

2.3.3 Pairing the scanner with a receiver .............................................................................................. 22

2.3.4 Warming up the laser scanner ..................................................................................................... 24

2.4 Aligning the scanner for measuring........................................................................................................... 25

2.4.1 Marking of the transmission window on the scanner housing ...................................................... 25

2.4.2 Measuring edges and special characteristics............................................................................... 26

2.4.3 Interrupting the beam path........................................................................................................... 27

2.4.4 Direct reflections.......................................................................................................................... 27

2.4.5 Secondary reflections .................................................................................................................. 28

2.5 Optical Status Display............................................................................................................................... 29

2.6 Troubleshooting........................................................................................................................................ 30

2.6.1 Problems with data quality ........................................................................................................... 30

Table of Contents LS-R-4.8

4

2.6.2 Error during operation.................................................................................................................. 30

2.7 Maintenance and Cleaning ....................................................................................................................... 31

2.7.1 Cleaning the optical windows of the laser scanner....................................................................... 31

2.7.2 Cleaning the calibration sphere.................................................................................................... 32

2.7.3 Inspection .................................................................................................................................... 33

LS-R-4.8 Description

5

1 Description

1.1 General

1.1.1 Preface

The safety instructions in this manual have to be strictly observed to guarantee a safe and reliable function of the

touch probe and to avoid personal and material damage. The meaning of the symbols related to the safety

instructions is described in the table below:

CAUTION CAUTION indicates a hazardous situation that, if not avoided, could result in

injury.

NOTICE NOTICE indicates important information that, if not observed, could lead to

property damage/malfunctions.

INFORMATION INFORMATION indicates important information or helpful advices for the work with

the described device.

1.1.2 Safety Instructions

CAUTION

Risk of injury!

At high spindle rotation speeds, there is a danger that the device will come out of the spindle, or that parts of the

device will be ejected.

•Make sure that the laser scanner is only used with no spindle rotation speed

CAUTION

Risk of injury due to hot device surface!

Especially with high ambient temperatures, the device can get hot during operation.

•If the laser scanner has been in operation, it must only be handled with protective gloves.

Description LS-R-4.8

6

CAUTION

Risk of eye injuries due to laser radiation!

The LS-R-4.8 laser scanner is a laser class 2 product according to EN/IEC 60825-1:2014. To avoid eye injuries,

the following instructions must be followed:

•Do not look directly into the laser beam.

•Do not point the laser beam at people.

•When the laser scanner is not in use, protect it against unauthorised access.

•Switch off the system before cleaning or maintenance work.

Hazard labels on the laser scanner housing

NOTICE

Risk of damage to the equipment!

Rotating the spindle at high speed can damage the laser scanner.

•Make sure that the laser scanner is only used with no spindle rotation speed.

NOTICE

Risk of damage to the equipment!

When the battery compartment is open, there is a risk that dirt and moisture can penetrate the sensor. The

specified protection class (IP68) only applies when the battery compartment is closed.

•Make sure that the laser scanner is only used with no spindle rotation speed.

NOTICE

Risk of material damage!

•The laser scanner is not monitored for collisions. All travel paths must be programmed so that no collisions

can occur.

NOTICE

Risk of material damage caused by third-party parts!

•Only use the original spare parts listed in these operating instructions to perform maintenance and repairs.

LS-R-4.8 Description

7

NOTICE

Possible damage to the laser scanner

Deposits on the optical windows have a significant effect on the measuring accuracy of the laser scanner.

•Avoid drips or heat damage to prevent a decrease in accuracy or sensitivity.

•Do not touch the optical windows on the laser scanner.

•Do not use solvents to clean the housing of the laser scanner.

•Store only within the specified storage temperature range, see chapter 1.5.1.

•Avoid the formation of condensation on the optical elements, e.g. by quickly changing the temperature.

INFORMATION

The information given in this manual can be changed by the manufacturer at any time. Thus the user is

responsible to regularly inquire about updated information.

1.1.3 Validity

These operating instructions are valid for the hardware available at the date of creation of these operating

instructions. The manufacturer reserves the right to make technical modifications.

1.2 Purpose

The LS-R-4.8 laser scanner is used for measuring and detecting various workpiece geometries (e.g. arches,

surfaces, corners, edges, areas, slots, grooves, curves, cut-outs, polygons, shanks and spherical surfaces). It is also

suitable for measuring complex geometries, like three-dimensional surfaces and for measurements involving pivot

axes. The measured workpieces can consist of a variety of different materials (e.g. processed, semi-finished,

punched, forged, cast material, as well as dark materials such as rubber and carbon fibre).

Radio-wave transmission ensures that the measuring signals from the laser scanner can be transmitted to the

receiver over large distances.

The measuring results are evaluated using the program HxGN NC Measure.

Description LS-R-4.8

8

1.3 Declarations and Approvals

1.3.1 Europe and UK (EU an UKCA Declarations of Conformity)

The EU and UKCA Declarations of Conformity can be found at the end of these operating instructions.

If required, a copy of the signed original declarations of conformity may be requested from the address given on the

back cover.

1.3.2 USA (FCC Declaration)

This device complies with Part 15 of the FCC. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesired operation.

This device has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

device is operated in a commercial environment. This device generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this device in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

In order to comply with FCC and IC RF Exposure requirements, the device must be installed and operated such that

a minimum separation distance of 20 cm is maintained between the device and all persons during normal operation.

Changes or modifications not expressly approved by m&h Inprocess Messtechnik GmbH may void the FCC/RSS

authorization to operate this equipment.

FCC ID: MFFLSR48

1.3.3 Canada (IC /RSS Declaration)

English:

This device complies with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesired operation.

Français:

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence.

L'exploitation est autorisée aux deux conditions suivantes:

(1) l'appareil ne doit pas produire de brouillage, et

(2) l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d'en

compromettre le fonctionnement.

IC: 5782A-LSR48

1.3.4 China

This device has an RTA certificate (Radio Transmission Equipment Type Approval Certificate) issued by the SRRC

(State Radio Regulatory Committee) for use in China.

CMIIT ID: 2016DJ1391

1.3.5 Japan

This device has a certificate issued by the Japanese MIC (Ministry of Internal Affairs and Communications) for use in

Japan. This certification complies with the Japanese Radio Law:

202-LSI069

R

Description LS-R-4.8

10

1.5 Technical Data

1.5.1 Laser scanner technical data

Transmission frequency

2400-2483.5 MHz (2.4 GHz)

5.18-5.24 GHz (WLAN 5GHz)

(20 MHz channels 36, 40, 44, 48)

Transmission/reception range

Up to 15 m

Laser class

2 (EN / IEC 60825-1:2014)

Laser manufacturer

OSRAM Opto Semiconductors GmbH

Laser type

PL450B (laser diode)

Emitted wavelength (blue)

450 nm

Maximum average radiation power

1 mW

Beam spread

24° (visual)

17,2° (measuring range)

Laser type

CW Laser (Continuous Wave)

Working distance and depth (Z)

(outer housing edge to average working distance)

115 ±40 mm

Line width

27,1 mm (minimum working distance)

39,2 mm (average working distance)

51,3 mm (maximum working distance)

Zoom mode 1

Frame rate

42 Hz

Raw points per line (µm)

841

Raw point spacing (µm)

32 (minimum working distance)

47 (average working distance)

61 (maximum working distance)

Zoom mode 2

Frame rate

80 Hz

Raw points per line (µm)

421

Raw point spacing (µm) 65 (minimum working distance)

93 (average working distance)

122 (maximum working distance)

Zoom mode 3

Frame rate

144 Hz

Raw points per line (µm)

211

Raw point spacing (µm)

129 (minimum working distance)

187 (average working distance)

244 (maximum working distance)

Data rate

30.000 to 36.000 Pt/sec

Sensor’s insensitivity to extraneous light

5,000 lx (diffused, indirect artificial light)

Operating temperature

5 to 40 °C (41 to 104 °F)

Temperature range for specified accuracy

15 to 40 °C (59 to 104 °F)

Storage temperature

-25 to +70 °C

Ambient humidity

90 % non-condensing

Weight

1900 g (without batteries)

Power supply

4x 3.7 V battery, 26650, Li-ion, 5000 mAh

Battery lifetime (continuous measurement)

10 h

System booting time

5 s

Protection against dust and water

IP68 (IEC 60529)

1.5.2 Calibration sphere technical data

Material

Epoxy resin

Coating thickness

30 to 50 µm

Diameter

25,4XX mm (1")

Colour

White (Munsell N9.4)

Gloss (60°)

3 ±2.5

LS-R-4.8 Description

11

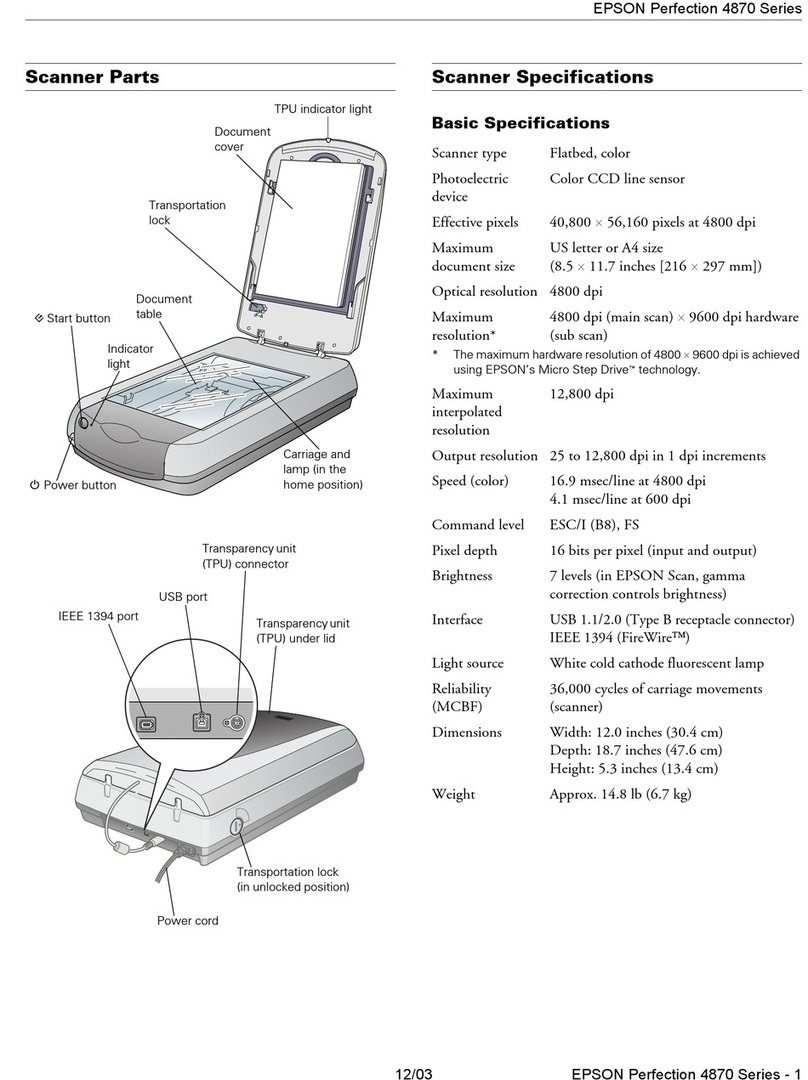

1.6 Dimensions

Dimensions of LS-R-4.8

INFORMATION

The dimension X for the length of the shank, required to calculate the total length L of the laser scanner system,

can be found in the accessories catalogue.

The total length L is the sum of the laser scanner length and the dimension X.

Battery compartment,

Customer specified

shank

LED status indicators (4x)

Transmission/reception window

for laser

IR programming interface

in battery compartment

Average working distance

LS-R-4.8 Description

13

Position Labeling Description

1

Laser warning, complete

2

Laser warning with information on the laser class and

position indicator for the laser transmission window

(refer to chapter 2.4.1)

3

Approval numbers for national and European radio

approvals and conformity labels

4

Registered applicant for radio licenses

5

Compliance information for FDA Laser Regulations

(21CFR 1040.10 and 1040.11) and radio declaration for

indoor use

6

Devive information:

•Product name

•Part numberr

•Serial number

•Manufacturing date

7

Manufacturer address

Description LS-R-4.8

14

1.8 Function parameters

1.8.1 Measuring Range

The following illustration shows the recommended average working distance and the permissible working range

between the minimum and maximum possible working distance:

Measuring Range

* Distance is measured from outer housing

edge to average working distance.

LS-R-4.8 Description

15

1.8.2 Sensitivity and gain factor (Laser Sensor Gain)

The gain factor set depends on the workpiece to be measured (material, surface condition). This setting increases

the sensitivity of the laser scanner during data acquisition. Depending on the measuring result, it may be useful to

adjust the gain factor in the measuring software.

INFORMATION

The gain factor setting significantly affects the quality of the recorded measuring data. If data quality is poor,

adjusting the gain factor can improve data quality. The following gain factor settings are recommendations and

can be adapted to individual ambient/material conditions.

Gain factor White Grey/Bright steel Carbon

5

-

-

X

4

-

X

X

3

X

X

-

2

X

X

-

1

X

-

-

INFORMATION

If the acquisition of measuring data is difficult when scanning dark, shiny or transparent surfaces, the gain factor

should be set to one of the settings "4" or "5".

However, this setting, and the resulting higher sensitivity of the laser scanner, increases the probability of

recording low quality data.

In order to automatically filter out this data from the measurement, the quality filter can also be activated.

1.8.3 Quality filter

The quality filter is used to filter out low quality measuring points from the measurement.

The following quality filters are used here:

•Error data filter for 3D data

•Angle filter

•Outlier filter

•Edge filter

INFORMATION

If the acquisition of measuring data is still difficult when scanning dark, shiny or transparent surfaces, despite

setting the gain factor to "4" or "5", the quality filter should be deactivated.

However, this setting reduces both the measuring accuracy of the system and the data quality.

Description LS-R-4.8

16

1.9 Transmission and Reception Area

INFORMATION

The transmission/reception ranges shown below only apply under optimum operating conditions. For a secure

signal transmission, laser scanner and receiver must be located in the transmission area of the other device. The

range for a secure signal transmission is up to 15 m.

Transmission and reception area (emission/reception behaviour of antenna)

0…1

≙

0%...100%

of the maximum possible

transmission/reception area

under the given conditions of use

Example:

If the receiver is mounted at an angle of

60° above the touch probe, then:

S = 0.9 * Smax

S = Transmission/reception range

Smax = Max. transmission/reception range

LS-R-4.8 Description

17

1.10 Delivery Contents, Accessories and Spares

1.10.1 Delivery Contents

Order Number

Description

LS-R-4.8-SENSOR#

Laser scanner LS-R-4.8

4x batteries, type IMR26650 (6401)

USB stick with operating Instructions (LS-USB-KEY-OI)

Transport case (LS-R-4.8-CASE)

1.10.2 Accessories, General

Order Number

Description

Illustration

03939542 M8 calibration sphere V2 - Standard

QUAL-SPHERE-HOLDER Calibration sphere holder

6402 Battery charger

6409 Programming clip

6259 IR-RAW stick

LS-R-TB

Tool box, consisting of:

4x batteries, type IMR26650 (6401)

4x cleaning cloths (4297)

1x battery charger (6402)

1x programming clip (6409)

1x IR-RAW stick (6259)

1x Cylindrical pin 1.5x16 (6412)

1x USB 2.0 Extension 1.8 m

1x Storage box (6410)

1x USB Charger with quick charge 3.0 (H00028517)

1.10.3 Shanks

In conjunction with laser scanner LS-R-4.8, only shanks for a shaft diameter of 28 mm can be used. It is

recommended to use a shank with indexing. An overview of available shanks for the laser scanner can be found in

the accessories catalogue.

INFORMATION

If a shank is used without indexing, a calibration must first be performed to determine the exact alignment of the

system in the spindle before using the laser scanner.

Description LS-R-4.8

18

1.10.4 Spares

Order Number Description Illustration

0506 Clamping screw

LS-R-4.8 Operation

19

2 Operation

2.1 Tools, Measurement and Test Equipment

Order Number Description Illustration

3489 Hexagon key AF4 mm

4297 Optics cleaning cloth

LS-R-TB#

Tool box, consisting of:

4x batteries, type IMR26650 (6401)

4x cleaning cloths (4297)

1x battery charger (6402)

1x programming clip (6409)

1x IR-RAW stick (6259)

1x Cylindrical pin 1.5x16 (6412)

1x USB 2.0 Extension 1.8 m

1x Storage box (6410)

1x USB Charger with quick charge 3.0 (H00028517)

2.2 Consumables for maintenance

In addition to the supplied tools, measuring and test equipment, the following auxiliary equipment and consumables

can be used for cleaning. These are not part of the delivery contents and must be purchased separately if necessary.

Activity

R i d t l

Auxiliary equipment/Consumables

Dry cleaning Optical windows Clean, soft, lint-free micro-fibre cloth

Calibration sphere Clean, lint-free gloves

Clean, soft, lint-free micro-fibre cloth

Wet cleaning Optical windows Clean, soft, lint-free micro-fibre cloth

Camera lens cleaner or isopropyl alcohol

Operation LS-R-4.8

20

2.3 Commissioning and Setup of the Scanner

2.3.1 Mounting/dismounting the shank

1. Dismounting the shank:

1.1 Remove clamping screws from the shank.

1.2 Remove shank.

2. Mounting the shank:

2.1 Slide the shank onto the laser scanner.

2.2 Insert the clamping screws and tighten to the torque specified in Fig. 7.

3. Calibrate the laser scanner.

Mounting/dismounting the shank

Shank

Clamping screw

AF4 mm

(2x)

(0506)

M=10 Nm (7 lbf.ft)

Hexagon key

AF4 mm (3489)

Laser scanner

LS-R-4.8

Table of contents

Other Hexagon Scanner manuals

Popular Scanner manuals by other brands

Bosch

Bosch D-TECT 100 operating instructions

Canon

Canon DR-9050C - imageFORMULA - Document Scanner user manual

AEI Security & Communications

AEI Security & Communications DigiSender DGXDSDV112-EU manual

Avision

Avision FL-1801 user manual

Epson

Epson 4870 - Perfection Pro Product information

Panasonic

Panasonic KV-S1015C operating manual