USER'S GUIDE R18 AXIAL FAN , Iss: 6.05.2021

03 OPERATING CONDITIONS

The fans are rated for S1 (IEC 60034-1) continuous operation.

Extreme ON-OFF switching operating must be avoided, because it has negative influence on life expectancy and power consumption.

Cycling operating mode should only with cycling ON/OFF via control signal (0/10V analog input or PWM input).

Do not cycling the power supply for cycling operating mode – use control signal! High 'In-rush current' can occur during cycling power supply!

Permissible ambient temperature is specified as indicated on the motor nameplate for actual fan and in chapter 03 OPERATING CONDITIONS in the

INSTALLATION, MAINTENANCE AND USER'S GUIDE.

If the end use requires compliance with the IEC/EN 60335 standards, due to the temperature limitation of the connecting cable, the temperature range

of the fan is limited to max. + 60 °C, even if the fan on the nameplate is specified for use up to a higher ambient temperature. If the fan is used at an

ambient temperature above 60 °C, always use temperature-resistant cables (PVC 105°C).

Figures on the motor name-plate refer to nominal values according to rule specified on the nameplate next to the written values. The rules (EN_60335,

'free air', 'max.load', 'max.eff.', cust. unit / cust. spec., UL, IEC 60034-1) are described in the example shown below.

Continuous sound pressure level may exceed 70dBA (depends of fan model).

Protection (motor & electronics): IP55 according to EN60529.

Power consumption in stand-by mode: les than 5W.

DIMENSIONS

Nominal diameter: 800 mm - see Appendix - technical drawing: VENTILATOR / R18R-080MPS-ET120B-01A01

Weight: 50 kg

NOMINAL DATA - defined according to ' MAX. LOAD '

Phase: 3~

Nominal Voltage: 400 V

Operating Voltage range: 380-480 V

Frequency: 50 Hz

Input power: 2900 W

Nominal current: 4,6 A

Rotational speed: 1140 RPM

Operating ambient temperature range: -25°C .. +65°C

Altitude: 2000 m

Insulation class: 155

Protection provided by PE: Class I

Overvoltage category (OVC): III

Operating humidity ambient: up to 95% (non condensing).

Max. pressure: 260 Pa

ErP DATA

Overall Efficiency, Effes: 47,8 %

Installation category: A

Efficiency category: static

Efficiency grade, N: 51,4

Variable speed drive: INTEGRATED

Power Input , Pelec: 2708,1 W

Airflow volume , qV: 18519 m³/h

Pressure Increase, ps: 250 Pa

Rotational Speed, n: 1146 RPM

Specific ratio: 1,002

Airflow volume max., qV: 27336 m³/h

Pressure Increase max., ps: 610 Pa

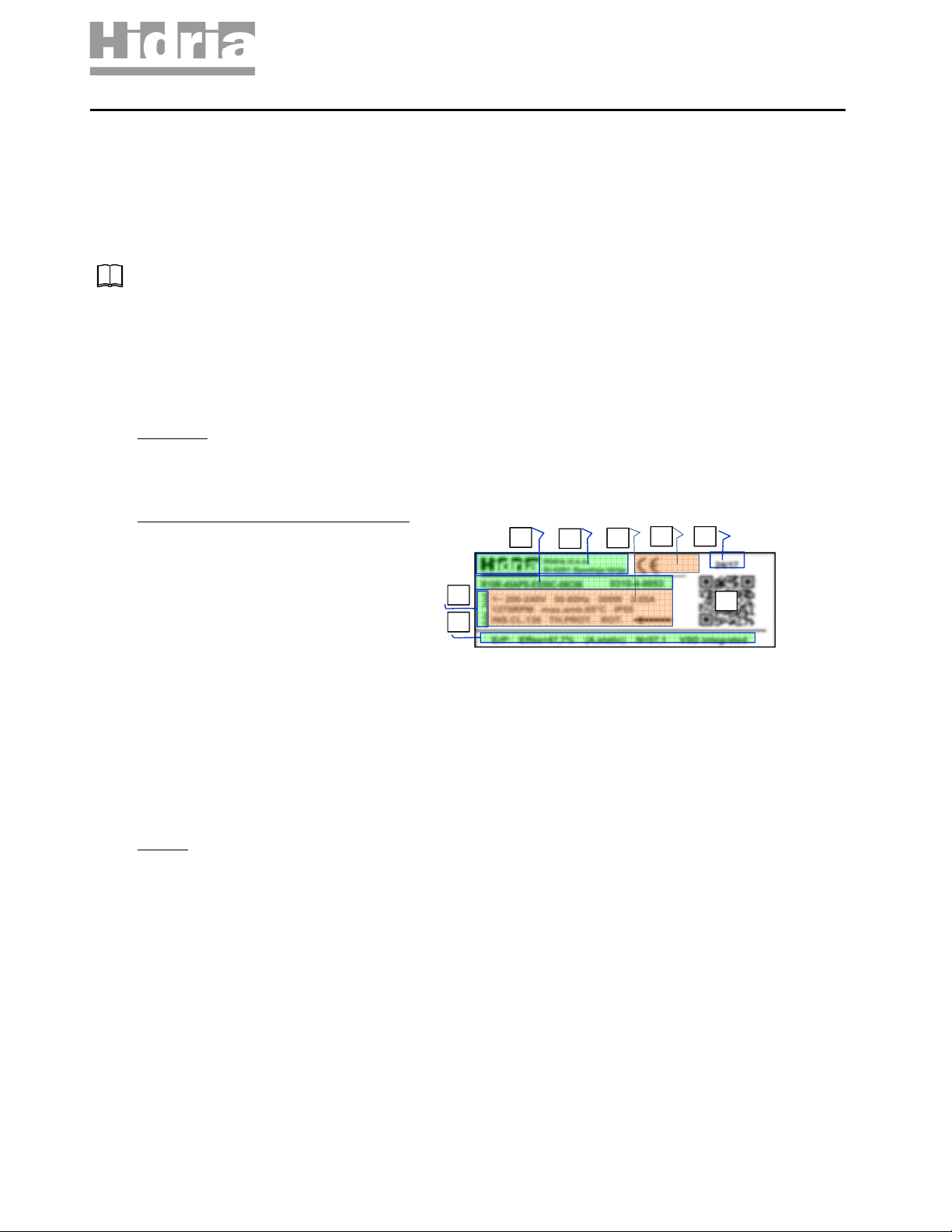

1. Fan type and code

2. Trade mark and manufacturer address

3. Nominal values (Voltage, frequency, lectric Power, Current...)

4. Certification marks

5. Date of production (week of the year/year)

6. QR code which includes code number, production date, serial number

and link to website.

7. Data acc. to U regulation 327/2011 ( rP)

8. NOT INDICAT TO WHICH STANDARD/RUL S COR SPOND DATA ON TH

NAM PLAT :

- N 60335-1 : Name-plate data are made according to standard EN

60335-1, Household and similar electrical appliances – Safet – Part 1,

Articles 10.1 and 10.2:

If an appliance is marked with rated power input, the power input at

normal operating temperature shall not deviate from the rated power

input b more than: + 20% if Pn<300W or +15% (or 60W whichever is

the greater) if Pn>300W.

If an appliance is marked with rated current, the current at normal

operating temperature shall not deviate from the rated current b more

than: +20% if In<1.5A or +15% (or 0,30A whichever is the greater) if

In>1.5A.

- FR AIR : Data on the nameplate established at a point 0Pa static

pressure at normal operating temperature.

- MAX LOAD : Data on the nameplate established at a point of maximal

static pressure regarding max. ambient temperature.

- MAX. FF. : Data on the nameplate established at a point of maximal

static efficienc at normal operating temperature.

- CUST. UNIT / CUST. SP C. : Data on the nameplate specified according

to customer specifications or at working point in customer's unit .

- UL - Data on the nameplate defined according to specifications in UL

standards.

- I C 60034-1 - Data on the nameplate established at a point of nominal

load according to standard for Rotational electrical machines.

An example of a label and explanation of the content:

© Copyright HIDRIA d.o.o., All rights reserved. Document is subject to change without prior notification.

4 / 10