High Voltage PFT Series Guide

Safety,Operation,andProcedureInstructionsforthePFTSeriesof

ACHipots

Danger- Lethal Voltages:

Equipment to be used by trained personnel only

This Operator Manual contains instructions for the operation of a High Voltage power source. The operator of this equipment

must use good judgement and follow all safety precautions noted in this guide to ensure the protection of himself and others in

close proximity to the test area. Failure to follow the instructions could result in injury or

death. Proper grounding of the test set must be done prior to connecting this unit

to a power source.

PFT

SERIES

Please Refer to

Documentation

Before Operation

OperatorManual

Last saved 1/29/2009

T:\PRODUCT\DOCUMENTS\Manuals\PFT\MANpft_2k9Re.doc

TableofContents

About the Operator Manual 1

SECTION 1

General Information 2

Features and Specifications 2-3

Controls and Indicators 4-5

SECTION 2

Setting up the Equipment 6

Operating the Equipment 7-10

Blank Page for Notes 11

SECTION 3

Performing Special Operations 12

Meter Re-calibration 12,13

Miscellaneous 14

Packing the Cables 14

Return Material 15

Warranty 16,17

OPERATOR MANUAL

- 1 -

AbouttheOperatorManual

Important

ThisOperatorManual describesthe featuresand safeoperation ofa High

VoltageTestSet.The instructionsare intended to be clear and simple, but

the operator must betrained and qualified according to established

procedures forthe use of thistype of equipment.

ThisOperator Manual isorganized toprovide information onthe PFT Series ofHipots in steps that familiarize

thenew operator withthe operationof thistestset.

Section1: Specifications andControls.

Section2: Setup andOperation.

Section3: Performing SpecialOperations.

TheFunctions,Features,andSpecifications ofthePFTSeriesof ACHipotsarealsodiscussedinthePFTBrochure

availablefromHighVoltage,Inc.

2

GeneralInformation

Thissection familiarizes theoperator withthe features andspecificationsof the

PFT Series ofPower Frequency AC Test Sets manufacturedby HIGH VOLTAGE, INC.

Features and Specifications

The PFT Series of AC hipot test sets provide continuously adjustable output voltages for the GO/NO-GO

testing of high voltage insulation. Earlier versions of the PFT Series were equipped with operator controlled

capacitive compensation switches to minimize input primary currents. The new simplified controls incorporate

thisfeature transparently.

Standardfeatures ofthe PFT Seriesof include:

•Continuouslyadjustable output voltage

•Fixed overload, factoryset to 120% of variabletransformerrated outputcurrent

•“ZeroStart” and ExternalInterlock provision

•Secondaryconnected dual-range voltmeter

•Shieldedoutput cable (50kV andbelow) precludesunnecessary insulated support ofthe cable

•Onepiece portable design(50 kV andbelow)

•Transitprotected meters preventmeter damagebetween test sites

•Capacitive load compensation incorporated to allow up to 3 KVA output power with less than 15

Amperesinput line current.

•FaultBurn Reactor (Optional)

SECTION

1

3

PFT MODEL SPECIFICATIONS

PFT-103

PFT-303

PFT-503

PFT-1003

SEE SPECIFICATIONS

ON LAST SHEET OF PARTS LIST

Table 1 PFTSeries Specifications.

4

VOLTMETER

LOW HIGH

OUTPUT

GROUND

INPUT

FUSE

MAIN

POWER HIGH

VOLTAGEOFF ON

EXT

INTLK

AC TEST SET PFT SERIES

RETURN

MODE

GUARDGROUND

LOAD

RETURN

CURRENT RANGE

X10 X1

X100

PLEASE REFER TO

DOCUMENTATION

BEFORE OPERATION

Figure1 PFT Series front panel controls.

MAIN POWER

TheMAIN POWER pushbutton switch provides the power to the controland powercircuits. Theneon lamp in

the switch will light when the power is on and voltage is available through the input line cord. The INPUT

FUSE located electrically beforetheMAIN POWER switch provides linefault protectionfor theunit.

EXT INTLK (EXTERNAL INTERLOCK)

The Ext Intlk connector is provided to allow for a normally open safety interlock switch to control the

energizingof the highvoltage output.

HIGH VOLTAGE ON/OFF

The HIGH VOLTAGE ON and OFF pushbuttons control the high voltage power circuits. The red and green

LEDs provide life long positive indication of the circuit status. The red LED lights when high voltage is

energizedand the greenLED lights whenthe highvoltage isde-energized.

OUTPUT CONTROL

TheOUTPUT control variable transformer adjusts the output voltage.The0-10 markings onthe knobindicate

the low to high setting. The control must be at ZERO (0) to energize the high voltage circuits. The output

control must always be returned to zero at the completion of testing, prior to de-energizing the output

5

VOLTMETER AND RANGE SWITCH

The KILOVOLT METER and associated range switch allows for more accurate output voltage readings. 1-%

precision resistors minimize the need for re-calibration due to aging shift. See Voltmeter Re-calibration in

Section3 for detailson calibration.

CURRENT METER

The CURRENT METER is for accurate secondary load current readings. The range multiplier switch (X1,

X10,X100) allows readingsto betaken aslow as.1mA (5divisions) andup to 100mA.

LOAD RETURN CONNECTOR

The LOAD RETURN connector is for the low side of the test load. It connects to the shielded return lead for

moreaccurate load currentreadings.

RETURN MODE

The RETURN MODE switch allows for accurate secondary load current readings. In the GUARD position, all

ground currents are shunted around the meter. The load must be isolated from ground to use in the GUARD

position. In the GROUND position, the return point is grounded and all currents (load and ground losses) are

metered.

BURN(OPTIONAL)

The BURN toggle is provided for tests when the load has faulted and the insulation must be further scored to

find the problem. The BURN feature will limit current on the output below the overload value and allow for

thoroughmarking ofthefaultarea.

Listofincludedcomponents

Blacktest lead withblack bootfor ground connections.(2 leadsfor PFT-1003)

Ext.Intlk. Jumperplug

Attached20 ft.X-Ray shielded outputcable (50kV andbelow)

Alligatorand hook connectionsfor workingend of outputcable (50kVand below)

20 ft. RG58/U coax returnlead

6

SETTINGUPTHEEQUIPMENT

The setup of this equipment has been minimized by careful consideration of the operator during design. The

PFT Series’ one-piece construction (50kV and below) minimizes misplaced components while allowing for

convenientportability.

1. Select a location for the unit that will allow easy viewing of the meters at a safe distance

fromthe testobject.

2. Be sure that all the controls are off,in their de-energized or fully counterclockwise

position.

3. Secure a ground test lead to the panel. TheGroundpost on the front panel should be

used for that purpose. A black test lead with black boot has been provided for the ground

connection. A second ground lead is provided for two-piece units for the grounding of the high

voltagesection.

4. Insert the EXT INTLK plug into the socket on the panel. The plug may also be

wired to a normally open contact of a safety switch for added protection. Hand-held safety

switchesare available fromHigh Voltageto plug directlyinto theEXT INTLK socket.

5. If applicable, connect the interconnect cable between the control and high

voltage section.

6. Thered booted alligatorclamp onthe output cableis usedto connecttheoutput cableto thetest

object. (50kV and below). Connection of the output toroid on the PFT-1003 high voltage section

to the load is accomplished by using a customer provided test lead or tubing (metallic) between

thetoroid (HVoutput) and testobject.

SECTION

2

7

OperatingtheEquipment

This section provides step-by-step instruction on various test methods. Many facilities have their own

in-house test procedures that should not be superceded by this manual. The purpose of this section

isto explain thecapabilities ofthis test setin real-worldapplications.

AC InsulationTesting

1. Ensure that all the steps listed in Setting up the Equipment have been accomplished. Take

special note to ground the control panel to a solid earth ground using the supplied black test

lead.

2. Select the desired VOLTMETER RANGE forthetest voltagelevel expected.

3. Prior to connecting the output cable (toroid) to the test sample, be sure that the test sample is

de-energized.

4. Connect the output lead to the test sample. Be sure that there is enough clearance to

grounded objects for the expected test voltage. The minimum clearance in air is 10 kV

ac/inch.

5. Return the low side of the test sample to the LOAD RETURN connector using the supplied

shielded return lead. See the GUARD/GROUND explanation (pp. 9,10) for direction on which

modemay beappropriatefor your testingrequirements.

6. Connect the input power cord to a grounded source (See the specification table for unit input

requirements).

7. Depressthe MAIN POWER switchtoenergize thecontrol circuits.

8

***CAUTION***

POTENTIALLY LETHAL VOLTAGES

MAY BE PRESENT

8. With the OUTPUT control at zero (zero start interlock engaged), depress the HV ON

pushbutton.The HV ON lightwill glow.

9. Increase the output by rotating the OUTPUT control slowly clockwise until the desired output

voltageis reached.

Note: The high voltage output cable shield is grounded. This grounded shield appears as a

load even under ‘no load’ conditions. The current on a PFT-503CM is about 18mA at full

output with the RETURN MODE in the GROUND position.

10. Maintainthe outputvoltage for thetest timespecifiedin yourstandard procedures.

11. After the test is complete, rotate the OUTPUT control to zero, prior to depressing the HV OFF

pushbutton.

12. If the test sample fails during the test, the internal overload relay will de-energize the high

voltage. This relay is in the primary circuit and is sensitive to primary current overloads.

The overload is set to 120% of the rated current of the variable transformer. The use of a

gappedtransformer in thehigh voltagetank will nullthe primarycurrents (up to1.5 KVA)and the

overload will allow operation to the full output rating of 3 KVA. When testing purely resistive

loads, the unitwill overload above1500 VAof inputpower to thetank.

13. Prior to removing theoutput cable from theload, observe thatthe outputvoltmeter isat zero.

14. Always ground the output cable (or toroid) and test sample prior to disconnecting the

test object.

9

Using the Guarded Return

The use of the GUARD/GROUND return feature of this test set provides for very accurate leakage current

measurements if certain conditions exist allowing for the GUARD circuit to be employed. The following

explanation will detail different test samples and methods that lend themselves to the use of this circuit. The

samesetup precautions suchas proper groundingstill applyto the testbut the groundswill bemanipulated to

accomplishthe test requirements.

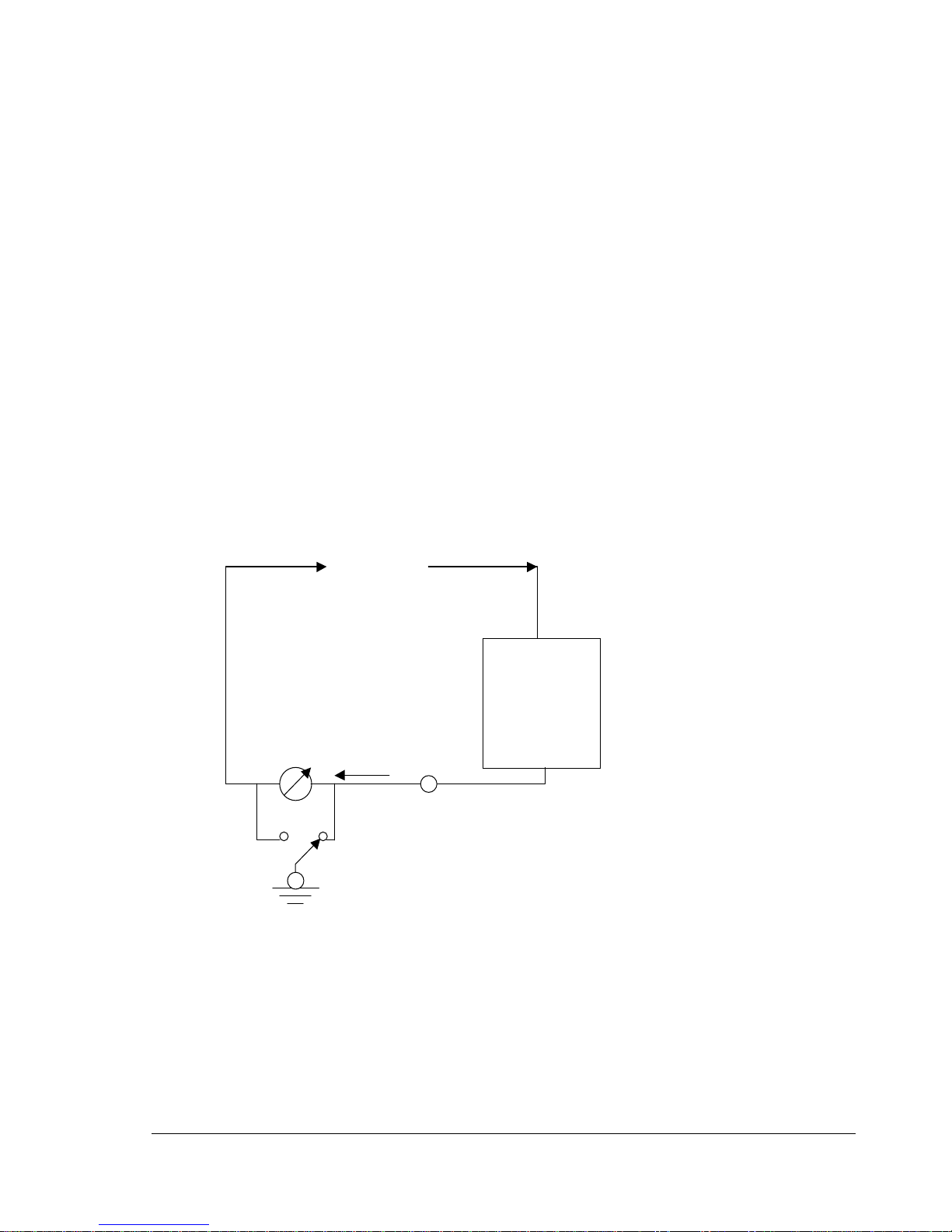

1. Grounded Return- With the output return in the grounded mode, the current meter reads all

currentto ground, internaland externalto the testset. Thiscurrentmight includecorona, surface

tracking, and any shunt resistance. The typical diagram for grounded return operation is shown

inFigure 2 below.

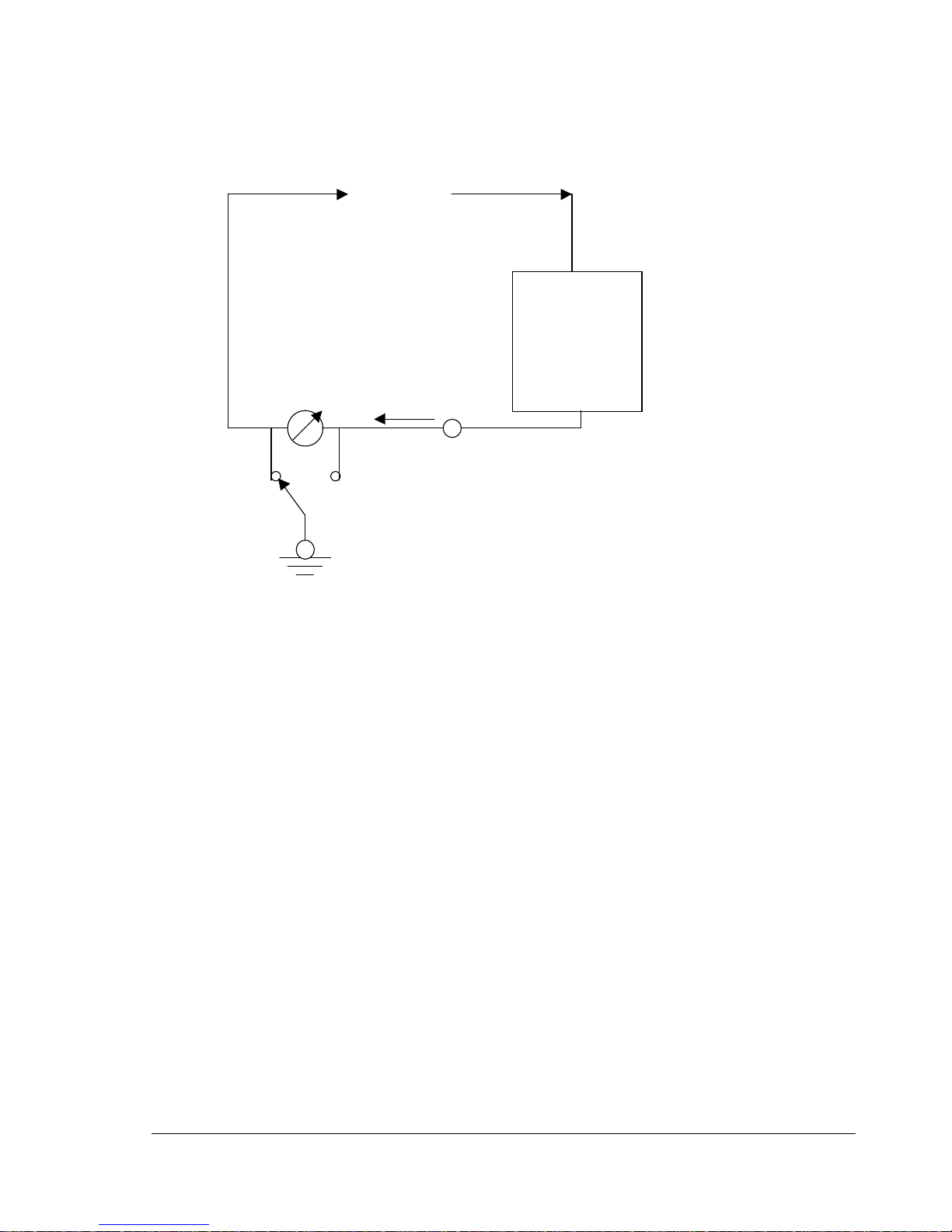

2. Guarded Return- With the output return in the guarded mode, the current meter will only read

currents through the test sample. The test sample must be isolated from ground on the low side

asshown in Figure 3 below.

Figure 2, Grounded Return Diagram

Test

Sample

High

Voltage

From Test

Set

Current flow through

return includes all

current to ground

Meter

GUARD GROUND

RETURN

POST

GROUND

POST

10

Figure 3, Guarded Return Diagram

Test

Sample

High

Voltage

From Test

Set

Current flow through

return includes only current

through the test sample.

Note that the current to

ground is returned after the

meter.

Meter

GROUNDGUARD

RETURN

POST

GROUND

POST

11

THIS PAGE LEFT BLANK FOR APPLICATION NOTES

12

PERFORMINGSPECIALOPERATIONS

The following section contains information on the care and upkeep of your new PFT SERIES Power

Frequency AC Test Set. There are some notes on troubleshooting and service, which will save much time

andmoney over thelife oftheunit.

MeterRe-calibration

The PFT SERIES of hipots use precision metal film resistors for measurement and calibration of the

voltmeter. The use of these resistors in both the high voltage tank and the metering circuits has minimized

circuit drift due to aging and temperature. Adjustment of potentiometer (R4) on the voltmeter and current

meterPCB can beused tocorrect formovementchanges fromthe agingof the meter.

The certification of meters on a yearly basis is recommended to ensure accurate test

results.

Voltmeter Re-calibration

1. Locatethe unit ina positionthat will alloweasy readingof themeters.

2. Remove the panel screws and support the panel vertically to gain access to the calibration pot

onthe back ofthe voltmeter.

3. Zerothe meter movementusing thezero adjustment belowthescale window.

4. Perform the steps in Setting up the Equipment at the start of SECTION 2. Be sure to ground

the front panel to a solid earth ground using the supplied black ground test lead prior to

connectingthe unit toinput power.

5. Setthe VOLTMETER RANGE toLOW position.

6. Connect the output cable to a calibrated reference meter with ability to read to the full output

voltageof theunit. Besure toground thelow sideofthe meter.

SECTION

3

13

7. Raisethe output toone halfscale onthe unitmeter. Adjust R4as required.

8. Check calibration at full scale and on the high range at both half and full scale. If the customer

facility calibration certification requires more points of reference, follow those procedures instead

ofthese.

9. Calibration must then be verified with the panel in the horizontal operating position to check for

anymeter balance affecton thecalibration.

Current Meter Re-calibration

10. Locatethe unit ina positionthat will alloweasy readingof themeters.

11. Remove the current meter panel screws and support the panel vertically to gain access to the

calibration poton the backof thecurrentmeter.

12. Zerothe meter movementusing thezero adjustment belowthescale window.

13. Perform the steps in Setting up the Equipment at the start of SECTION 2. Be sure to ground

the front panel to a solid earth ground using the supplied black ground test lead prior to

connectingthe unit toinput power.

14. Setthe CURRENT RANGE toX1 position.

15. Connect the output cable to a calibrated reference meter with ability to read 1mA ac. Use a

series resistance or capacitance to allow for precise resolution when calibrating. Be sure to

connect the low side of the reference current meter to LOAD RETURN and place the RETURN

MODE switchin GUARD position.

16. Raisethe output toone halfscale onthe unitmeter. Adjust R4 asrequired.

17. Check calibration at full scale. If the customer facility calibration certification requires more points

ofreference, follow thoseprocedures insteadof these.

18. Calibration must then be verified with the panel in the horizontal operating position to check for

anymeter balance affecton thecalibration.

19. Check other ranges to verify accuracy. 1% range resistors should not require any adjustment on

higher ranges. The output current can only be run to full output current with a capacitive load.

Resistiveloads are limitedto about 1/2rated current.

14

Miscellaneous

Oil Insulated High Voltage Tanks

The oil-filled tanks in all the PFT SERIES of hipots are field serviceable. The only requirement is that the tank

must be oil filled under vacuum at re-assembly if left out of the oil for longer than 3 hours. The parts to service

the tank are available from HIGH VOLTAGE, INC. at the address noted on the inside front cover of this

manual.

Theoil level inthe tankshould be.5 inchesfrom the lid when the oiltemperature is20°C.

Packing the Cables

The output cable will easily fit into the cable storage area next to the control panel. Care should be used to

avoid damaging the output cable jacket when coiling into the compartment. As the final step, the ground and

returnleads will coilneatly insidethe outputcable coil.

15

RETURNED MATERIAL

If for any reason it becomes necessary to return any equipment or materials to High Voltage,

Inc., the Service Department of High Voltage, Inc. must be notified, and authorization received,

prior to the shipment of the equipment. When notified, the following information must be

provided:

MODEL:

SERIAL NO:

PART NO:

REASON FOR RETURN:

SUSPECTED DEFECT:

CAUSE OF DEFECT:

With the above information provided, High Voltage, Inc. will determine if the return of the

equipment is appropriate. If deemed appropriate, a Return Authorization Number will be

issued. At that time, the Purchaser will be instructed how to mark and return the equipment.

The above procedure must be adhered to in order to ensure prompt service. No equipment

should be returned without the prior knowledge and authorization of High Voltage, Inc.

REPLACEMENT PARTS ORDERING

To order replacement parts, first refer to the Parts List for the product in question. Every part is

issued a part number. It is necessary for this part number and the product model and serial

number to be provided. When calling High Voltage, Inc. request the Service Department.

16

* * * * * * * * * * * * * * * * * * * * *

LIMITED WARRANTY; LIMITED RESPONSIBILITY FOR DAMAGES

High Voltage, Inc. (“High Voltage”) warrants to the original purchaser of any new product, purchased

from High Voltage, that the product is free from defects in material and workmanship under normal use

and service for a period of one year from the date of shipment to the original purchaser by High

Voltage.

This warranty is valid only for normal use of the product. Any use outside High Voltage’s written

operation instructions will void this warranty. In addition, any one of the following events will void this

warranty: (a) any defects due to negligence, alteration, modification, accidental or intended physical

abuse, faulty installation, and/or misuse: (b) attempted or actual dismantling, service or repair by any

person or firm not authorized in writing by High Voltage: (c) defects caused due to handling or transit,

either by carrier or purchaser.

This warranty only covers those parts deemed defective by High Voltage The liability of High Voltage

is limited to only the repair, replacement with new or reconditioned parts, or issuance of credit for those

parts deemed defective within the scope of this warranty. Any additional costs incurred by the

purchaser for labor and/or materials incidental to the inspection, repair, replacement or issuance of

credit for product or materials under warranty is the sole responsibility of the purchaser. This warranty

applies solely to products manufactured by High Voltage. It does not apply to parts, accessories, or

materials not manufactured by High Voltage, or to consumables. If purchaser’s claim relates to

materials manufactured by a supplier to High Voltage, High Voltage reserves the right to disclaim

responsibility and liability and may require the purchaser to deal directly with the other manufacturer of

the defective part. High Voltage may elect to assist the purchaser in settling such claim against such

other manufacturer without prejudicing High Voltage’s position as to its own liability.

WARRANTY CLAIM PROCEDURE

Compliance with the following Warranty Claim Procedure is a condition precedent to the obligation of

High Voltage under this warranty:

a) Purchaser must notify High Voltage as soon as is reasonably possible of any alleged defect in

material, workmanship, or operation of any product covered under this warranty, provided that

any notification must be received by High Voltage within twelve months after the shipment date

of the product in question. Such notice must describe in detail the defect, any and all defective

parts, and the alleged cause of the defect.

17

b) At the exclusive option of High Voltage, purchaser may be directed to dismantle the product at

the purchaser’s cost and expense and ship the product prepaid to High Voltage Refer to the

Returned Material section for instructions regarding the return of any material to High Voltage

If High Voltage elects to inspect the product at the purchaser’s site, and possibly repair,

replace, or ship the defective product to High Voltage’s factory, purchaser, at its own cost and

expense, shall provide suitable facilities for such work as needed to inspect and evaluate and

possibly repair/replace subject product. If inspection discloses that the defect is not one for

which High Voltage is liable, that is, is outside the stated terms of this warranty provided by

High Voltage, then the purchaser agrees to reimburse High Voltage for all expenses incurred.

c) Upon receipt of the defective material or product, or following access to the same, High

Voltage shall inspect and evaluate the material or product and determine the validity of the

purchaser’s claim.

The validity of any warranty claim, the purchaser’s compliance with this warranty and Warranty Claim

Procedure, and the obligation to replace, repair, or issue credit for any product, shall be solely and

exclusively determined by High Voltage and any determination shall be final and binding.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR

IMPLIED ON THE PART OF HIGH VOLTAGE, INCLUDING THE WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR USE, AND NON-INFRINGEMENT ARISING

FROM ANY BREACH THEREOF AND HIGH VOLTAGE NEITHER ASSUMES NOR AUTHORIZES

ANY OTHER PERSON, FIRM , OR CORPORATION TO ASSUME ANY LIABILITY OR OBLIGATION

IN CONNECTION WITH THIS WARRANTYON ITS BEHALF AND PURCHASER ACKNOWLEDGES

THAT NO REPRESENTATIONS EXCEPT THOSE MADE HEREIN HAVE BEEN MADE TO

PURCHASER. THIS WARRANTY SHALL BE GOVERNED AND CONSTRUED ACCORDING TO

THE INTERNAL LAWS OF THE STATE OF NEW YORK.

LIMITATION OF LIABILITY. TO THE MAXIMUM EXTENT PERMITTED UNDER APPLICABLE LAW,

AND NOTWITHSTANDING ANYTHING ELSE IN THIS DOCUMENT OR OTHERWISE, INCLUDING

THAT HIGH VOLTAGE WAS WARNED THAT DAMAGES WOULD OCCUR OR WERE LIKELY TO

OCCUR, HIGH VOLTAGE SHALL NOT BE LIABLE UNDER ANY CONTRACT, NEGLIGENCE,

STRICT LIABILITY OR OTHER LEGAL OR EQUITABLE THEORY FOR (A) ANY AMOUNTS IN

EXCESS IN THE AMOUNT PAID TO HIGH VOLTAGE FOR THE PARTICULAR PRODUCT OR

PART THEREOF WHICH GAVE RISE TO THE APPLICABLE CAUSE OF ACTION, OR CLAIM, OR

(B) ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, LOST PROFITS OR LOST DATA, OR (C)

COST OF PROCUREMENT OF SUBSTITUTE GOODS, TECHNOLOGY OR SERVICES. HIGH

VOLTAGE SHALL HAVE NO LIABILITY FOR ANY FAILURE OR DELAY DUE TO MATTERS

BEYOND ITS REASONABLE CONTROL.

This manual suits for next models

1

Table of contents

Popular Inverter manuals by other brands

Sofar solar

Sofar solar SOFAR 3KTLM-G3 Installation and operating manual

CO/Tech

CO/Tech ig2400s Original instructions

Power Drive

Power Drive PD3000 owner's guide

Delta

Delta M250HV Installation and commissioning instructions

Sofar solar

Sofar solar 7KTLM-G3 user manual

MQ Power

MQ Power WHISPERWATT Series Operation manual

FRONIUS

FRONIUS Symo GEN24 3.0 operating instructions

FRONIUS

FRONIUS Primo installation instructions

Global Sources

Global Sources Stepup-Tech GTB Series quick start guide

i-MO

i-MO Jaguar VXM instruction manual

APsystems

APsystems QS1 Installation and user manual

FRONIUS

FRONIUS Symo GEN24 quick start guide