Highland Supercell User manual

Lithium-ion powered electrofusion processor

TM

Operations Manual

3

TABLE OF CONTENTS

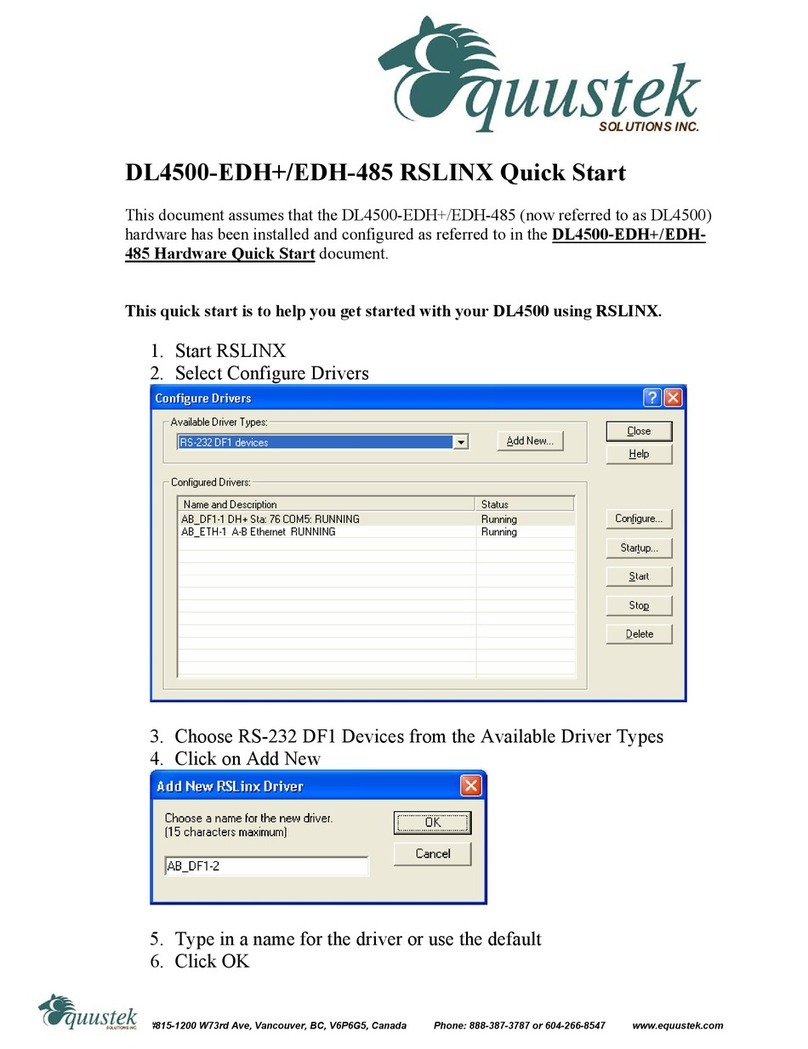

Operang Controls .................................................................4

Delivered Items ......................................................................5

Intended Use ..........................................................................5

Introducon............................................................................5

Product Specicaon ..............................................................6

Safety Notes ...........................................................................7

Electrical Safety ......................................................................8

Transport of Dangerous Goods ...............................................9

Capacity ................................................................................10

Baery Charging ...................................................................10

Using the Equipment – Screen Symbols ...............................12

Using the Equipment – On / O ...........................................13

Using the Equipment – Barcode Welding .............................14

Using the Equipment – Manual Welding ..............................17

Using the Equipment – Checking Baery Capacity ..............20

Using the Equipment – Main Menu .....................................20

Using the Equipment – Downloading Data Log ....................21

Using the Equipment – View Logs ........................................22

Using the Equipment – View Details ....................................23

Service and Calibraon .........................................................24

Fault Finding .........................................................................24

Hardware Reset ....................................................................29

Disposal – End of Life ...........................................................30

Warranty ..............................................................................31

Repair ...................................................................................33

8 Helpful Tips ........................................................................34

4

OPERATING CONTROLS

5

DELIVERED ITEMS

Carefully remove the welding processor from its packaging and check that you have the follow-

ing items:

• Welding processor.

• Wireless bar code scanner.

• Mains powered baery charger.

• +12V dc car charging lead.

• USB memory drive.

Note: to download a copy of this manual, visit www.supercellef.com

INTENDED USE

This equipment is intended to fuse constant voltage electrofusion ngs suitable for low, me-

dium, and high-pressure pipe work systems, up to a maximum diameter of 14 inch (355mm).

This welding processor has been designed to comply with the Internaonal Organizaon for

Standardizaon standard ISO12176-2:2000 “Plasc pipes and ngs, equipment for fusion

joinng polyethylene systems, part 2, electrofusion”.

INTRODUCTION

This manual gives instrucons on the correct assembly and safe use of your electrofusion pro-

cessor. It is important that you read these instrucons and always keep these instrucons with

the unit.

This manual does not detail the specic welding procedure for the ngs: peeling, clamping

and assembly of joints. For this informaon, please contact the ngs manufacturer or refer

to your organizaon’s internal procedures.

6

PRODUCT SPECIFICATION

Operang Type: Controlled voltage.

Operang Modes: Manual, Bar Code

Operang Languages: English, French, Spanish

(Others on request)

Operang Temperature: -4oF to 113oF #1

Welding Voltage: 8 to 48 V (39,5 V) (true rms)

Welding Current: 1 to 65 A (true rms)

Welding Power: 8 VA to 2600 VA

Welding Time: 1 to 3000 seconds

Data log memory: >10,000 welds (solid state internal storage)

Data download/upload: USB ash memory drive

Protecon Level: IP54

Weight: 30.8 lb

Size: 17.5” x 11.5” x 12”

Supply voltage: Lithium-Ion rechargeable baeries.

Baery charger.

Supply voltage: 100V to 240V

Supply Power: 550W (@ 240V)

#1 The baeries can only be charged between 32oF to 113oF.

Highland has a policy of connuously improving product design, and as such reserve the right

to change specicaon of its products without prior noce and with impunity.

7

SAFETY NOTES

• WARNING: RISK OF ELECTRIC SHOCK! Do not open. No user serviceable parts inside.

Only to be opened by an approved service agent.

• WARNING: RISK OF EXPLOSION! This electrofusion processor is NOT intrinsically safe

and must NOT be used in a gaseous atmosphere. Do not use this equipment in the

trench.

• WARNING: This product can expose you to chemicals which are known to the state of

California to cause cancer. For more informaon, visit www.p65warnings.ca.gov

• Before use, always visually inspect the unit to see that the cords and connectors are not

worn or damaged. Replace any damaged parts before use.

• Switch o before adjusng, cleaning, or if the cords are entangled and before leaving the

unit unaended for any period.

• To avoid damaging the unit, do not disconnect the output cables, while the unit is fusing.

• Do not li or pull the unit by its cords.

• Do not disconnect the output cables by pulling on them, always carefully pull o the

connectors from the ng using the integrated grips.

• Do not start a fusion without the pipe correctly inserted into the ng.

• Do not touch the ng while fusing.

• Do not operate the unit or leave the unit outdoors in precipitaon (rain, snow, hail,

etc…).

• Operate the unit in daylight or in good arcial light.

• The operator is responsible for accidents or hazards occurring to other people or their

property while using this equipment. Keep the work area safe!

• Keep bystanders a safe distance away from the machine while welding.

• Never allow people unfamiliar with these instrucons to use the electrofusion processor.

8

ELECTRICAL SAFETY

Supercell is baery powered and there is no requirement to carry out in-service electrical

tesng. However, baeries in equipment can potenally fail and cause res. Supercell must be

visually inspected for damage before each use.

The operator should carry out a visual inspecon of Supercell every me it is used. If the case

is split or broken, or any connectors are damaged, then the equipment must not be used, and

it should be returned to your distributor for immediate repair.

The wall powered charger requires addional tesng and is subject to both a visual inspecon

and an in-service electrical test.

The operator should carry out a visual inspecon on the charger every me it is used.

9

TRANSPORT OF DANGEROUS GOODS

Supercell contains a baery pack made from Lithium-ion baeries. These have been classied

by the United Naons as hazardous materials and been assigned to Class 9 - Miscellaneous

Hazard Classicaon.

Addionally, the United Naons Commiee of Experts on the Transport of Dangerous Goods

have classied them under UN 3481 Lithium-ion baeries contained in equipment.

The equipment has passed all relevant tests to allow it to be transported.

There is a requirement under UN3481 that the product is packaged and labeled correctly for

transport. Please save the original packaging in case the machine needs to be transported. It is

mandatory that the following label is aached to the outside of the packaging and the carrier

is informed that it contains Lithium-ion baeries.

If you do not have the original packaging, then please contact your distributor, or visit www.

supercellef.com/baeries for informaon on how to ship Supercell.

10

CAPACITY

Due to dierences in ng type and ng manufacturing, each ng will have dierent ener-

gy requirements for fusion. As such, capacity cannot be explicitly given. However, in tesng the

energy requirements of various ng types from various manufacturers, the expected capaci-

ty on a full baery charge is as follows:

1” ngs: 195 on a full charge

2” ngs: 74 on a full charge

3” ngs: 21 on a full charge

4” ngs: 8 on a full charge

6” ngs: 5 on a full charge

14” ngs: 1 on a full charge

Note: This is given as a guide only, and exact capacity will depend on a range of factors.

BATTERY CHARGING

IMPORTANT. Supercell can only be charged at temperatures between 32°and 113°Fahren-

heit. If the baery pack is above 113F then you must allow it to cool before charging.

An exclamaon mark will be shown on the baery to signify it is too hot.

Keep the charger dry at all mes. Do not charge in the rain.

Do not use the charger if it is damaged.

Supercell will only charge when it is turned o.

The charger will become hot with prolonged use.

11

Supercell can be charged using two methods:

• using the wall charger connected to the 120V/240V wall power, or a 120V/240V vehicle

mounted inverter.

• using the +12V dc charger cord, connected to a 12V vehicle auxiliary socket.

Wall Charger

1. Make sure Supercell is turned o, (hold the red stop buon in for 3 seconds to power o

the machine).

2. Plug the charger into the wall and power it on. The green light will ash once per sec-

ond.

3. Plug the charger output into the charging socket of Supercell.

4. The charger’s indicator light will turn solid red, and the baery pack will start to charge.

5. The baery pack will charge from 0% to 100% in approximately 90 minutes (on 120V).

When charging is complete, the charger’s indicator light will turn solid green.

6. Power o the charger and unplug it. CAUTION: the charger will become hot with extend-

ed use.

7. If the charger’s indicator light ashes red while charging, then there is a fault with either

the charger or Supercell. Contact your distributor for help.

8. If the baery pack exceeds 113°F while charging, Supercell will detect this and halt

charging, and the light will go solid green. This will happen even if the baery pack is not

completely charged. Turn Supercell on and check the charge percentage to make sure

the charge completed.

+12V Auxiliary charger.

1. Make sure Supercell is turned o, (hold the red stop buon in for 3 seconds to power o

the machine).

2. Plug the charger cord into the 12V auxiliary socket of the vehicle.

3. Plug the charger into the charging socket of Supercell.

4. The baery pack will start to charge. There is no indicaon of charge.

5. The baery pack will charge from 0% to 100% in approximately six hours.

6. To check the state of charge of the baery pack, turn Supercell on and check the baery

percentage. If it is not fully charged turn Supercell o to resume charging.

12

USING THE EQUIPMENT – SCREEN SYMBOLS

The le-hand side of the screen shows prompts to the operator for the next steps that need to

be taken, in this example, connect the welding cord to the ng or press the star key for the

menu. The right-hand side shows informaon icons. In this example the baery is at 98%, the

me is 13:00, the GSM radio is disconnected (if ed) and the Blue Tooth is disconnected.

The right-hand side can also show symbols such as press the Start buon:

In this example buons A, B or C can be pressed:

This shows the ng welding icon:

13

USING THE EQUIPMENT – ON / OFF

Turning the machine ON.

To turn the machine on, press and hold in the green START buon for three seconds. The dis-

play will show:

The manufacturer logo.

The product name.

The owner details.

The main screen.

Turning the machine OFF.

To turn the machine on, press and hold in the red STOP buon for three seconds. The display

will turn o.

The machine will auto power o aer ve minutes of inacvity.

14

TEMPERATURE MEASUREMENT

The processor’s temperature sensor is located on the side of the enclosure. The temperature

sensor does not respond immediately to thermal changes. To assure accurate ambient tem-

perature measurements, the output cable end should be le in the ng environment for

at least 15 minutes. Direct exposure to sun light and other heat sources will adversely aect

accuracy.

TEMPERATURE COMPENSATION

When using the Highland Electrofusion Processors in Barcode Fusion Mode or Manual Barcode

Mode, to fuse ngs that require temperature compensaon it is essenal that care be given

to ensure that the correct inial fusion temperature is measured. The processor will automat-

ically adjust the fusion me per the measured temperature as specied by the fusion parame-

ters.

THE PROCESSOR WILL NOT AUTOMATICALLY COMPENSATE FUSION TIME IN MANUAL MODE

USING THE EQUIPMENT – BARCODE WELDING

Make sure that a barcode scanner/dongle is aached to the USB port.

Connect the output leads to the ng.

Scan the barcode on the ng. If this doesn’t read, then the numbers can be entered by press-

ing the A key.

When the barcode is read correctly this screen is shown.

15

The capacity of the baery is checked and the number of this type of ng that can be fused

is shown.

The resistance of the ng is checked with the barcode to make sure the right code has been

scanned.

Scan the traceability code on the ng or press the A key to move on.

The ng details are shown. Press the green START buon to begin fusion.

A couple of seconds aer the start, the calibraon is checked. This is the smart-calibraon

check.

16

As fusion progresses, the welding voltage and current are shown.

The me counts down to zero and the clock on the graphic lls up to show the fusion progress.

When fusion is complete the cooling me is shown. Allow to complete or press the A key to

skip.

At the end of the cooling me, the fusion number is shown.

Disconnect the output leads from the ng to reset the machine.

17

USING THE EQUIPMENT – MANUAL WELDING

Make sure that a barcode scanner/dongle is NOT aached to the USB port or, during the bar-

code fusion opon, press the B key when the scan ng message is shown.

Connect the output leads to the ng.

Enter the fusion me and press the A key.

Enter the fusion voltage. Press the D key to select 39.5 volts.

When the voltage is entered, press the A key.

18

The capacity of the baery is checked and the number of this type of ng that can be fused

is shown.

The ng details are shown. Press the green START buon to begin fusion.

A couple of seconds aer the start, the calibraon is checked. This is the smart-calibraon

check.

As fusion progresses, the welding voltage and current are shown.

The me counts down to zero and the clock on the graphic lls up to show the fusion progress.

19

When fusion is complete the cooling me is shown. This will count upwards, press the A key to

stop.

At the end of the cooling me, the fusion number is shown.

Disconnect the output leads from the ng to reset the machine.

20

USING THE EQUIPMENT – CHECKING BATTERY CAPACITY

If you want to know what capacity the baery has or if you can fuse a specic ng, scan the

ng barcode and the required energy will be checked from a lookup table held in memory.

When the screen shows connect ng, with no ng aached to the output leads, scan the

ng barcode.

The capacity for this type of ng is shown.

USING THE EQUIPMENT – MAIN MENU

When the screen shows, press the star key to enter the main menu.

Three opons are shown on the screen. Use the B and C keys to select the required opon

then press A.

21

USING THE EQUIPMENT – DOWNLOAD DATA LOG

Select data download from the menu.

Select the data download type. The default is 1: Encrypted. This requires supporng soware

to view. Visit www.supercellef.com for more informaon

Opon 2 is an unencrypted XML which can be viewed using most spreadsheet soware.

Insert a USB memory drive into the USB port on the machine. You may have to remove the

barcode dongle rst.

The data log will start to download.

I

Table of contents