Hill EC3000 Operator's manual

EC3000 PORTABLE AIR COMPRESSOR

USER INSTRUCTION MANUAL

Rev 4.04

April 2020

Rev 4.06

May 2020

IMPORTANT

THIS PRODUCT IS DESIGNED TO FILL PRE-CHARGED PCP AIR GUNS AND PAINTBALL GUNS

DIRECTLY. IT CAN ALSO BE USED TO TOP UP SMALL BOTTLES.

LARGE CYLINDERS/TANKS SHOULD ONLY BE FILLED BY COMPETENT/QUALIFIED PEOPLE.

NOT FOLLOWING THE INSTRUCTIONS OR MISUSE OF THE COMPRESSOR WILL VOID YOUR

WARRANTY AND MAY RESULT IN DEATH OR INJURY

DANGER OF EXPLOSION

DO NOT EXCEED MAXIMUM FILL PRESSURE OF YOUR BOTTLE AT ROOM TEMPERATURE.

ONLY FILL BOTTLES THAT ARE IN GOOD CONDITION AND ARE IN DATE OF INSPECTION.

IMPORTANT

READ ALL INSTRUCTIONS BEFORE USE.

TO PROTECT YOURSELF YOU SHOULD ALWAYS WEAR

SAFETY GLASSES AND EAR PLUGS WHEN OPERATING THIS

COMPRESSOR

WARNING

THIS COMPRESSOR PRODUCES CLEAN AIR SUITABLE FOR FILLING PCP AIRGUNS.

IT DOES NOT PRODUCE AIR SUITABLE OR CERTIFIED FOR BREATHING APPARATUS

NOT USE IT TO FILL SCUBA TANKS THAT MAY LATER BE USED FOR BREATHING.

Contents

3

4-5

5-8

9

9

9

9

Parts Included

Set Up

Operating Instructions

Troubleshooting

Closedown

Storage

Maintenance

DANGER

FROM OVERFILLING OF COMPRESSED AIR BOTTLES

1x EC-3000 Compressor

1x Power Cable

1x High Pressure Filling Hose 1/8” and male Quick Release Coupling

1x Hill A73 Crank Oil

1x Hill A72 Silicone Oil

3

Parts Included

With the compressor positioned on a level surface,

check that the oil level meets the

red dot on the sight glass.

Top up as necessary using the following:

Remove redcap - screw anti-clockwise

4

CAUTION - please read and understand the following instructions before use.

CAUTION - ONCE YOU HAVE CORRECTLY FILLED THE COMPRESSOR

WITH LUBRICANTS, THE COMPRESSOR MUST BE KEPT UPRIGHT AND

LEVEL AT ALL TIMES. ENSURE THE COMPRESSOR IS USED ON A NON-SLIP

FLOOR, PREFERABLE SAT ON ANTI-SLIP MATTING. IF THE COMPRESSOR

IS TO BE MOVED OR TRANSPORTED FOR STORAGE OR MAINTENANCE,

ENSURE ALL LUBRICANTS ARE DRAINED FIRST.

1. Oil Level

Slowly squeeze the A73 crank oil into the

exposed hole until the lubricant level meets the

red dot in the sight glass this should use more or less

the complete bottle

DO NOT MIX CRANK OIL AND SILICONE OIL AND DO NOT OVERFILL

After an oil change or fill...

Leave the oil to settle for 5 mins, if the oil level drops

below the red dot apply more oil until the oil level

is maintained

Replace the red cap until finger tight

Set Up

Remove blue cap - screw anticlockwise

Slowly squeeze the Hill A72 Silicone Oil through the exposed hole until the oil reaches the

limit indicated on the reservoir by the blue line

DO NOT MIX CRANK OIL AND SILICONE OIL

Replace blue cap until finger tight

3. Power connection and Operating Instructions

Connect filling probe to hose, ensure spanner tight or use Quick Release Coupling fitted

2. Silicone Lubricant Level

Fill the lubricant reservoir using the following:

5

Connect filling probe to bottle or gun and ensure spanner tight

Ensure bleed screw is closed (finger tight)

CAUTION: If using a quick release release coupling,

always check and make sure the collar on the female

quick disconnect is in the forward position and secure

on the male fitting you are connecting it to. It is

recommended that you check the connection by attempting

to pull the female and male ends apart while the collar

on the fitting is in the forward position before pressurising.

Insert power cable into pump

Please avoid using any electrical extension leads if possible. However, if you must use a 3rd

party extension lead, this must be as short as possible and must be rated to a minimum of

110v/16A or 230v/13A depending on your local power supply. If unsure, please determine

what your local power supply is before operating the compressor.

...before requesting confirmation that the lubricant levels have been checked and are

correct.

Press the rotary control knob

to confirm the lube check.

The screen will briefly show the Hill logo, the software version and the accumulated running

hours...

6

Switch compressor on

Rotate the knob again to alternate between BAR,PSI and MPa. When you have chosen the

unit of measure, press the control knob to confirm. The chosen unit of measure will be retaine

d for future use even when the compressor is switched off. This can be changed at any time.

To return to the “set pressure” screen, rotate the knob anticlockwise and press to confirm.

The display will then change to “set pressure”. A default pressure of 100BAR (1450PSI/10MPa)

is displayed.

If you are using the compressor for the first time, the unit of measure will display in BAR.

To change the unit of measure to PSI or MPa, rotate the control knob clockwise and press

to confirm

To set the pressure, rotate the control knob clockwise to

increase the fill pressure required. When you reach the

desired pressure, press the control knob to confirm.

The maximum pressure that can be set is 300BAR

(4350PSI/30MPa). DO NOT SET THE COMPRESSOR ABOVE THE MANUFACTURER’S

RECOMMENDED PRESSURE FOR THE BOTTLE YOU ARE FILLING. As a safety feature the

target pressure is not retained and will require resetting each time.

Rotate the control knob to reach the start display

Press the control knob and the compressor will commence filling.

The display will show the operating temperature, the current

working pressure and the target set pressure.

You can manually pause the filling at any time by pressing the

rotary control knob once, the display will show “Fill Abort?”

You can either confirm the fill abort by depressing the control

knob once more or to resume the fill,

rotate the control knob once more to show “Fill Resume”

and then press the knob to confirm.

The compressor is programmed to only operate within a pre-set

temperature range. The compressor will automatically pause if

the working temperature exceeds this pre-set. This is normal

and no operator intervention is required. The display will show

the progress of the cooling cycle and when the working

temperature falls below the pre-set the compressor will restart. If you are filling a larger b

ottle, this could happen multiple times. You can abort the fill at any time within the cooling

cycle if required.

DO NOT disconnect the bottle until the compressor has been depressurised.

Depressurise by unscrewing the bleed screw. Whilst

depressurising, the compressor may expel some moisture and

silicone from the moisture trap. Suitable precautions should be

taken to protect any floor coverings under the compressor.

When the target pressure is reached the display will show

“Fill complete” along with confirmation of the achieved pressure

and the target pressure.

7

The display will show the progress of the depressurisation

until it confirms depressurised. You can then disconnect

the bottle.

8

The display will revert to the “set required pressure screen”.

The compressor will occasionally automatically stop and request that you check the lubricant

levels. The compressor will not restart until you press the control knob. At this time you must

bleed the moisture trap. If connected to a bottle without a nonreturn valve, close the valve

on the bottle and bleed the EC3000 using the bleed screw at the bottom of the silver moisture

trap. If your rifle or bottle has a non return valve you can just bleed the EC3000 as above.

If in a very humid part of the world, you will need to bleed the moisture trap more often.

DO NOT LEAVE THE COMPRESSOR UNATTENDED WHEN IN USE!

IN THE UNLIKELY EVENT THAT YOUR COMPRESSOR MALFUNCTIONS, DO NOT

ATTEMPT TO FIX THE PROBLEM YOURSELF. PLEASE CALL THE DISTRIBUTOR

YOU PURCHASED IT FROM.

PLEASE RETAIN THE ORIGINAL RECEIPT OF PURCHASE

The most up to date version of this instruction manual will be available at:

www.airriflepump.com Please check this website regularly

PARTS OF THIS COMPRESSOR GET VERY HOT. DO NOT TOUCH THESE HOT PARTS

DO NOT TOUCH MOVING PARTS, FOR EXAMPLE THE COOLING FAN.

KEEP FINGERS AND LOOSE CLOTHING AWAY FROM MOVING PARTS

WARNING

DANGER

WARNING

DANGER OF ELECTRIC SHOCK

DO NOT OPERATE OUTSIDE IN THE RAIN

DO NOT OPERATE WITH WET HANDS OR WET CLOTHES

DANGER

This compressor features 5000psi burst disks for backup over-pressure protection. These burst disks can be

replaced with equal or lower pressure burst disks if required but NOT with higher pressure ones. Always

ensure appropriate measures are in place to prevent over-pressurisation of vessles.

Make sure that the power cable is inserted correctly and that the

compressor is switched on, check that the fuse in the switch has

not blown.

- Pressure does not exceed 50BAR and air escapes from the Pressure

Relief Valve

- Pressure achieved in the bottle is lower than the target pressure

With the bleed screw open, run the compressor for 5 mins and then

attempt another fill. If the problem persists contact your retailer..

Bottle valve may cause small pressure loss, adjust pressure on

compressor to compensate.

Shutting the compressor down

Make sure that the cylinder is removed and bleed screw is opened to release

pressure.

Maintenance

Change crank oil every 50 running hours or once yearly (whichever comes

first)

Unscrew sight glass to change Crank Oil (make sure you have a

suitable container underneath) and drain.

Regularly check that the Silicone lubrication is free from dirt and

debris

Troubleshooting

9

Storage

- Compressor will not start

Keep upright at all times

ERNEST H. HILL LIMITED

L

ONGACRE WAY - HOLBROOK - SHEFFIELD S20 3FS - ENGLAND

T

elephone; +44 (0) 114 248 4882

www.hillpumps.com sales@hillpumps.com

Other manuals for EC3000

1

Table of contents

Other Hill Air Compressor manuals

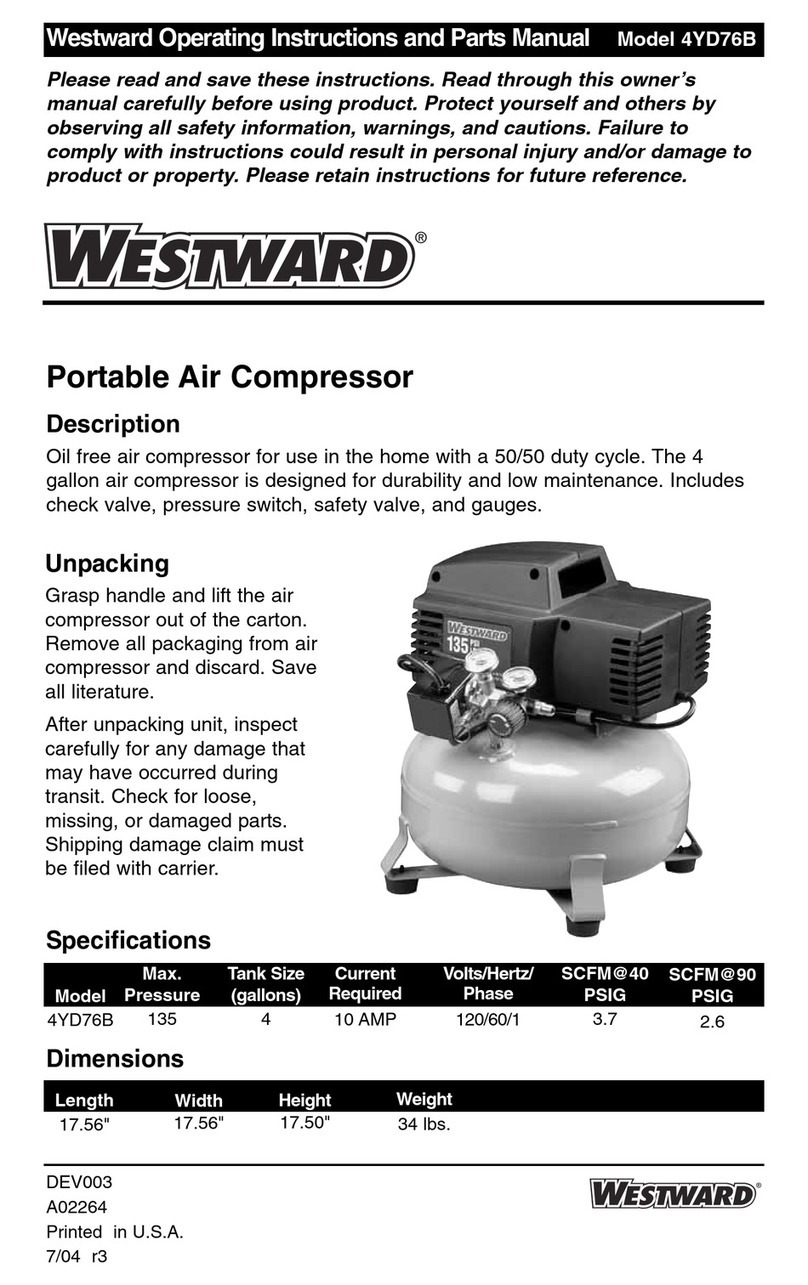

Popular Air Compressor manuals by other brands

Clarke

Clarke RAIDER 15/1000 Operation & maintenance instructions

Sparmax

Sparmax TC-610H user manual

Oshkosh Corporation

Oshkosh Corporation IMT CAS40P Installation, Operation, Maintenance & Parts Manual

Conrad

Conrad 85 66 48 operating instructions

DeWalt

DeWalt D55684 instruction manual

Welbilt

Welbilt Multiplex APKV3D Installation, operation and maintenance manual