Hirschmann Manitex vSCALE D3 User manual

vSCALE D3

Operating console

SLI system

Manitex Telescopic Crane Contents

Safety instructions 1

Product description 2

Installation / Wiring 3

Commissioning 4

Operation 5

Maintenance / Repair 6

Appendix 7

User manual

Issue B - 03/2012

This document has the order no.

50-700-19-2001_422175_en

Pub Mtx p/n: 7600004-023

Date: April 2012

For System: 4800850-001

TABLE OF CONTENTS

1Safety instructions...........................................................................................6

1.1 EC conformity declaration ............................................................................6

2Product description..........................................................................................7

2.1 Product identification ....................................................................................7

2.2 Use for the intended purpose.......................................................................8

2.3 Overview of functional elements...................................................................9

3Installation and wiring....................................................................................10

3.1 Installation...................................................................................................10

3.1.1 Surface mounting.................................................................................10

3.1.2 Recessed mounting .............................................................................11

3.2 Electrical connection...................................................................................14

3.2.1 Central connector –X1 .........................................................................15

3.2.2 Ethernet connection.............................................................................16

3.2.3 Camera connection (optional)..............................................................16

4Commissioning...............................................................................................17

4.1 Switching device on and off........................................................................17

4.2 Adjust SLI to latest set-up status................................................................19

4.3 Zero point adjustment of sensors...............................................................24

4.3.1 Zero point adjustment of the main boom angle sensor........................26

4.3.2 Zero point adjustment, slewing angle sensor.......................................27

4.3.3 Sensor adjustment, main boom length sensor.....................................28

4.3.4 Zero point adjustment of inclination sensor (X/Y) on superstructure...29

5Operation.........................................................................................................30

5.1 Functional elements....................................................................................31

5.2 SLI main menu............................................................................................32

5.2.1 Function keys (soft keys) .....................................................................33

5.2.2 Warning lights / acoustic alarm............................................................34

5.3 SLI setup.....................................................................................................35

5.4 Illustrated overview of crane configurations...............................................36

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 2/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

5.5 Working area monitoring.............................................................................37

5.5.1 Height monitoring.................................................................................38

5.5.2 Radius monitoring................................................................................39

5.5.3 Luffing angle monitoring.......................................................................40

5.5.4 Slewing angle monitoring.....................................................................41

5.6 Fade in live video image (optional).............................................................42

5.7 Inclination display .......................................................................................43

5.8 Load taring..................................................................................................44

5.9 Switching off alarm .....................................................................................44

5.10 Info menu....................................................................................................45

5.10.1 Status of digital inputs..........................................................................46

5.10.2 Readings of CAN bus sensors.............................................................47

5.10.3 Status of digital outputs........................................................................48

5.11 Service menu..............................................................................................49

6Maintenance and Repair................................................................................50

7Appendix .........................................................................................................51

7.1 Technical data ............................................................................................51

7.2 Error codes table........................................................................................52

VERSION OVERVIEW

Issue Date Description Editor

A 2012-03-08 First issue for Manitex telescopic crane application

Translation from the original german manual:

Issue A (2012-02-24) - rk

R. Konopka

B 2012-03-13 Corrections R. Konopka

Hirschmann Automation and Control GmbH

Hertzstr. 32-34

76275 Ettlingen

Phone +49 7243 709-0

Germany

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 3/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Introduction

INTRODUCTION

This manual is a component of the equipment or system supplied by Hirschmann Automation and

Control GmbH. Keep this manual in a safe place and ensure that it is available to all users.

About this manual

The contents of this manual are subject to change. Hirschmann Automation and Control GmbH

does not provide any guarantee for this material, including the associated guarantee regarding

marketability and suitability for certain intended purposes. Hirschmann Automation and Control

GmbH accepts no liability for errors in the contents of the manual or for direct or indirect damage in

connection with the provision and use of the manual.

Liability disclaimer

This manual is protected by copyright. All rights reserved. The manual may not be duplicated,

reproduced or translated into another language, either wholly or partly, without the prior written

permission of Hirschmann Automation and Control GmbH.

Copyright notice

The rendition of common names, trade names, trademarks etc. in this documentation should not be

construed to mean that such names, even without special identification, are free in the sense of

trademark and trademark protection legislation and hence usable by anyone.

Trademarks

This device / system is intended exclusively for the tasks described in this manual. Any other use

shall be construed as being inappropriate. The manufacturer accepts no liability for damage caused

by inappropriate or impermissible use. This device / system may only be used if it is in perfect

technical condition.

Use for the intended

purpose

Only appropriately qualified personnel may work with this device / system, i.e. persons:

Qualification of the

operating personnel who are familiar with the operation or installation and commissioning

who know the current regulations for the prevention of accidents

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 4/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Introduction

Marking of notices

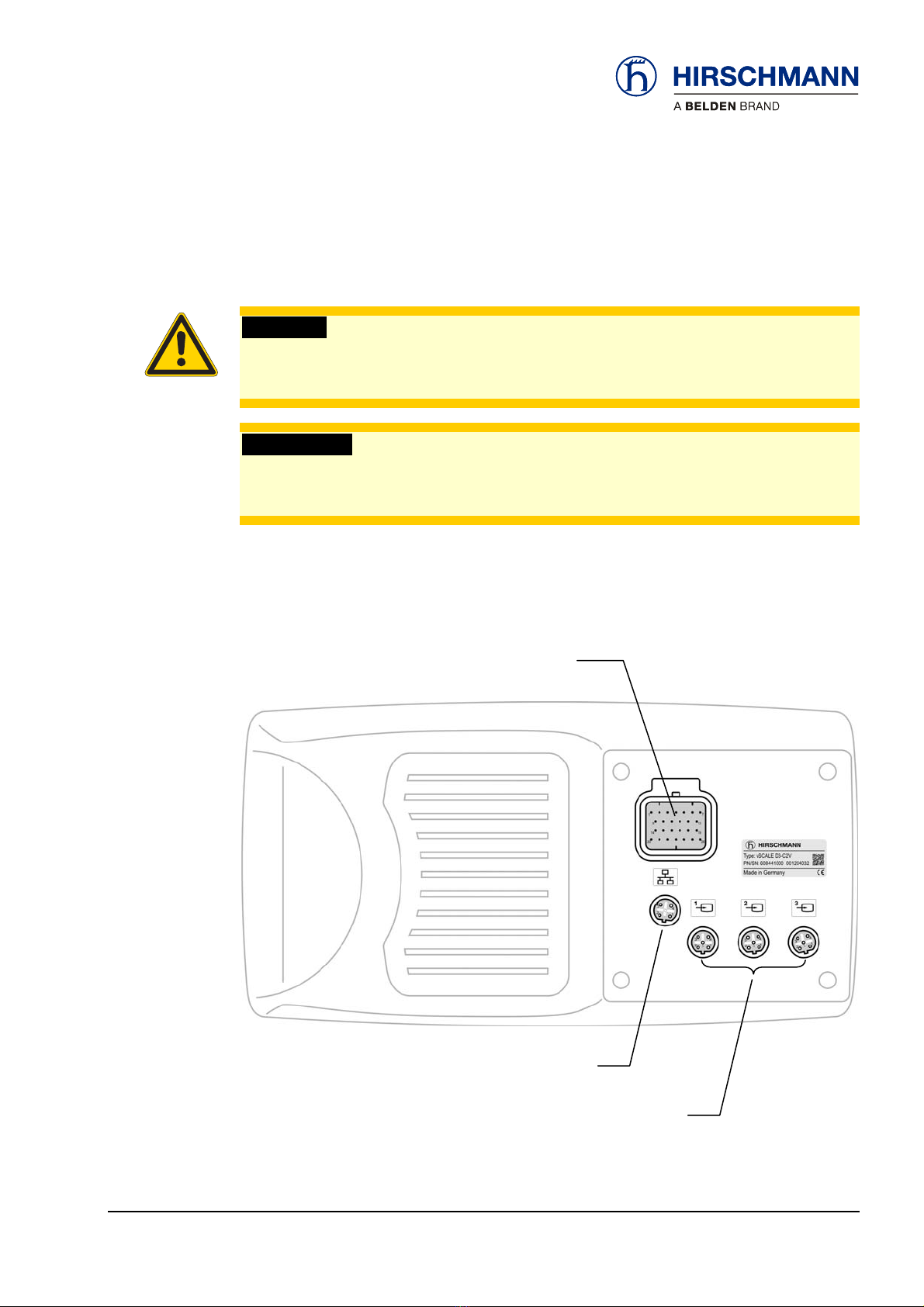

Dangers and other important notices are marked as follows in this user manual:

WARNING

Warning of direct threat of personal injury and damage to property.

Instructions on precautions to avert the danger.

CAUTION

Warning of dangerous situations. Also warns of damage to property.

Instructions for averting the danger.

IMPORTANT

Warning of possibly damaging situation for the product.

Instructions for avoiding the possibly damaging situation.

NOTE

Usage instructions and information, but no dangerous situation.

HINT

Supplementary comments and recommendations for the user.

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 5/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Safety instructions

1 Safety instructions

WARNING

Imminent threat of personal injury and damage to property due to incorrect system settings!

The correct adjustment of the SLI to the current set-up status is essential for the correct

function of the system and of the crane.

The SLI can only operate correctly if all settings are entered correctly according to the

current set-up status during the SETUP procedure.

The settings can only be carried out by operators who are completely familiar with the

operation and functions of the crane and the SLI.

The correctness of these settings must be guaranteed before starting the crane operations!

IMPORTANT

Connection to the wrong power supply will cause damage to the device.

The device may only be connected to a DC voltage source of 10 V to 30 V!

1.1 EC conformity declaration

The technical design and construction of the vSCALE D3 console corresponds to requirements of

the EMC directive 2004/108/EC and therefore carries the CE symbol.

The device complies with the following harmonised standards:

EN 12895:200, EN 13309:2010, EN ISO 14982: 2009

The full conformity declaration is available from the manufacturer on request.

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 6/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Product description

2 Product description

The vSCALE D3 console is the operable component of the programmable safe load indicator,

referred to below as the “SLI”. The SLI detects the readings from different sensors and recognises

crane overload statuses depending on further parameters. Visual and acoustic signals alert the

user of the overload status.

The SLI comprises:

a cSCALE S6 central control unit

the vSCALE D3 display and operating console

various sensors for detection of readings

The control unit, sensors and operating consoles are installed in suitable positions onto or inside

the crane.

The vSCALE D3 console is used for:

programming and inputting operating parameters

displaying the current crane operating data

This user manual contains information about installation, commissioning, operation and sensor

calibration and about repairs and maintenance.

Scope of manual

2.1 Product identification

The type plate carries the unique identification of the operating console. It is located on the back of

the device.

Please ensure you make a note of all the information on your type plate for queries about this

product.

Type plate

(Example)

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 7/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Product description

2.2 Use for the intended purpose

The vSCALE D3 is the operable component of the safe load indicator (SLI).

The SLI detects a crane overload status depending on various parameters.

The crane driver is warned well before the onset of an overload status via visual and acoustic

warning signals.

Although the system has signal outputs to switch off the crane movements which increase the load

moment, this power-off should only be effective with corresponding external wiring.

Although the system incorporates functions for monitoring adjustable geometrical limit values with

visual and acoustic warnings and a relay output in the event of limit values being exceeded, the

system cannot be used as an operational limit switch.

The crane driver is responsible for the safe operation of the crane.

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 8/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Product description

2.3 Overview of functional elements

1 TFT colour display

2 Function keys F1 - F12

3 Light sensor and status displays (LED)

4 Rotary control (encoder) with pushbutton function

5 Function key (SYSTEM) for system settings (not used here)

6 Function key (Home) for return to SLI main menu

7 Function key (Esc) for return or abort (not used here)

8 Front- USB 2.0 interface (use for service purposes)

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 9/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Installation and wiring

3 Installation and wiring

This chapter contains instructions for mounting and installation of the console.

For the electrical wiring of the system and the console, please refer to the relevant connection and

wiring diagram, which is not part of this manual.

3.1 Installation

The console is intended for vertical surface mounting or recessed mounting. Depending on

installation type, corresponding installation accessories are required which may be supplied with

the device depending on the version type.

3.1.1 Surface mounting

For surface mounting you will require the optionally available installation adapter and the RAM

Mount articulated mounting.

RAM Mount

(Art. no. 320795)

Installation

adapter

(Art. no. 608464)

4 pcs.

screw M5x12

(Art. no. 300990)

4 pcs.

washer 5.3

(Art. no. 320795)

3 pcs.

screw M5x12

(Art. no. 300990)

3 pcs.

washer 5.3

(Art. no. 320795)

ball head 38mm (1.5“)

(part of RAM Mount)

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 10/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Installation and wiring

3.1.2 Recessed mounting

An installation frame, which is available as an accessory, is provided for recessed mounting in

operating panels or instrument panels.

Installation frame: Art. no. 608465

NOTE

Please note that the material thickness of the operating panel may not exceed 10 mm!

Installation frame

4 off M5 x

(see table for length)

Material

thickness Screw length

1…3 mm M5 x 12

4…6 mm M5 x 16

7…10 mm M5 x 20

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 11/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Installation and wiring

The dimensions for the cut-out in the operating panel can be taken from the following sketch:

Cut-out dimensions

On request you can also print out the templates (last page in this manual).

Template

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 12/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Installation and wiring

4 x M5 screws, DIN EN ISO 4762 (DIN 912) and matching spacers are used for mounting of the

installation frame.

Installation

Installation frame

IMPORTANT

Console could be damaged by use of screws of the wrong length and excessive torque!

Note the screw length information in the following overview.

The maximum screw tightening torque is 1 Nm.

The length of the screws depends on the material thickness of the operating panel:

Material thickness 1 to 3 mm: M5 x 12 4 to 6mm: M5 x 16 7 to 10 mm: M5 x 20

4 off

spacers

Length:

Material thickness

+0.5 mm

4 off M5 screws,

DIN EN ISO

4762 (DIN 912)

Length:

Depending on

material thickness

secure screws with e.g. Loctite 243!

max. ti

g

htenin

g

tor

q

ue 1 Nm!

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 13/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Installation and wiring

3.2 Electrical connection

The electrical wiring for the system and the console can be found in the current connection and

wiring diagram for your crane. It is not included in this manual.

CAUTION

Danger of electrical short-circuits.

Switch off all systems before commencing with the installation work!

IMPORTANT

Connection to the wrong power supply will cause damage to the device.

The device may only be connected to a DC voltage source of 10 V to 30 V!

Connections and interfaces can be found on the back of the device. You need to remove this first if

using the installation adapter.

Camera connector 1-3

Central connector -X1

Ethernet connection

Back of device

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 14/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Installation and wiring

3.2.1 Central connector –X1

The central connector –X1 contains terminals for the power supply, ignition, grounds,

CAN-Bus (1 and 2), USB, RS232 and further signals.

Connector kit: 1x connector, 26x crimp contacts, 26x dummy plug Art. no. 536276

Matching counter-

connector parts Crimping tool: special tool Art. no. (on request)

Connector overview

1 Vcc +8…36 V (terminal 30) 14 USB D-

Pin assignation 2 Ignition (terminal 15) 15 USB D+

3 GND (terminal 31) 16 RS232 RxD

4 Chassis GND 17 RS232 TxD

5 n.c. 18 RS232 GND

6 n.c. 19 AI/DI 3 (optional)

7 n.c. 20 AI/DI 1 (optional)

8 CAN1 high 21 AI/DI 2 (optional)

9 CAN1 low 22 AI/DI 4 (optional)

10 CAN2 high 23 SERV_ENABLE

11 CAN2 low 24 DO 3

12 USB Vcc (+5 V) 25 DO 1

13 USB GND 26 DO 2

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 15/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Installation and wiring

3.2.2 Ethernet connection

There is an Ethernet interface available for programming purposes.

Patch cable, 5m, M12, 4-pin, <-> RJ45 Art. no. 325900

Matching counter-

connector parts

Connector overview

1 TD+

Pin assignation 2 RD+

3 TD-

4 RD-

3.2.3 Camera connection (optional)

Three video interfaces are available for integrating video signals.

Round connector M12, 5-pin, PIN, B-coded, according to EN 61076-2-101.

Cable available on request.

Matching counter-

connector

Connector overview

1 Video Signal +

Pin assignation 2 Camera Control

3 Camera +

4 Camera -

5 Video Signal GND

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 16/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Commissioning

4 Commissioning

This chapter contains information, advice and instructions for commissioning the device.

4.1 Switching device on and off

The load limiting device has no on/off switch. The console automatically switches on after

connecting the power supply and control voltage (ignition, terminal 15)

After boot-up the following appears on the display:

Device has been switched off

for longer than 2 hours Device has been switched back on

within 2 hours:

Display after

boot-up:

Carry out SETUP procedure next!

(See chapter 4.2)

If the crane configuration has not changed within

the last 2 hours, check displayed configurations.

If OK, confirm.

The SLI menu is then displayed.

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 17/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Commissioning

In the event of a system malfunction an error code is displayed in the bottom right of the display:

System malfunction?

The error codes and what they mean are explained in the error codes table in chapter 7.2.

The device is not ready for operation until all faults have been rectified and no error codes are

displayed.

If the console is not started as described, please contact your nearest service department.

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 18/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Commissioning

4.2 Adjust SLI to latest set-up status

The SLI must be adjusted to the current crane set-up status by completing the full SETUP

procedure after start-up (device has been switched off for longer than 2 hours) and after any

change to the crane configuration. The process is step-by-step and is menu-guided. Operation is

with the rotary control.

SETUP procedure

The system is not ready to operate until the full SETUP procedure has been completed.

WARNING

Imminent threat of personal injury and damage to property due to incorrect system settings!

The correct adjustment of the SLI to the current set-up status is essential for the correct

function of the system and of the crane.

The SLI can only operate correctly if all settings are entered correctly according to the

current set-up status during the SETUP procedure.

The settings can only be carried out by operators who are completely familiar with the

operation and functions of the crane and the SLI.

The correctness of these settings must be guaranteed before starting the crane operations!

Depending on the inputs during the SETUP procedure and on various sensor values, the system

automatically determines the corresponding operating mode with the associated lifting capacity

table. The operating mode used by the system at any one time is displayed as a code in the status

row:

Selecting operating

mode

Operating

mode code

The settings made during the SETUP procedure are saved for 2 hours. When the system is

switched back on, e.g. after a short interruption to the work, the settings need simply to be checked

and confirmed.

Saving settings

The process for setting the SLI to the current crane set-up status (SETUP procedure) includes the

following steps:

Process

Selecting the outrigger and support base

Selection of the boom configuration and fly jibs

Selection of the man basket / load block

Entering the number of rope reevings

Selection of hoisting winch

Overview of inputs

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 19/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Commissioning

Operation is with the rotary control:

Operation

Optionally press to confirm.

Back to previous menu option with

Calling up SETUP procedure from the SLI main menu:

Start SETUP

All inputs must correspond to the current set-up status of the crane!

Selection:

Crane operation with outriggers

Select outriggered

or on wheels

Crane operation on wheels

© 2012 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.hirschmann.com 20/59

50-700-19-2001_422175_en (Manitex)_Rev_B.doc / 2012-03-13 / Issue B / rk.

Table of contents

Other Hirschmann Music Mixer manuals