Hirschmann PAT IFLEX5 User manual

HIRSCHMANN

P/N 031-300-190-147 REV E- 11/12/2008

LOAD MOMENT INDICATOR

iFLEX5

vertical/horizontal console

OPERATOR’S MANUAL

© Hirschmann Rev. E 11/12/08 190147_E

NOTICE

PAT America, Inc. makes no warranty of any kind with regard to this material, including, but not limited

to, the implied warranties of merchantability and/or its fitness for a particular purpose.

PAT America, Inc. will not be liable for errors contained in this manual or for incidental or

consequential damages in connection with the furnishing, performance, or use of this manual. This

document contains proprietary information, which is protected by copyright, and all rights are reserved.

No part of this document may be photocopied, reproduced, or translated to another language without

the prior written consent of PAT America, Inc.

PAT America, Inc. reserves proprietary rights to all drawings, photos and the data contained therein.

The drawings, photos and data are confidential and cannot be used or reproduced without the written

consent of PAT America, Inc. The drawings and/or photos are subject to technical modification

without prior notice.

All information in this document is subject to change without notice.

MANUAL REVISIONS

REV DATE NAME DESCRIPTION

- 2/22/02 MO ECN 02-64

A 11/11/02 CH ECN 02-278

B 05/19/03 SB ECN 03-065

C 02/22/05 MS ECN 05-041

D 01/06/06 SB ECN 05-217

E 11/12/08 WG ECN 08-179

© 2006 Hirschmann, Chambersburg, PA 17201, USA

Operator's Manual iFLEX5

© Hirschmann Rev. E 11/12/08 190147_E

TABLE OF CONTENTS

1GENERAL INFORMATION.............................................................................................................1

2WARNINGS.....................................................................................................................................1

3SYSTEM DESCRIPTION ................................................................................................................2

3.1 SYSTEM FUNCTION ........................................................................................................................4

3.2 OPERATING CONSOLE ...................................................................................................................5

3.3 CONTROL IDENTIFICATION..............................................................................................................5

4CONFIGURATION SETUP ........................................................................................................... 11

4.1 LMI SETUP PROCEDURE..............................................................................................................11

4.2 QUICK SETTING OF THE REEVING.................................................................................................15

4.3 QUICK HOIST LINE SELECTION.....................................................................................................16

5OPERATION .................................................................................................................................17

5.1 LIMIT SETTING.............................................................................................................................20

5.1.1 Slewing Angle Limitation / Work Area Definition...........................................................21

5.1.2 Tip Height Limitation ........................................................................................................26

5.1.3 Boom Angle Limitation.....................................................................................................27

5.1.4 Radius Limitation..............................................................................................................29

5.1.5 Wind Speed .......................................................................................................................30

5.2 INFO CRANE CONFIGURATION ......................................................................................................31

5.3 DISPLAY CONTRAST CONTROL.....................................................................................................32

6PRE-OPERATION INSPECTION AND CALIBRATION VERIFICATION.....................................33

6.1 MACHINES WITH ONLY A MAIN HOIST............................................................................................33

6.2 MACHINES WITH MAIN AND AUXILIARY HOISTS .............................................................................33

6.3 INSTALLATION OF ANTI TWO-BLOCK RETAINER IN LOCKING POSITION ..........................................34

6.4 REMOVAL AND STORAGE OF THE ANTI TWO-BLOCK RETAINER.....................................................34

6.5 PRE-OPERATION INSPECTION AND CALIBRATION VERIFICATION ....................................................35

7SERVICE AND MAINTENANCE...................................................................................................36

8TROUBLESHOOTING ..................................................................................................................37

8.1 GENERAL ....................................................................................................................................37

8.2 MALFUNCTION TABLE ..................................................................................................................37

8.3 OPERATING ERRORS ...................................................................................................................38

9APPENDIX A: DETAILED SYMBOL EXPLANATION OF BOOM EXTENSIONS .......................40

10 APPENDIX B:DETAILED SYMBOL EXPLANATION OF COUNTERWEIGHT OPTIONS.......41

General Information

© Hirschmann Rev. E 11/12/08 190147_E

1

1 GENERAL INFORMATION

The PAT Load Moment Indicator1(LMI) has been designed to provide the crane operator with

the essential information required to operate the machine within its design parameters.

Using different sensing devices, the Load Moment Indicator monitors various crane functions

and provides the operator with a continuous reading of the crane’s capacity. The readings

continuously change as the crane moves through the motions needed to make the lift.

The LMI provides the operator with information regarding the length and angle of the boom,

working radius, rated load and the total calculated weight being lifted by the crane.

If non permitted conditions are approached, the Load Moment Indicator will warn the operator

by sounding an audible alarm, lighting a warning light and locking out those functions that may

aggravate the crane’s condition.

2 WARNINGS

The LMI is an operational aid that warns a crane operator of approaching overload conditions

and of overhoist conditions that could cause damage to equipment and personnel.

The device is not, and shall not, be a substitute for good operator judgment, experience and use

of accepted safe crane operating procedures.

The responsibility for the safe crane operation shall remain with the crane operator who shall

ensure that all warnings and instructions supplied are fully understood and observed.

Prior to operating the crane, the operator must carefully and thoroughly read and understand

the information in this manual to ensure that he knows the operation and limitations of indicator

and crane.

Proper functioning depends upon proper daily inspection and observance of the operating

instructions set forth in this manual. Refer to Section 6. Pre-Operation Inspection and

Calibration Verification of this handbook.

The LMI can only work correctly, if all adjustments have been properly set. For correct

adjustment, the operator has to answer thoroughly and correctly all questions asked

during the setup procedure in accordance with the real rigging state of the crane. To

prevent material damage and serious or even fatal accidents, the correct adjustment

of the LMI has to be ensured before starting the crane operation.

1LOAD MOMENT: generally the product of a force and its moment arm; specifically, the product of the load and the load-radius. Used in the

determination of the lifting capacity of a crane

Operator's Manual iFLEX5

© Hirschmann Rev. E 11/12/08 190147_E

2

3 SYSTEM DESCRIPTION

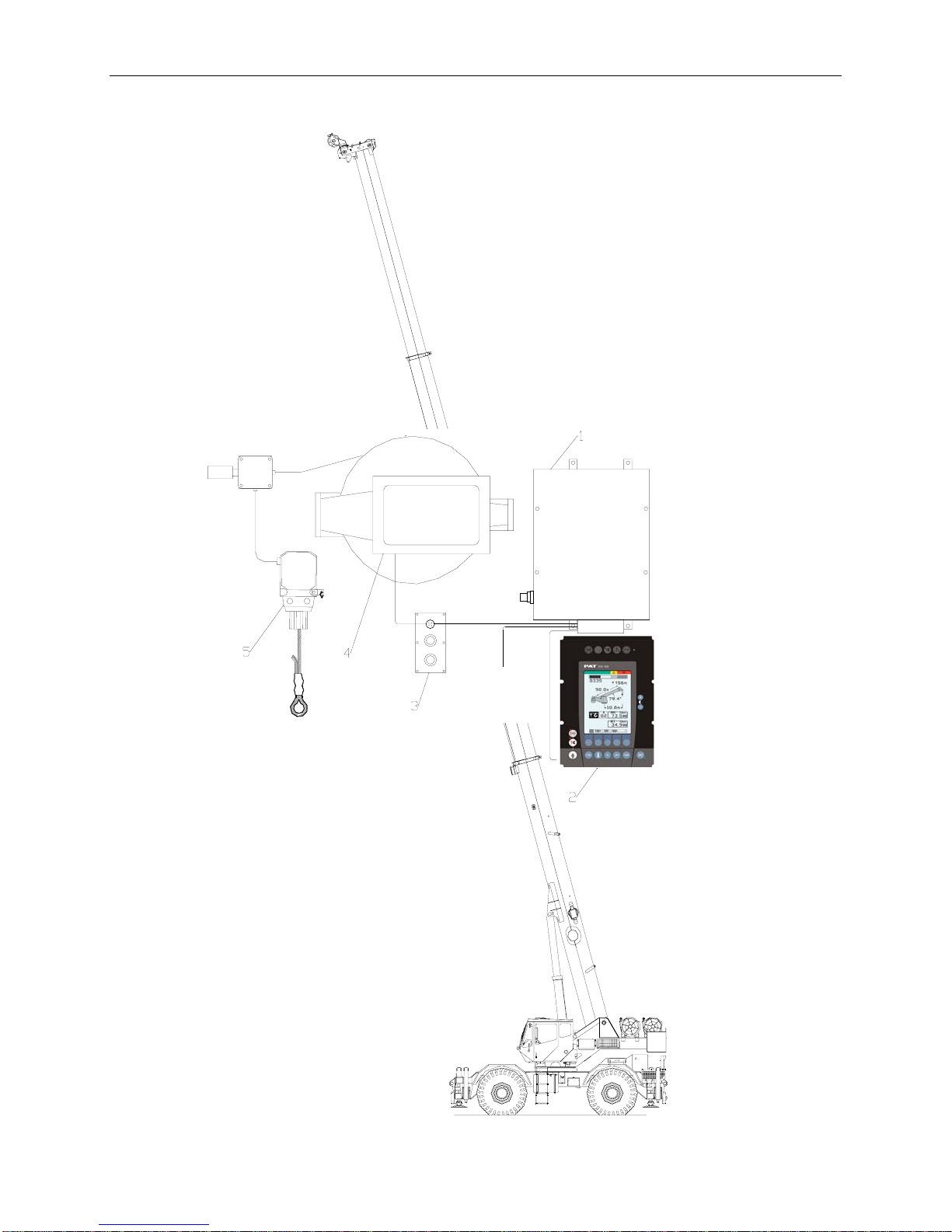

The PAT Load Moment Indicator consists of a central micro processor unit, operating console,

length/angle sensor, pressure transducers, and anti-two block switches.

The system operates on the principle of reference/real comparison. The real value, resulting

from the pressure measurement is compared with the reference data, stored in the central

processor memory and evaluated in the micro processor. When limits are reached, an overload

warning signal is generated at the operator’s console. At the same time, the aggravating crane

movements, such as hoist up, telescope out and boom down, will be stopped.

The fixed data regarding the crane, such as capacity charts, boom weights, centers of gravity

and dimensions are stored in memory chips in the central processor unit. This data is the

reference information used to calculate the operating conditions.

Boom length and boom angle are registered by the length/angle sensor, mounted inside the

cable reel which is mounted on the boom. The boom length is measured by the cable reel cable

which also serves as an electrical conductor for the anti two-block switches.

The crane load is measured by pressure transducers attached to the piston and rod side of the

hoist cylinders.

The interactive user guidance considerably simplifies the input of operating modes as well as

the setting of geometry limit values.

System Description

© Hirschmann Rev. E 11/12/08 190147_E

3

Fig. 1: Components of the LMI system PAT iFLEX5

1 Central-Micro-Processor Unit

2 Operating Console

3 Pressure Transducers

4 Length/Angle Sensor

5 Anti Two-Block Switch(es)

POWER

LOCKOUT

OTHER

PAT

Operator's Manual iFLEX5

© Hirschmann Rev. E 11/12/08 190147_E

4

3.1 SYSTEM FUNCTION

Upon switching on, the system starts with an

automatic test of the LMI system, of lamps

and audible alarm. During the test, the LC

display shows the initial logo.

If the system was turned off for more than

two hours, the setup configuration has to be

entered after the system test. (⇒chapter 4)

First, the operating mode is determined by

an interactive step-by-step interrogation of

the rigging states.

Next is the interactive input of the reeving.

Now the LC display shows in symbols all

inputs and awaits acknowledgment or

canceling.

Upon acknowledgment of the inputs the

system is ready for operation.

System Description

© Hirschmann Rev. E 11/12/08 190147_E

5

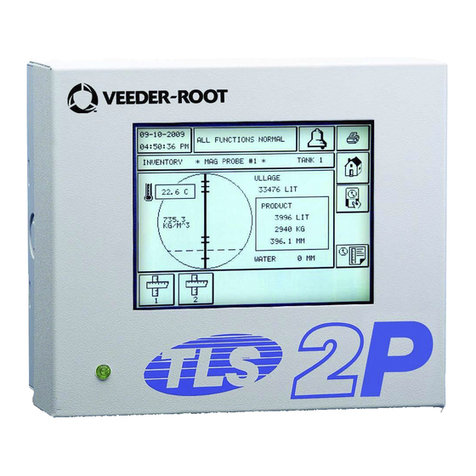

3.2 OPERATING CONSOLE

The console has 3 functions:

•inputs by the crane operator (operating mode, reeving)

•input of geometry limit values and signalization of exceeded limit values

•display of important data and information

The operator’s console is mounted in the crane’s cab in the operator’s field of vision. For a

better identification of displays and operating elements, they are continuously backlit during

operation.

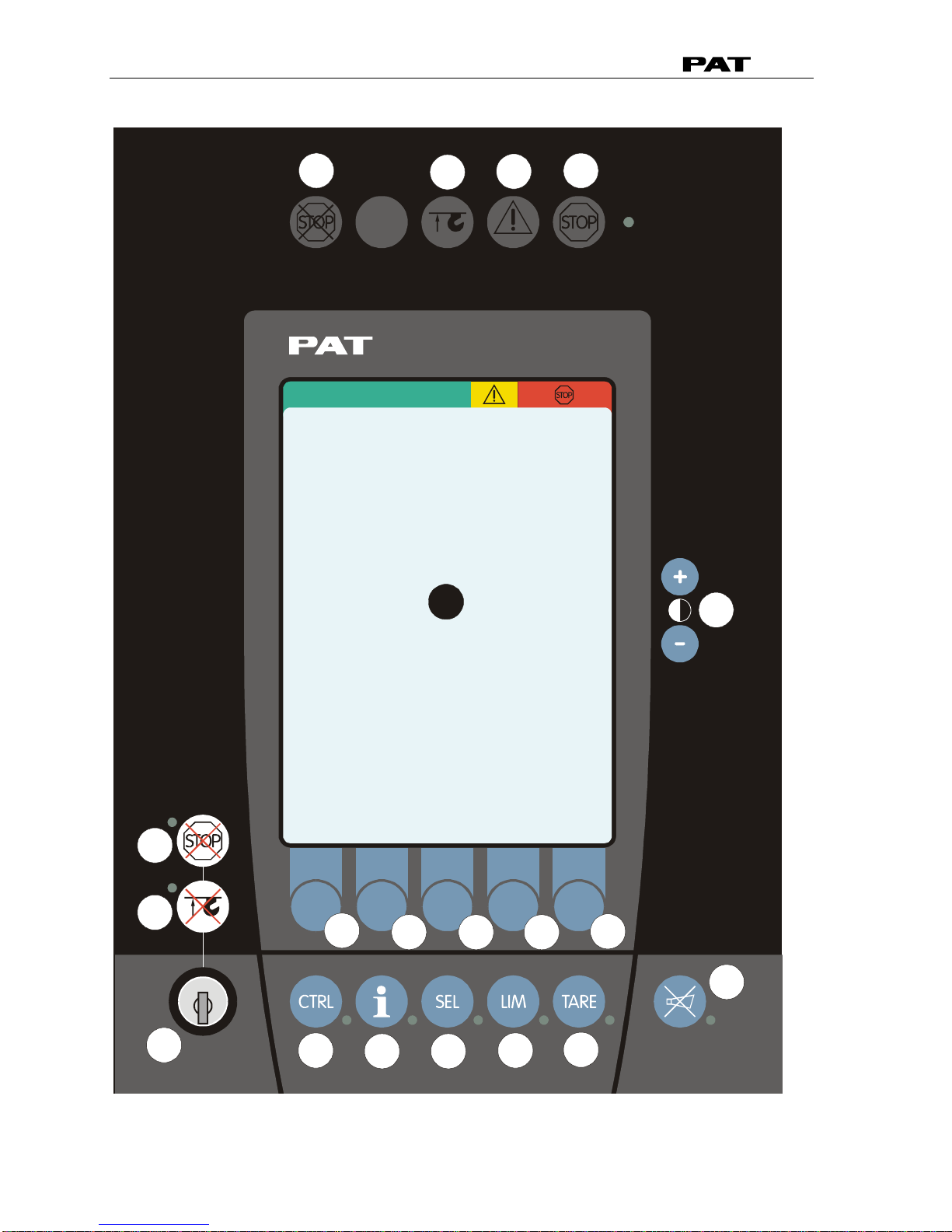

3.3 CONTROL IDENTIFICATION

This unit contains a display and different controls which are described as follows:

Legend to Fig 2:

1 LC Display Area 10 Button and Control Light "INFO"

2 Load Moment Limit Light 11 Button and Control Light "CONTROL"

3 Load Moment Prewarning Light 12 By-Pass Key Switch

4 Alarm Light “Anti-Two-Block” 13 Button and Control Light "By-Pass Anti-Two-Block"

5 Override Key Warning Light 14 Button and Control Light "By-Pass LMI shut-off

function"

6 Button “Alarm Stop” 15 Contrast Control

7 Button and Control Light “TARE” F1 Button "Function 1"

8 Button and Control Light “LIMITS” F2 Button "Function 2"

9 Button and Control Light “SELECT F3 Button "Function 3"

OPERATING MODE” F4 Button "Function 4"

F5 Button "Function 5"

Operator's Manual iFLEX5

© Hirschmann Rev. E 11/12/08 190147_E

6

Fig. 2a: Operating Console (vertical)

2

3

4

5

6

7

8

10

11

12

13

14

15

F1

F2F3

F4

F5

9

1

System Description

© Hirschmann Rev. E 11/12/08 190147_E

7

Fig. 2b: Operating Console (horizontal)

1 LC Display Area 10 Button and Control Light "INFO"

2 Load Moment Limit Light 11 Button and Control Light "CONTROL"

3 Load Moment Prewarning Light 12 By-Pass Key Switch

4 Alarm Light “Anti-Two-Block” 13 Button and Control Light "By-Pass Anti-Two-Block"

5 Override Key Warning Light 14 Button and Control Light "By-Pass LMI shut-off

function"

6 Button “Alarm Stop” 15 Contrast Control

7 Button and Control Light “TARE” F1 Button "Function 1"

8 Button and Control Light “LIMITS” F2 Button "Function 2"

9 Button and Control Light “SELECT F3 Button "Function 3"

OPERATING MODE” F4 Button "Function 4"

F5 Button "Function 5"

2

3

4

5

6

7

8

10

11

12 13 14

15

F1

F2

F3

F4

F5

9

1

Operator's Manual iFLEX5

© Hirschmann Rev. E 11/12/08 190147_E

8

LC-Display

The LC display visualizes graphical symbols, texts and numerical

values. Depending on the selected operating mode (setup, limit mode

or LMI representation), the corresponding information is indicated on

the display.

Please refer to the description of the different operating modes for the

signification of the individual elements.

Load Moment Limit Light

The red LOAD MOMENT LIMIT LIGHT (2) warns the operator that a

rated load condition has been reached. It lights up when the load on

the crane reaches the crane load capacity. The audible alarm also

sounds when this condition has been reached.

The following crane movements will be stopped concurrently:

− hoist up

− telescope out

− boom down

Load Moment Prewarning Light

The yellow LOAD MOMENT PRE-WARNING LIGHT (3) will light up

when the load on the crane reaches the defined prewarning area,

thus indicating that an overload condition is approaching.

This means for the operator to continue his crane operation with

extreme caution.

Alarm Light “Anti-2-Block”

The red “Anti Two-Block Alarm Light” (4) lights up when the anti-two-

block limit switch contacts open, indicating that a two-blocking

condition is approaching. At the same time the audible alarm will

sound.

The following crane movements will be stopped subsequently: hoist

up, telescope out, boom down.

Override Key Warning Light

The red OVERRIDE KEY WARNING LIGHT (5) flashes to indicate

that the cut-off function of the A2B / LMI system is deactivated.

Button and Control Light “Alarm Stop”

This ALARM STOP BUTTON (6) allows the audible alarm to be

silenced for approximately 15 seconds by pressing this button.

Reference ⇒“Audible Alarm” (12).

System Description

© Hirschmann Rev. E 11/12/08 190147_E

9

Button and Control Light “TARE”

The button “TARE” (7) is used to indicate the “Net load” on the LC

Display (1). Net load is the present load, less lifting tackle and hook

block. The Tare Button (7) has to be activated before lifting.

After pushing the “Tare Button” (7) the load display is set to zero

(taring) and the control light lights up. After lifting a load the display

shows the net load (pay load).

The net load display will change to the actual load display when the

boom radius is changed (either by angle or length).

Button "LIMITS"

Button to start the function "program limit values".

For the proceeding please refer to ⇒chapter 5.1.

Button "SELECT"

Button to start the function "set operating mode".

For the proceeding please refer to ⇒chapter 4.1.

The correct setting is of utmost importance for the proper function of the system and

the crane. Therefore only operators who are thoroughly familiar with use and

operation of the system shall set this button.

Button "INFO"

Button to start the function "information crane configuration"

Please refer to ⇒chapter 5.2.

Button "CONTROL"

Button to start additional functions.

Please refer to ⇒chapter 5.3.

Operator's Manual iFLEX5

© Hirschmann Rev. E 11/12/08 190147_E

10

Key Switch

The anti-two-block switch cut-off function is deactivated when

the KEY SWITCH (12) is turned to position "B" and the “By-pass

A2B” button (13) is pushed.

OR

The LMI cut-off function is deactivated when the KEY SWITCH

(12) is turned to position "B" and the “By-pass LMI” button (14) is

pushed.

KEY SWITCH (12) can be operated only by using the matching key.

Button "By-pass A2B"

This button can be operated only if key switch (12) is turned to

position B.

After pushing this button, the cut-off function of the anti-two-block

switch is deactivated.

The Override Key Warning Light (5) flashes to indicate that the cut-off

function is deactivated.

Since button (14) and (15) deactivate the cut-off function of the LMI system / the anti two-

block system, the following instructions must be obeyed:

•The by-pass function shall be used with discretion, as unwarranted use of it to override

the control lever lockout system can result in harm to the crane and danger to property

and persons.

•Never use the by-pass function to either overload or operate the crane in a non-

permissible range.

Button "By-pass LMI"

This button can be operated only if the key switch (12) is turned to

position B.

After pushing this button, the control lever lockout function of the LMI

is deactivated.

The Override Key Warning Light (5) flashes to indicate that the cut-off

function is deactivated.

Contrast Control

This function serves for the contrast adjustment of the LC display.

The last adjustment is stored and does not have to be repeated at

every system start.

During normal LMI operation the display contrast can be adjusted by

pressing the “+” or “-“ button.

Configuration Setup

© Hirschmann Rev. E 11/12/08 190147_E

11

4 CONFIGURATION SETUP

The LMI setup procedure allows the operator to input the crane configuration using interactive

displays. The operator must complete the setup procedure for the Load Moment Indicator

system if the system has been turned off for more than two hours or the crane operation

configuration has been changed.

4.1 LMI SETUP PROCEDURE

...starts: automatically, if the system was turned off for more than

two hours.

manually at each modification of the crane configuration

by pressing key (9) "SEL"

9

...is operated: by answering the different questions using functional keys

F1...F5 in accordance with the actual configuration of the

crane.

...is cancelled: any time by pressing again key (9) "SEL". The system,

however, is only ready for operation, if the procedure has

been completed and the inputs have been confirmed.

If the system is turned off, for example during short breaks (less than 2 hours), all adjustments

remain stored. When turning on again the system these adjustments can be acknowledged by

merely pressing one key (provided that the crane configuration has not been modified!).

During the programming procedure the Load Moment Prewarning Light (3) and the Load

Moment Limit Light (2) will light up and the aggravating crane movements will be interrupted.

Note: If a configuration is selected which is not available, the display will indicate error code

E04. In this case, the procedure has to be repeated with valid values!

The correct setting is of utmost importance for the proper functioning of the system

and the crane. Therefore, only operators who are thoroughly familiar with the crane

and the operation of the system should execute the setting of the system according

the operating configuration of the crane.

Operator's Manual iFLEX5

© Hirschmann Rev. E 11/12/08 190147_E

12

The LMI programming procedure consists of the following steps:

•setting the boom configuration

•setting the counterweight configuration (where applicable)

•setting the hoist configuration

•setting the outrigger configuration

•setting the reevings

•confirmation of the programming procedure

For easy operation, the computer guides the operator through the procedure step by step

(interactive operation.)

Definition of the Displayed Symbols:

The following illustrations define the symbols appearing on the display during the setup

procedure. Not all symbols will be shown, depending on the crane type and the answers to the

questions.

•Select interactive configuration setup / special mode setup

interactive configuration setup

special mode setup

Note: Refer to manufacturer load

chart for special LMI operating code

•(if selected special mode setup only)

increase selected numeral

decrease selected numeral

select next numeral

confirm selected operating code

•Setting the boom configuration

main boom / aux. boom nose operation

operation with boom extensions, includes luffing jib operation

rigging mode operation*

*

for cranes with rigging mode for outrigger box installation only

or

main boom

operation with boom extensions

Configuration Setup

© Hirschmann Rev. E 11/12/08 190147_E

13

•Setting the luffer configuration

extension retracted

extension extended

main

boom aux.

boom

nose

A-

frame

boom

ext.

fixed

ext. fixed,

offsettable

extension

tele-offsettable

extension fixed jib Luffing jib

For detailed symbol explanation of extensions, please refer to Appendix A in this manual.

•Setting the counterweight configuration

If your crane is equipped with counterweight options, please

refer to Appendix B in this manual for detailed symbol

explanation of counterweight.

•Setting the hoist configuration

Front Hoist

Rear Hoist

•Setting the outrigger configuration (If no outrigger configuration is skipped,

configuration can only be used with 100% outrigger position).

on rubber

outrigger position 0%

outrigger position 50%

outrigger position 100%

Operator's Manual iFLEX5

© Hirschmann Rev. E 11/12/08 190147_E

14

•(if selected on rubber mode only)

static

pick & carry

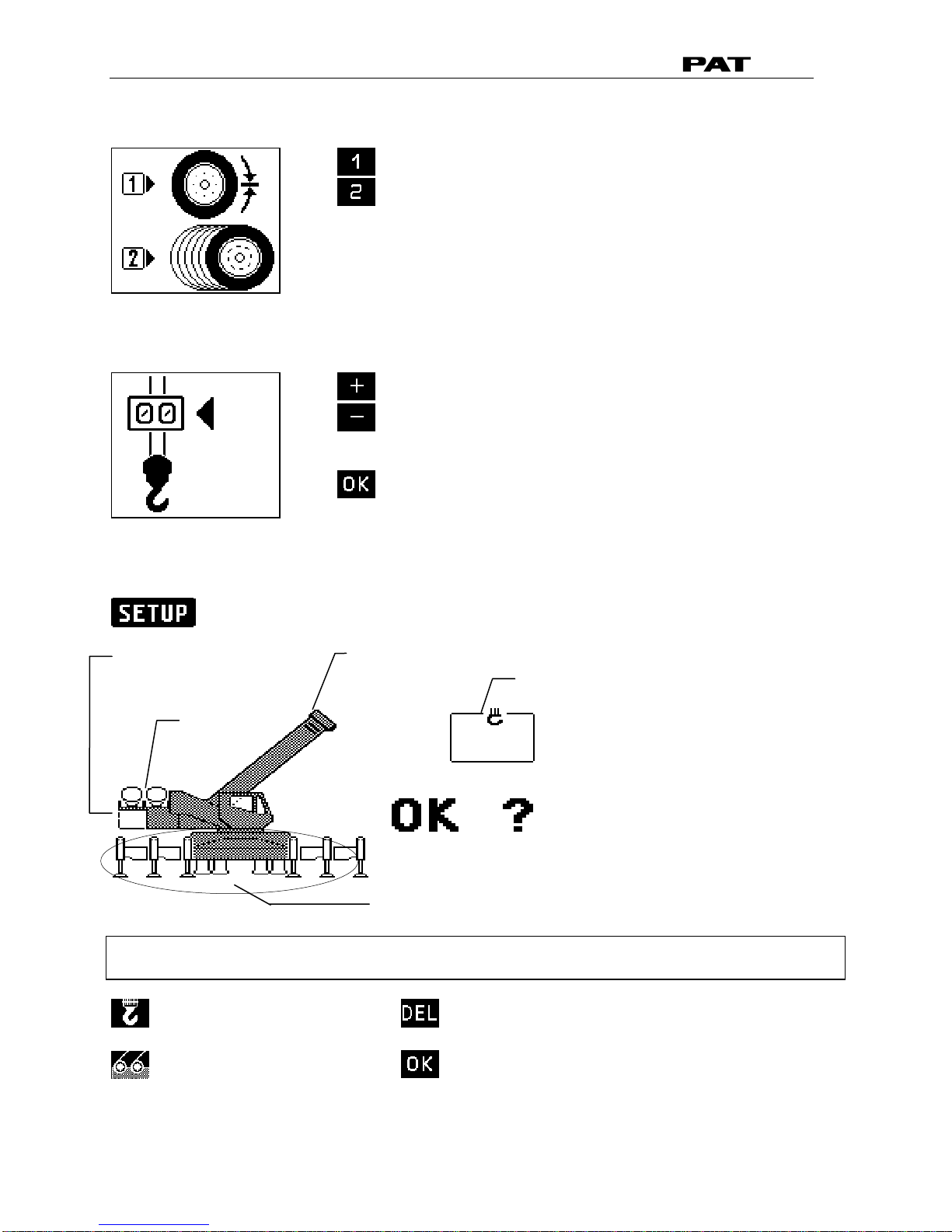

•Setting the reeving (parts of line)

increase reeving

decrease reeving

confirm reeving

•Confirmation of the programming procedure

At the end of the procedure all selections are shown once again in symbolic forms. If selections have

been made, the corresponding symbols are filled black.

quick setting the reeving

(⇒chapter 4.3)

quick hoist line selection

(⇒chapter 4.2)

cancel procedure

confirm inputs

counterweight

configuration

(optional)

hoist

selection

boom

configuration

outrigger

configuration

reeving

(parts of line)

Other manuals for PAT IFLEX5

1

Table of contents

Other Hirschmann Music Mixer manuals