Hisun 450ATV-2 User manual

450ATV-2 Maintenance Manual

eneral Information

1 Description

1.1 Identification code

1.1.1. Frame No.

1.1.2. Engine No.

1.2 Special tools, instruments and meters

1.3 Periodic maintenance chart

Chassis

4.1 Steering operation system

4.2 Brake system

4.3 Wheels and tires

4.4 Transmission system

4.5 Reverse mechanism

4.6 Suspension

4.7 Cooling system of engine

4.8 Parking mechanism

4.9 Oil circulation System

4.10 Speed sensor

Electrical system

5.1 Ignition system

5.2 Magneto and charging system

5.3 Battery

5.4 Lighting system

5.5 Meter and signal system

5.6 Starting system

Appendix

6.1 Specification

6.2 Requirements for torque of fastener

6.3 Electrical circuits

General Information

1 Description

1.1 Identification code

1.1.1. Frame No.

The frame No. is engraved in the right bottom of the supporting frame. See Figure

1-1

Figure 1-1

1.1.2. Engine No.

The engine No. is engraved in the right side of the engine. See figure 1-2

Figure 1-2

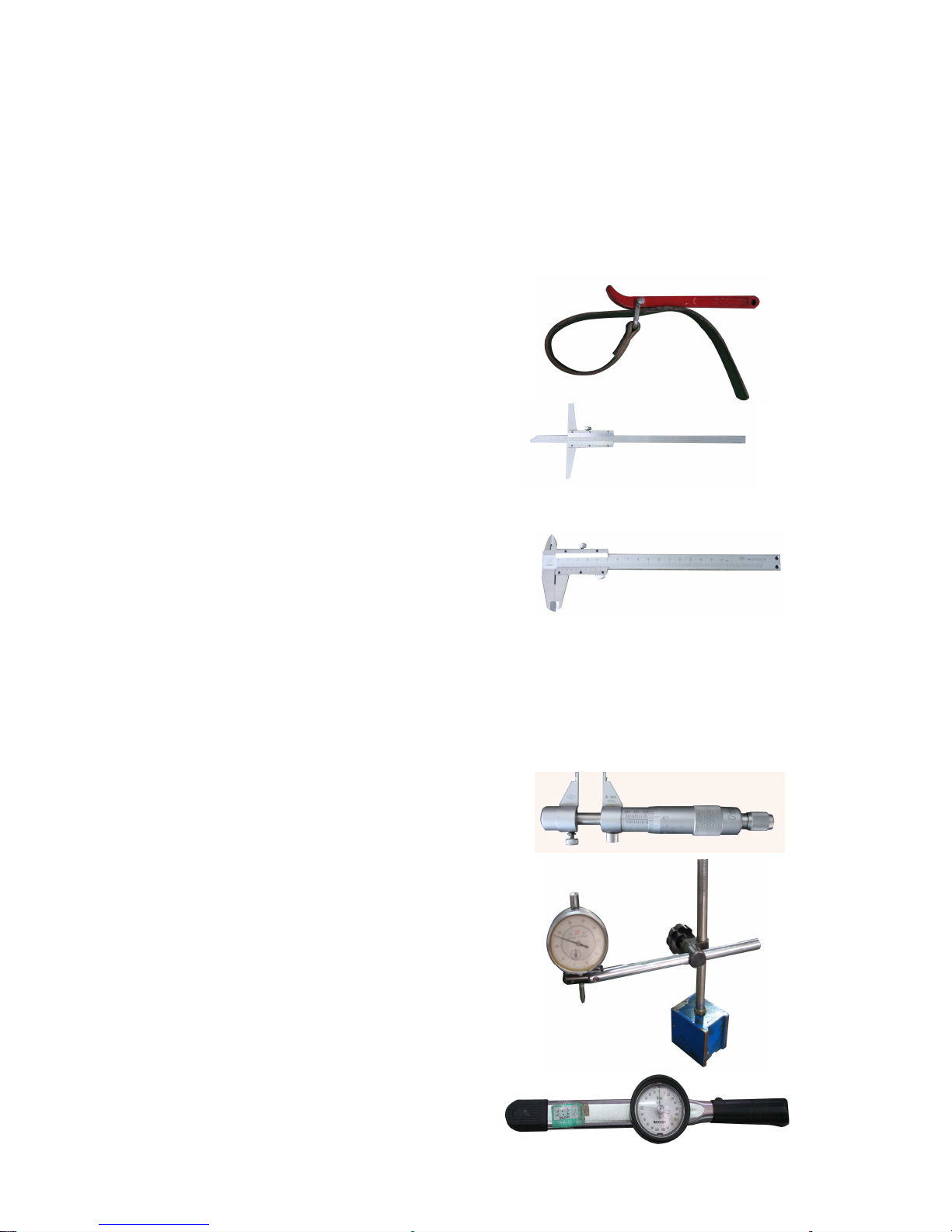

1.2 Special tools, instruments and meters

1.2.1 Oil filter detacher

To fasten and detach the oil filter

1.2.2 Height gauge

To gauge the height of various components

1.2.3 Vernier

To measure the length of various components

1.2.4 Outside micrometer

To accurately measure external

diameter of a column

1.2.5 Inside micrometer

To accurately measure internal

diameter of a hole

1.2.6 Dial indicator

To accurately measure a small

distance

1.2.7 Torque Spanner

To measure torque force

1.2.8 Feeler gauge

To measure gap-width

1.2.9 Multimeter

To check electrical circuits and parts

1.2.10 Barometer

To measure pressure of the tyre

1.2.11 Magneto drawing device

To detach the magneto

1.2.12 Snap ring clamp

To install and detach snap rings

1.2.13:

Spark tester of spark plug

1.3 Periodic maintenance chart for the emission control system

NOTE:

●For ATVs not equipped with an odometer or an hour meter, follow the month maintenance intervals.

●For ATVs equipped with an odometer or an hour meter, follow the km (mi) or hours maintenance intervals. However, keep

in mind that if the ATV isn’t used for a long period of time, the month maintenance intervals should be followed.

INITIAL EVERY

ITEM ROUTINE Whichever

Comes first

Month 1 3 6 6 12

Km

(Mi) 320

(200) 1,200

(750) 2,400

(1,500) 2,400

(1,500) 4,800

(3,000)

Hours 20 75 150 150 300

Valves★Check valve clearance.

Adjust if necessary. ○○○○

Spark plug Check condition.

Adjust gap and clean.

Replace if necessary. ○○○○○

Air filter element

Clean.

Replace if necessary. Every 20-40 hours

(More often in wet or dusty areas.)

Carburetor★Check starter (choke) operation.

Adjust engine idling speed. ○○○○

Crankcase

breather system★

Check breather hose for cracks or damage.

Replace if necessary. ○○○

Exhaust system★

Check for leakage.

Tighten if necessary.

Replace gasket(s) if necessary. ○○○

Spark arrester Clean. ○○○

Fuel line★Check fuel hose for cracks or damage.

Replace if necessary. ○○○

Engine oil Replace (Warm engine before draining.) ○○○○

INITIAL EVERY

Month 1 3 6 6 12

Km

(Mi) 320

(200)

1,200

(750)

2,400

(1,500)

2,400

(1,500)

4,800

(3,000)

ITEM ROUTINE Whichever

Comes first

Hours 20

75

150 150 300

Engine oil filter element Clean.

Replace if necessary. ○

○○

Engine oil strainer Clean. ○

○○

Drive chain Check and adjust slack/alignment/clean/lube. ○

○○○○

Brakes★Check operation/fluid leakage/See NOTE.

Correct if necessary. ○

○○○○

Clutch★Check operation.

Adjust if necessary. ○

○○○

Wheels★Check balance/damage/run out.

Replace if necessary. ○

○○○

Wheels bearings★Check bearing assemblies for looseness/damage.

Replace if damaged. ○

○○○

Steering system★

Check operation.

Repair if damaged.

Check toe-in.

Adjust if necessary.

○

○○○○

Front and pan fork★Check operation.

Correct if necessary. ○○

Upper and lower arm pivot and steering shaft

★Lubricate every 6 months with lithium-soap-based

grease. ○○○

Rear arm pivot★Lubricate every 6 months with lithium-soap-based

grease. ○○○

INITIAL EVERY

Month 1 3 6 6 12

Km

(Mi) 320

(200)

1,200

(750)

2,400

(1,500)

2,400

(1,500)

4,800

(3,000)

ITEM ROUTINE Whichever

Comes first

Hours 20 75 150 150 300

Fittings and fastener★Check all chassis fittings and fasteners.

Correct if necessary. ○○○○○

Lights and a witches★Check operation.

Adjust headlight beams. ○○○○○

★Science these lets require special tools, data and technical skills, Have the dealer perform the service.

NOTE:

Recommended brake fluid:DOT4

Brake fluid replacement:

When disassembling the master cylinders or calipers, replace the brake fluid.

Normally check the brake fluid level and add fluid as required.

On the inner parts of the master cylinders and scalpers, replace the oil seals every two years.

Replace the brake hoses every four years, or if cracked of damaged.

Chassis

10

4.1

Steering system

Structure of Steering Vertical Column

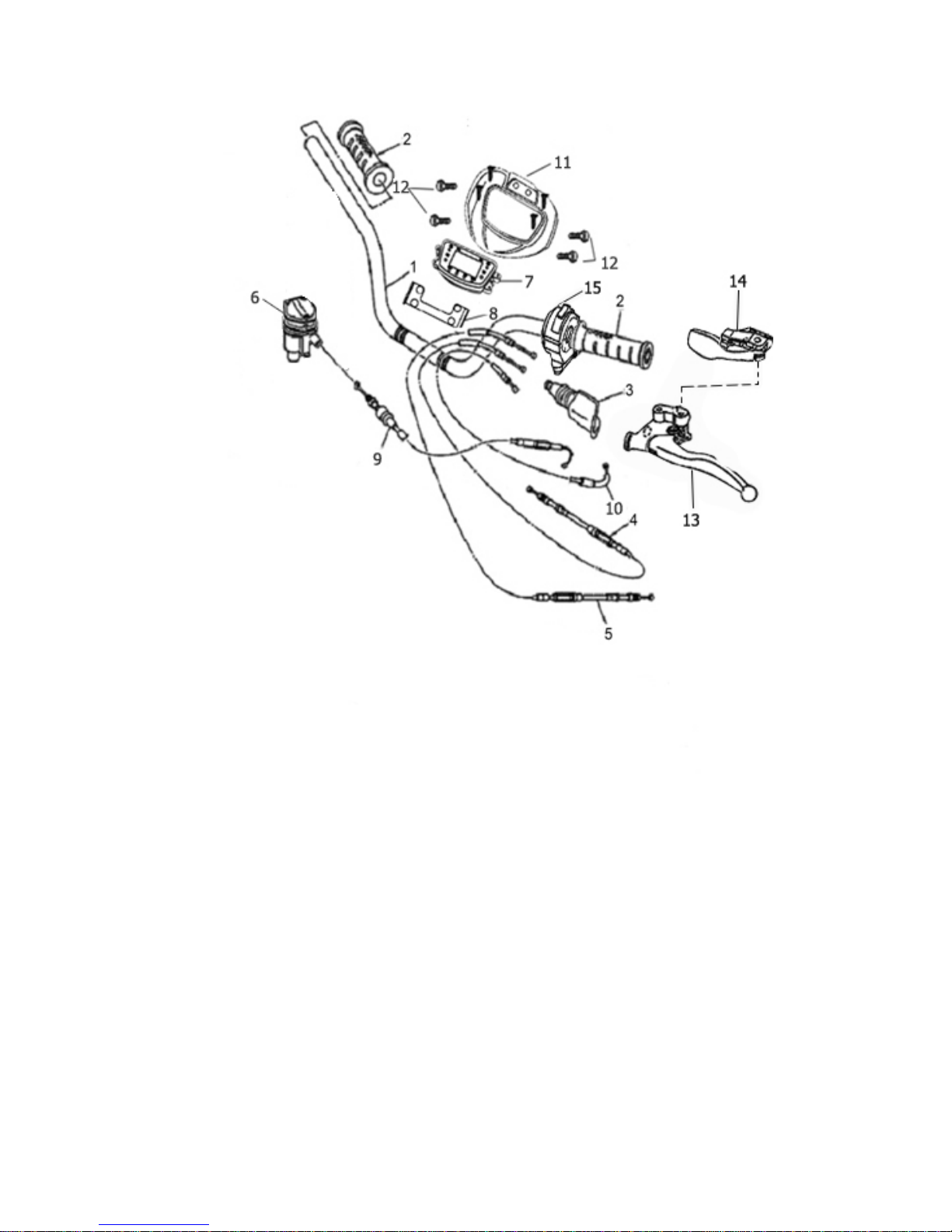

Components of Steering Bar

11

4.1.1

Disassembly, inspection and assembly of Steering

System

12

4.1.1.1 Disassembly of Steering Vertical Column (Steering Bar

included)

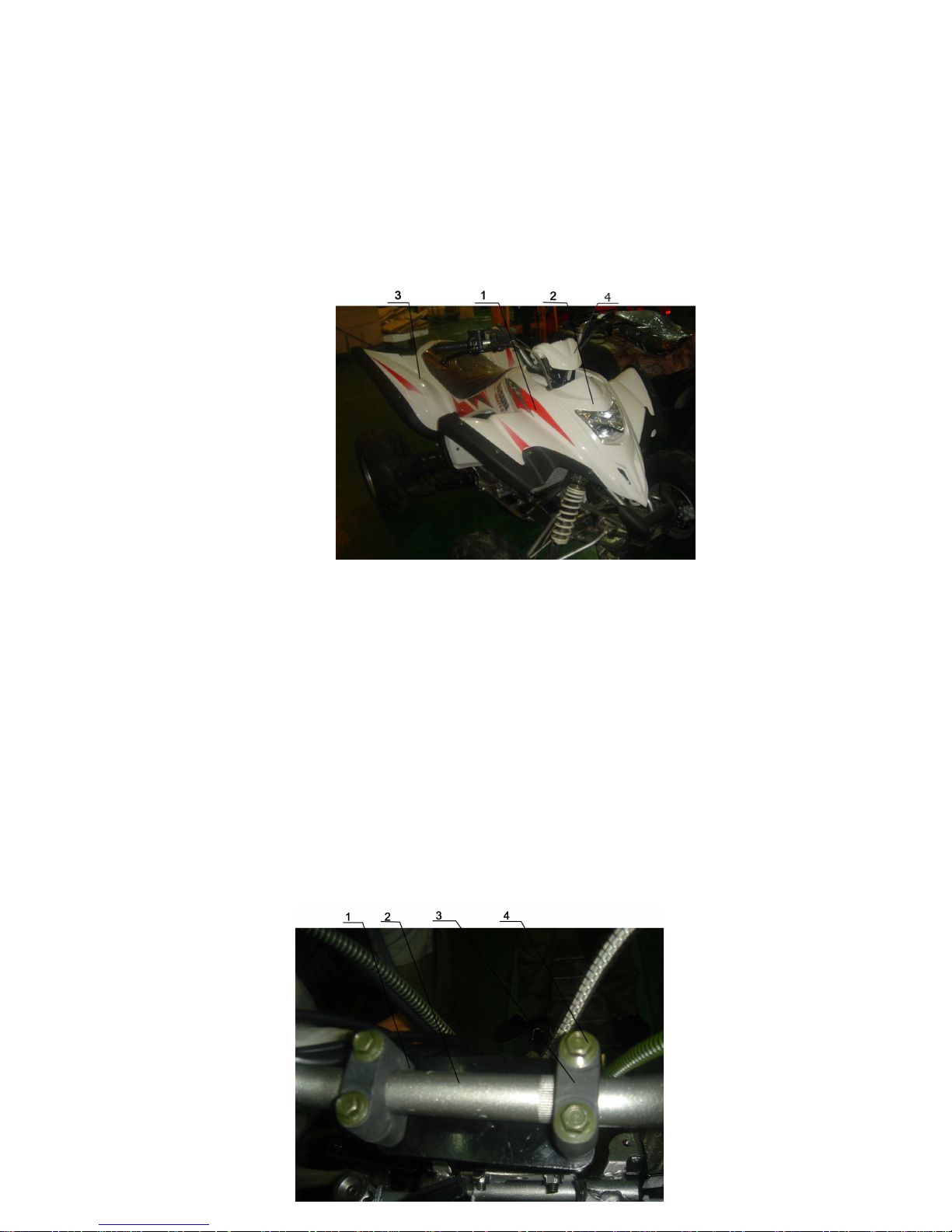

1、Remove the Front Faceplate and Meter Cover (Figure

4-1-1)

Figure 4-1-1

1、Front Mud Shield

2、Front Faceplate

3、Rear Mud Shield

4、Meter cover

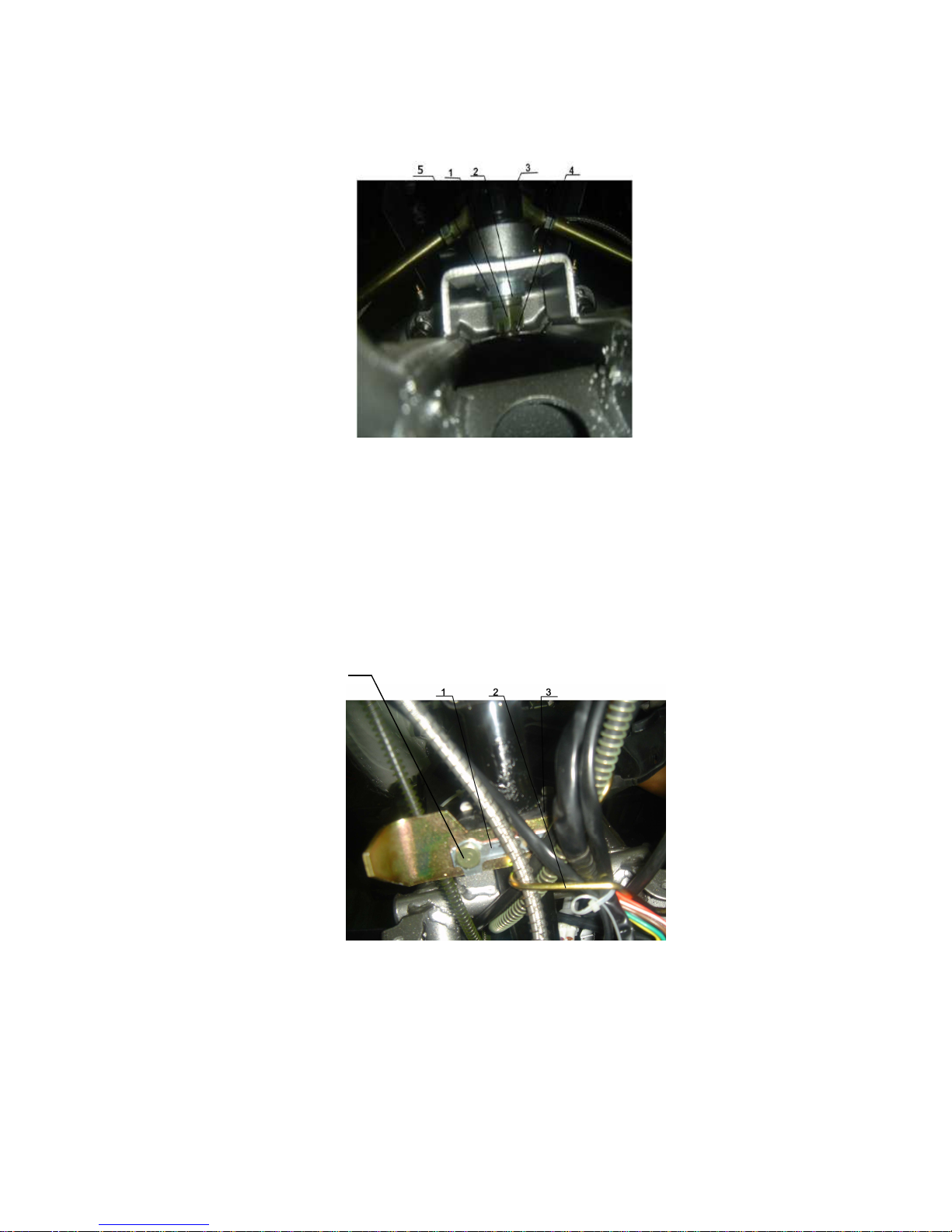

2、Release the hexagon flange bolt M8×30(4pcs) and

remove the steering bar clip

13

Steering Bar Holder

1、Steering Bar

2、Steering Bar Clip

3、Hexagon Flange Bolt M8×30

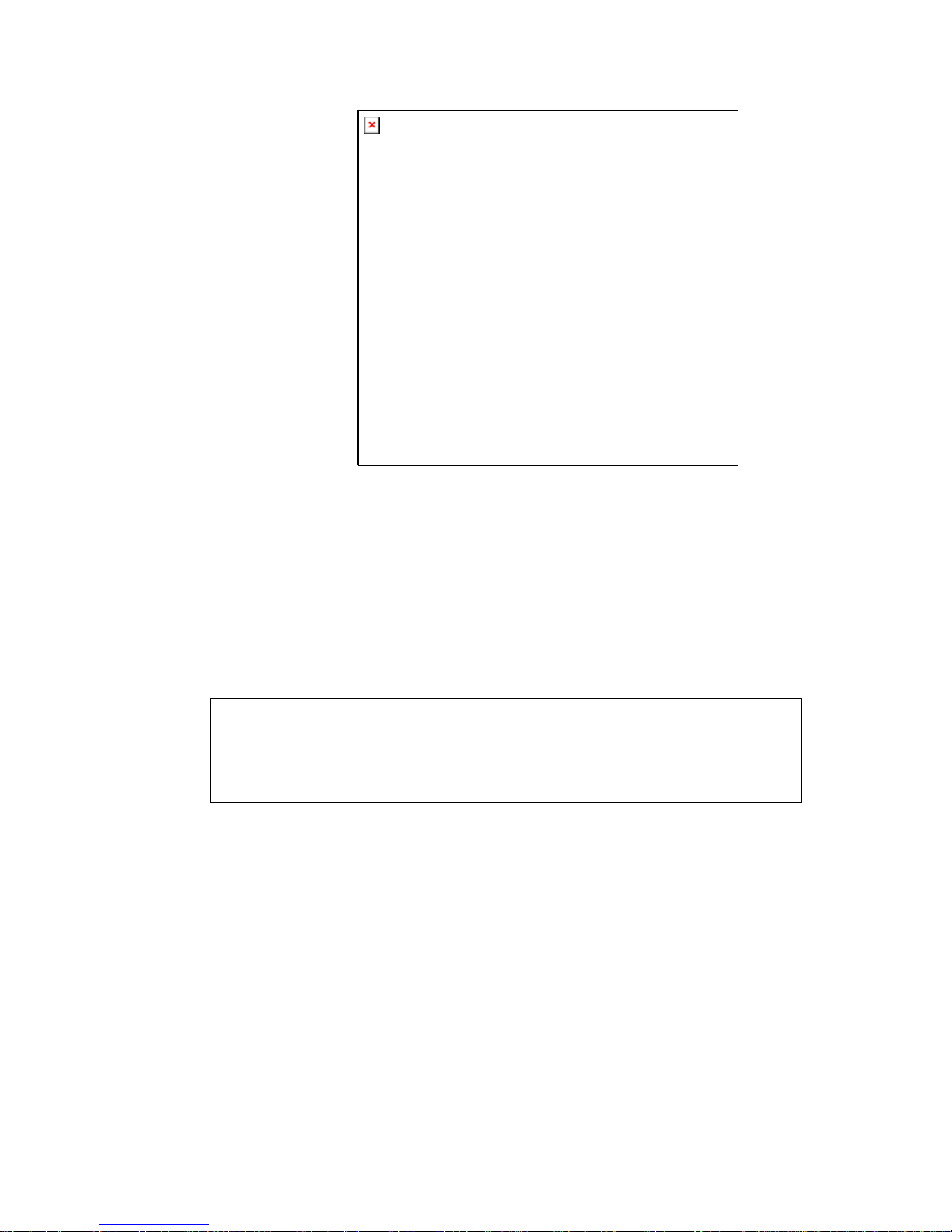

3、 Remove Front Brake Lever and unplug all cables and

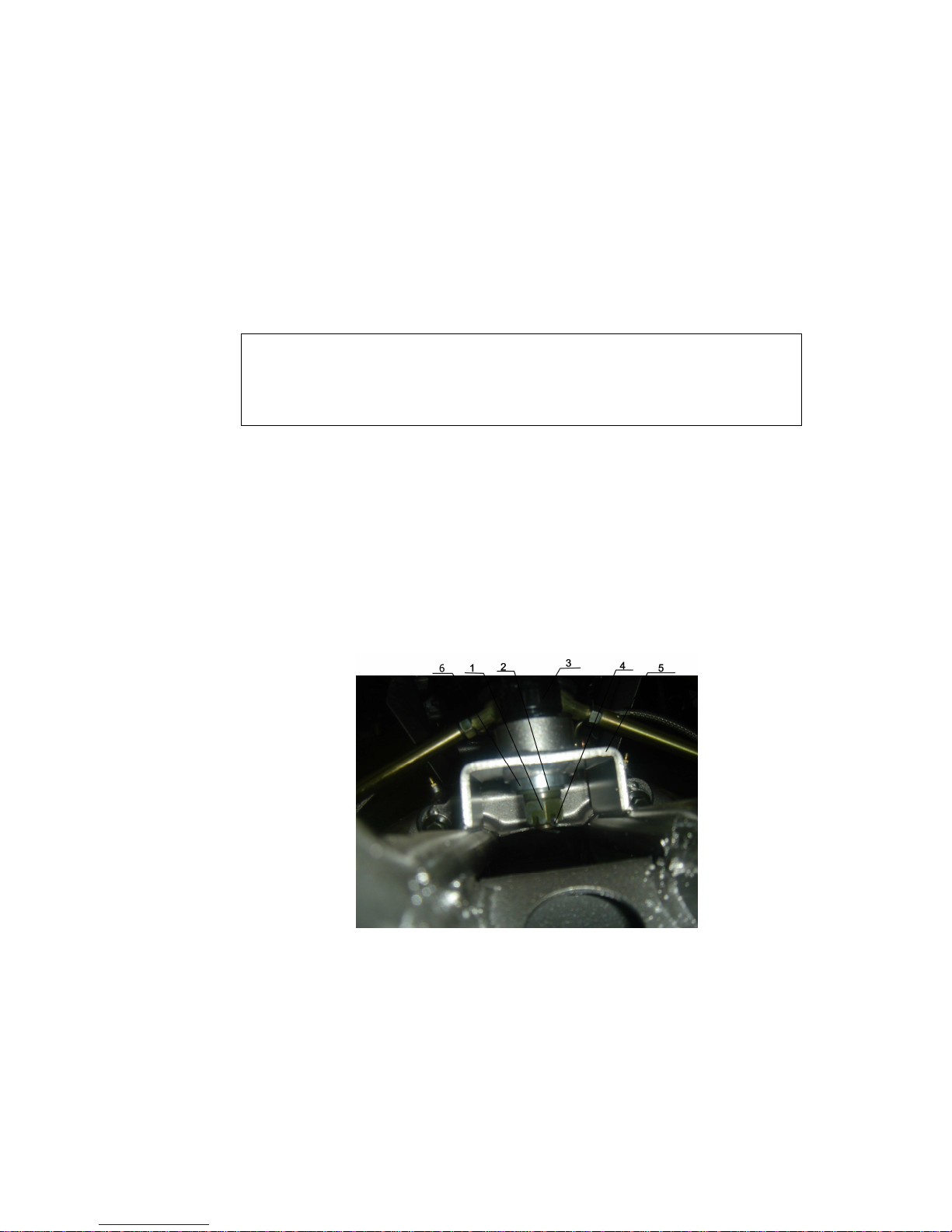

connecting wires. (Figure 4-1-3)

Figure 4-1-3

1、 Throttle Cable 2、Connecting Wire

3、 Clutch Cable 4、Brake fuel pipe

4、 Front Brake Handlebar 6、Choke Cable

7、Parking Cable

4、Remove the cotter pin, M14 open-groove nut, cushion

and lower collar sheath at the bottom of the

14

Steering Vertical Column. (Figure 4-1-4)

Figure 4-1-4

1、Hexagon open-groove nut 2、4 cushionф14×ф32×4

3、Steering vertical column 4、 cotter pin 3.2×32

5、Lower collar sheath

5、

Release M8*32 Bolt (2pcs) and remove the supporting brackets of the

steering vertical column

4

6、Rotate the tension rod to detach it from the balance

(Figure 4-1-6)

15

Figure 4-1-6

1、Tension rod

7、Pull out the components of the steering vertical

column from the bottom seat.

Steering Vertical Column 2、Bottom Seat

4.1.1.2 Inspection of steering vertical column components:

1、Check whether the hexagon open-groove nut between the

inner ball pin and tension rod is tightened

16

4-1-8

1、Tension rod

2、cotter pin 3.2*32

3、Turning shaft arm 4 、 Hexagon

open-groove nut

5、Ball pin

In case of loosen or worn out, tighten it with proper tools

or replace with identical nuts.

Torque of the open-groove nut: 32-36N.m

2、Check whether the inner and outter ball pin of the tension

rod is loosen or got stuck.

17

1. Tension rod

In occasion of above defects, further inspection of the

exact causation must be carried out and replace with new

ball pin components.

Caution: Continuous use of defective ball pin might

cause severe injury or death.

Additionally, check whether the tension rod is bended,

cracked or rusted.

In occasion of above problems, please have the tension

rod replaced.

18

。

3、Check whether the hexagon open-groove nut and cottor pin

are intact. (No crack or flaw is allowed)

Figure 4-1-10

1.M14 Open-groove nut 2、Cushion

3、Steering vertical column 4、Cotter pin

3.2*32

5、collar sheath

Those two components are crucial and should be

replaced whenever there is a potential problem.

4、Check whether the supporing bracket is firmly fixed to

the steering vertical column.

Caution: tension rod should not be repaired by

welding

19

1. inner and outter supporting

bracket 2、steering vertical column

Inspection method:

Assemble the steering vertical column to the main frame

with supporting bracket and M8 bolts etc. and rotate the

steering bar to ensure the column is not stuck or swinging.

In occasion of above problems, the supporting bracket

must be replaced.

Rotating Torque of the steering vertical column:

3-5N.m

5、Check whether the bearing in the bottom seat is rotating

smoothly and oil seals on both ends are not damaged.

Should there occurs any problem, the bearing or oil seal

must be replaced immediately.

4.1.1.3 Assembly of steering vertical column

20

1、Plug the steering vertical column into the bottom seat

and fix it with M14 open-groove nut (1pcs),ф14×ф36

×4 cushion (1pcs), collar sheath (1pcs) and 3.2*32

cotter pin (1pcs).

Fastening Torque of M14 open-

groove nut:

80-85N.m

Caution: before inserting the steering

vertical column into the bottom seat, both upper and

lower oil seals must be greased with lithium

lubrication.

4-1-12

1、Hexagon open-groove nut M14×1.5

2、 Cushion

3、 Steering vertical column

4、Cotter pin 3.2×32

5、 Steering bottom seat

6、Lower collar sheath

Table of contents

Other Hisun Motorcycle manuals