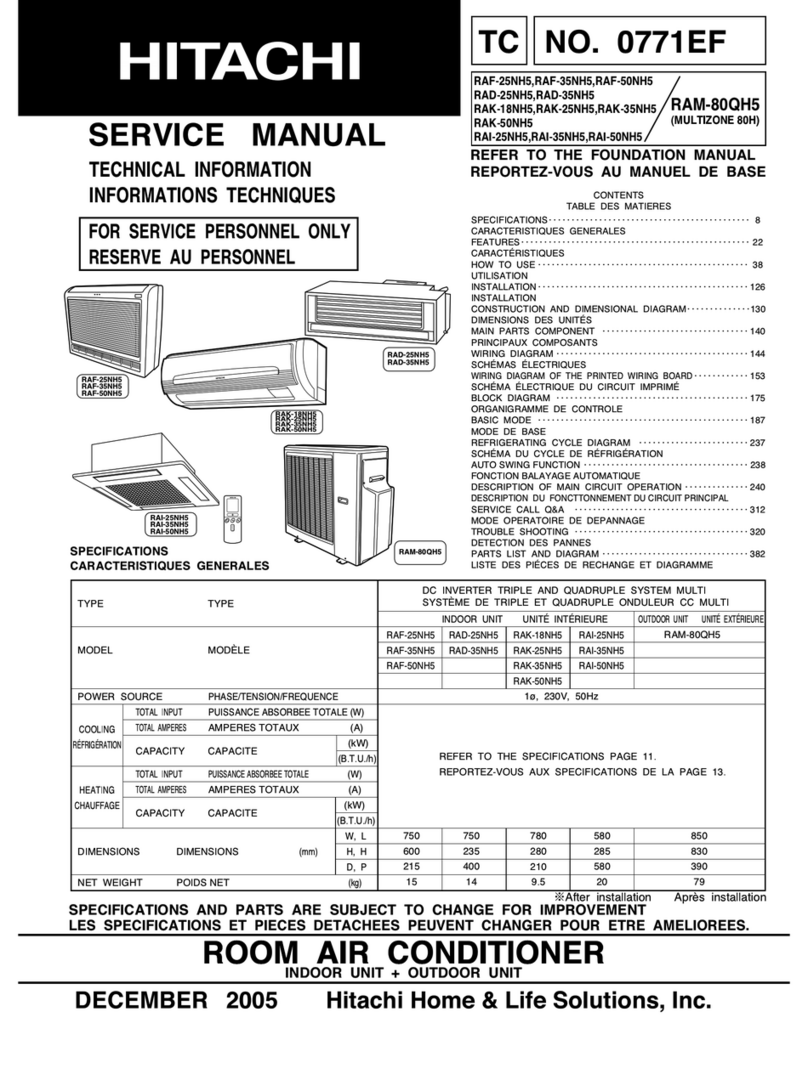

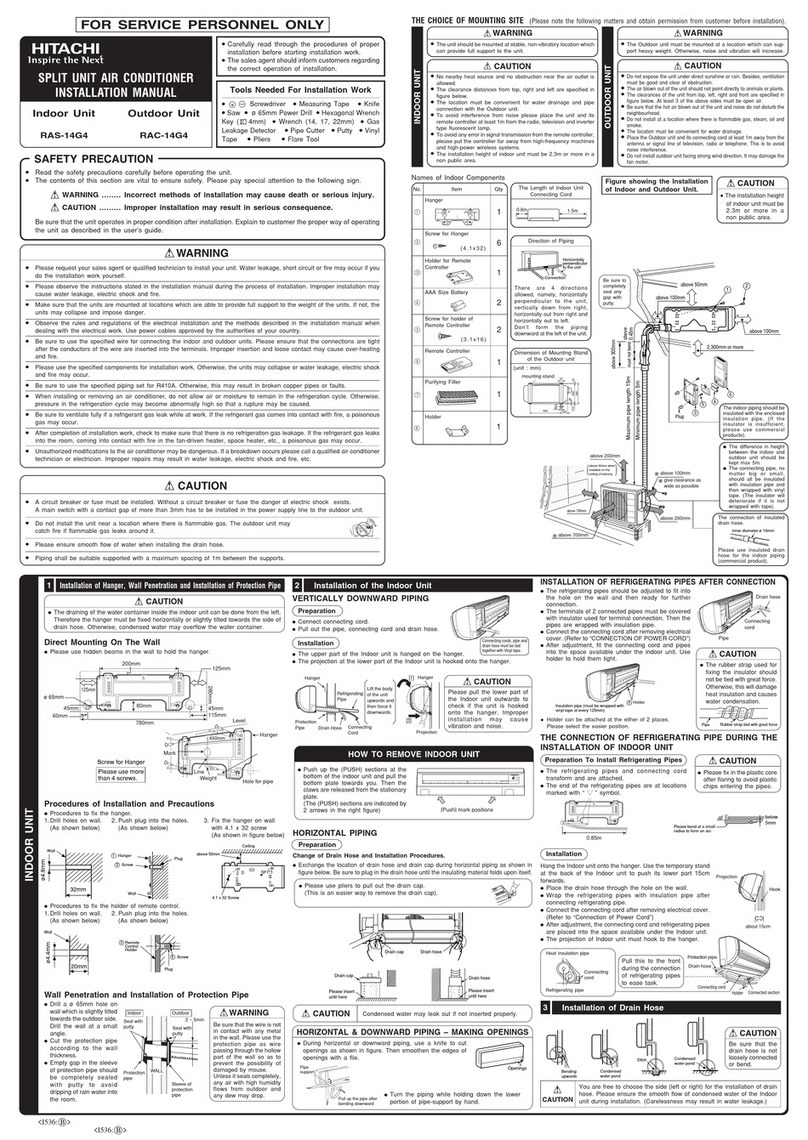

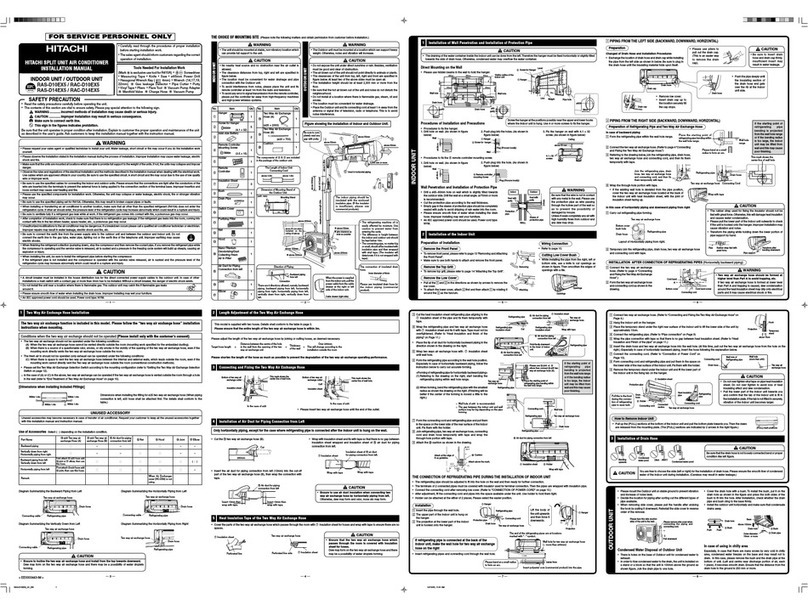

a Preparation of Pipe

•

Use

a pipe cutter to cut the copper pipe. B Pipe Connection

.1,CAUTI0N

In

case of removing flare nut of an Indoor unit, first remove a nut of small diameter side, or a seal cap

of big diameter side will fly out. Prevent water from entering into the piping when working.

~

~~--

Trimmingtool

Copper

pipe

'

~

Outer diameter Torque

N.m

of pipe (kgf.cm)

mm

(inch)

it.

CAUTION

~~t

Small dia. side 6.35 (1/4") 13.70 ~18.60 (140 ~190)

9.52 (3/8") 34.30 ~44.10 (350 ~450)

• Jagged edge will cause leakage. Large dia. side 12.7 (1/2") 44.10 ~53.90 (450 ~550)

• Point the side to be trimmed downwards during trimming

to

prevent copper chips from entering the pipe.

Wrench

~

/l4__

Torque

ff

)'~......_wrench 15.88 (5/8") 49.00 ~58.80 (500 ~600)

• Before flaring, please put

on

the flare nut. Small dia. side 6.35 (1/4") 19.60 ~24.50 (200 ~250)

Valve 9.52 (3/8") 19.60 ~24.50 (200 ~250)

head cap Large dia. side

D~

~A

Copper

pipe

• Recommend

to

use

R41

0A

flaring tool Valve core cap

12.7 (1/2") 29.40 ~34.30 (300 ~350)

15.88 (5/8") 29.00 ~31.00 (296 ~316)

12.30 ~15.70 (125 ~160)

Outer

Diameter

Thickness

Flare

tool

for

R41

0A

mm

(inch)

mm

Clutch

type

6.35 (1/4) 0.8 0.0 ~0.5

9.52 (3/8) 0.8 0.0 ~0.5

(

Lt

WARNING

I • THIS APPLIANCE MUST

BE

GROUNDED.

Procedures of Wiring

In

case that power

is

supplied

from

Indoor Unit

Indoor

Unit

Connecting

Cord

Detail of cutting the connecting cord

Indoor Unit

Green+

Yellow

(ground)

Control line

Lt WARNING

• The naked part

of

the wire core should be 10mm and fix

it

to

the terminal

tightly.

Then

try

to

pull

the

individual

wire

to

check

if

the

contact

is

tight.

Improper

insertion may

burn

the terminal.

• Be sure to use only power cables approved from the authorities

in

your

country.

If

the

supply

cord

is

damaged,

it

must

be

replaced

by

the

manufacturer,

its

seivice agent or similarly qualified person

in

order

to

to

avoid a hazard.

• Please refer

to

the following for wire connection

to

the terminals

of

the

units. The cabling must meet the standards

of

electrical installation.

• There

is

a

AC

voltage drop between the L and N terminals

if

the power

is

on.

Therefore,

before

servicing,

be

sure

to

remove

the

plug

from

the

AC outlet

or

switch

off

the main switch.

(~

________

G_a_s_L_ea_k_a_g_e_ln_s_p_e_c_t_io_n

________

)

L'.t,.WARNING

Amm

Please use gas leakage detector to check

if

leakage

Clutch

type

Wing

nut

type

occurs

at

the connection of Flare nut as

shown

on

the right. BURST HAZARD

Do

not

allow

air,

etc.

to

get

into

refrigerant

cycle

(piping)

1.0 ~

1.5

1.5 ~2.0

1.0 ~

1.5

1.5 ~2.0

If

gas leakage occurs, further tighten the connection

to

stop leakage. (Use the detector provided for

R410A)

RISK OF EXPLOSION

Compressor

must

be

stopped

before

removing

refrigerant

pipes.

All

service

valve

must

be

fully

closed

after

pumping

down

operation.

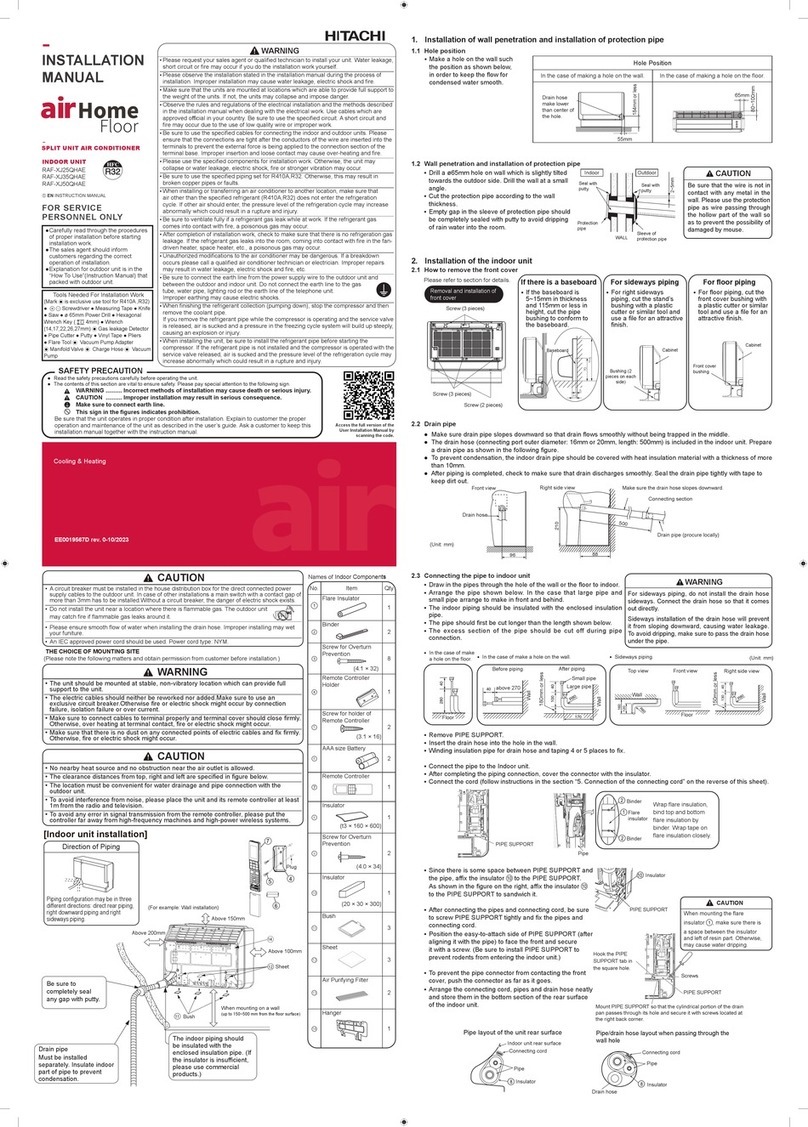

Wiring Of The Indoor Unit

• For wire connection of the indoor unit,

you

need

to

remove the front cover,

the low cover under the body of the unit and terminal cover.

• Remove the cover from the terminal base and screw the cable.

After remove the

screw and terminal

cover,

and

put

the

connecting cords and

fix the terminal cover

with

screw.

Method

to

remove

electrical

cover

• Remove

the

screw and electrical cover.

3

Cord

band

• Insert the connecting cord

(1,

2,

3)

from the back of unit.

• Fixed

the

wire to terminal wires firmly

as

shown

as

below.

Electrical

cover

Sere Connecting

cord

!l

D

.1, WARNING

• Leave some space

in

the connecting cord for

maintenance purpose and

be

sure

to

secure it

with the cord band.

• Secure the connecting cord along the coated part

of the wire using the cord band.

Do

not exert

pressure

on

the

wire

as

this may cause overheating

or

fire.

How

to

connect

the

optional

parts

(Dry

contact, H-Link/Wi

Fi

(optional},

Wired

remote, Run status)

• For cable connection

to

control

P.W.B.,

you

need

to

remove front cover and electrical box cover.

Each connecting location

is

as

below.

G)

Dry contact:

CN6

® H-LINK/Wi

Fi:

CN7

@ Wired Remote Controller: CN18

@)

Run

status:

CNS

• Please check and confirm manuals attached

to

each

optional parts for more connection details.

•

You

can refer

to

this installation manual how to

remove and re-attach the front cover.

• Please

be

careful not

to

damage lead wires by

edge of plate when connecting the optional parts.

CN7

a Insulation

And

Maintenance Of Pipe Connection B Installation Of Remote Controller ( How to remove the front cover ) ( How to attach the front cover )

• The connected terminals should

be

completed sealed with heat insulator

and then tied

up

with rubber strap.

• Please tie the pipe and power line together with vinyl tape

as

shown

in

the figure showing the installation of indoor and outdoor units. Then fix

their position with holders.

•

To

enhance the heat insulation and to prevent water condensation, please

cover the outdoor part of the drain hose and pipe with insulation pipe.

• Completely seal any gap with

putty.

Insulation

material

for

pipe

connection

~~

Sleeve

of

protection~ipe

/

'i

:·:

,:

Putty

:..

Putty

:i

::

El

Power Source And Operation Test

( Power Source )

.1, CAUTION

• Please use a new socket. Accident may occur due

to

the use of old

socket because of poor contact.

• Please plug

in

and then remove the plug for 2 - 3 times. This

is

to

ensure that the plug is completely plugged into the socket.

• Keep additional length for the power cord and

do

not render the plug

under external force as this may cause poor contact.

•

Do

not fix the power cord with U-shape nail.

( Operation Test )

• Please ensure that the air conditioner is

in

normal operating condition

during the operation test.

• Explain

to

your customer the proper operation procedures as described

in

the user's manual.

<IA2156:@>

• The remote controller can

be

placed

in

its holder which

is

fixed

on

wall or beam.

•

To

operate the remote controller

at

its holder, please ensure that

the

unit can

receive signal transmitted from the controller

at

the place where the holder

is

to

be

fixed. The unit will beep when signal

is

received from

the

remote controller.

The signal transmission

is

weaken by the florescent light. Therefore, during the

installation of the remote control holder, please switch

on

the light, even during

day time,

to

determine

the

mounting location of the holder.

The controller should

be

insert from top into bottom side of the holder

as shown

in

figure

below.

~

J

~

Romom

c,,.,m""

b-

Screw (2 pieces)

~

Holder for Remote Controller

• How to check pipe bending.

-Compare bended pipe with the picture below.

-

If

bended pipe

is

not good enough, cut bended area and bend

it

again.

all areas are smooth,

no

notching area

r==========~/··1

I '

s.

~============================================s=-~-~.,J

\_"'t

t

r"'

CD

CD

CD

CD

Remove the caps and unscrew at lower

portion of the front cover.

® ® ®

® Firmly press 4 hooks at top of front cover

by

tools until the hook release from slot

® Pull the front cover to front side.

®

@

©

no

scratch or mark inside

all have the same length

CD

®

@

there

are

scratches around bending area

crack

TI

I I

@ phase of bending

is

too long different length

® slanting

CD

sample of bending pipe cannot

be

used

CD CD

CD

CD

~

+ + + I

CD

To

assemble front cover back to the unit,

certainly hook at upper portion (4 places).

(Li

J

~f

t t

@ ® @ ® @

® Insert the bottom of front cover into the

slot at "PUSH" marking

and

ensure bottom

area

is

align from left to right.

® Tighten the screw and cover by caps

(3

places)

TI

i: l

Q