3

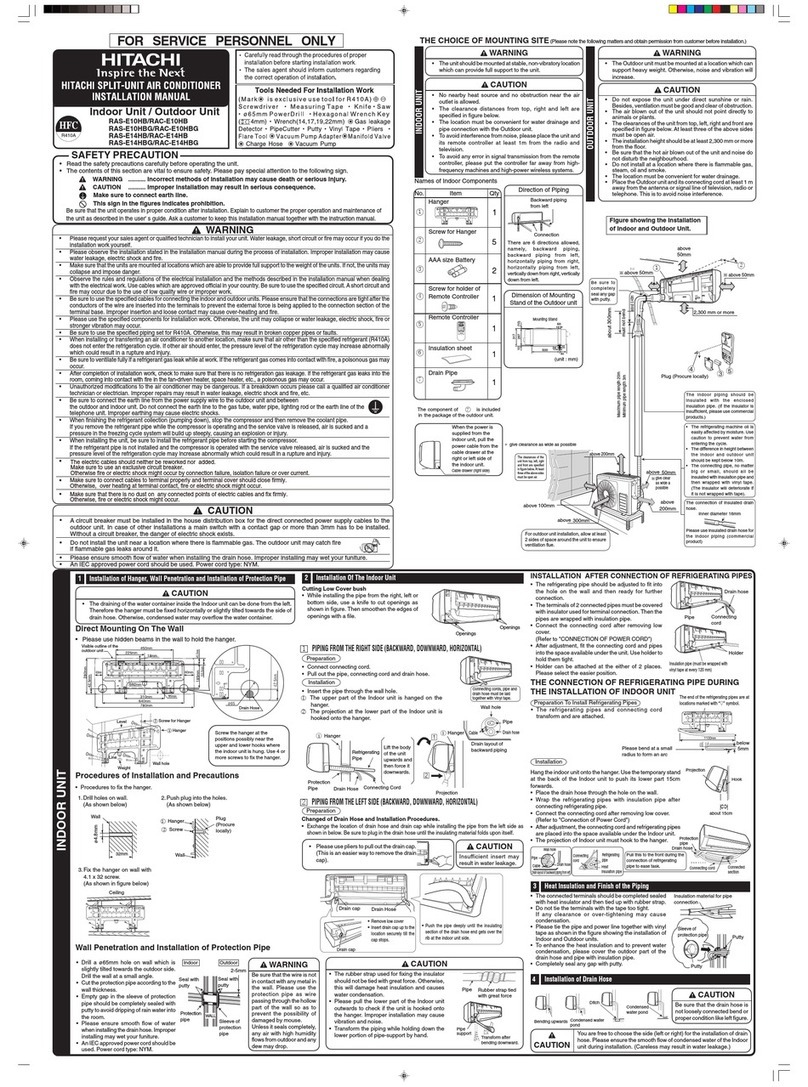

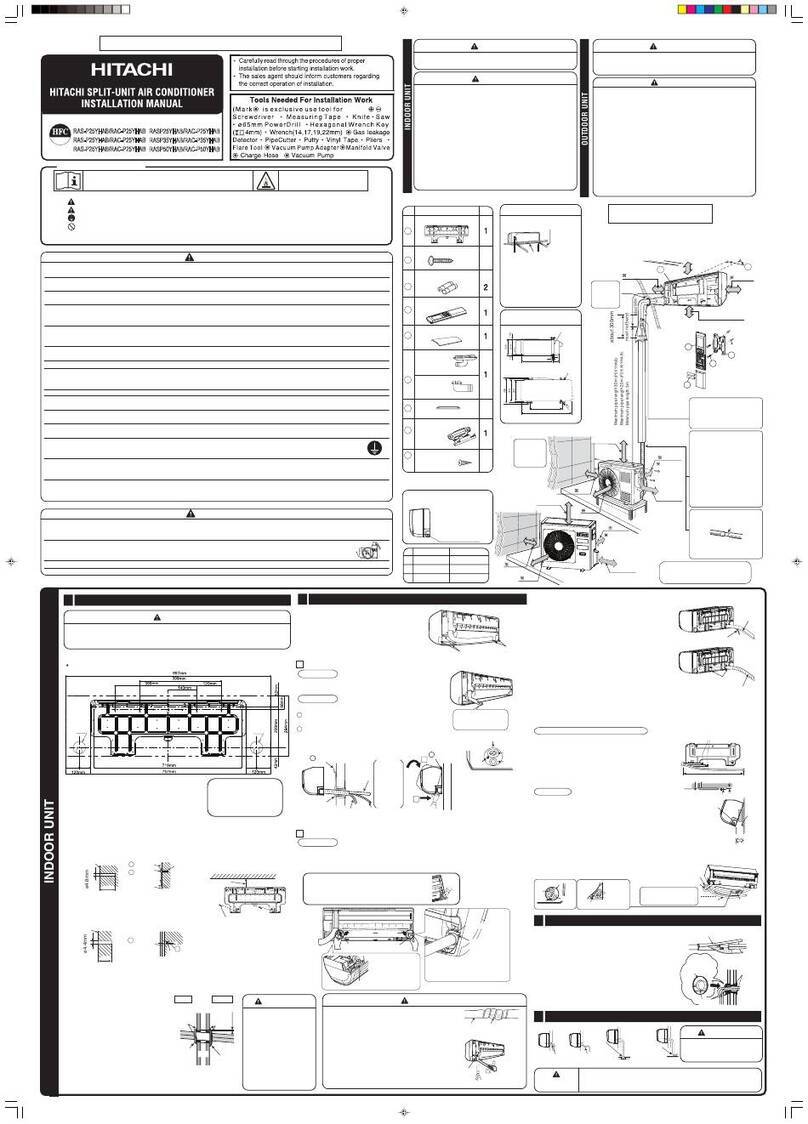

2. INSTALLATION

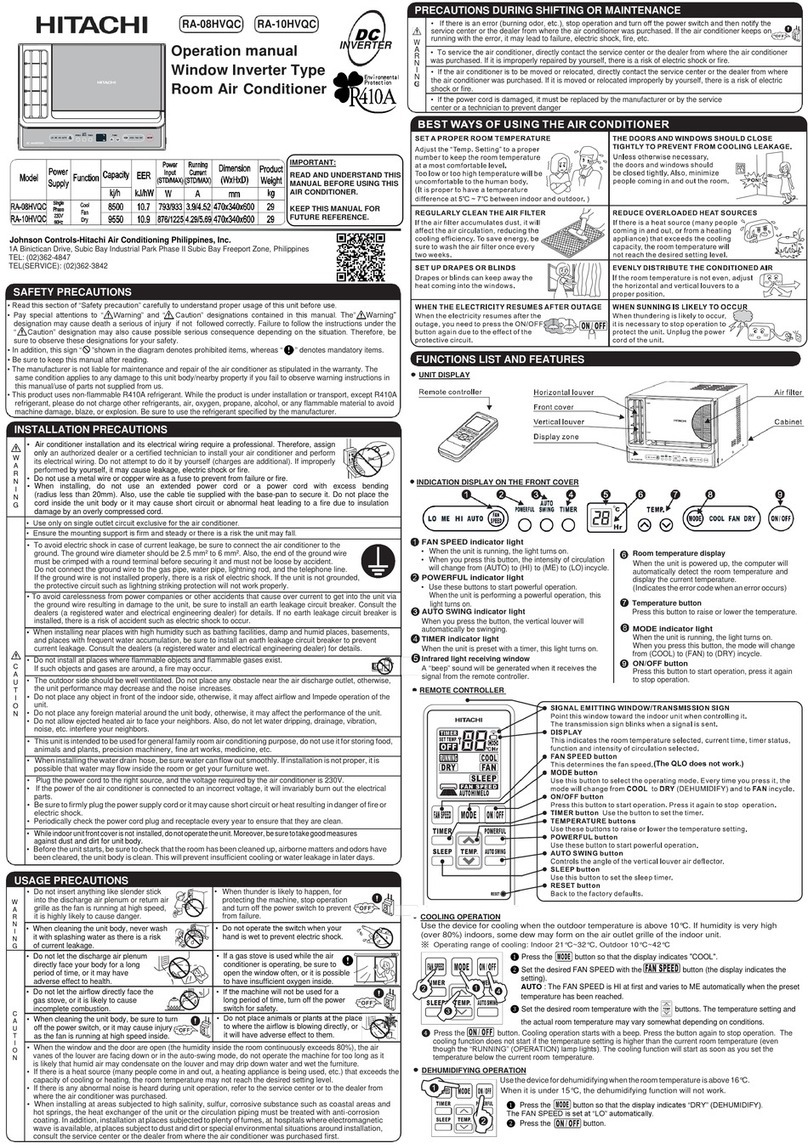

Tools and Instruments –General tools for

ducting.

Connection –Pre-drilled duct flanges are

provided at the supply and return air duct

connections. A field-supplied or optional filter box

with filter must be installed at a proper location in

the return air duct. It is recommended that flexible

duct connections be installed to minimize sound

and vibration transmission. All ducts running

outside must be sufficiently insulated and

weatherproofed.

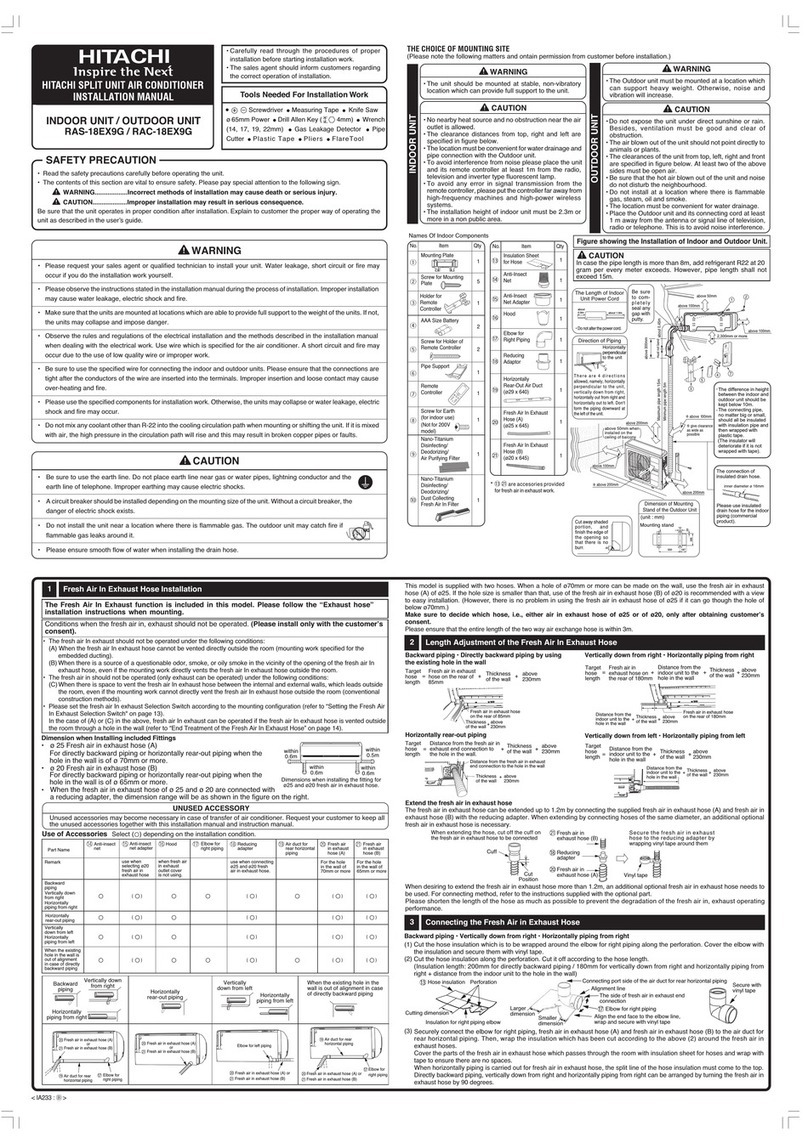

2.2 Condensate Drain Piping

Tools and Instruments –General piping tools.

Drain Trap –A female piping thread screw

connection is provided at side of the unit.

Dimension "L" in Fig. 5 should be sufficiently

longer than the negative fan pressure at the drain

connection (50mm to 100mm, depending on the

return air duct design). Always fill the trap with

water.

For Models RUA-13AT3S and RUA-15AT3S

Fig. 5. Condensate Drain Connection

Fig. 4. Rolling,Lifitng and Rigging

2.1 Ducting Arrangement

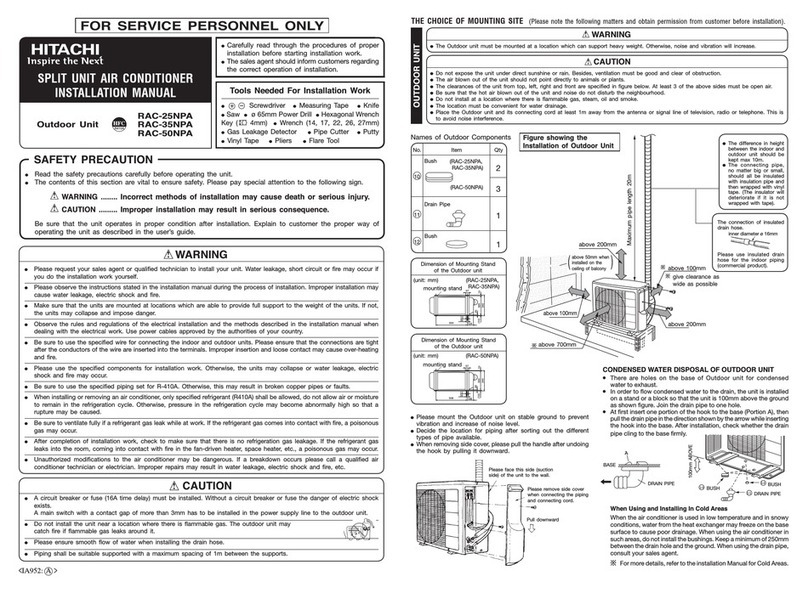

3. ELECTRICAL WIRING

Tools and Instruments –One set of wiring tools,

electrical tester (Clamp meter).

Confirm that electrical power is not being supplied

to the installation location prior to any electrical

installation work.

1. Install the field-supplied main switch box at the

properly selected location.

2. Install conduit connectors in the hole for power

wiring (knockout holes).

3. Lead the main power wires and the earthing

wire through the connector to the screw

terminals for main power and earthing in the

magnetic switch box. The neutral wire to 220V

power supplies should also be led through the

connector. Firmly connect the wires with wire

terminals to the unit screw terminals R(L1),

S(L2) and T(L3) for 220V power supplies

according to Fig. 6 or the wiring label attached

to the magnetic switch box.

Schedule Check –Confirm that the field selected

electrical components (main power switch, fuses,

wires, conduit connections, wire terminals) are

properly selected and ensure that they comply

with national and local codes. It is recommended

that the main power switch be locked at the OFF

position, to prevent against accidental supply of

the power during unit servicing.

Service Panel –Access to the magnetic switch

box is provided from the service panel, which is

fixed with screws (see the panel location in the

Operation Instructions.)

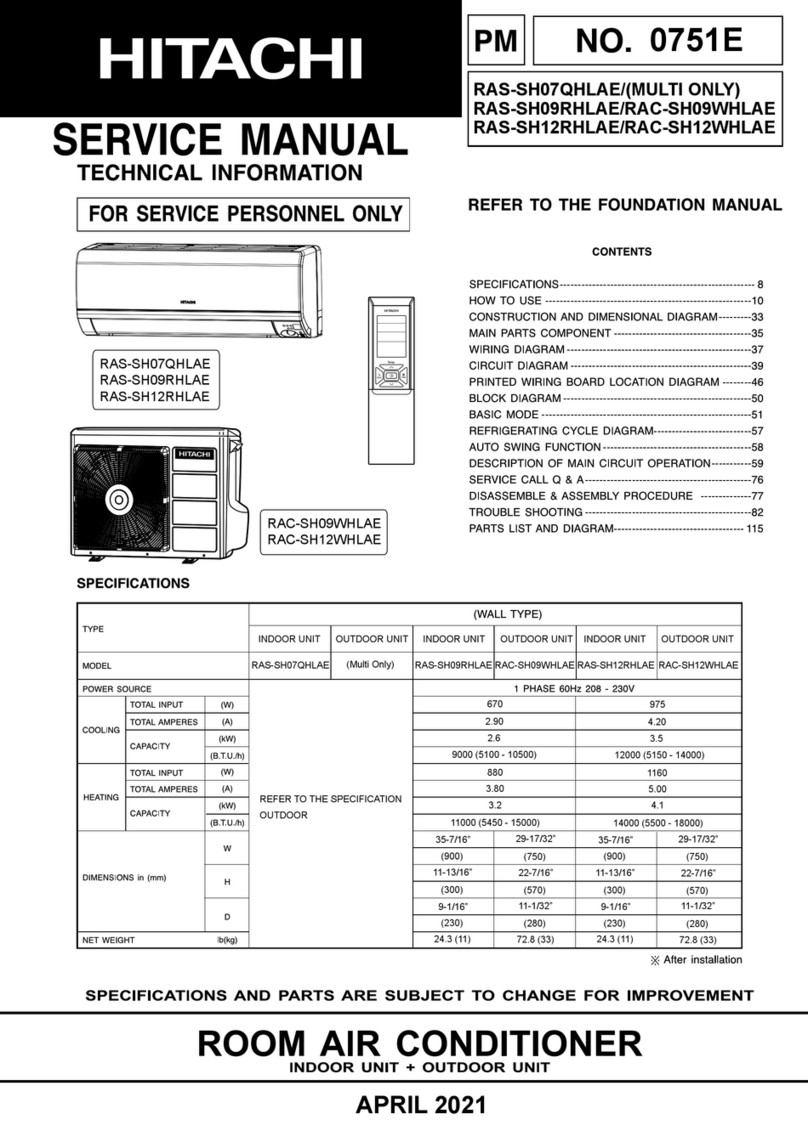

3.1 Main Power Wiring Procedures

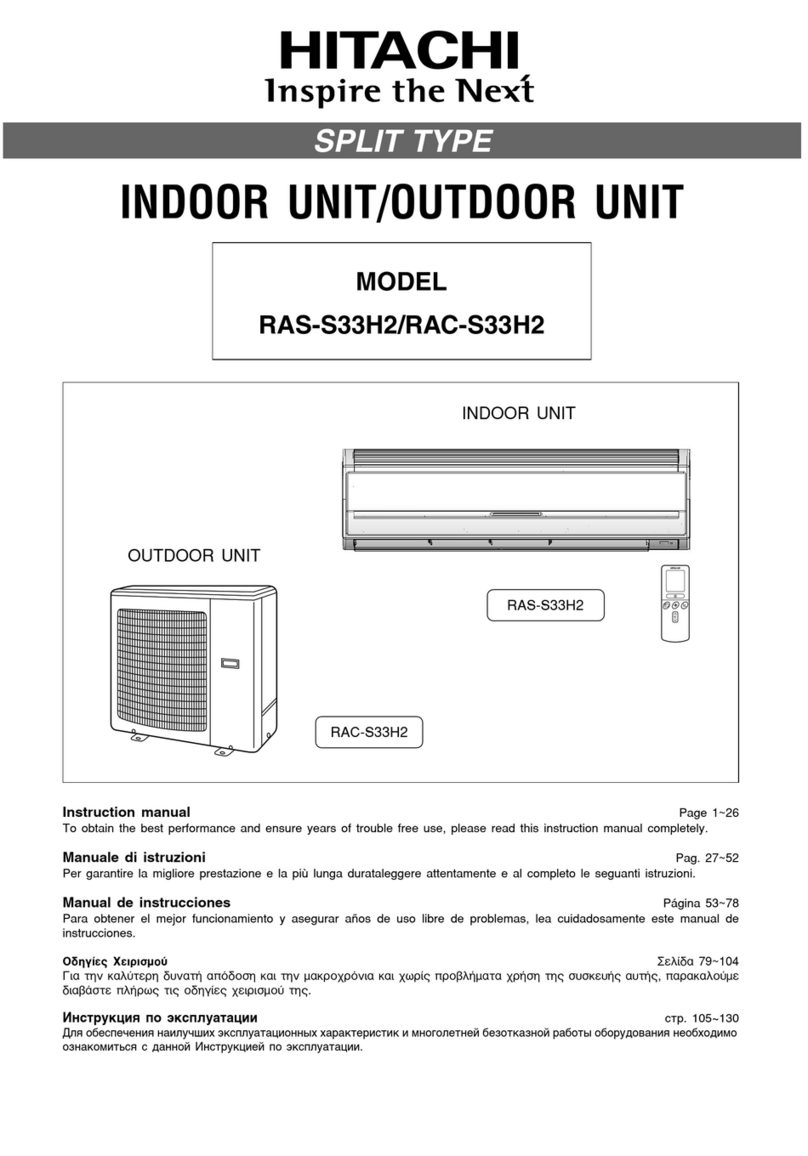

A scroll compressor is equipped. Because that

the rotation direction of the orbiting scroll of the

HITACHI scroll type compressor is fixed,

therefore a reverse & single phase sequence

protection relay is equipped in this unit.

ELECTRICAL WIRING