Holemaker Technology HMT MAX 200 User manual

Other Holemaker Technology Drill manuals

Holemaker Technology

Holemaker Technology HMT MAX30 User manual

Holemaker Technology

Holemaker Technology MAX50T User manual

Holemaker Technology

Holemaker Technology VERSADRIVE V125T User manual

Holemaker Technology

Holemaker Technology RTQ 40 User manual

Holemaker Technology

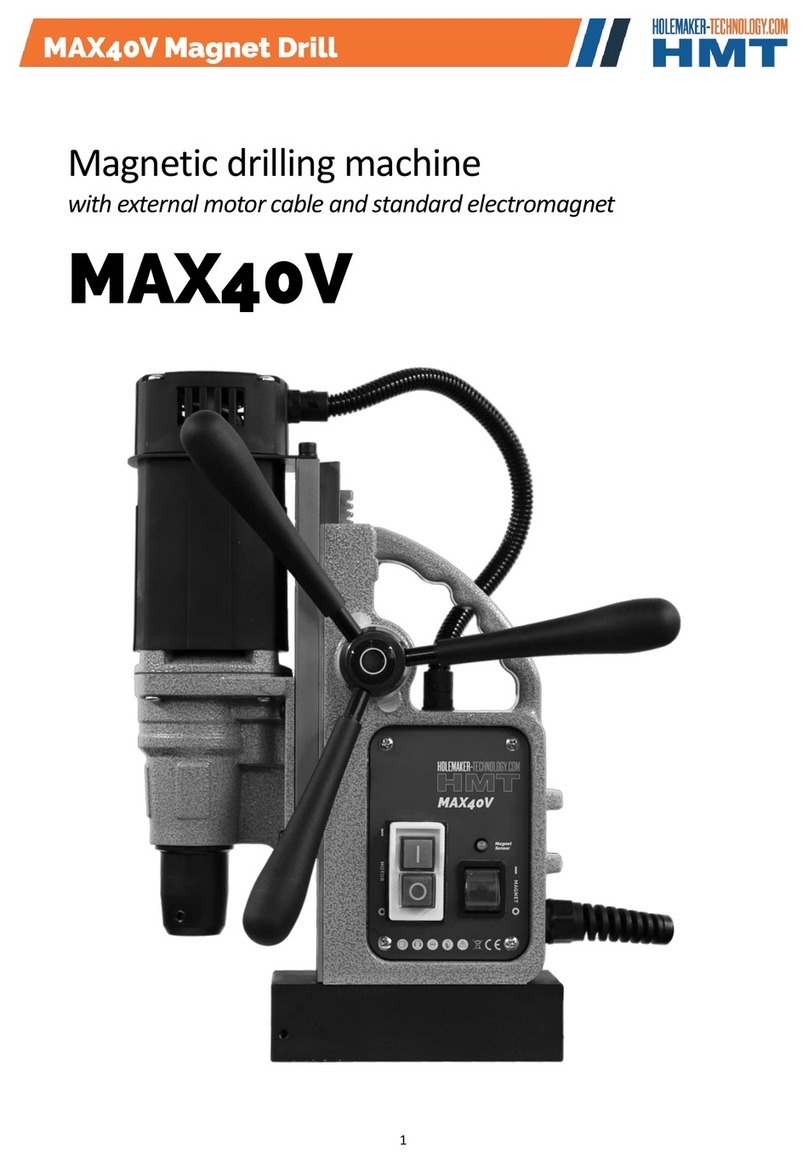

Holemaker Technology MAX40V User manual

Holemaker Technology

Holemaker Technology VERSADRIVE V60T User manual