3

EN

Your new Horizon Hobby vehicle has been designed and built with

a combination of waterproof and water-resistant components to

allow you to operate the product in many “wet conditions,” including

puddles, creeks, wet grass, snow and even rain.

While the entire vehicle is highly water-resistant, it is not completely

waterproof and your vehicle should NOT be treated like a submarine.

The various electronic components used in the vehicle, such as the

Electronic Speed Control (ESC), servo(s) and receiver are waterproof,

however, most of the mechanical components are water-resistant and

should not be submerged.

Metal parts, including the bearings, hinge pins, screws and nuts, as

well as the contacts in the electrical cables, will be susceptible to

corrosion if additional maintenance is not performed after running in

wet conditions. To maximize the long-term performance of your vehicle

and to keep the warranty intact, the procedures described in the “Wet

Conditions Maintenance” section below must be performed regularly

if you choose to run in wet conditions. If you are not willing to perform

the additional care and maintenance required, then you should not

operate the vehicle in those conditions.

CAUTION: Failure to exercise caution while using this

product and complying with the following precautions could

result in product malfunction and/or void the warranty.

GENERAL PRECAUTIONS

• Read through the wet conditions maintenance procedures and make

sure that you have all the tools you will need to properly maintain your

vehicle.

• Not all batteries can be used in wet conditions. Consult the battery

manufacturer before use. Caution should be taken when using Li-Po

batteries in wet conditions.

• Most transmitters are not water-resistant. Consult your transmitter’s

manual or the manufacturer before operation.

• Never operate your transmitter or vehicle where lightning may be present.

• Do not operate your vehicle where it could come in contact with salt

water (ocean water or water on salt-covered roads), contaminated

or polluted water. Salt water is very conductive and highly corrosive,

so use caution.

• Even minimal water contact can reduce the life of your motor if it

has not been certified as water-resistant or waterproof. If the motor

becomes excessively wet, apply very light throttle until the water is

mostly removed from the motor. Running a wet motor at high speeds

may rapidly damage the motor.

• Driving in wet conditions can reduce the life of the motor. The

additional resistance of operating in water causes excess strain. Alter

the gear ratio by using a smaller pinion or larger spur gear. This will

increase torque (and motor life) when running in mud, deeper puddles,

or any wet conditions that will increase the load on the motor for an

extended period of time.

WET CONDITIONS MAINTENANCE

• Drain any water that has collected in the tires by spinning them at high

speed. With the body removed, place the vehicle upside down and pull

full throttle for a few short bursts until the water has been removed.

CAUTION: Always keep hands, fingers, tools and any loose

or hanging objects away from rotating parts when performing

the above drying technique.

• Remove the battery pack(s) and dry the contacts. If you have an air

compressor or a can of compressed air, blow out any water that may

be inside the recessed connector housing.

• Remove the tires/wheels from the vehicle and gently rinse the mud

and dirt off with a garden hose. Avoid rinsing the bearings and

transmission.

NOTICE: Never use a pressure washer to clean your vehicle.

• Use an air compressor or a can of compressed air to dry the vehicle

and help remove any water that may have gotten into small crevices or

corners.

• Spray the bearings, drive train, fasteners and other metal parts with

a water-displacing light oil. Do not spray the motor.

• Let the vehicle air dry before you store it. Water (and oil) may

continue to drip for a few hours.

• Increase the frequency of disassembly, inspection and lubrication of

the following:

-Front and rear axle hub assembly bearings.

-All transmission cases, gears and differentials.

-Motor—clean with an aerosol motor cleaner and re-oil the

bushings with lightweight motor oil.

WATER-RESISTANT VEHICLE WITH WATERPROOF ELECTRONICS

TABLE OF CONTENTS

Water-Resistant Vehicle With Waterproof Electronics.............................3

Box Contents.....................................................................................................4

Required Equipment ........................................................................................ 4

Recommended Tools....................................................................................... 4

Getting Started Checklist................................................................................ 5

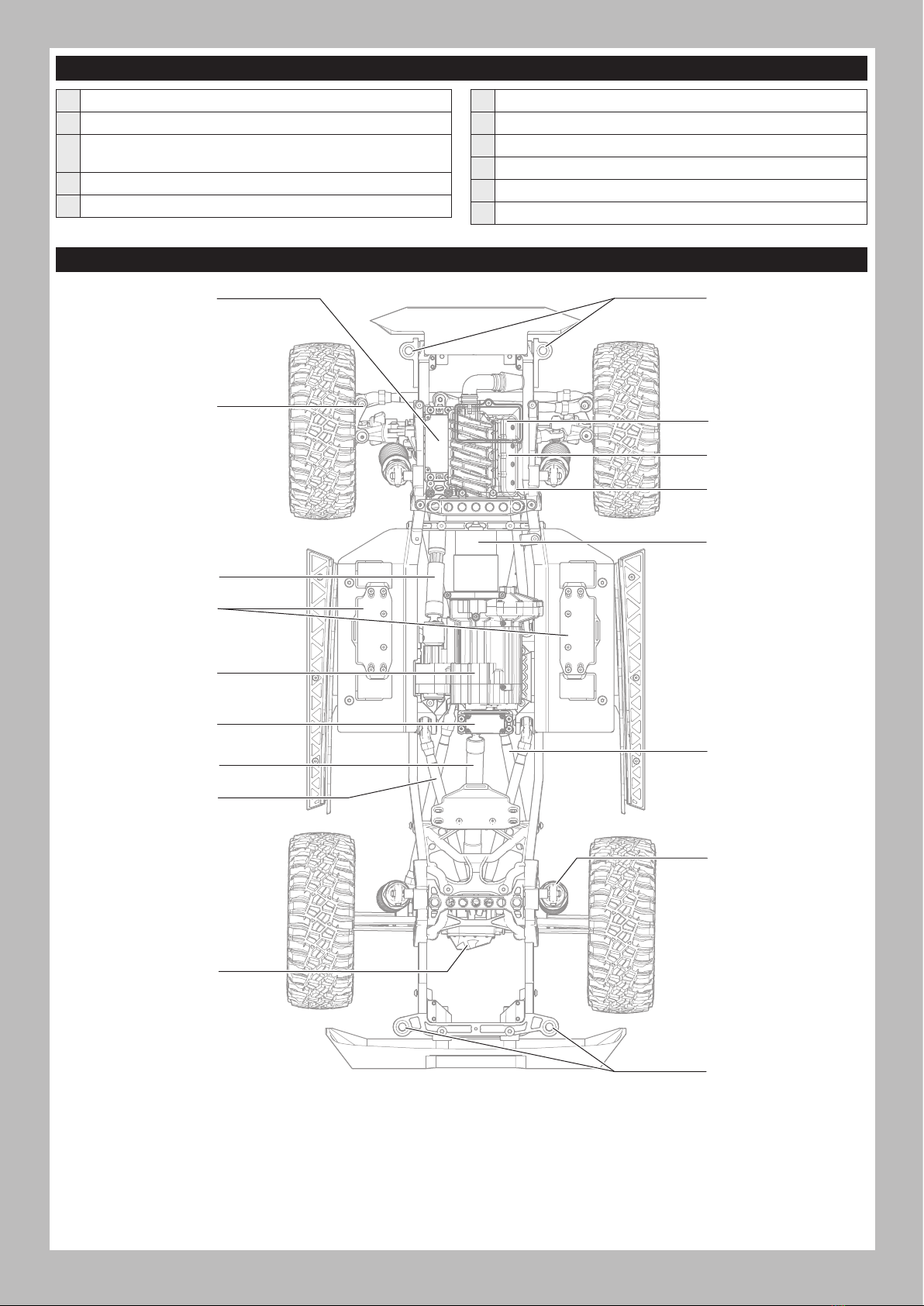

Vehicle Parts..................................................................................................... 5

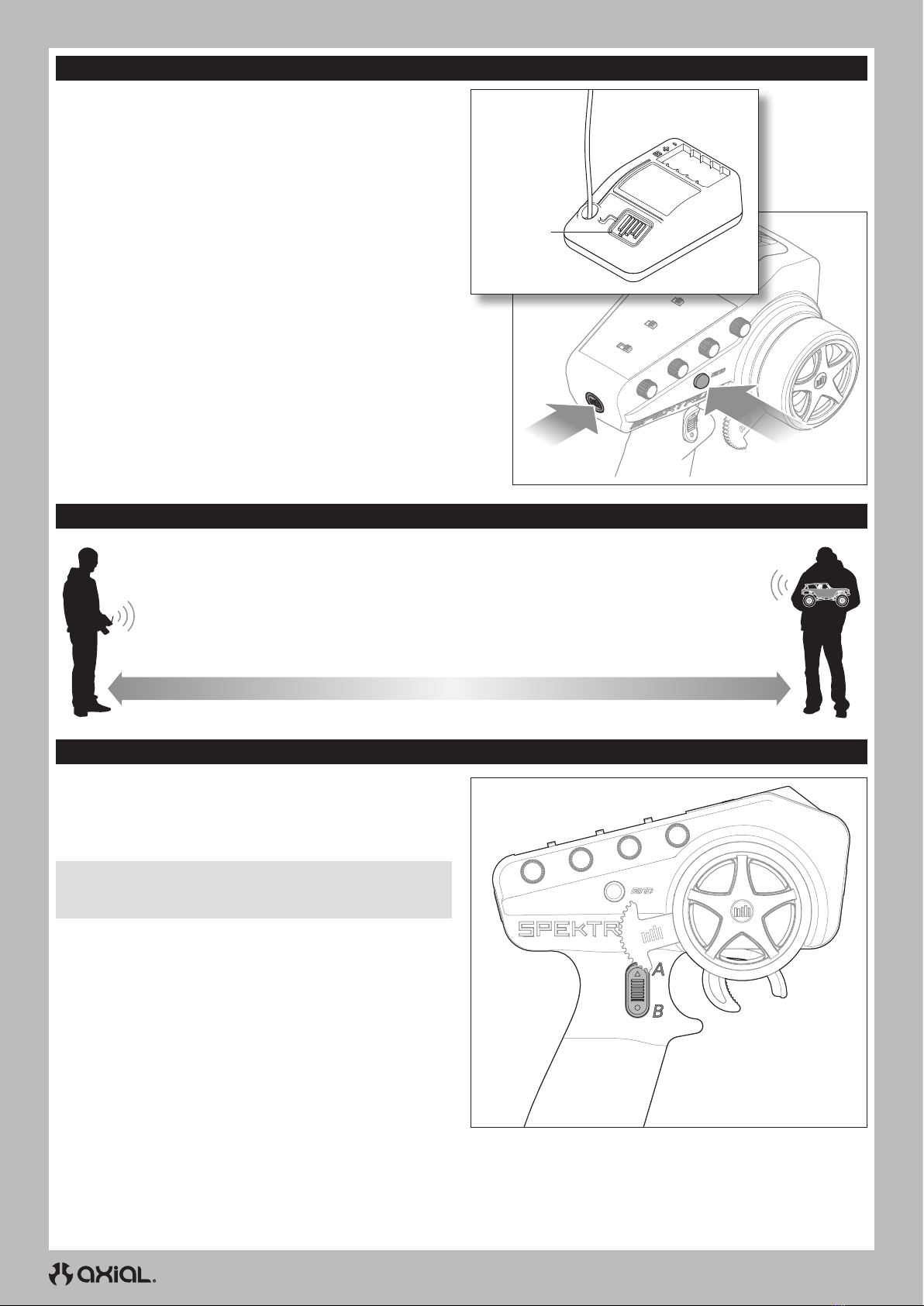

Charge the Vehicle Battery ............................................................................ 6

Install the Transmitter Batteries....................................................................6

Transmitter Functions......................................................................................6

Adjusting the Vehicle Battery Tray................................................................7

Install the Vehicle Battery .............................................................................. 7

Binding............................................................................................................... 8

Range-Checking the Radio System ..............................................................8

Using the Two Speed transmission...............................................................8

Vehicle Maintenance ...................................................................................... 9

ESC Operation.................................................................................................10

ESC Programming..........................................................................................10

Gear Ratios......................................................................................................11

Troubleshooting..............................................................................................11

Limited Warranty............................................................................................ 12

Warranty and Service Contact Information ..............................................13

FCC Information.............................................................................................. 13

IC Information.................................................................................................13

Compliance Information for the European Union.....................................14

Exploded Views..............................................................................................54

Parts List.......................................................................................................... 59

Electronics ......................................................................................................61