Congratulations,

You have just purchased the original and the very best high flow / high volume pump available

for your “Barra” engine. HPJ highly recommends installation to be completed by a qualified

“Engine Builder”.

Each pump set is pre-assembled, blue printed ready to install...

Once the pump is removed from the packaging, you will find a set of four (4) M6 cap screws

these are used to retain the pump to the block, an o’ring and an instruction card. If any of these

are missing please contact us immediately.

1. Block preparation the mating interface between the block and oil pump must be clean and

flat! All nicks/ burrs or any other damage must be repaired prior to installation.

Run a tap through the threads to clean and clear all debris, hand screw one of the M6

fasteners in there should be no resistance till the fastener bottoms out.

Crankshaft preparation the crankshaft nose should be free of damage any nicks/ burrs

removed. Allowing the pump gear a locational clearance fit.

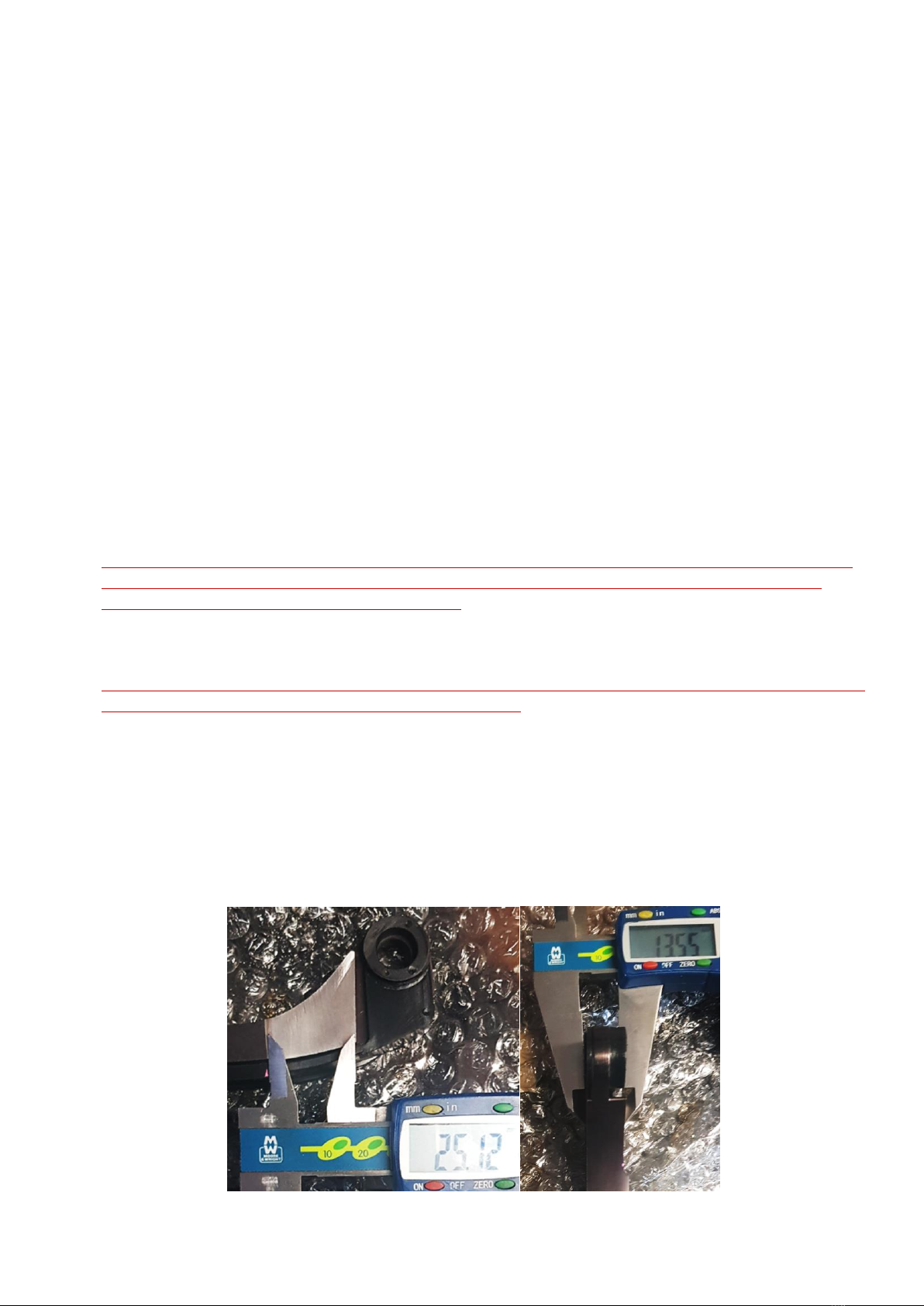

4. The pump gears are manufactured to extremely accurate tolerances; there is a small amount

of clearance. Between the inner gear and the drive flats of the crankshaft.

Care must be taken to align flats, due to the slight variations in OEM crankshafts. Note this is

the actual design of the gears the snug fit will prolong gear and crankshaft life. DO NOT

ATTEMPT TO MODIFY CLEARENCE YOURSELF!

Install the o'ring into the groove on the outlet of the pump a small amount of sealant can be

used to “coat” the o’ring HPJ recommends Loctite Master Flange sealant 518.

Care should be taken to prevent o’ring falling out this is why we recommend a very light film

of sealant, if this also migrates on to the face it’s ok

Coat pick up tube o’ring and chain lube port face with a very light film of Sealant.

Apply a small amount of Loctite 222 or equivalent to the threads and a small amount of anti-

seize under the head of the cap screw to prevent galling.

Each M6 cap screw should be torqued to 14Nm, note the two bolts holding the pump outlet

(o’ring side should be torqued first)

Pivot chain guide may require some relief between guide and housing. Should you require

any assistance please contact HPJ directly.

All care should be taken while installing your pump the HP_1000+ is a race application pump

only. HPJ accepts no responsibility for incorrect installation including damaged parts and

components related as such.

11. All responsibility resulted in not following this installation resides with the individual / installer.