- 2 -

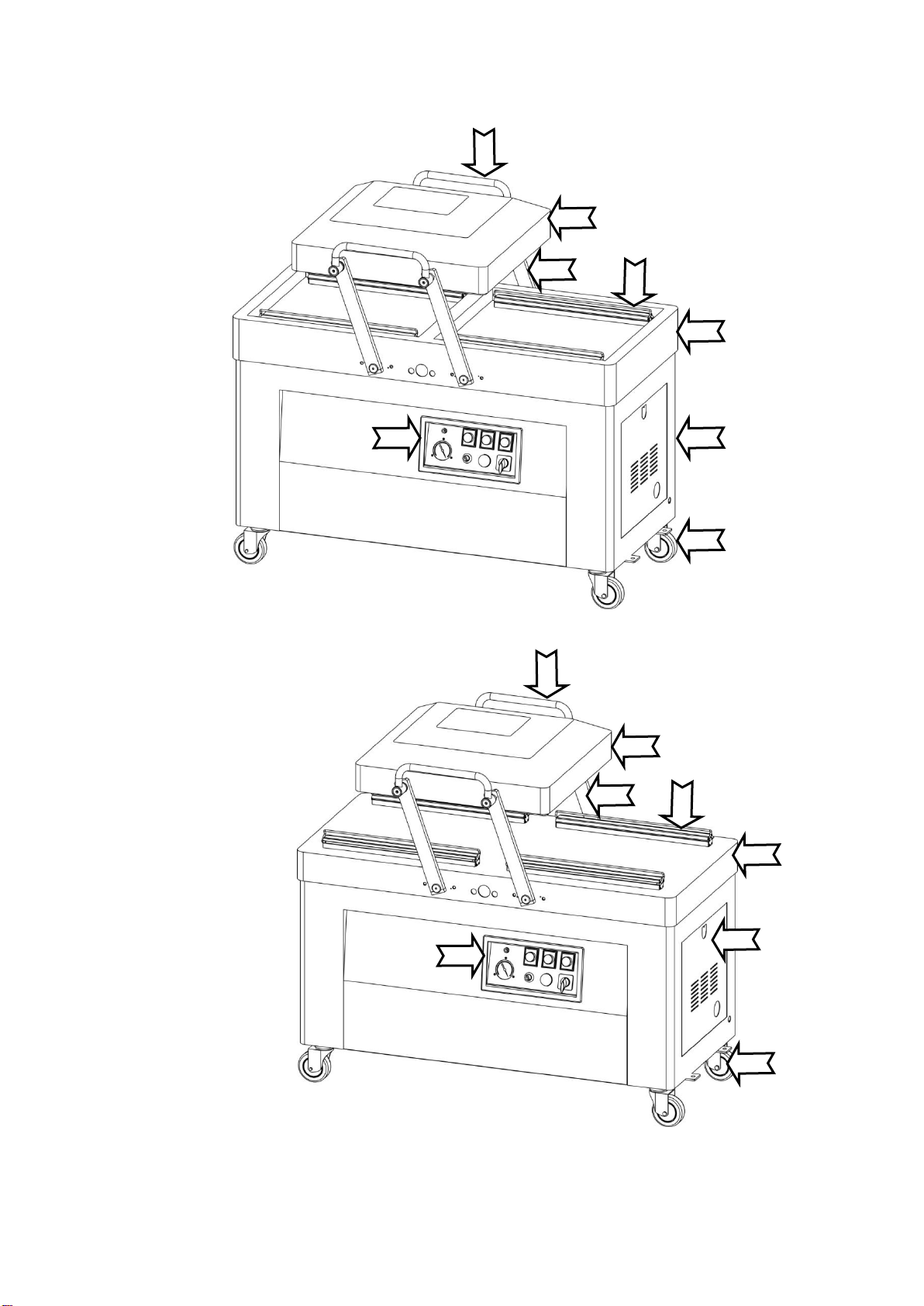

1. Product Description

1.1 Usage and Application

HVC series vacuum packaging machine possesses the advantages of superior function, easy

operation, simple maintenance, wide application etc. It applies to the soft packing material such as

composite film or aluminum-plastic composite film and so on. It can pack grain, food, fruit, seed,

medicine, chemical product, electronic product, precision instrument and meter, rare expensive

metal solid etc in liquid, powder or paste shape. The products after packing can be prevented from

oxidization, mildew, moth, rot and damp, so quality and freshness is guaranteed to prolong the

food’s storage period.

1.2 Product Features

The machine possesses oil-mist removing function, so it unnecessary to connect a pipe for

exhaust.

It is easy to operate this machine. The whole procedure, including lowering the synthetic glass

vacuum lid, vacumizing, gas-filling (if any), heat-sealing, label printing, cooling, air intake and

lifting the vacuum lid, is completed automatically.

The wide range of the temperature of sealing mouth can be applied to the packing bags with

different materials and thickness

There is an emergent stop switch in the control panel. If any exception in the extracting

process, press STOP can interrupt the packing procedure and return to standby state.

1.3 Operating Principle

Put the bags in the vacuum chamber and lower the vacuum lid. Startup the machine, the vacuum

pump runs and will form a vacuum space between the vacuum lid and the vacuum chamber.When

the vacuumizing finished, fill the gas to the vacuum chamber if it is needed. Then the airbag or the

cylinder will force the heating block to lift to hold down the bags in the effect of the pressure

difference inside the vacuum chamber and the outside. The flat heating wire in the heating plate

will become hot and the seal the bag when it is connected with low-voltage heavy current.

Consequently, fill the vacuum chamber with air after cooling down. The whole vacuum packing is

completed