- 6/39 -

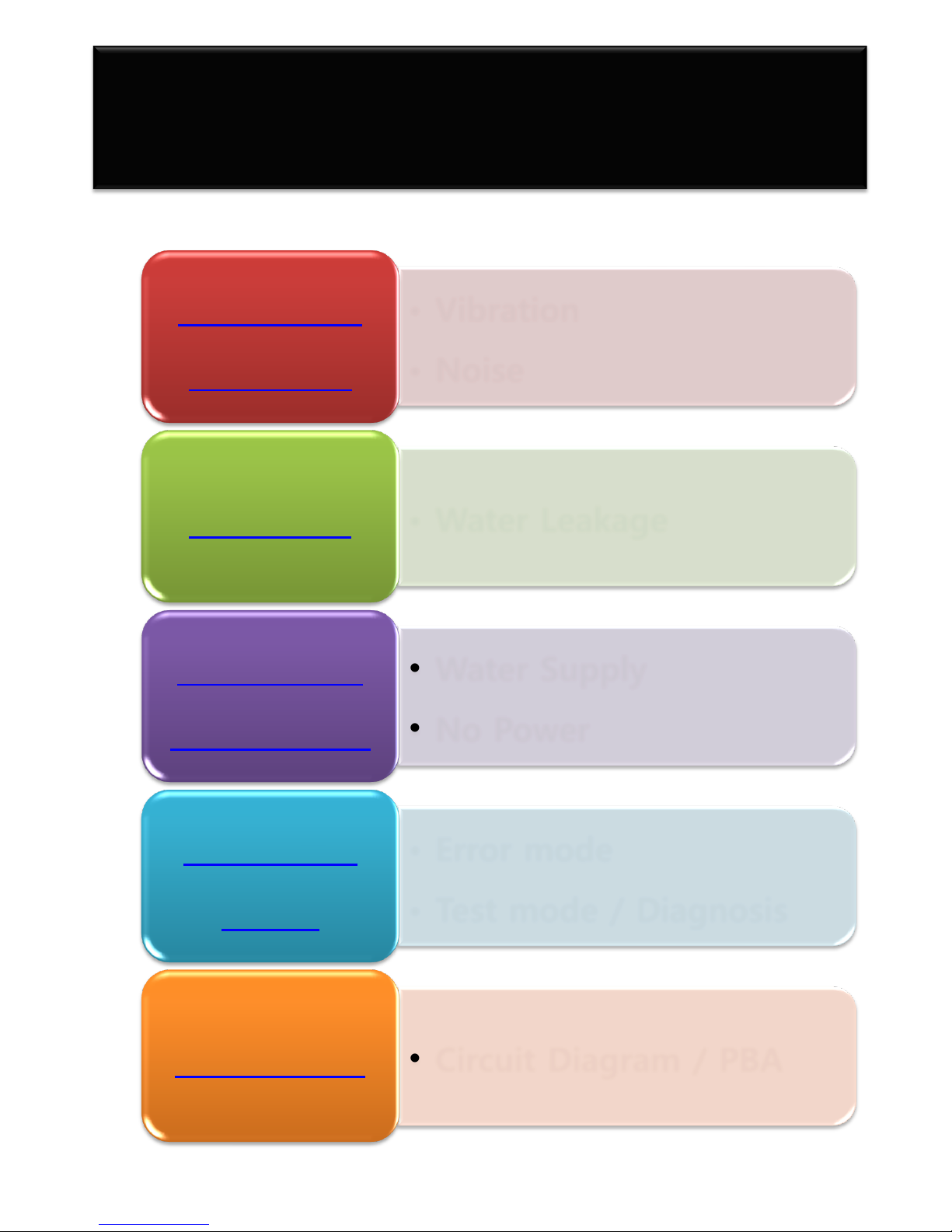

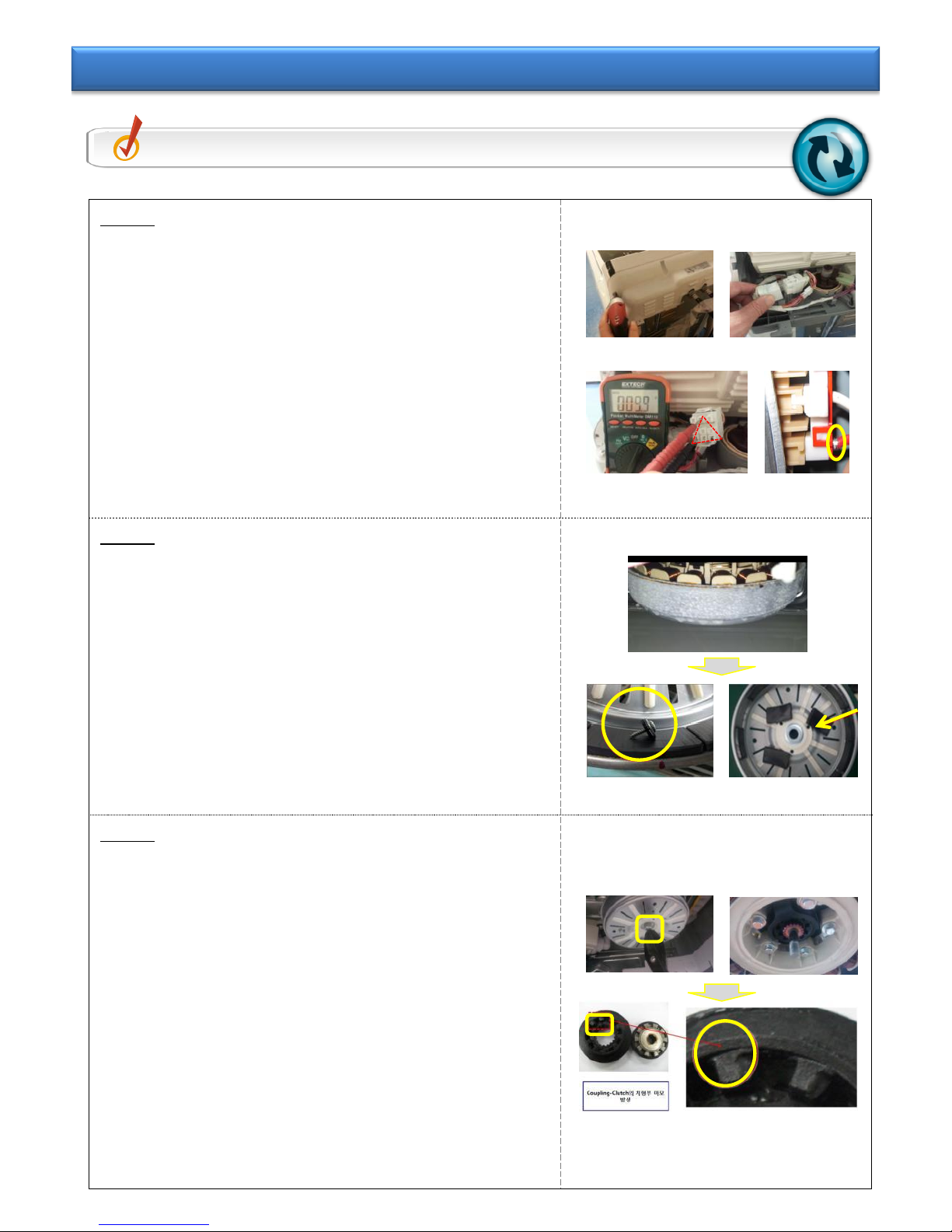

Step 1

①Check the frictional relationship with the

surroundings when installing.

- Install a pair of dryers attached. If frame is shaking

during spinning mode, interference noise is

generated.

②Friction occurs due to unstable shaping of water

supply/drain hose

- Prevent friction between water supply/drain hose and

product or wall.

③Floor is shaking, which makes the product move.

Case#1 –Levelness defect due to floor damage.

Case#2 –Shaking due to old laundry room

floor(lumber).

=> It is recommended to contact the installer and request

for re-installation such that it does not influence on

the vibration.

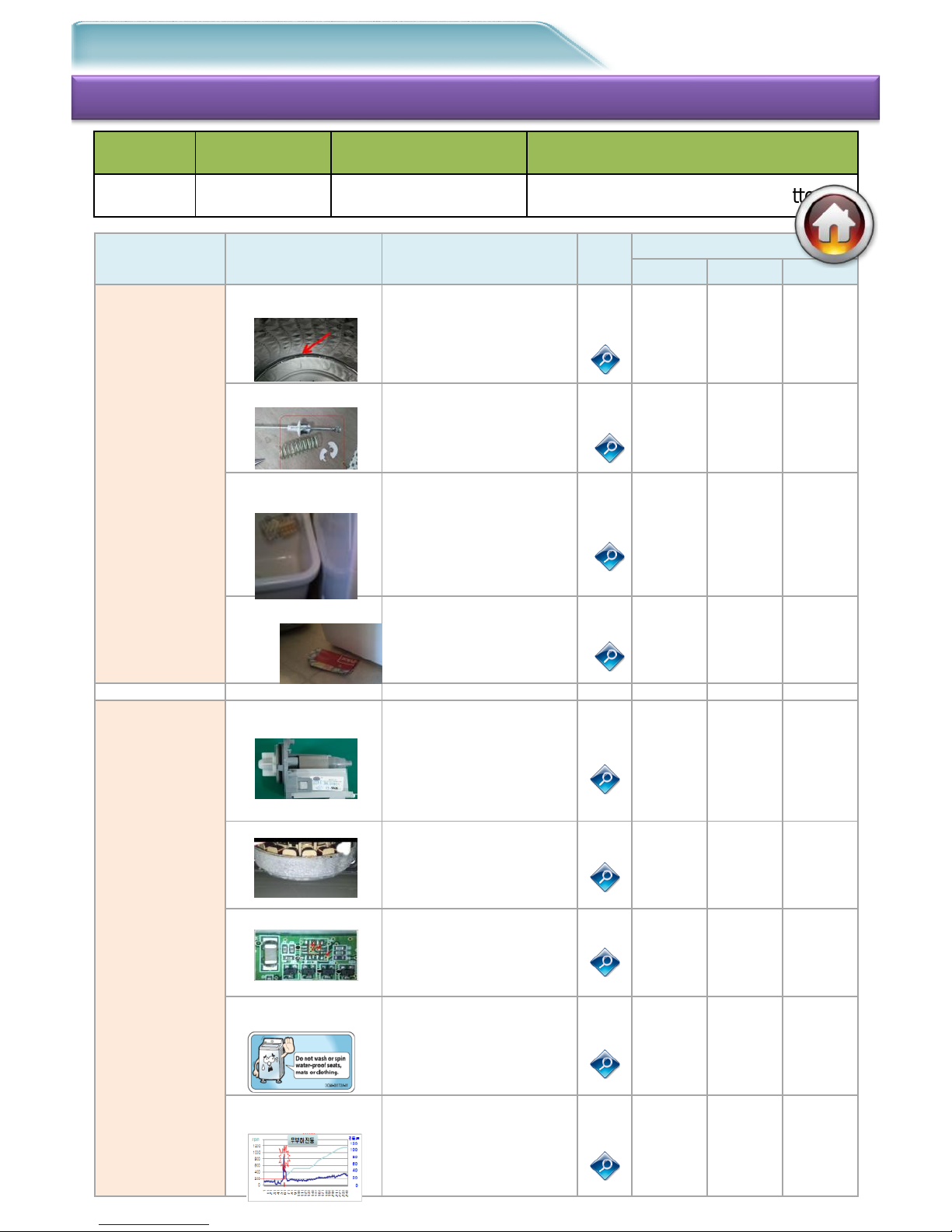

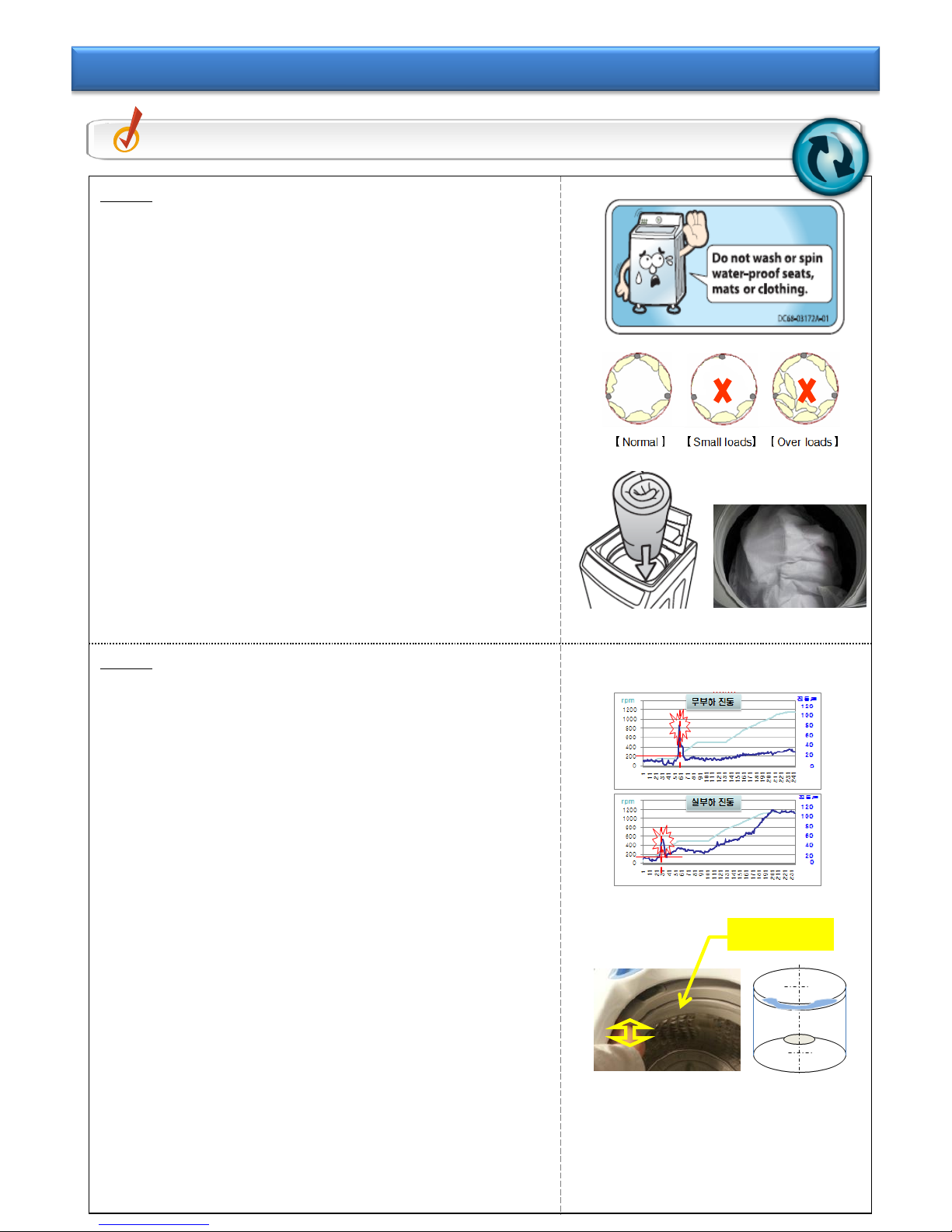

Step 2

①Check the condition of levelness of product

installation.

- For the left and right of product, check the level at

the top of Lid-T/C.

- For the front and rear of product, check the level on

the side of product.

※ When checking the left-and-right level of the product,

Tub is inclined to one side due to tension of Drain-

hose. (During water supply, it is in the right place.)

※ For level installation, adjust Leg to be attached to the

floor.

②Noise from Set on slippery floor (Tile, Moisture)

- Attach Non-Slip Pad to both front legs on the floor.

- Install the front legs of product to be located on the

Non-Slip Pad.

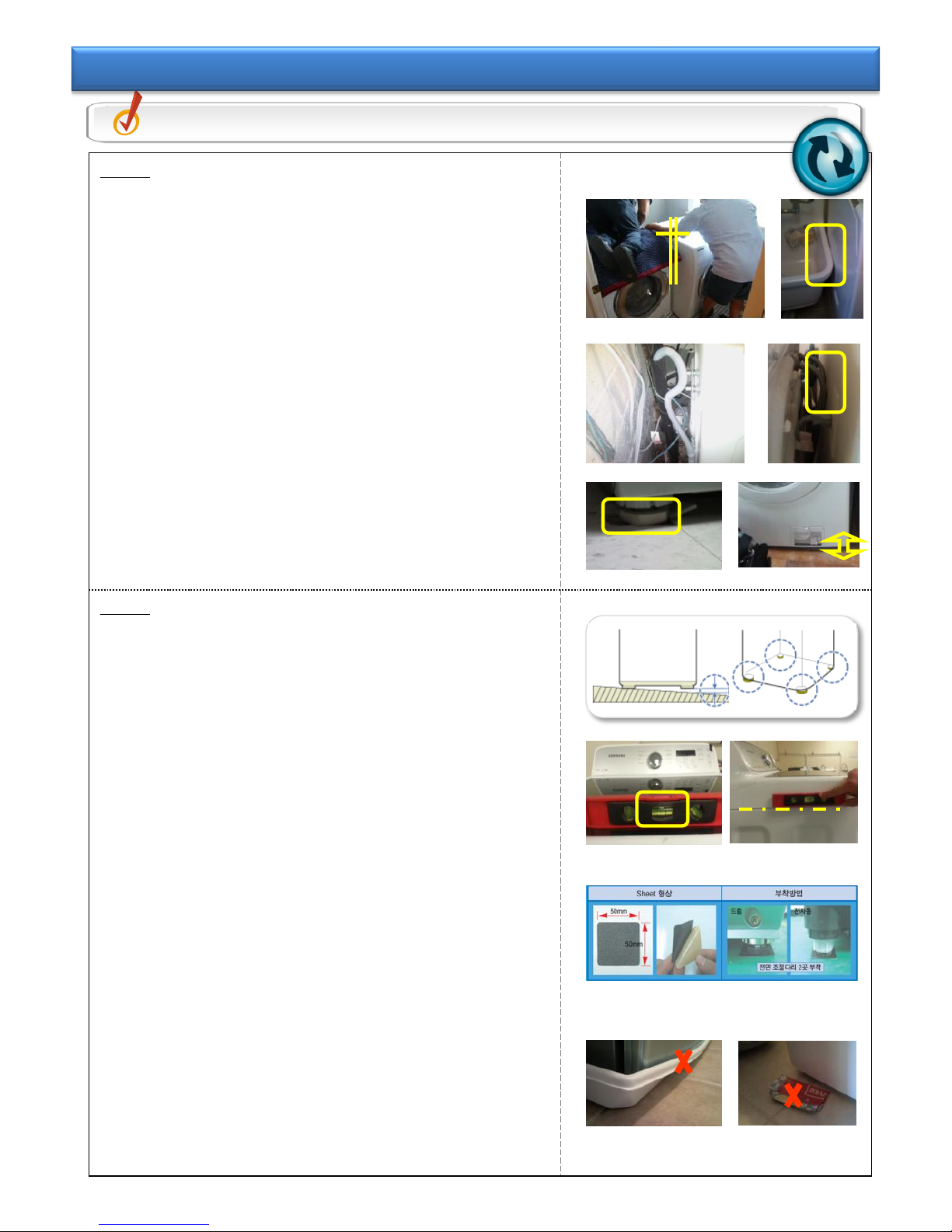

③Inappropriate material of leg for the floor

Case#1 Pan Drain Friction Noise

Case#2 Use paper for floor protection on the Leg

bottom.

=> It is recommended to contact the installer and request

for re-installation such that it does not influence on

the vibration.

Check Point Check the installation place & the condition of unstable installation.

Tip 1-3. Install Place & Unstable Install Abnormality