3 Product and installation

3.1 Main components for installation

The robotic system involves 4 main components:

• Robotic lawn mower

• Charging station

• Power supply

• Loop wire

Go to the manufacturer's website or read the Operator's

manual for further descriptions about the product and

the installation.

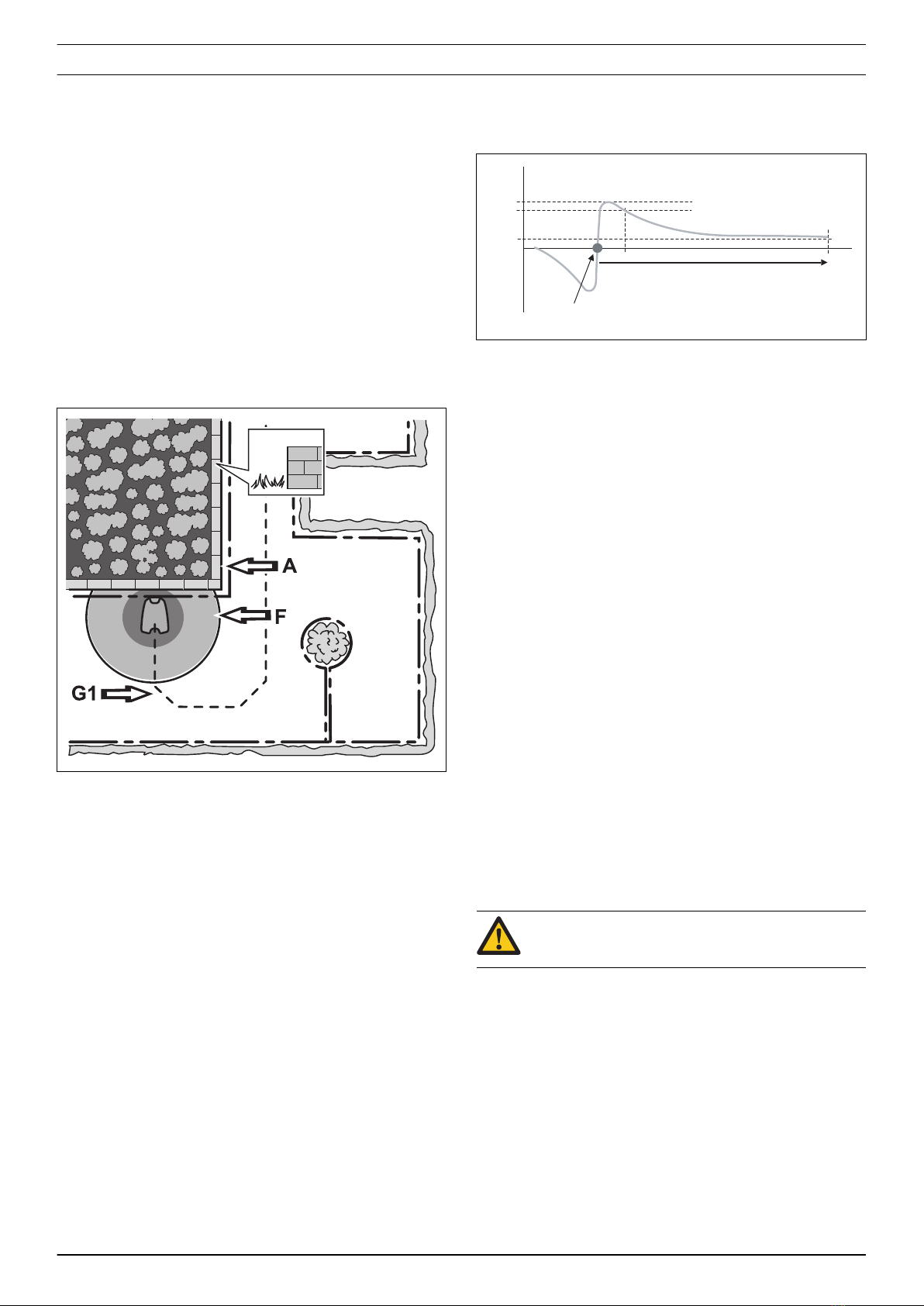

3.2 The loop system's control signals

The loop system consists of boundary wire and guide

wire connected to the charging station. The loop system

essentially comprises these different signals:

• A signal, sets the boundary for the working area.

• F signal, is generated by a loop in the charging

station so that the product knows that it is in the

vicinity of the charging station.

• Guide signal, leads the product to the charging

station, but can also be used to guide the product

from the charging station to a remote area.

To check the A, F and Guide signals, refer to the

Loop

signal on page 30

.

3.3 LED indicator lamp on the charging station

The loop system’s status is easily checked using the

LED indicator lamp on the charging station. Refer to

Loop signal on page 30

.

3.4 Boundary loop

The strength of the A signal varies depending on the

distance. The strength of the signal is high close to the

wire. The strength subsequently diminishes the farther

away from the wire you get. Outside the work area the

signal is negative and its strength diminishes more

rapidly. Signal quality should always be 100% for

satisfactory function.

The strength of the signal is affected by the size of the

work area, islands, headlands, passages and corners.

The signal can also be affected by magnetic objects in

the ground or in nearby walls and buildings. Examples of

magnetic objects are iron fences, iron girders and

reinforcement bars. Grass areas laid on concrete roofs

can therefore lead to a weaker signal.

The A signal’s reception and amplification can vary by

+/- 10% from one product to another. This means that at

the same point in an installation, one product can

display A=90 and another one A=100. The charging

station’s circuit board and the product’s loop sensor can

also give certain variations between different products.

3.4.1 To test the boundary loop

The product displays the

No loop signal

message if an

attempt is made to start the product before the

installation is complete.

However, it is possible to test the product before the

installation is completed by doing one of the following:

• Connect a short, temporary loop around the product.

• Temporarily deactivate the product’s loop detection.

Refer to

Autocheck service tool on page 9

.

3.4.2 Obstacles

To demarcate an obstacle, you can put the boundary

wire from the edge of the work area to the obstacle,

around it and then back.

CAUTION: The boundary wire must not be

crossed on its way to and from an island.

3.5 Guide loop

The guide wire, together with the part of the boundary

loop that comprises the return to the charging station, is

called the guide loop. The current in the guide loop

always goes from the guide wire to the left in the

connection between guide wire and boundary loop.

The strength of the guide signal varies like the A signal

depending on the distance to the guide loop. Inside the

guide loop the signal is positive and the strength

subsequently diminishes the farther away from the wire

6 - Product and installation 1595 - 001 - 01.02.2021