2

1. Safety Precautions

•The earth drill must always be operated by two operators.

•The operators must pay extra attention and show caution when working in

difficult working areas, such as slopes and other dangerous nature of the ground.

Do not reach too far with the earth drill, but always maintain a good footing and

keep your balance.

•The operators must always use protective goggles, earplugs, hard hat and shoes

when operating the earth drill.

•The operators must be properly trained in using the earth drill or under

supervision of a qualified instructor.

•A fine jet of oil at pressure can penetrate the skin. It is therefore important never

to use your fingers to check for oil leaks and never to hold your face close to su-

spected leaks – use a piece of cardboard instead. If oil has penetrated the skin,

you should get medical treatment immediately.

•Never leave the earth drill, when it is connected to the powerpack.

•Use only original HYCON augers.

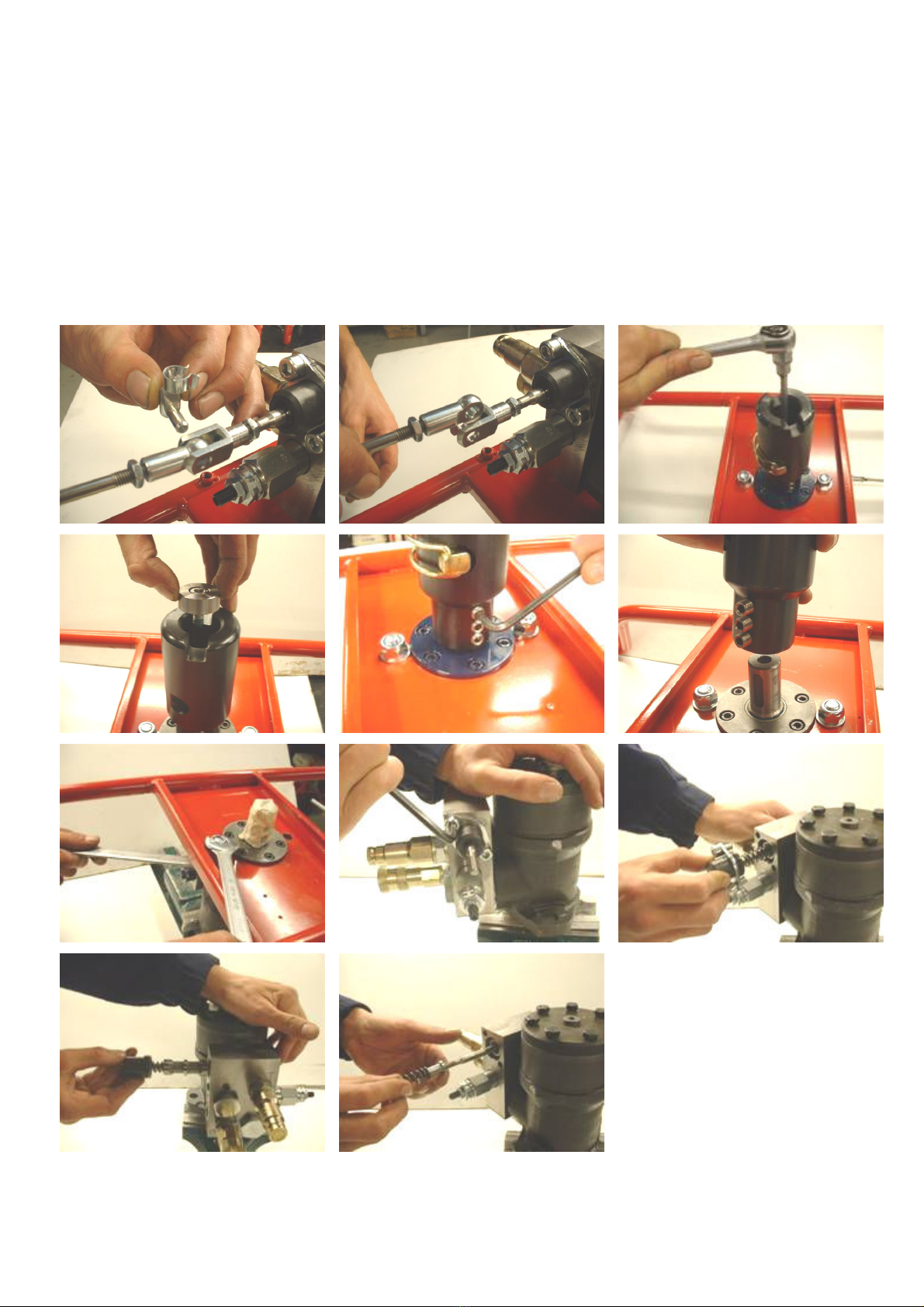

•Always use approved hoses. Contact your dealer if necessary. Be careful to mount

the hoses correctly. The earth drill is marked with “P” and “T”, and “P” should be

connected to pressure and “T” to tank.

•Never use the earth drill close to electric cables. Prior to operation, check if there

are hidden or buried cables.

•The earth drill is mounted with a pressure relief valve (torque limiter). It has been

adjusted to 90 bar from the factory and may never be changed as this may cause

severe personal injury.