Model VIP+ 2 Owner's Manual

Table of Contents

Scope and Recommendations ................................................................................................................................................ 1

Technical Specifications .......................................................................................................................................................... 3

Material ............................................................................................................................................................................... 3

Weight / Standard Thickness .............................................................................................................................................. 3

Venting Applications ........................................................................................................................................................... 3

B ilding Heating Appliance (BHA) Chimney (UL 103 Listing) : ...................................................................................... 3

1400°F Chimney (UL 2561 Listing) : .............................................................................................................................. 3

Positive Press re Listing (UL 103 and UL 2561) : ......................................................................................................... 3

540°C and 760°C Ind strial Chimneys (ULC C-959 Listing) : ........................................................................................ 3

S rro ndings / Enclos re ................................................................................................................................................... 3

Clearance to Comb stibles ................................................................................................................................................. 4

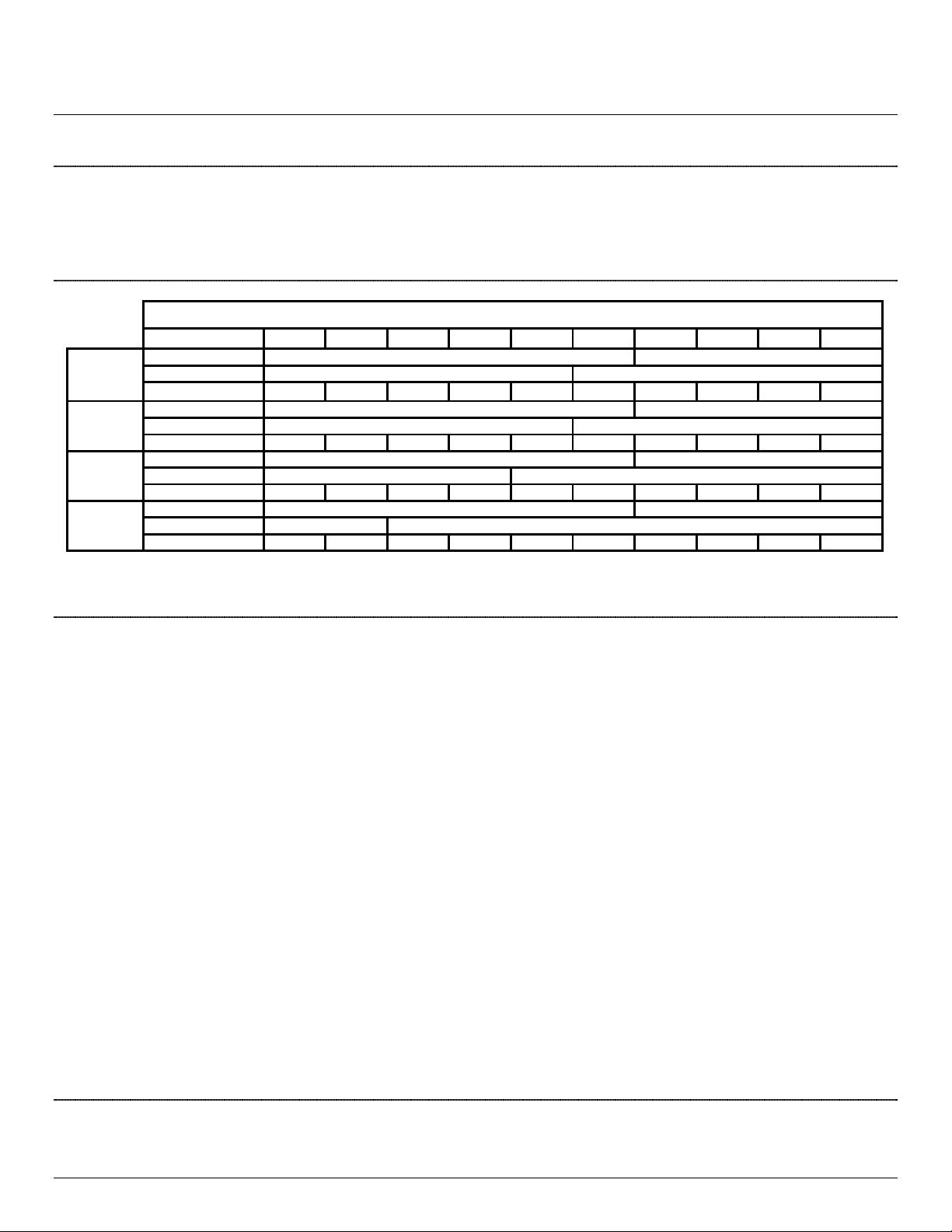

Part N mbers ...................................................................................................................................................................... 4

Chimney Sizing ................................................................................................................................................................... 5

Operation and Maintenance .................................................................................................................................................... 6

General Installation Notes .................................................................................................................................................. 6

Planning yo r Installation .................................................................................................................................................... 6

Tool checklist .................................................................................................................................................................. 6

R les of Safety ............................................................................................................................................................... 6

Chimney Joint Connection ...................................................................................................................................................... 7

S rface Preparation ............................................................................................................................................................ 7

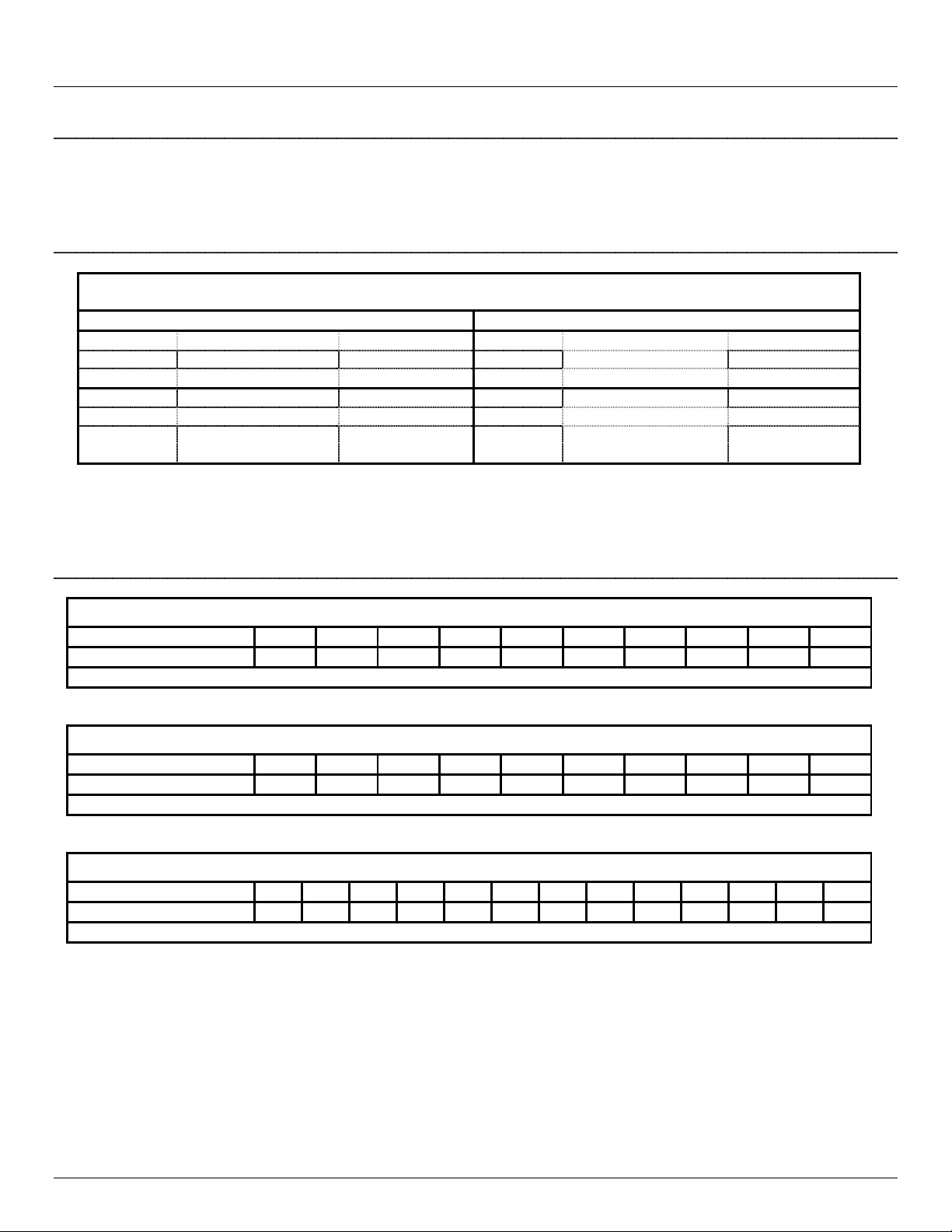

Sealant Application Chart ................................................................................................................................................... 7

Sealant Coverage ............................................................................................................................................................... 7

Joint Assembly – Low temperat re (600°F Max) Applications ........................................................................................... 8

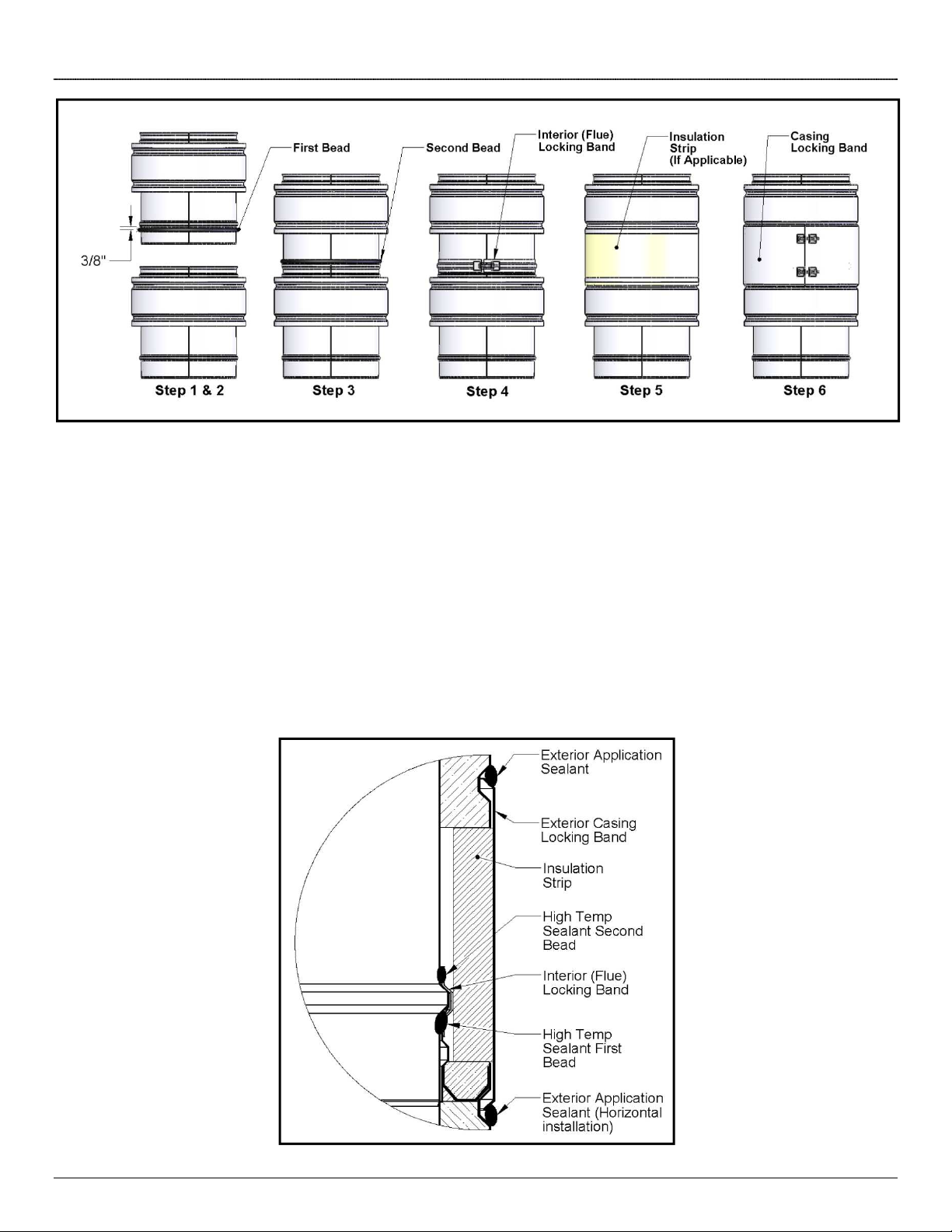

Joint Assembly – High Temperat re (Above 600°F) Applications ...................................................................................... 9

Str ct ral S pports and G ides ............................................................................................................................................ 10

Base S pport .................................................................................................................................................................... 10

Wall S pport ..................................................................................................................................................................... 11

Wall G ide ........................................................................................................................................................................ 12

Floor G ide ....................................................................................................................................................................... 12

S pport Methods and System Design Limits .................................................................................................................... 13

Rigid Str ct ral Brace Specifications................................................................................................................................ 14

Elbows and Offsets ........................................................................................................................................................... 14

G y Wire ........................................................................................................................................................................... 15

Roof and Floor Penetrations ................................................................................................................................................. 16

Non-Comb stibles Floor Penetration................................................................................................................................ 16

Comb stible Floor Penetration – 1000°F Chimney (UL 103 & ULC C-959 Listings) ....................................................... 16

Comb stible Roof Penetration – 1000°F Chimney (UL 103 & ULC C-959 Listings) ........................................................ 17

Comb stible Roof Penetration – 1400°F Chimney (UL 2561 & ULC C-959 Listings) ...................................................... 18

Thermal Expansion ............................................................................................................................................................... 19

General Considerations .................................................................................................................................................... 19

Bellows Joint ..................................................................................................................................................................... 20

Expansion Length ............................................................................................................................................................. 21

Expansion Joints Installation ............................................................................................................................................ 22

Bellows Joint and Expansion Length in vertical r ns ................................................................................................... 22

Bellows Joint and Expansion Length in horizontal r ns ............................................................................................... 22

Adj stable Lengths ........................................................................................................................................................... 22

Grease D ct .......................................................................................................................................................................... 25

Listings and Applications .................................................................................................................................................. 25

Clearances and S rro ndings .......................................................................................................................................... 25

General Installation Instr ctions ....................................................................................................................................... 25

Fan Adapter ...................................................................................................................................................................... 26

Nozzle Length and Drains ................................................................................................................................................ 26

Cleano t and maintenance ............................................................................................................................................... 27

Access Door Section .................................................................................................................................................... 27

Wyes and Tees (Cleano t) ........................................................................................................................................... 28

Typical Grease D ct Installation ....................................................................................................................................... 29

WARRANTY .......................................................................................................................................................................... 30