ELECTRONIC CIRCULATOR FOR SOLAR THERMAL SYSTEMS - Art. S166

FI.S166.EN.C - 10/2022

Icma

SpA

-

Via

Garavaglia,

4

-

20012

C

uggiono

(MI)

IT

AL

Y

T

el:

+39

02

97249134

-

+39

02

97249135

-

w

ww.icmaspa.it

-

[email protected] Icma

SpA

-

Via

Garavaglia,

4

-

20012

C

uggiono

(MI)

IT

AL

Y

T

el:

+39

02

97249134

-

+39

02

97249135

-

w

ww.icmaspa.it

-

[email protected]4 5

5. Improper use

This is a circulator to be used in heating plants and for the circulation of clean water

without abrasive particles. This is not a submersible pump. Do not use this circula-

tor:

• With liquids other than water (e.g. ammable liquids, etc.) (EN60335-2-51);

• For handling drinkable water or food related liquids;

• For the circulation of domestic water;

• In locations where special condition prevail, such as the presence of a corrosive or

explosive atmosphere (dust, vapor or gas) (EN60335-2-51);

• For other than intended use.

Never run the circulator dry. The circulator must be always fully lled with water

when operating.

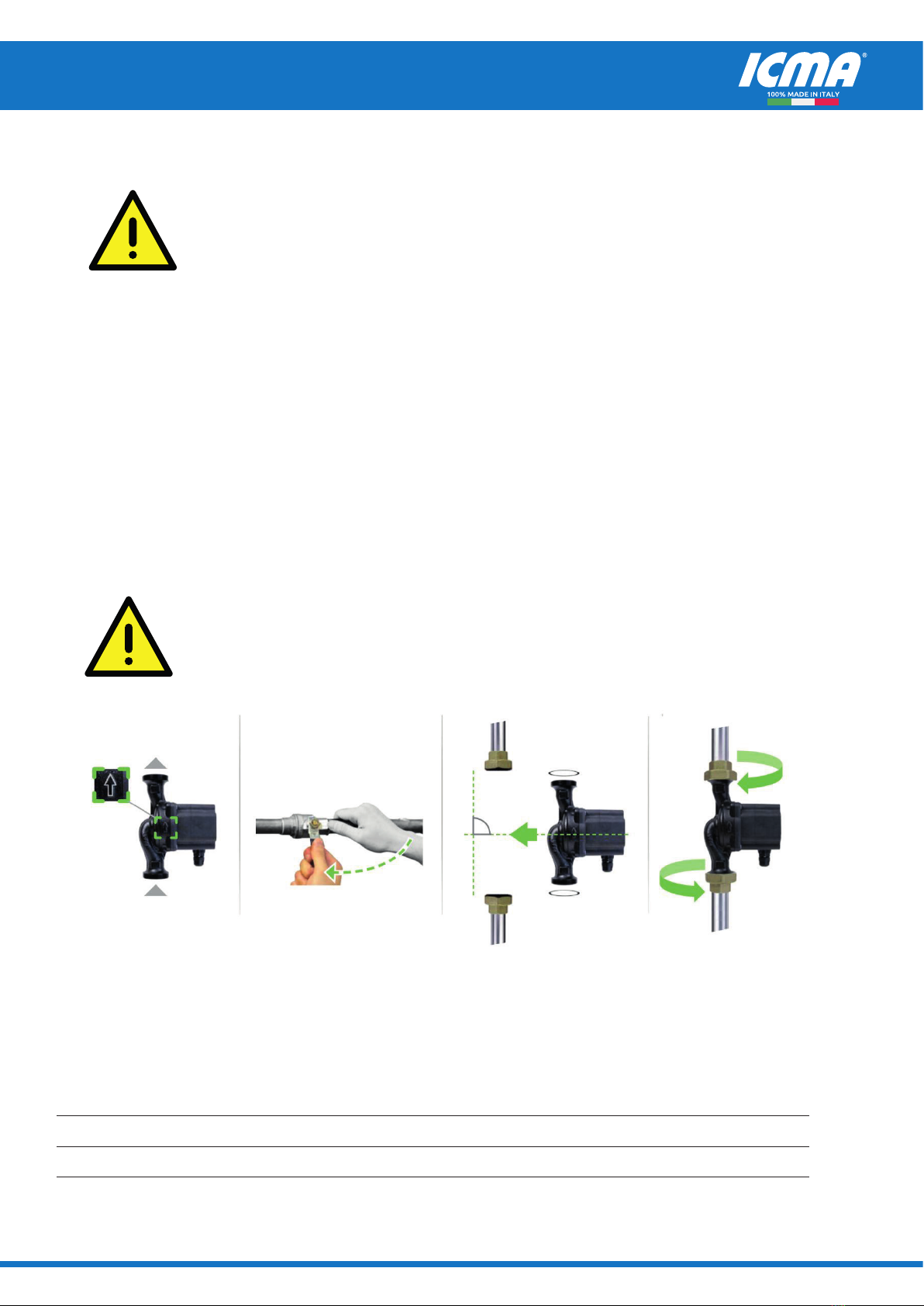

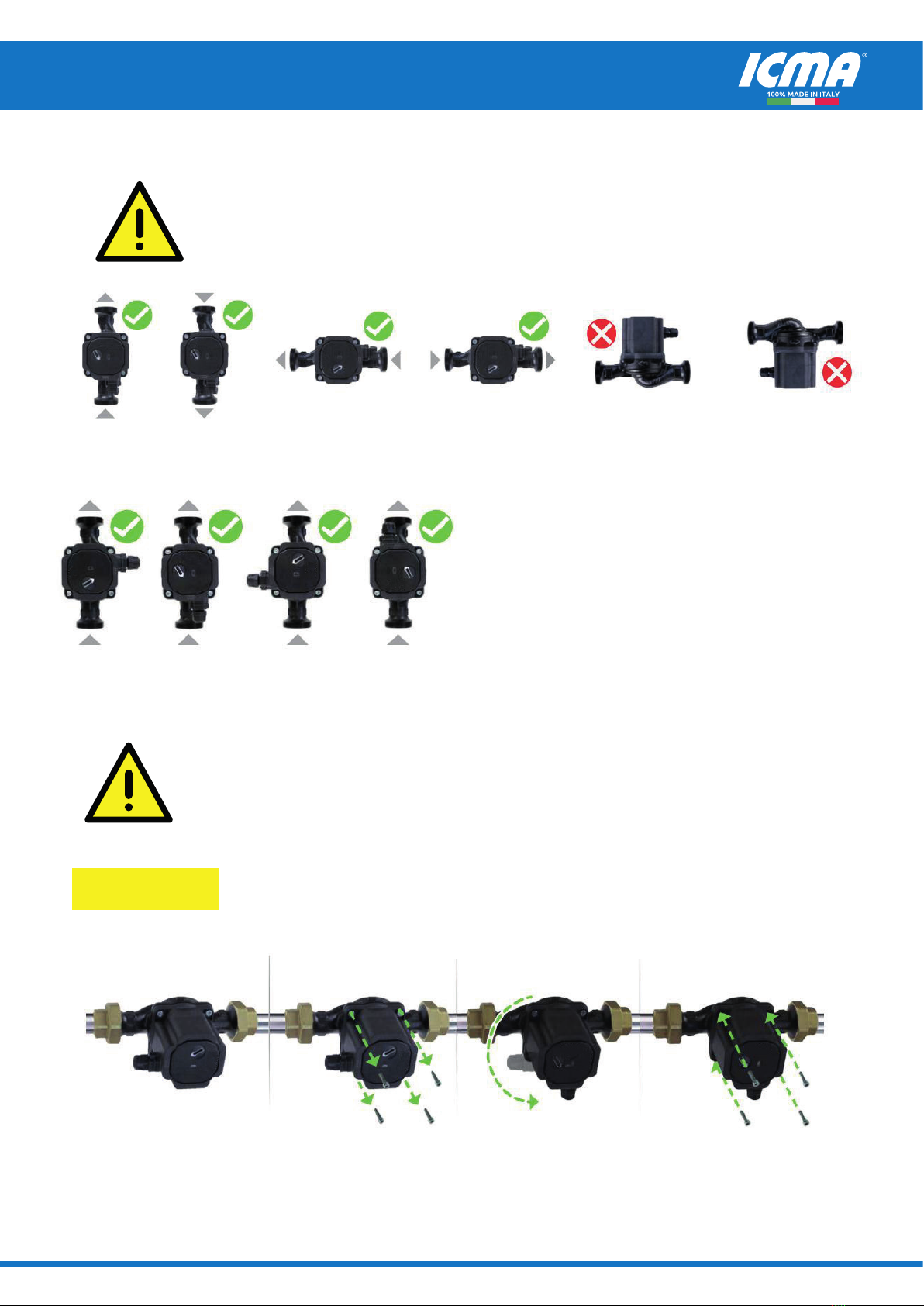

6. Installation

The circulator must be mounted in a stable/xed position in a dry, well ventilated,

frost-free, waterproof and protected place, with sucient ventilation around it. As-

semble the circulator only after having ended all welding and brazing works on the

hosing. Before installing the circulator, make sure that the internal part of the tubes

is clean. Install the circulator in an accessible place for future checks and disassem-

bly procedures. Foresee enough space for inspections and disassembling.

To avoid circulator overheating, do not place any object on the circulator itself.

7. Electric connection

IMPORTANT: Connection to the power supply must be eected by means of a xed

power cable which is tted with a plug-type connection or an all-pole isolating

switch with a minimum contact opening of 3 mm.

Electrical connection must be carried out only by a qualied electrician and in

accordance with local regulations and both data on the name-plate and the

appropriate diagram inside the terminal box cover.

Follow all safety standards.

Do not connect to mains supply unless circulator is fully and correctly assembled.

8. Supply cord must be selected following the requirements of EN60335-2-51

Chapter 25. Supply cord must be protected against any kind of mechanical damage

(cuts, abrasion, etc.). It must not touch the pipe or the pump. (EN 60335-2-51). If the

insulation of the Supply cord can come in contact with parts having a temperature

exceeding 70°C the supply cord insulation must be protected, for example, by

insulating sleeving having an appropriate temperature rating. (EN60335-2-51).

9. Connect circulators only to a mains supply protected by a Residual Current

Device (RCD or Ground-Fault Circuit-Interrupter) with a rated residual operating

current not exceeding 30mA.