Assembly and installation instructions

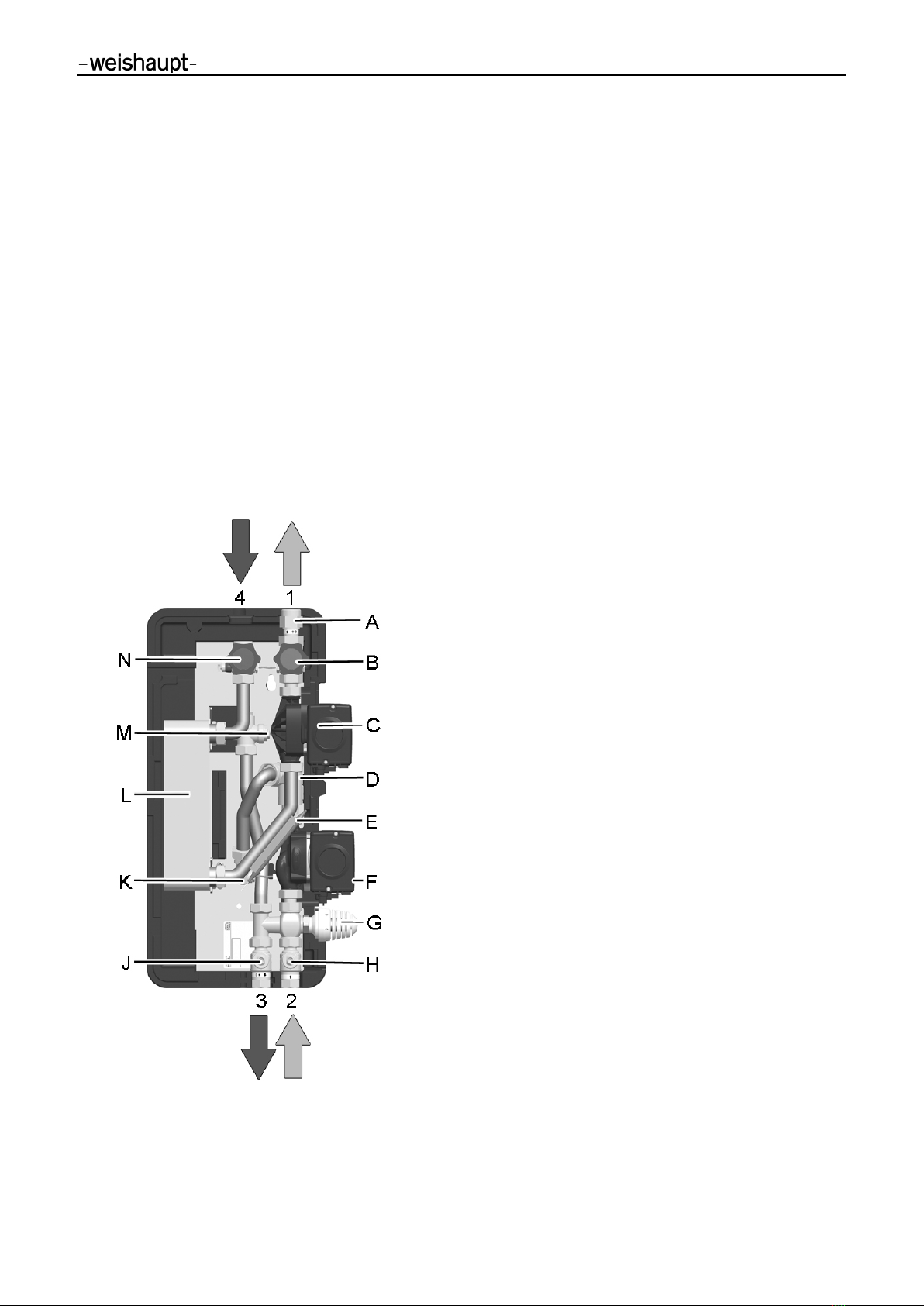

Circulation station WHI circuload 9 #1; Circulation station WHI circuload 9 #2

▪ 1/2014-02 ▪ Ext. PAW 3-24

Information for the user ..................................................................................... 4

User guidance...............................................................................................4

Symbols........................................................................................................4

Target group .................................................................................................4

Warranty and liability.....................................................................................4

Safety ............................................................................................................... 5

Designated use.............................................................................................5

Safety instructions ........................................................................................5

Safety measures...........................................................................................6

Electrical connection.....................................................................................6

Structural modifications.................................................................................6

Disposal........................................................................................................6

Product description............................................................................................ 7

Function........................................................................................................8

Technical data of the circulation stations ......................................................9

Technical Data Pumps................................................................................10

PWM input signal (solar profile) ..................................................................10

Hydraulilc performance data.......................................................................11

Dimensioning and Planning ............................................................................. 12

Installation ...................................................................................................... 14

Assembly ....................................................................................................14

Connection..................................................................................................15

Controller connection..................................................................................16

Electrical connection of the solar controller WRSol2.1................................16

Operation........................................................................................................ 16

Commissioning ............................................................................................... 17

Filling the primary circuit.............................................................................18

Commissioning the controller......................................................................19

Venting the circulation station.....................................................................19

Setting the temperature ..............................................................................20

Setting the pump revolution speed .............................................................20

Maintenance ................................................................................................... 20

Spare parts ..................................................................................................... 21

Spare parts list WHI circuload 9 #1 (40900015152) ...................................21

Spare parts list WHI circuload 9 #2 (40900015162) ...................................22

Commissioning log.......................................................................................... 23