ELECTRONIC CIRCULATOR FOR SOLAR THERMAL SYSTEMS - Art. S167

FI.S167.EN.C - 03/2023

Icma

SpA

-

Via

Garavaglia,

4

-

20012

C

uggiono

(MI)

IT

AL

Y

T

el:

+39

02

97249134

-

+39

02

97249135

-

w

ww.icmaspa.it

-

[email protected]2

INDEX

IMPORTANT SAFETY AND INSTALLATION INSTRUCTIONS...................................................................................................3

1. SYMBOL DESCRITPION.............................................................................................................................................................4

2. OVERVIEW....................................................................................................................................................................................4

2.1 Advantages of installation of the pump..........................................................................................................................4

3. SERVICE CONDITIONS...............................................................................................................................................................5

3.1 Ambient Temperature............................................................................................................................................................5

3.2 Relative humidity (RH)..........................................................................................................................................................5

3.3 Media (conveying liquid) temperature...............................................................................................................................5

3.4 System Pressure......................................................................................................................................................................5

3.5 Protection Level......................................................................................................................................................................5

3.6 Inlet Pressure...........................................................................................................................................................................5

3.7 Pumping Liquid........................................................................................................................................................................5

4. INSTALLATION.............................................................................................................................................................................6

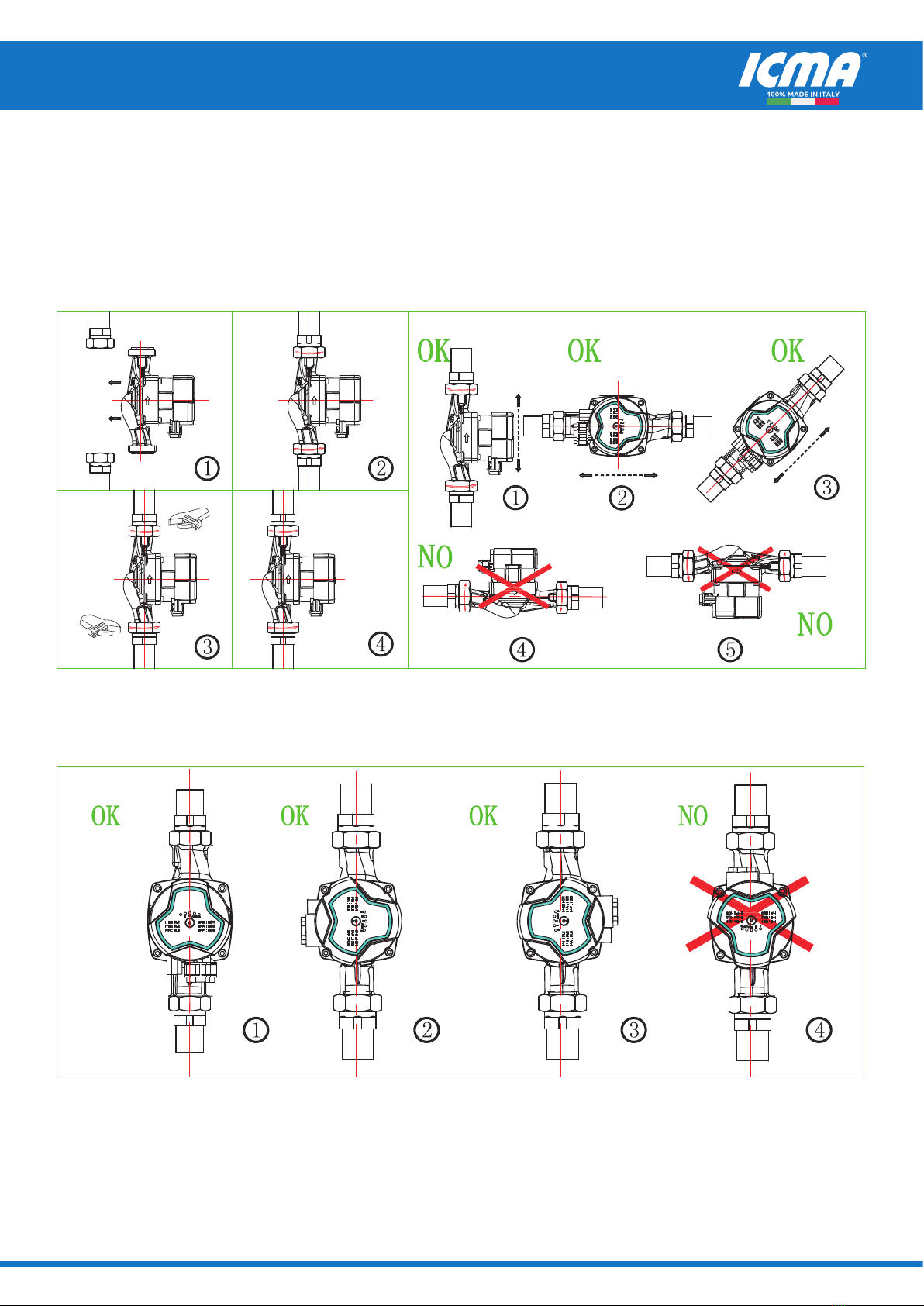

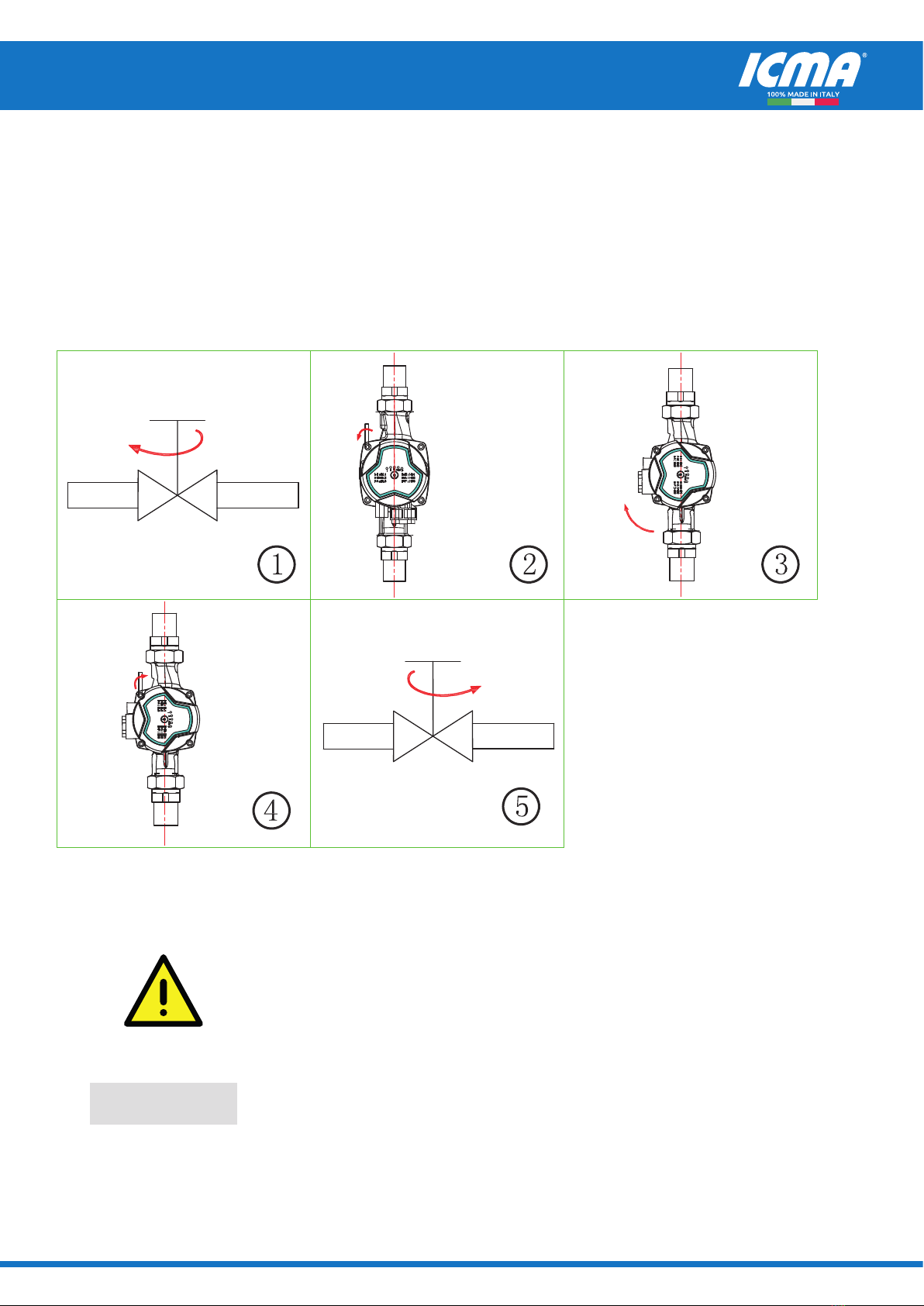

4.1 Position of Junction Box.......................................................................................................................................................6

4.2 Thermal insulation of the pump body...............................................................................................................................8

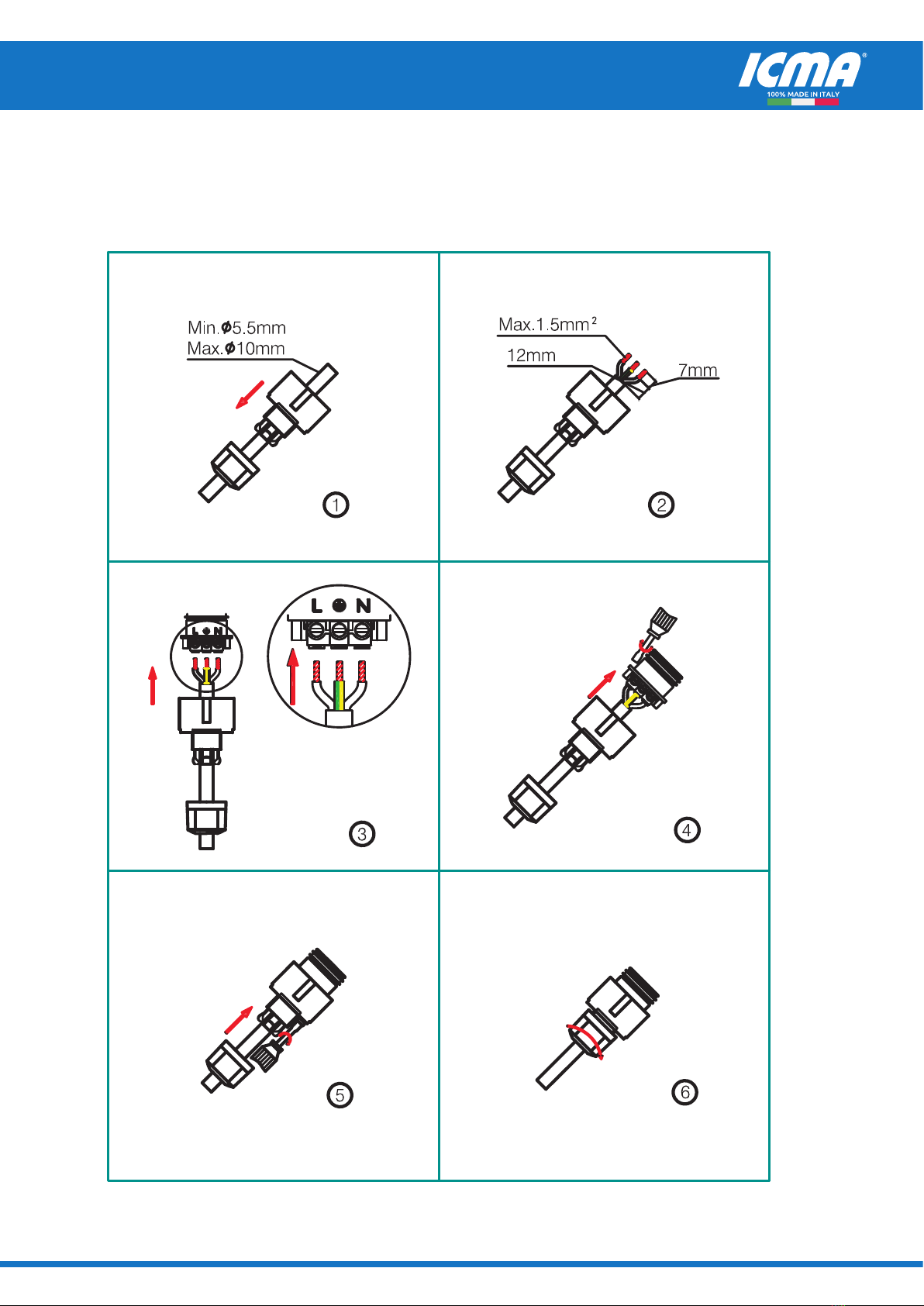

5. ELECTRICAL CONNECTION......................................................................................................................................................9

6. CONTROLS ON CONTROL PANEL..........................................................................................................................................11

6.1 Fault code display status....................................................................................................................................................11

6.2 Light area displaying the settings of the pump.............................................................................................................12

6.3Buttonforselectingthepumpsettings............................................................................................................................12

7. SETTING OF THE PUMP...........................................................................................................................................................12

7.1 The control on the pump..................................................................................................................................................13

8. PWM SIGNAL CONTROL MODE............................................................................................................................................14

8.1 Control and Signal................................................................................................................................................................14

8.2 Interface..................................................................................................................................................................................14

8.3 PWM Input Signal..................................................................................................................................................................15

8.4 PWM Feedback Signal.........................................................................................................................................................16

8.5 How to use the signals........................................................................................................................................................16

9. USE OF BYPASS VALVE............................................................................................................................................................17

9.1 Manually-operated bypass valve.......................................................................................................................................18

9.2 Automatic bypass valve (temperature control type).................................................................................................18

10. START UP.....................................................................................................................................................................................18

10.1 Before Start Up...................................................................................................................................................................18

10.2 Exhaust the Motor Pump.................................................................................................................................................18

10.3 Gas-exhausting of heating system.................................................................................................................................18

11. SETTINGS AND PERFORMANCE OF PUMP.......................................................................................................................19

11.1 Relationship between pump settings and its performance...................................................................................19

12. PERFORMANCE CURVE...........................................................................................................................................................20

12.1 Performance curve guide.................................................................................................................................................20

12.2 Curve conditions.................................................................................................................................................................20

12.3 Performance Curve............................................................................................................................................................20

13. CHARACTERISTICS...................................................................................................................................................................21

13.1 Description of nameplate................................................................................................................................................21

13.2 Model explanation.............................................................................................................................................................22

14. TECHNICAL PARAMETERS AND INSTALLATION DIMENSIONS...................................................................................23

14.1 Technical data......................................................................................................................................................................23

14.2 Installation Dimensions....................................................................................................................................................24

15. FAULT CHECKLIST.....................................................................................................................................................................25