Your newest and most innovative supplier of global mining components

Visit our website at www.icsweargroup.com

SAFETY

ICS Wear Group Inc. slurry pumps have been designed for safe and reliable operation. A pump is a pressure-

containing device with rotating parts that could be hazardous. Operators and maintenance personnel must

realize this and follow the necessary safety measures. All statutory requirements relating to this equipment must

be complied with at all times and site safety procedures strictly adhered to.

ICS shall not be liable for damage or delays caused by a failure to observe either the instructions in this manual

or the usual industry safety procedures.

CAUTION

Never completely restrict the discharge flow. It may result in adverse temperature increase and possible

explosion (as applicable to all centrifugal pump brands).

Never apply heat to the impeller to assist removal from shaft. Heating may result in shattering the impeller

RESULTING IN INJURY OR EQUIPMENT DAMAGE

Direction test driven WITHOUT belt drives or couplings fitted. The impeller is threaded and incorrect rotation

may cause personnel injury or equipment damage.

If pump is operating with a very hot or very cold liquid, gradually change pump temperature to prevent damage

by thermal shock. Thermal shock may cause personnel injury or equipment damage

NOTE

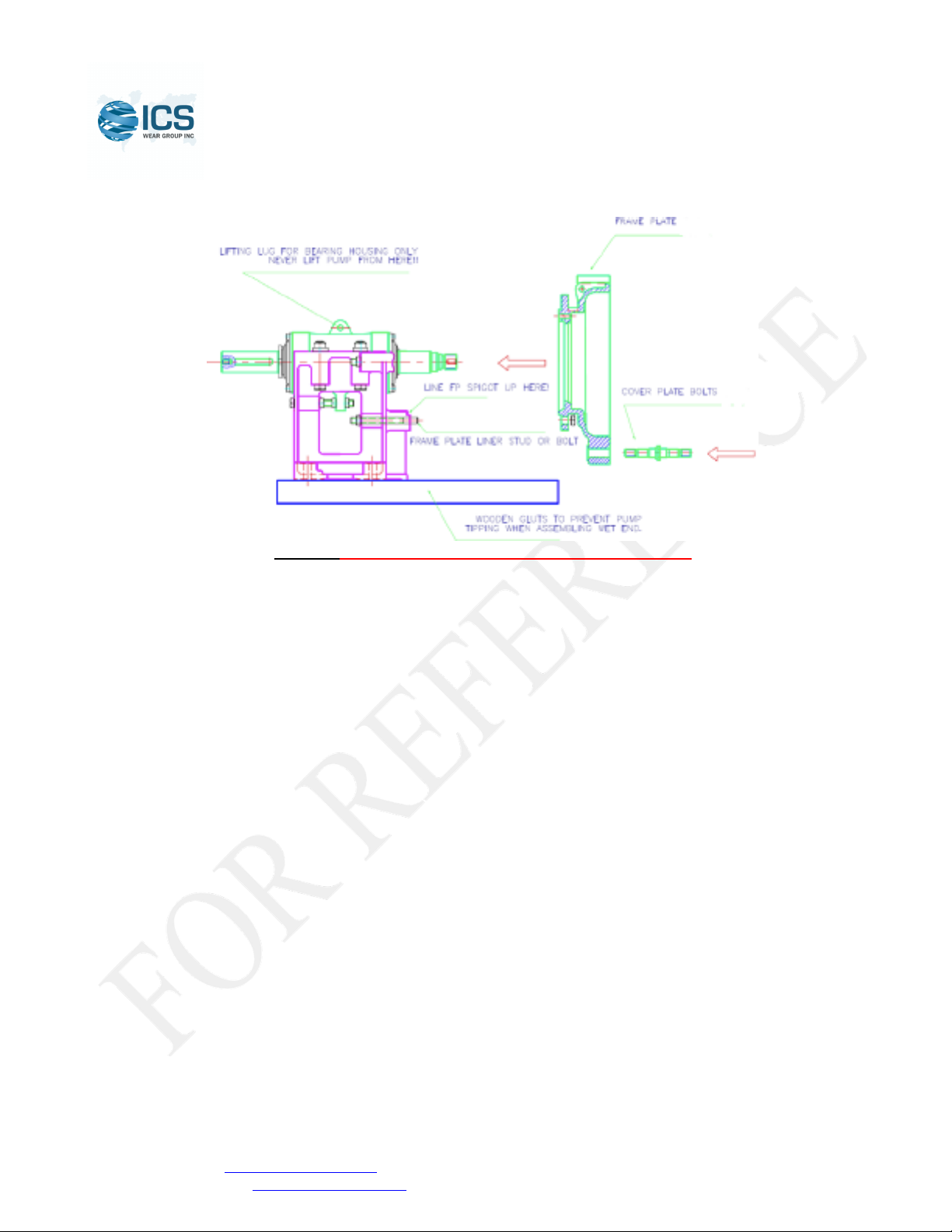

Proper alignment is essential for long pump life.

GENERAL PRECAUTIONS

• Warning: Personal injuries will result if procedures outlined in this manual are not followed.

• Never work on the pump set with the power connected.

• Never work on the pumpsets without the appropriate work tags (eg ‘Danger Tags’) fitted in compliance

with site safety procedures.

• Never operate pump without drive guard correctly installed.

• Never operate pump beyond the rated conditions for which the pump was sold.

• Never run pump below the recommended minimum flow or when dry.

• Never operate pump without safety devices installed.

• Never operate pump with discharge valve closed.

• Never use heat to disassemble pumps due to risk of explosion from trapped liquid.

• With the pump disconnected from the driver, check the motor rotation. Incorrect motor rotation can

cause the impeller to back off of its threads and rupture the casing. It may also cause personal injury.

WHERE AUXHILIARY EQUIPMENT IS ASSOCIATED WITH A PUMP (eg. MOTORS, DRIVE BELTS,

DRIVE COUPLINGS, SPEED REDUCERS, VARIABLE SPEED DRIVES, ETC), ALL RELEVANT

INSTRUCTION MANUALS SHOULD BE CONSULTED, AND RECOMMENDED PROCEDURES

IMPLEMENTED, DURING INSTALLATION, OPERATION AND MAINTENANCE OF THE PUMP

SYSTEM.