ikitchening YKZ-5D User manual

www.ikitchening.com CONVECTION OVEN YKZ-5D 1 of 11

CONVECTION OVEN YKZ-5D USER’S MANUAL

�ELECTRIC POWERED CONVECTION OVEN USER’S MANUAL

�READ THIS MANUAL CAREFULLY BEFORE USING

By Ikitchening Food Machinery

Released date: Dec. 2012

www.ikitchening.com CONVECTION OVEN YKZ-5D 2 of 11

CONVECTION OVEN YKZ-5D USER’S MANUAL

Oven Control:

1. “power” key:ON/OFF power,press start power,press again close power。

2. light” key:ON/OFF light ,press start light,press again close 。

3. Temperature “plus” key ,“minus” key:”plus” or “minus” temperature parameter when setting temperature ,

left 、middle、right set the hundred 、ten 、unite of temperature parameter in separated .

4. Steaming “plus” “minus” key: when working press this key “flicker” show there are steaming time 3 seconds .

5. when setting parameter plus and minus the time of steaming -sparge

6. Steaming “ON/OFF” key:According to procedures to set working press steam hand- sparge, when releasing

steam hand- sparge to stop ,Hand working press keys ON/OFF steam action,At moment steam working

according to set time 。

7. Time “plus/minus” key:working count time according there are “flicker” show total 3 seconds of baking time,

When setting parameter plus minus baking time or the delayed time of steam-sparge.

8. Time“ON/OFF”key:when working the switch count time,when setting parameter to cut-over baking time or

the delayed time of steam-sparge.

9. Memory "down" key:when working choose 0~10 team to memory,when setting choose 1~10 steam

memory

10. Memory "up" key:when working choose 0~10 team to memory,when setting choose 1~5 segment

number

Memory and choose to parameter:

Hand-working:

Procedures number is“0-0” ,at moment just there is craft parameter to set,no matter when any time can correct

parameter according to the“plus”、“minus”keys of temperature、steaming time、backing time when working,after

correcting parameter will keep automatic。

Parameter range: hand backing temperature:0-set temperature upper limit℃

Hand backing steaming-time:0-99seconds

Hand backing-time:0-99minutes59seconds

Procedures working

:

Can set total 10 teams parameter,each team parameter can set more than 5 segments backing craft parameter

Parameter range:

Procedures team:10teams (each team can set max 5segments craft parameter)

Procedures segments :1-5segments(each segments can set temperature、backing-time、the delayed time of

steam-sparge、the continued time of steam-spare parameter)

Each segment backing temperature range: 0-set temperature upper limit℃

Each segment backing steaming-time:0-99seconds

Each segment backing time :0-99minutes59seconds

Each segment delayed time of steam-sparge:0-99minutes 59seconds

www.ikitchening.com CONVECTION OVEN YKZ-5D 3 of 11

CONVECTION OVEN YKZ-5D USER’S MANUAL

choose to parameter

:

1. Backing count time stop press memory“up/down”key,can choose 0~10 team had stored parameter,among

0 team is hand working;1~10team are stored parameter of procedures control。

2. Stored parameter:

3. Working count time stop as press (long time) stored “down” and stored “up” key several seconds,enter set

parameter ,at moment there are “flicker” from procedures window ,press stored “down” key

choose0~10team stored number,press stored “up” key choose1-5 segments procedures segments,after

choosing procedures team and segments,press temperature “plus” “minus” set temperature parameter of

this team procedures this segment,press steam “plus” “minus” set continued time of steam-spare,press

time “plus” “minus” set backing time and delayed time of steam-sparge,press time “on/off” key cut-over to

choose setting of backing time and delayed time of steam-sparge,(corresponding indicator show)

4. After finishing the whole set as press(long time )stored "down" and stored "up" key re-back working state ,

15 seconds do not press key will re-back working state automatic.

5. Wait for working ,press time key to start procedures count time ,now controller work according to had set

procedures parameter , each team procedures have most 5segments parameter,count time reach then

procedures window show“end”,hummer blow chimes of doom output,press time key re-back wait for

working

6. When working open the door of oven for heating 、assist heating、left and right circle air、steam output

closed,backing count time and steam count time stop ,procedures window cut-over show procedures and

"door",the door of oven closed then continue to working according to before working state

7. Alarm showing:

8. When actual temperature >(set temperature +upper limit deviation temperature ),actual temperature

window cut-over show actual temperature and "er1"

9. When actual temperature >(set temperature +50), actual temperature window cut-over show actual

temperature and "er2"

10. When actual temperature cut down,actual temperature window show "er3"

11. When actual temperature < (set temperature -assist heating deviation) assist heating output,

12. When actual temperature ≥ (set temperature - assist heating deviation) assist heating be closed

13. Inside parameter

14. When close the oven ,at moment press(long time )stored "down" and stored "up" key enter into setting

password state ,and now procedure show "0000",

15. Press stored "up/down" key input password,press time key to sure again

16. Input password "0005" enter into set inside parameter ,press" up/down" key go to choose the different

parameter ,

17. Press stored "up/down" key set parameter , press(long time ) time key means out

www.ikitchening.com CONVECTION OVEN YKZ-5D 4 of 11

CONVECTION OVEN YKZ-5D USER’S MANUAL

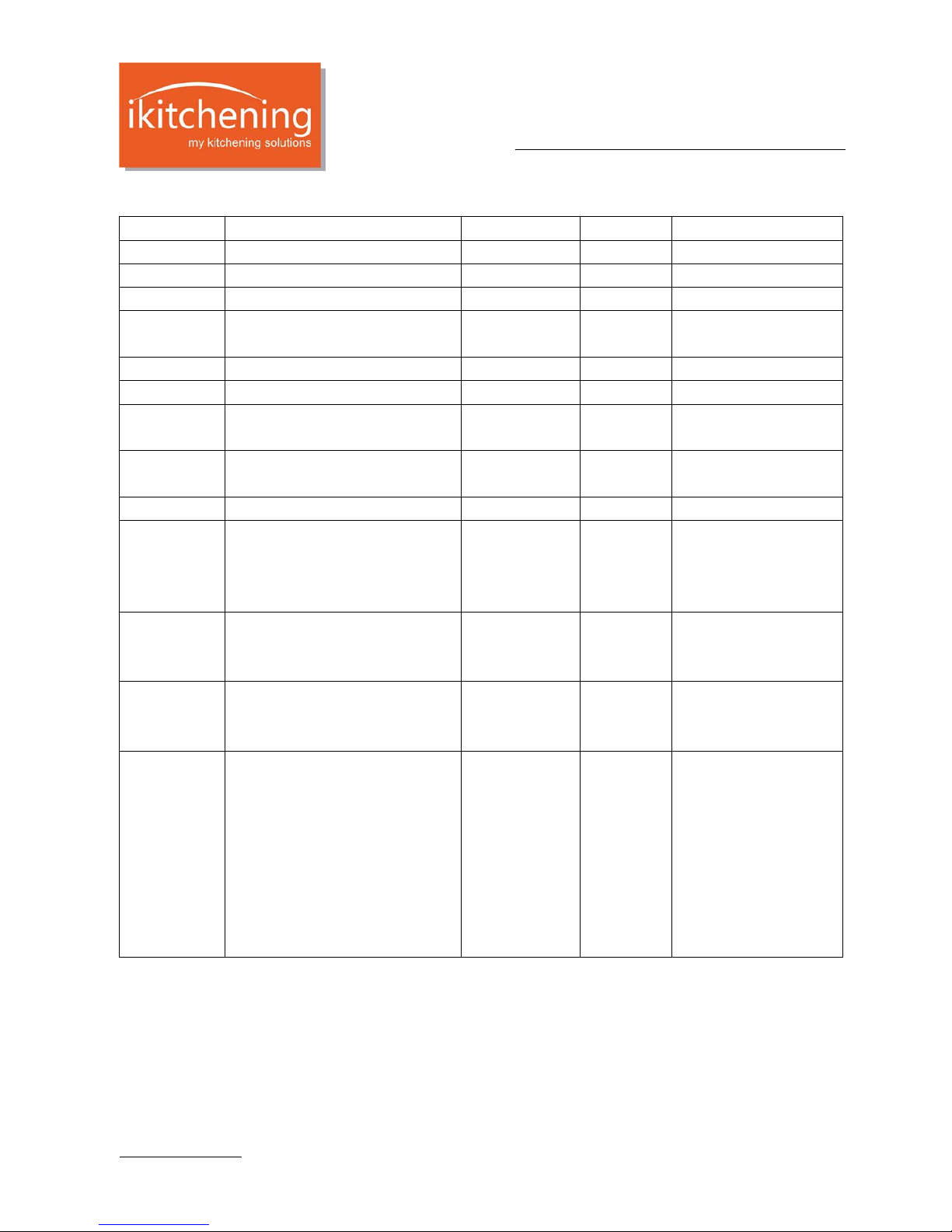

Show Content Range Basic Value Remarks

"Id.01 300" set temperature upper limit 100~400 ℃300

"Id.02 00" temperature connect value -30~30 ℃0

"Id.03 00" upper limit deviation temperature 0~99 ℃0 0:no using

"Id.04 30" temperature heating proportion 0~99 ℃30 0:heating location way

control

"Id.05 00" assist heating deviation 0~99 ℃0 0: no using

"Id.06 30" heating period 1~60 seconds 30

"Id.07 00" heating output min value 0~60 seconds 0 min heating output

value

"Id.08 00" temperature show min value 0~99 ℃0 actual temperature

show min value

"Id.09 0.4" heating finished region 0~9.9 ℃0.4

"Id.10 0.0" lighting count time 0~9.9 minutes 0.0 0:lighting without

counting time

control ,press lighting

key ON/OFF lighting

"Id.11 0" circle working ways 0~2 0 0: left and right circle

cut-over;1:left

circle;2:right circle

"Id.12 60" circle air start time 0~99 minutes 1 the start time of circle

air in left and right circle

cut-over way

"Id.13 10" circle air wait for time 0~99 seconds 10 the wait for time of

circle air in left and right

circle cut-over way

Input output input :

temperature , the door

of oven output :

heating , assist heating,

left circle ,right circle,

steam, alarm, lighting

www.ikitchening.com CONVECTION OVEN YKZ-5D 5 of 11

CONVECTION OVEN YKZ-5D USER’S MANUAL

Alarm ways

1. Temperature cut down line

2. Excess temperature

3. Temperature above upper limit deviation

4. Count time reach, alarm 60 seconds

Function and feature

The product is used for backing cake ,bread and so on 。

Adopted far infrared metal heating tube 、with rotary convection devices,makes faster heating 、average

temperature 、energy saving 。

Temperature can adjusted from 50℃-300℃

Over-heat protection device could disconnect the power supply when the temperature is too high,it is reliable

and secure 。

Adopted large glass structure ,strong intuition、beautiful 、durable 。

Installing

1. Please find a qualification electrician to install the machine because it has involved to the electrical security

and strict request. Because this equipment do not install with inside protecting device, the supply line should be

deploy special power switch when installing. The wire, protecting device and leakage protective device should be

match with the power of the machine. And deploy with good earthing device, guarantees uses electricity the

security.

2. The place of installing need to be ventilation, there is Non-corrosiveness goods and gas in the around. The

environmental temperature is 5-40℃; the relative hum idity is no bigger than 85%, below the elevation 2500

meters.

3. The laying aside of the oven should depart from the wall to be bigger than20cm, two sides should be bigger

than 30cm, must maintain the exhaust vent is unimpeded. In order to avoid affects the baking time and the quality,

and far away the flammable high explosive goods.

Matters needing attention

1. Please select the same specification electric cable line replaces the power line, this firing line and the zero

curves of the equipment should according to the electric cable line symbol wiring. Enable the outer covering to

have the reliable protective earthing the yellow and green line of the power must be meeting good grounding line.

It is the ordinary waterproof rank; therefore strictly prohibition to wash with water or clean in immerse, otherwise

will damage the equipment.

2. In order to lengthen the service life of the electric oven, do not use oven in high temperature and in long time

when baking, for reduce the thermal draining, and please reduce the opening time of door as far as possible

during getting the goods in and out of the furnace. When open the oven door, do not overexert, otherwise the

oven door will be damaged.

www.ikitchening.com CONVECTION OVEN YKZ-5D 6 of 11

CONVECTION OVEN YKZ-5D USER’S MANUAL

3. Thermostat is observed and controlled by temperature through thermocouple, therefore

usually should be careful in the operation or the cleaning up process, do not hit or curving; otherwise it will be

losing warming ability.

4. The steam enters the water: Behind the machine the left under angle has a water inlet pipe. Choose

φ12×8mm soft tube connection water pipe system and water inlet pipe.

Simple Control

、

Operating

1.Power、total power switch “ "connect power,“ ”turn off power

Before working, please turn on power switch firstly, connect power; working finished, please turn off the power at

end

2. Exhaust and tie bar

connect the power source, before start to work, pull out the exhaust tie bar, and make the electrical machine idle

operation 1 minute, and drain the inside of furnace exhaust.

3. Temperature controller

Electric temperature controller

Clockwise adjustment temperature high

Anti-clockwise adjustment temperature high

4. Backing timer

Adjust and increase time

Adjust and reduce time

Open the switch of the timer, set the time of bakery food needed. The timer will automatically enter Pours counts,

when the time is arrived, the buzzer will auto-alarm reminder bake completes.

5. Steam switch

It should be guarantee the temperature has 170℃in the stove,w hen baking food needs the steam .P resses

down the steam switch, the steam can automatically spout, the time controls by the steam timer (leave factory

setting 5 seconds.) Continuously two operations, the temperature must above in 170℃in the oven .

6. Lighting switch :“ " turn on lighting switch“ "turn off lighting switch ,If need to see the bakery food in

the oven, please turn on the light switch.

Attended Matters

1. The power line and the water pipe should be left the ground and to be fixed, in order to nipped by the mouse.

2. In the using elevation of temperature processing, cannot adjust the temperature of temperature controlling in

continuously, the high-frequency.

3. The temperature inside the oven above 250℃,w ork w ith U ltra tem perature,in the oven no longerw illheatup

the replacement to have to close the power switch, will reopen.

4. In the normal work process, forbids to in touch with left or right oven door with hand, in order to avoid scalds.

5. Please wait for the oven to cool and then clean it.

6. It is forbidden to cover the vent or put the goods.

www.ikitchening.com CONVECTION OVEN YKZ-5D 7 of 11

CONVECTION OVEN YKZ-5D USER’S MANUAL

Maintain and clean

1. After finish the work, please turn off all switches.

2. Inspects the power line frequently, appears bursts or the aging, should replace promptly.

3. Inspects whether the water is normal frequently.

4. After the work had ended, use dry cloth to clean the stove surface, it is forbidden to clean with water.

5. Clear the residuum with the hair brush in the chamber.

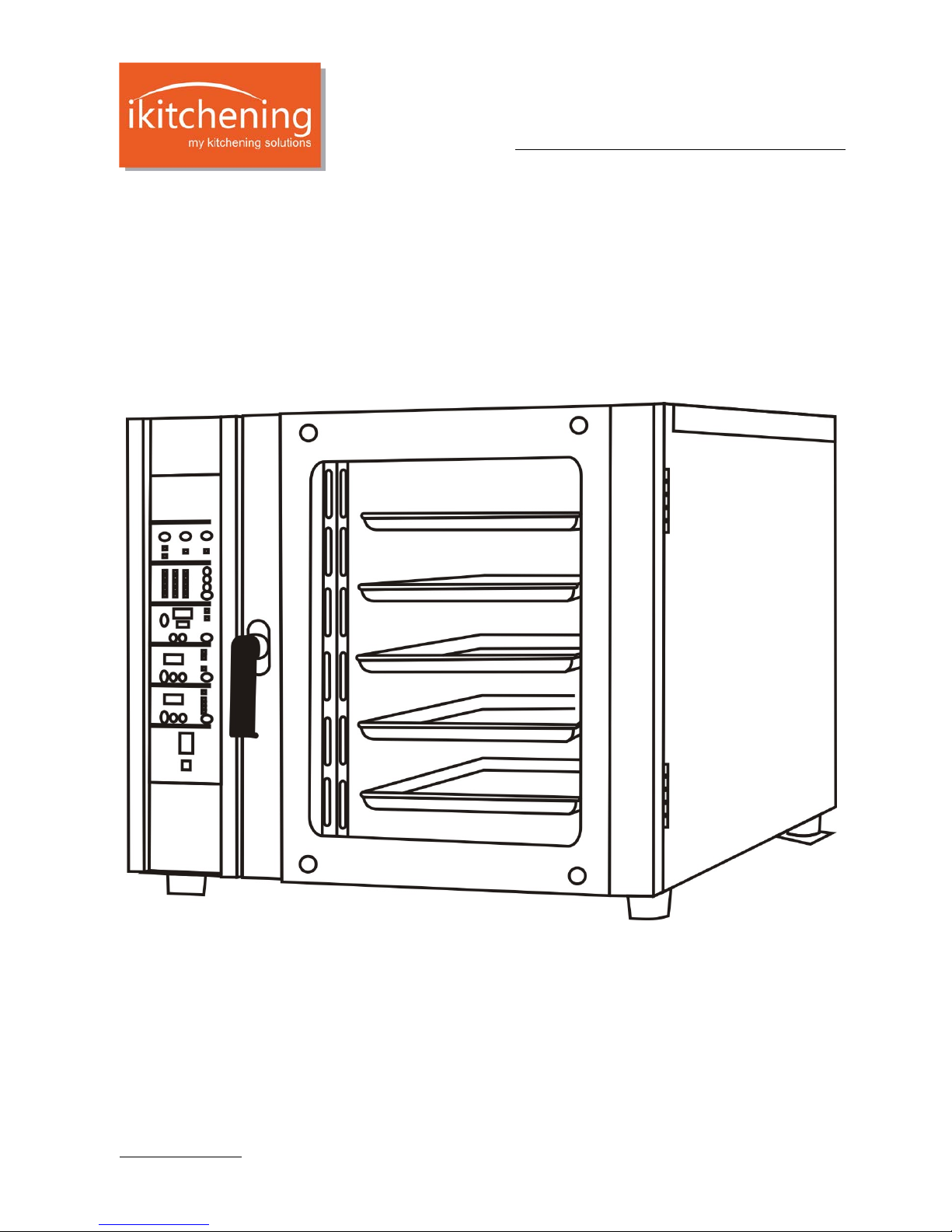

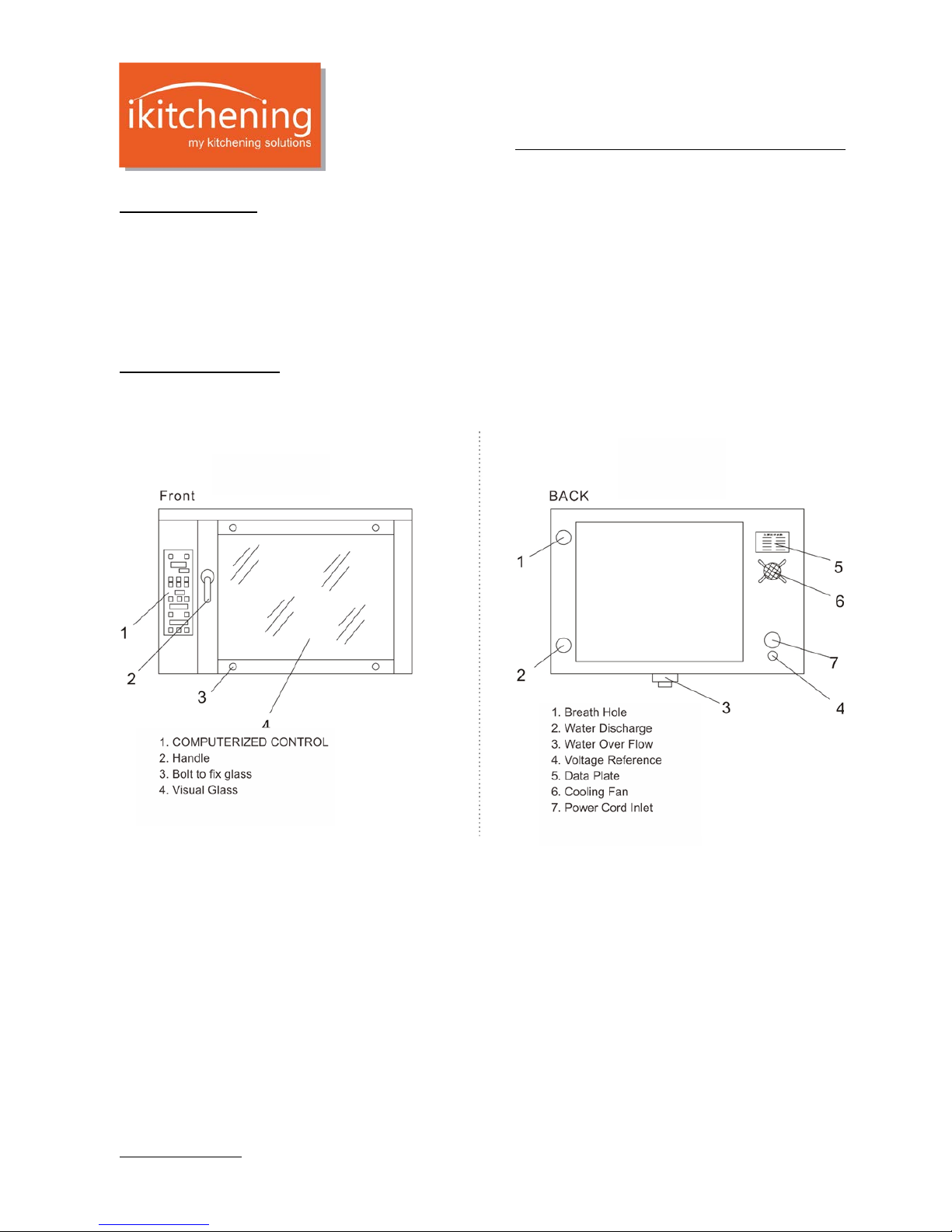

YKZ-5D model diagram

www.ikitchening.com CONVECTION OVEN YKZ-5D 8 of 11

CONVECTION OVEN YKZ-5D USER’S MANUAL

www.ikitchening.com CONVECTION OVEN YKZ-5D 9 of 11

CONVECTION OVEN YKZ-5D USER’S MANUAL

www.ikitchening.com CONVECTION OVEN YKZ-5D 10 of 11

CONVECTION OVEN YKZ-5D USER’S MANUAL

1、power switch ON/OFF press key(press one time“ON”,press again“OFF”,

2、lighting switch ON/OFF press (press one time“ON”,press again“OFF”)

3、temperature plus minus key(left)hundred ,( middle)ten ,( right)unite ,

4、steam plus minus key

5、steam switch

6、timing heating plus minus key

7、timer switch

8、stored “down”key

9、stored “up”key

10、show stored control

11、show timer control

12、steam ON/OFF indicator

13、steam time show

14、temperature working indicator

15、prepare setting temperature

16、actual temperature

17、blower reversible indicator

Technical parameter

�Model :YZK-5D

�Specified voltage:3N380V

�Specified frequency :50HZ

�Specified power:6600W

�Temperature range :room-300℃

�The main components parameter

�Water solenoid value~220V

�Heating tube 220/3×2.2KW

�Motor YS8014-370W4P ~220/380v

�Contact CJX2-0901 X2 只~220V

�Contact CJX2-1210~220V

�Air circuit breaker DZ47-63

�Over-temperature switch TEH-1

�K model thermocouple

�Lighting 12V/20W

�transformer :220V/12V

�Intellectual control

�Time reply 5S

�motor protector:HHD2-A

�Fuse:30A

www.ikitchening.com CONVECTION OVEN YKZ-5D 11 of 11

CONVECTION OVEN YKZ-5D USER’S MANUAL

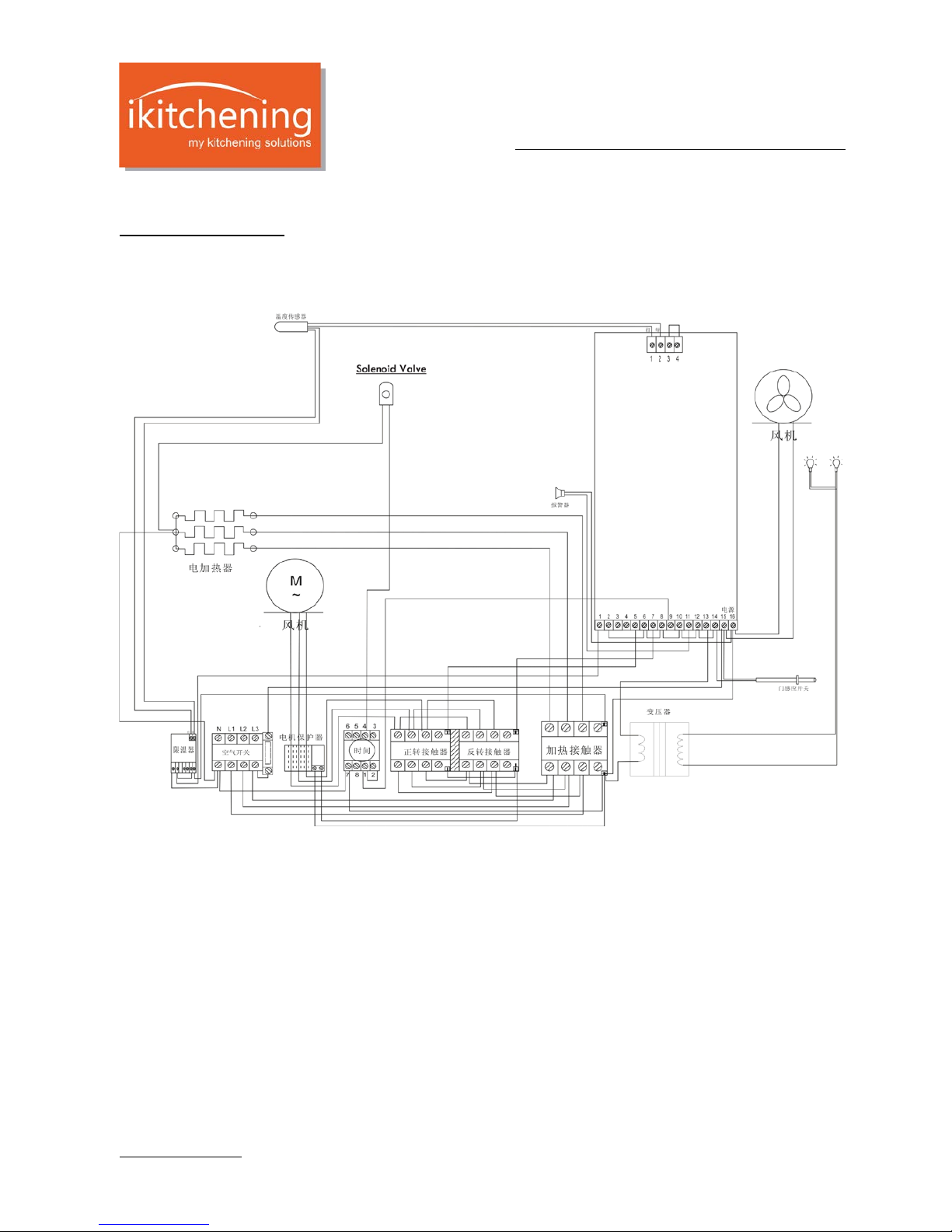

YKZ-5D Wiring Diagram