Ilsintech SWIFT KF2A User manual

Optical Fiber Arc Fusion Splicer

Read this user manual carefully before running KF2A

SWIFT KF2A

WWW.ILSINTECH.COM

USER MANUAL

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

Telephone 042 671 5607~8

Homepage www.ilsintech.com

E-mail saleskorea@ilsintech.com

Device Type Notification

A Class Device

(Broadcasting and

communication

device, commercial

use)

Users need to understand that this device(A Class) has

obtained EMI(Electromagnetic compatibility) and been

designed to be used in places other than home.

1

Contents

I. SAFETY INSTRUCTION 4

II. PRODUCT SPECIFICATIONS AND COMPONENT 8

2.1 Product specifications 8

2.2 Product package 9

III. PRODUCT OUTLINE 11

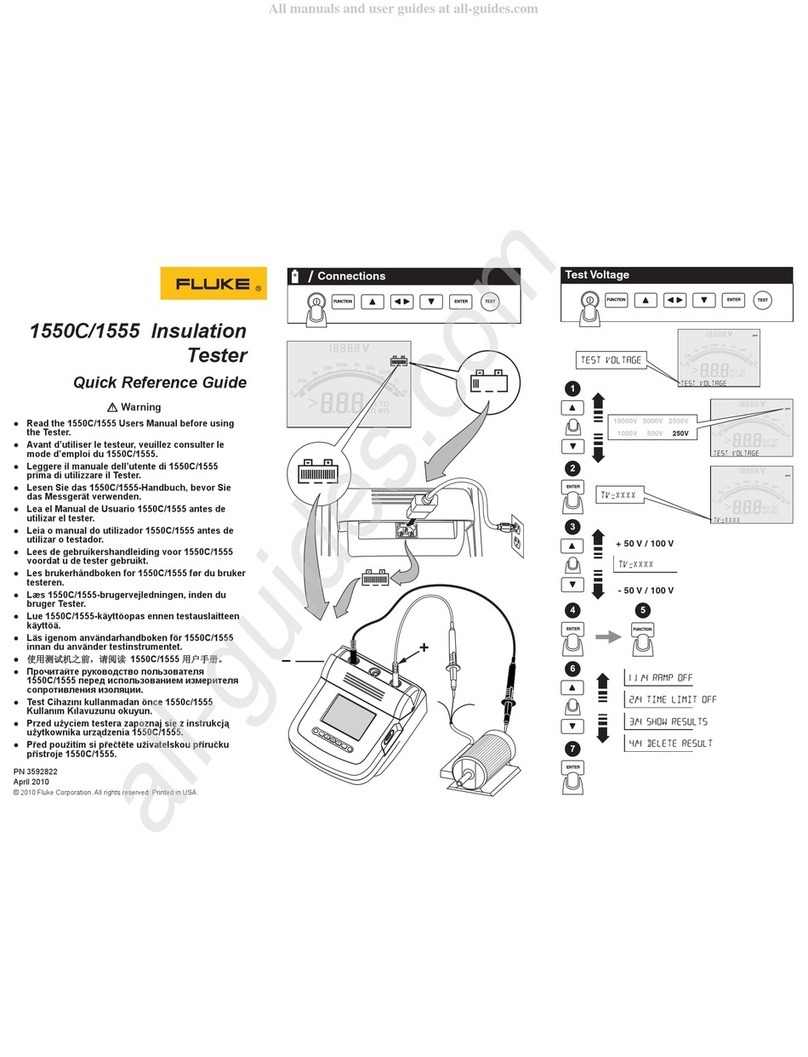

3.1 Function buttons 11

3.2 Component name 12

IV. INSTRUCTIONS FOR USE 14

4.1 Power supply 15

4.2 How to turn the power ON/OFF 17

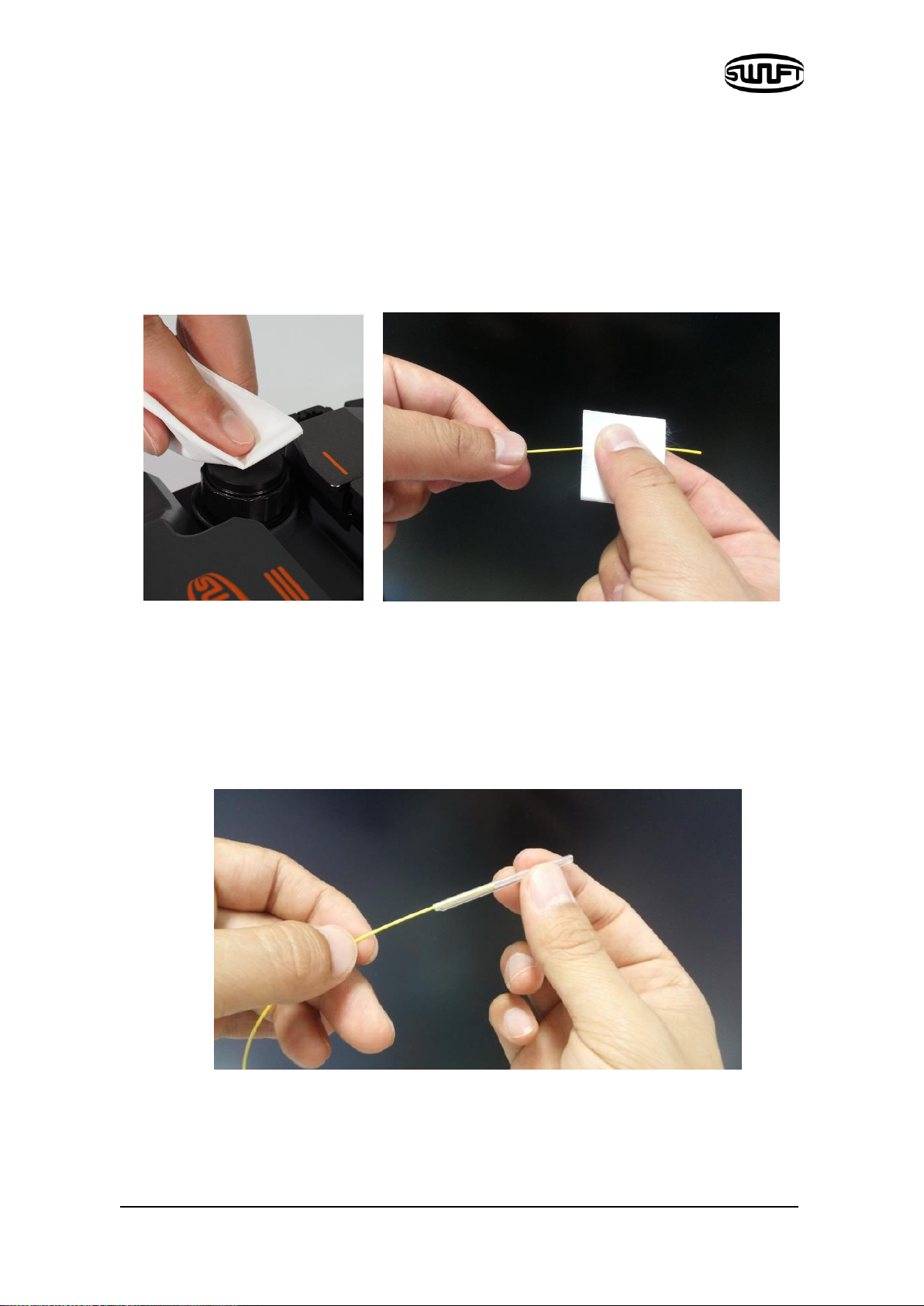

4.3 Fiber cleaning 18

4.4 Inserting fiber to protecting sleeve 18

4.5 Fiber stripping 19

4.6 Fiber cleaning 22

4.7 Fiber cleaving 23

4.8 Sleeve-Heater 28

4.9 Splice procedure 30

4.10 Removing the spliced fiber 31

4.11 Heating protection sleeve 31

4.12 Use of Work Belt 32

V. MAINTENANCE OF SPLICE QUALITY 33

5.1 Cleaning and Inspection before splice 33

5.2 Regular inspection and cleaning 36

VI. MENU 38

6.1 Splice Mode 38

6.2 Heater Mode 48

2

6.3 Stripper Mode 52

6.4 Optional Splice Function 54

6.5 Splice Result Saving 57

VII. SUB MENU 60

7.1 Language 60

7.2 Power Saving Function 61

7.3 Menu Lock 62

7.4 Other Option 65

VIII. AUXILIARY MENU 67

8.1 Calibration of Arc-discharge 67

8.2 Electrode 69

IX. MENU MANAGEMENT 75

9.1 Pop-up Menu Setting 75

9.2 Setting Automatic Heater 76

9.3 Setting or Cancelling Error 76

X. ERROR MESSAGE 77

10.1 FIBER DIRTY 77

10.2 ALIGNMENT ERROR 77

10.3 FIBER TOO LONG 78

10.4 FIBER OVER ANGLE 78

10.5 LOSS LIMIT OVER 78

10.6 FIBER THIN 79

10.7 FIBER THICK 79

10.8 Bubbles 79

XI. SPLICING PROBLEM SOLVING 80

11.1 When loss is high 80

11.2 Abnormal splicing operation 81

XII. OTHER MENU 82

12.1 Self-Diagnosis Test 82

12.2 Dust Test 83

3

12.3 Motor Operation 84

12.4 LED Test 84

12.5 Maintenance Information 85

XIII. PROBLEM OCCURRENCE AND QUESTION 86

13.1 Power Supply 86

13.2 Splice 87

13.3 Tube Heater Operation 88

13.4 Management 89

13.5 Other Settings 90

XIV. PC PROGRAM INSTALLATION 91

14.1 Installation Procedure 91

XV. WARRANTY AND REPAIR 97

15.1 Warranty Period and Limit of Responsibility 97

15.2 Before sending the equipment 97

15.3 For more effective maintenance and repair of the equipment, 98

15.4 Transport of the equipment 98

15.5 Repair 98

4

Safety instruction

Swift KF2A is designed to be used conveniently on both indoor and outdoor work sites. Its

use is easy and simple but make sure to read this instructions prior to prevent accidents

and malfunctions before using Swift KF2A. This user guide provides information necessary

for safe operation.

Ilsintech does not take any responsibility for the equipment’s damage and personal or

physical loss incurred due to improper use or alteration.

When any of the following occurs during the use, turn off the power immediately

and contact to Ilsintech.

Smoke, disgusting smell, noise or abnormal overheating.

When a foreign substance or liquid falls into the equipment

When the splicer falls down or it is damaged

Regarding AC power cord, use the one provided with Swift KF2A. If a power cord

other than provided is used, it may incur fire, electrical shock or injury.

Do not touch the Electrodes when power is on. High voltage and high

temperature generated from Electrodes may incur serious shock or burn.

Connect the provided AC power cord to a battery. Check if there is any foreign

substance on the terminal before connecting it to the AC power socket.

Incomplete splice may incur smoke, electric shock, fire, damage of equipment,

serious injury and even death.

Keep this users guide with the product at all times.

Warnings

5

Use proper power voltage.

AC power for the adapter is AC100-240V, 50~60Hz.

Test the AC power before use. When output voltage of AC power is high or

abnormal frequency is generated, the product is damaged and serious injury or

even death may be incurred to the user.

AC output voltage should be measured using circuit tester before connecting

AC power cable and regular inspection should also be conducted.

Do not pull AC power cord with excessive force, apply heat or transform it.

When a damaged power cord is used, it may incur fire or injury.

Use 3-plug AC power cord and do not ever use 2-plug power cord, cable or

plug.

Do not touch AC plug, AC power cord or splicer with wet hands. It may incur

electric shock.

Do not disassemble AC adapter, battery or Swift KF2A. Deformation may incur

fire, electrical shock or injury.

Refer to the following when using the battery.

When an improper battery which is not provided by Ilsintech is used, it may

incur smoke, damage of equipment, burn, injury or even death.

Do not dispose the battery into fire.

Do not charge the battery near flame.

Do not give an excessive shock to the battery.

When the battery does not completely charge in 2 hours or the green LED is

not turned on, stop charging immediately and contact Ilsintech.

Do not put anything on AC adapter while charging.

Use exclusively the AC adapter provided. Do not use another AC power cord

or battery. Excessive current may incur equipment damage or injury.

Do not use Swift KF2A where there is harmful gas or flammable liquid.

Explosion or fire may be incurred due to electrical arc.

Warnings

6

Do not use compressed air or compressed gas when cleaning Swift KF2A.

Inspect carry case belt before transportation. If the carry case is dropped due

to damage on the belt, it may incur equipment damage or injury.

Wear safety goggles when working on splicing. It is very dangerous if a piece of

fiber chips get in skin or eye.

Do not use Swift KF2A around high temperature or flame. It may incur injury

or equipment damage.

: Caution for high temperature

Do not spray Freon gas

: Caution for high voltage

Warnings

7

Do not touch sleeve heater or protecting sleeve while sleeve heater is operating

or right after heating is completed. It may incur injury due to high temperature.

Do not put Swift KF2A in an unstable place. When the equipment is dropped, it

incurs injury or equipment damage.

Swift KF2A should be accurately adjusted and treated in alignment. Do not

give it a strong shock, either.

Use a carry case to carry or to keep Swift KF2A. The carry case keeps the

equipment from humidity, vibration and shock during storage and

transportation and prevents possible damage to KF2A.

Replace the Electrodes in timely manner referring to the following.

Designated electrodes should be used.

Place new Electrodes to the right position.

Replace the Electrodes in pairs.

Abnormal arc is incurred when not following the aforementioned caution.

It may incur equipment damage or an abnormal splice.

Do not use any chemical other than ethyl alcohol (96% or higher) to clean

lens, V-Groove, LCD monitor and main body.

Using other chemicals may incur deformation, discoloration or deteriorated

performance.

Do not keep the equipment in any environment where the high temperature

or high humidity prevails. It may incur equipment damage.

Swift KF2A should be inspected by a qualified expert, or it may incur fire or

electric shock.

Discuss with Ilsintech to use the service.

Cautions

8

Product specifications and

component

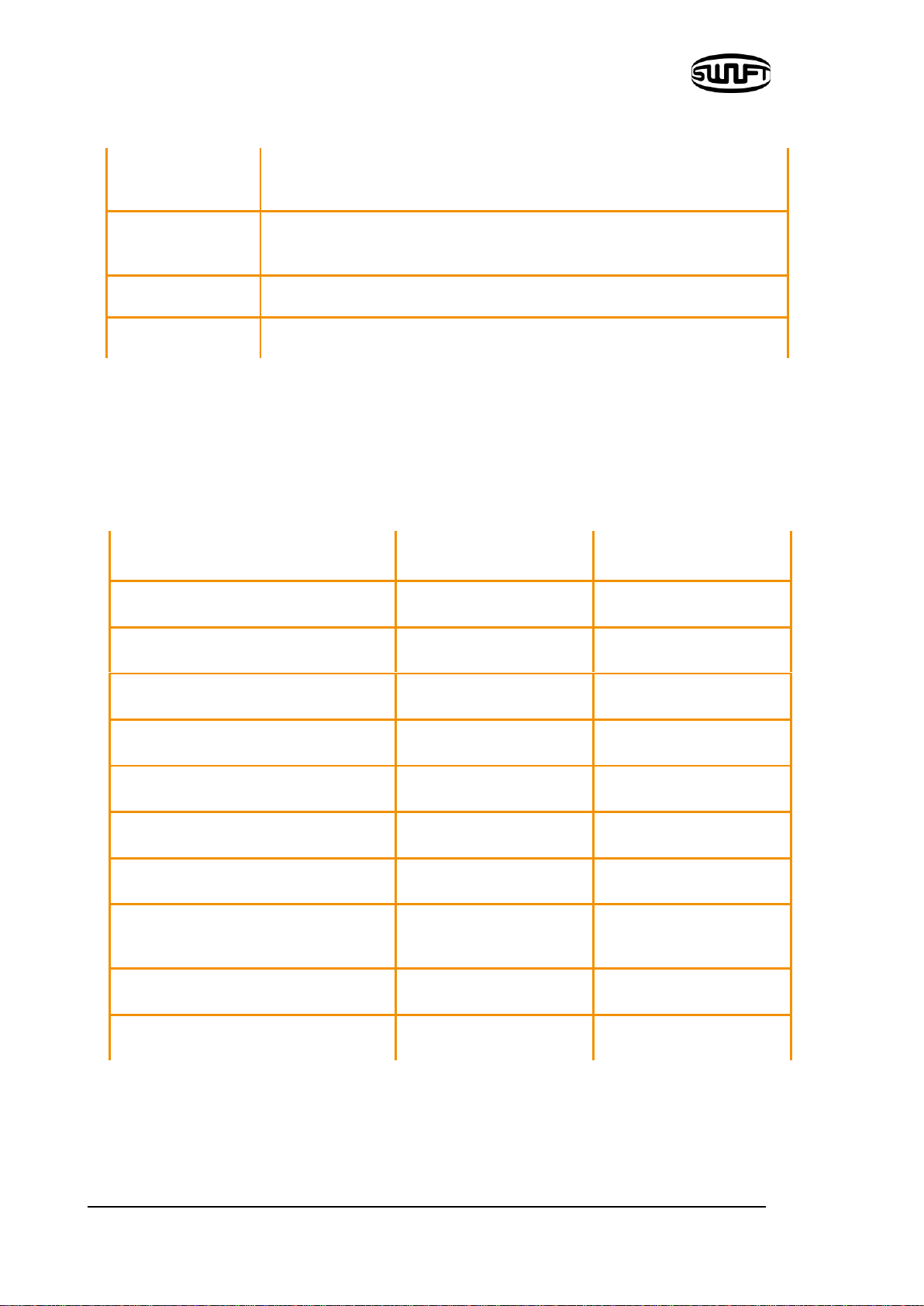

2.1 Product specifications

Item

Description

Fiber alignment

Fixed V-Groove (Clad to Clad Alignment)

Applicable fibers

0.25mm, 0.9mm, 2.0mm, 3.0mm Indoor cable

Number of fiber core

applicable

Single

Fiber diameter

Clad diameter: 125 ㎛, Coating diameter: 150 ㎛~3mm

Cleaved length

5.0mm~16mm

Splice mode

Splice mode: 40, Heater mode: 20

Splice loss

SM: 0.04dB, MM: 0.02dB, DS: 0.06dB, NZDS: 0.06dB

Reflection loss

> 60dB

Splice time

About 7 seconds (Quick mode)

Sleeve heating time

Typical 30sec

Applicable protecting

sleeve

40mm, 60mm and micro sleeves

Data storage

Internal memory capable of saving 2,000 times (Saving

2,000 images)

Tension test

1.96N

Size

133(W) x 212(L) x 70(H)mm

Weight

1.35kg

Fiber magnification

X/Y : 200X

9

Power

DC lithium polymer battery (DC 14.8V, 3400mAh),

100~240V AC adapter

Battery

capacity

Approximately 200 cycles

Electrodes life

3,000 splices

Terminals

USB, RCA, external power(DC 12V vehicle cigar jack splice)

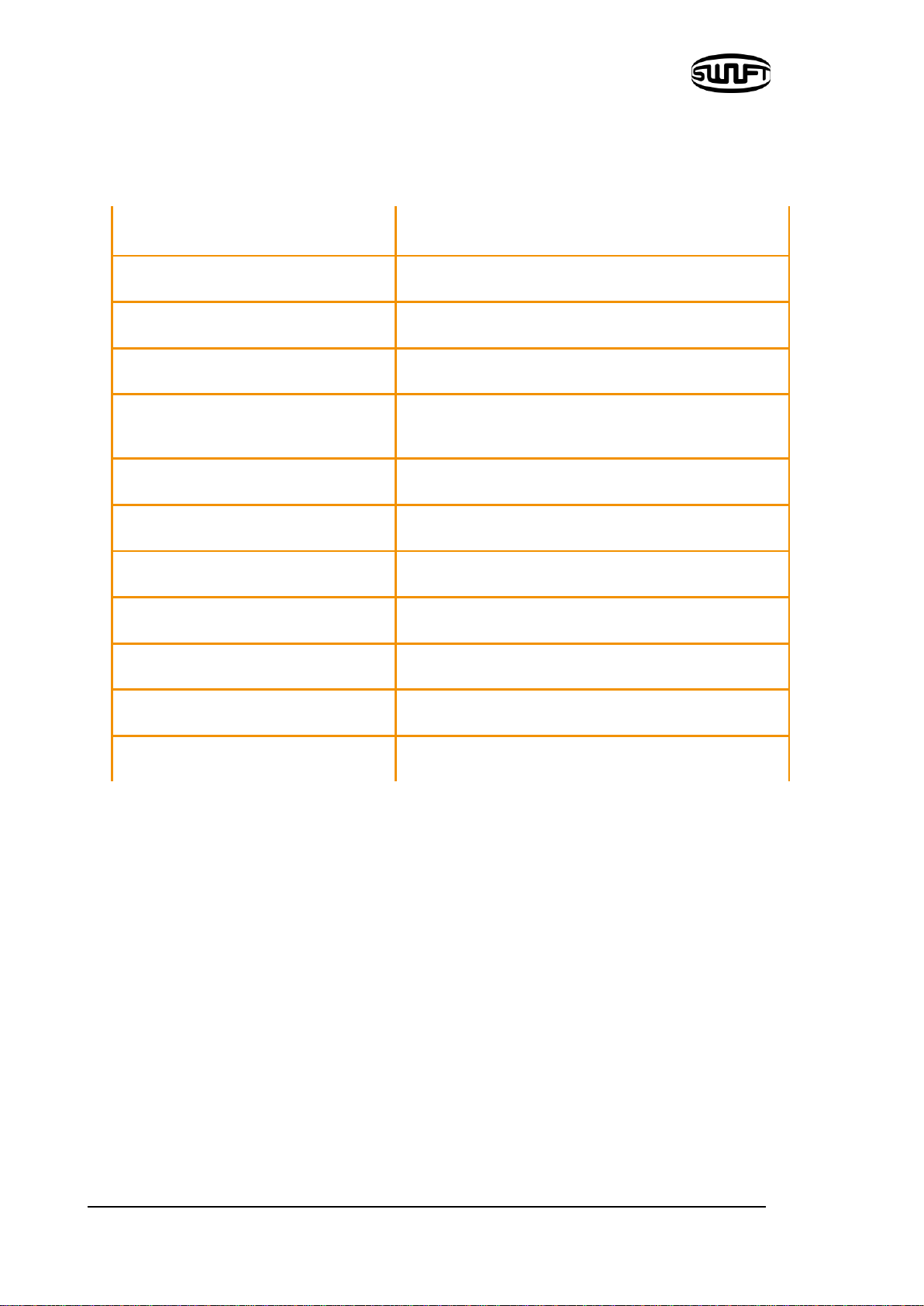

2.2 Product package

2.2.1 Standard package

Item

Model name

Quantity

Fusion splicer

Swift KF2A

1

AC adapter

-

1

Spare Electrodes

EI-19

1 set

Battery

KF-3400

1

Cooling tray

CT-01(40mm)

1

Fiver Holder

-

1 set

Users Guide

-

1

Carry case

ILST-SS03(L) (Soft

Case)

1

Screw driver

LD-3300

1

USB Cable

-

1

10

2.2.2 Optional package

Item

Model name

Battery

KF-3400

Cleaver blade

BI-05

Electrodes

EI-19

Fiber holder

KF-250, KF-900, KF-2.5, KF-IN,KF-SC/FC,

KF-LC, KF-ST, KF-L900 (Choose one)

Sleeve

S09-C, S09, S30-C, S30

Sleeve clamp

SC-01

Work belt

WB-01

SOC connector

SC, LC, FC, ST [See Ilsintech website.]

Carrying case

Hard Case

Manual Stripper

CF-02

External Power

DC 12V Available for car cigar jack

11

Product outline

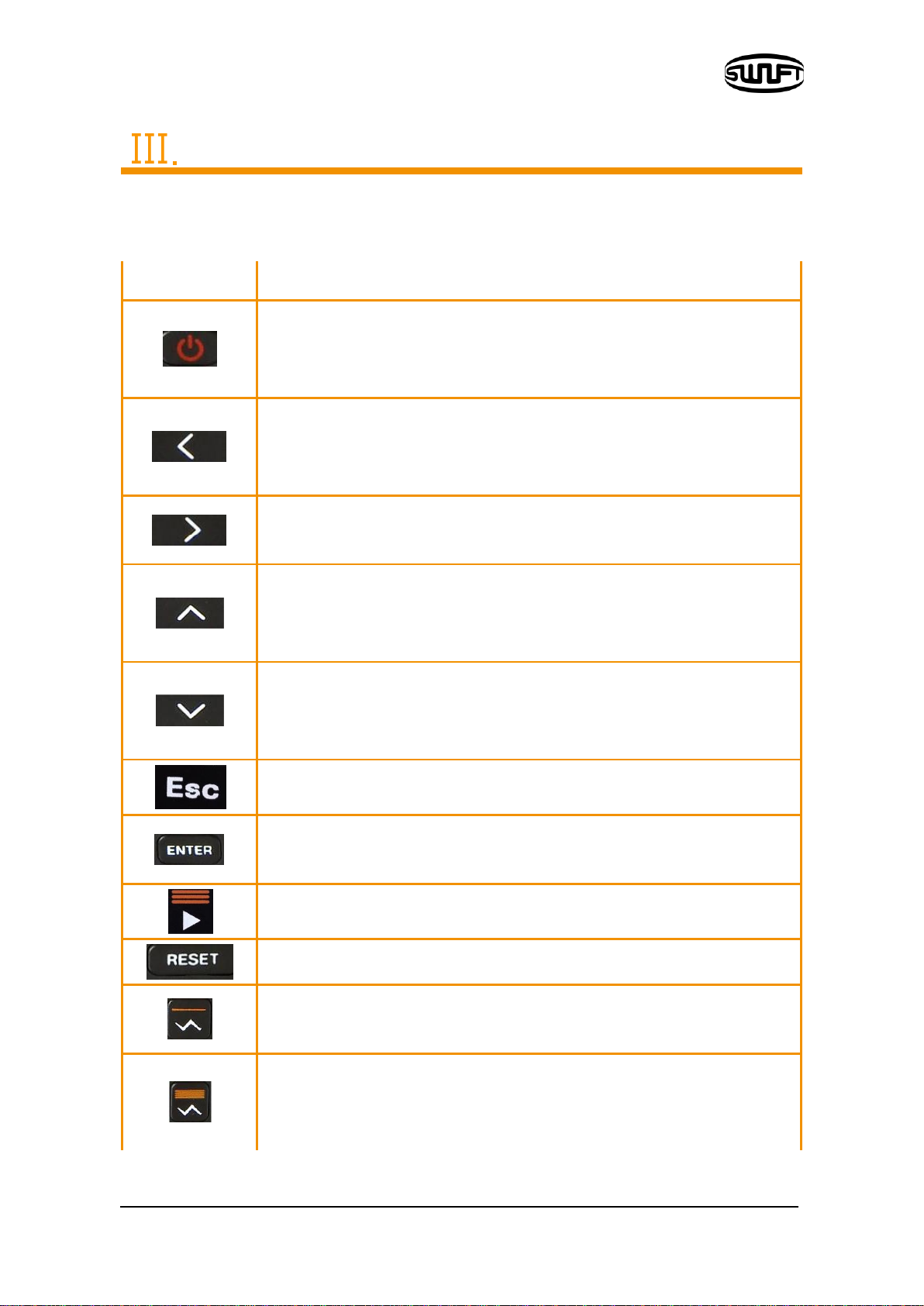

3.1 Function buttons

Button

Description

Press and hold about 1 second to turn the power ON/OFF.

Press and hold about 1 second when power is on and splicer

turns off.

Move the cursor to the left.

Move fiber on manual mode and adjusts camera’s focus.

It loads stripping popup menu.

Move the cursor to the right

Move fiber on manual mode and adjusts camera’s focus.

Move the cursor upwards.

It selects each motor on manual mode.

It loads splice popup menu.

Move the cursor downwards

It selects each motor on manual mode.

It loads heater popup menu.

Initialize the splice function.,It goes back to the menu screen.

Complete a selection

It goes to the next step on the menu screen.

Splice execution.

It goes back to the initial screen. It initializes splice function.

Turn on the stripper.,When it is ON, the lamp on the left is in red.

Press once more when it is ON and the heater is turned off.

Turn on the heater.

When it is ON, the lamp on the left is in red.

Press once more when it is ON and the heater is turned off.

12

3.2 Component name

Wind cover

Battery

Monitor

Sleeve heater

Stripper

Cleaver

13

Heater cover

Heater

DC OUT

USB

14

Instructions for use

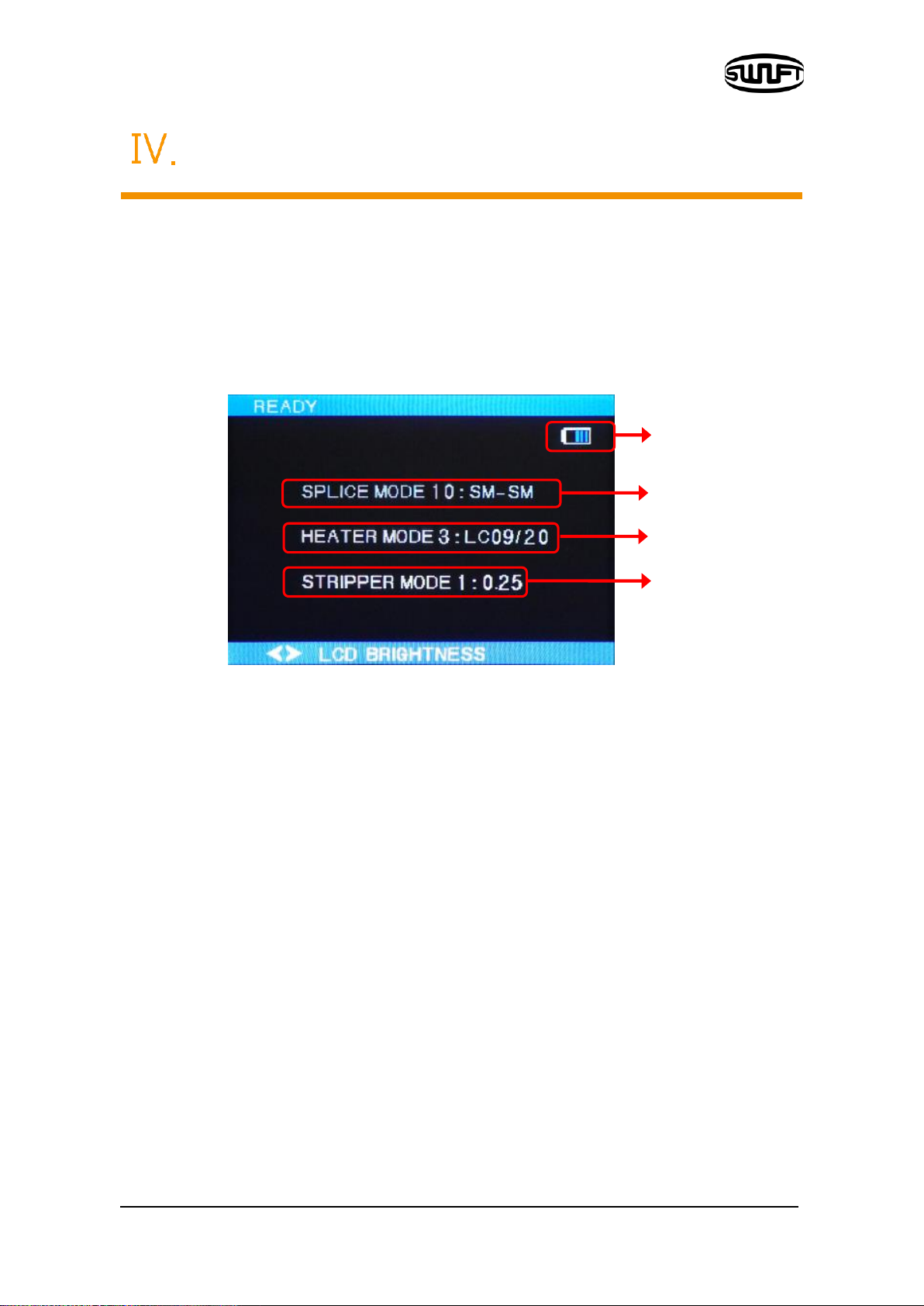

The following is the initial screen of Swift KF2A. For accurate splice result, splice mode,

stripping mode and heater mode should be properly selected. Basic information on

Swift KF2A is displayed on the initial screen. Check whether the proper mode is

selected before splice.

Battery status indicator

Current splice mode

Current heater mode

Current stripping mode

15

4.1 Power supply

Battery pack is built in at the battery chamber. Loosen the bolts at the bottom cover and

exchange battery. Please be cautious when you detach the battery from the chamber.

4.1.1 Built in battery

16

4.1.2 Battery charging

Make sure you check the voltage, frequency and then the DC cable of AC/DC adaptor

connects to the DC jack of the battery before charging the battery

When the battery is fully charged, LED will turn green and power is disconnected,

activating protection circuit to avoid overcharge. The power is turned back on as the

battery needs to be charged and charging resumes when the DC cable of adaptor is

connected to the DC jack of the battery.

17

4.2 How to turn the power ON/OFF

To turn on the power of Swift KF2A, press and hold about 1 second with the

wind cover closed. After the entire functions including motors are initialized, the initial

screen is subsequently displayed as follows. For accurate splice, splice mode and

heater mode should be properly selected. Current splice mode, stripping mode and

heater mode are displayed at the bottom of the screen.

18

4.3 Fiber cleaning

Wipe fiber clean with soft cloth or cotton moistened with alcohol. Fine dust on the

surface of the fiber may increase loss after splice and incur damage on the fiber after

heating.

4.4 Inserting fiber to protecting sleeve

Put fiber into the protective sleeve.

Table of contents

Popular Test Equipment manuals by other brands

Softing

Softing NetXpert XG2 PLUS quick start guide

Keysight Technologies

Keysight Technologies 85038A 7-16 User's and service guide

Viavi

Viavi SmartClass Fiber OLS-85 operating manual

Emerson

Emerson Rosemount FS-HR-975 Reference manual

Cadex

Cadex BatteryStore C5100B user guide

Ametek

Ametek Teseq NSG 3150 user manual