IMC DG60 User manual

装潢单 头液体灌装机

Manual

Cont ent s

※Wo r k P ri nci pl e

※Techni que Paramet er

※Ma c h i n e I ns t r uc t i on

※Instal lment and Debuggi ng

※Saf e Ope r at i on

※Ma c h i n e Mai nt ai n

※Ma n u a l a n d S e m i a u t o ma t i c O p e r a t i o n

※Op e r a t i o n o f Re s e t b u t t o n

※Op e r a t i o n o f Re e d s wi t c h

※Na me o f e a c h p a r t

※Electric Di a g r a m o f ma c h i n e

※Tr o u b l e s h o o t i n g

※Pac ki ng Li s t

※Ac c e p t a n c e c o n f i r ma t i o n

日高包装机械

Par t One : Wo r k P ri nc i pl e

Gr anul e f i l l i ng machi ne i s a semi -aut omat i c pi st on f i l l i ng machi ne whi ch used t o fi l l past e

wi t h s ma l l r o u n d g r a n u l e . By t h e p r i n c i p l e o f d r i v e s t h e p i s t o n a n d t h e t u r n v a l v e ’s t hree-wa y

cont act by ai r cyl i nder t o suck and rel ease t he pr oduct . The tralve of the

Ai r c y l i n d e r i s c o n t r o l l e d b y r e e d s wi t c h t o a d j u s t t h e f i l l i n g r a n g e .

The ma c hi ne o wn s s i mp l e a nd r e a s o na bl e s t r uc t u r e , h i gh a c c u r a c y a n d s i mp l e ope r a t i on

Par t Two : Techni que Paramet er

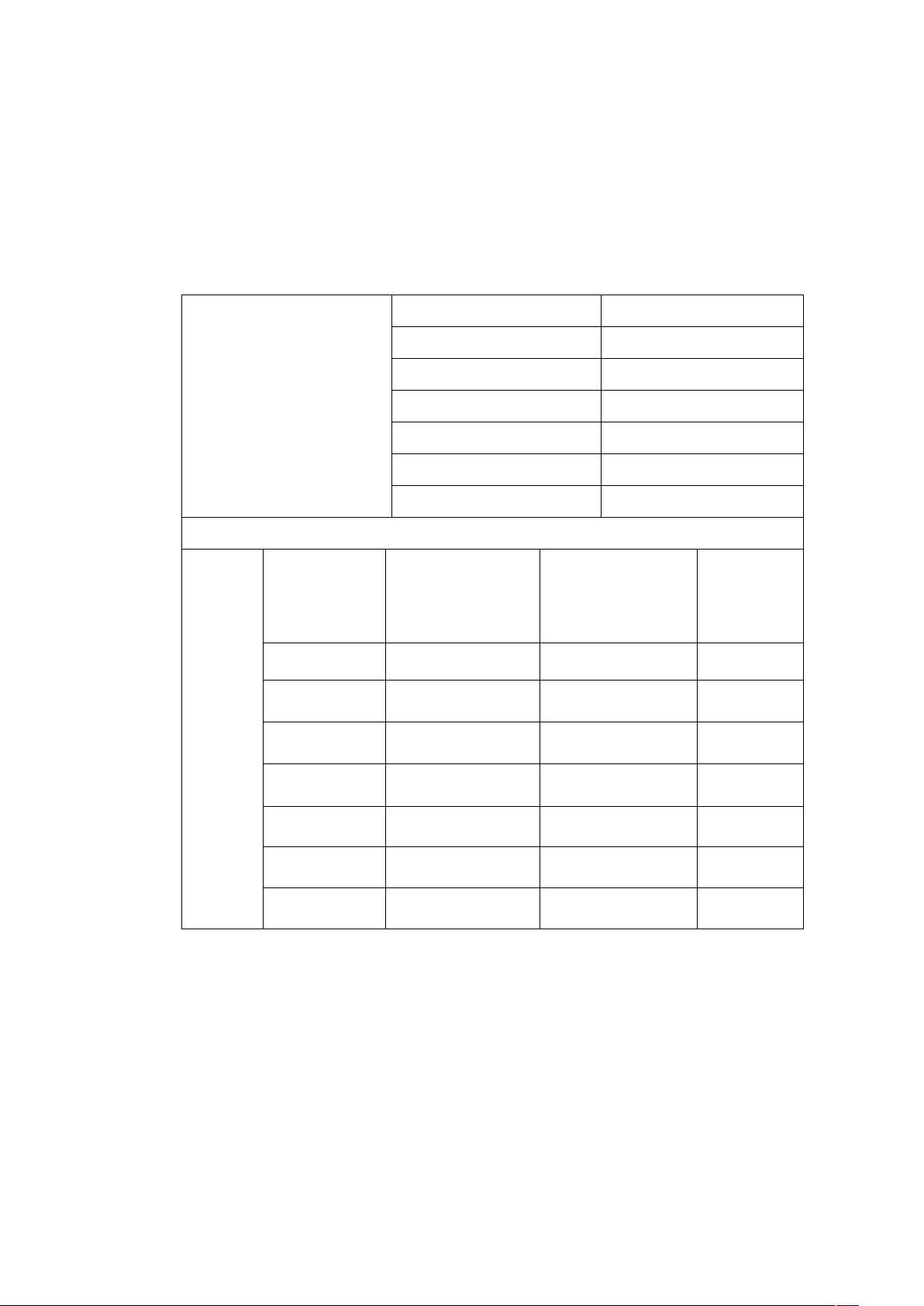

Techni que Paramet er

Cont ent

Par a me t er

Vol t age

220V±5V

Electric Cur r ent

1A

Power

10W

Rat i ng Ai r Pr es sur e

4- 6kg

Fi l l i ng Speed

0- 50

Fi l l i ng Pr eci s i on

±1 %

Fi l l i ng

Ef f e c t

Model

Fi l l i ng r ange

(ml)

Per f ect Fi l l i ng

Range

(ml )

Thi s

Machi ne

Model(√)

DG60

5~60

25~60

DG125

10~125

50~125

DG250

25~250

100~250

DG500

50~500

200~500

DG1000

100~1000

300~1000

DG2500

250~2500

500~2500

DG5000

500~2500

1000~2500

Par t Thr e e : Ma c h i n e I ns t r uc t i on

The ma c h i ne ma i n l y be used i n t he i ndust r i es of phar maceut i cs , f oods t uf f , cos met i c so on. The

ma c h i n e t wi l l b e a f f e c t e d b y f o l l o ws f a c t o r s d u r i n g t h e wo r k p r o c e s s .

1. The f i l l i ng pr eci s i on wi l l be af f ect ed by t he st abi l i t y of t he ai r pr es sur e, equal i t y of t he

pr oduct and t he f i l l i ng s peed.

2. The f i l l i ng speed wi l l be af f ect ed by t he vi s ci di t y of the product, travel of the air cylinder,

size of t he filling nozzle and the pr of i ci ency of t he wor ker s .

3. The machi ne wi t h t wo t ype f i l l i ng way: f oot pedal and aut omat i c. The t wo f i l l i ng way can

be chosen di scr et i onar i l y,

4. The t ur n val ve of t he machi ne is made up of we a r a b l e , aci d-resistant, heat -resistant F- 4.

Do n o t b e a t , h i t i t wh e n wa s h i t .

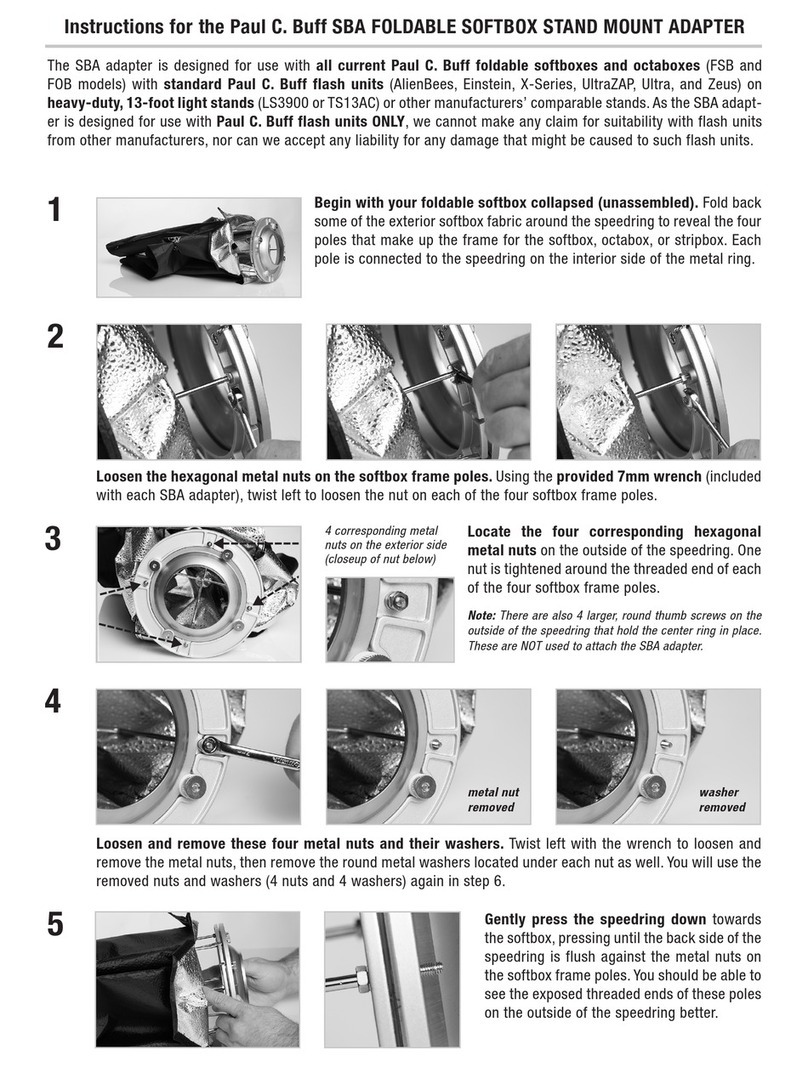

Par t Fo ur : I ns t al l me nt a nd Debuggi ng

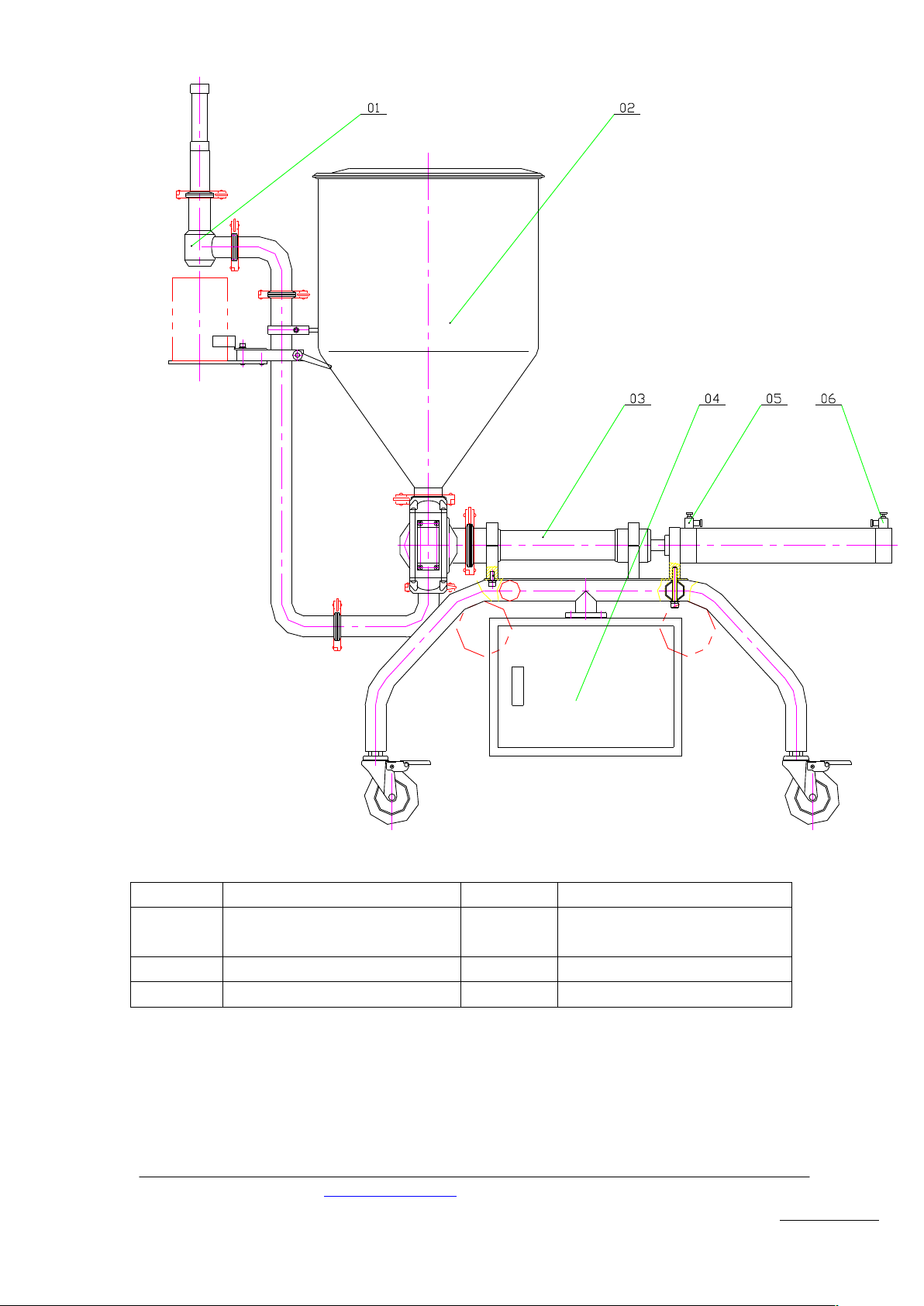

1. Put t he hopper ( pi c. 1) over t he t hr ee -wa y c o n t a c t b i g s q u a r e b o d y cont rol val e, and l ock

the connect par t wi t h Ar mf u l Ho o p.

2. I nst al l t he f i l l i ng nozzl e 01( pi c. 1) , connect t he bi g s quar e body por t and t he f i l i ng head

por t wi t h pr oduct f eedi ng t ube. l ock i t wi t h cl amp.

3. Conf i r m t he pos i t i on of t he r eed swi t ch( t he posi t i on of t he back r eed s wi t ch i s f i xed)

4. Connect wi t h t he el ect r i ci t y power and t ur n on t he el ect r i ci t y power swi t ch.

5. Connect wi t h t he ai r sour ce and t ur n on t he ai r s our ce s wi t ch.

6. Swi t ch t he wor k model t o manual , cont r ol t he f i l l i ng by pedal .

7. Adj us t t he t hr ot t l e 1( 05) and t hr ot t l e 2( 06) t o a sui table pr oduct suck and f i l l i ng s peed.

To ge t a b e t t e r wor k e f f i c i e n c y, c a n f a s t e r t h e p r odu c t s u c k s p e e d 0 6 , a n d s l owe r f i l l i n g s pe e d

05( i f t he f i l l i ng s peed i s t o f as t wi l l make t he pr oduct or bubbl e das h out of t he bot t l e,

affect t he fi l l i ng qual i t y. )

8. When adj ust t he fi ling range,

Slide the front reed switch to range you asked then fix it.

9. Put t he pr oduct to hopper, begi n f i l i ng.

10. When wor ker s ar e pr of i ci ent i n i t , can s wi t ch t he wor k model t o aut omat i c t o i mpr ove wor k

effi ci ency.

Par t Fi ve : Saf e Ope r at i on

The ma c hi n e i s us e d t o f i l l pa s t e , no o t h e r us a g e . To i s s u r e a s a f e o pe r a t o n , p l e a s e not e :

1. The machi ne adopt al t er nt i on cur r ent 220V, 1A, ai r pr es s ur e 4-6KGS.

2. Bef or e t ake apar t and cl ear t he machi ne, must cut of f t he el ect r i ci t y power and ai r s our ce.

3. When cl ear t he machi ne, can not use the wa t e r r i n s e t h e ma c h i n e b o d y d i r e c t l y i n c a s e des t r oy

the machine electricity contorl part inside.

4. For safet y of person, the machine need to be earthing properly.

5. When i ns pect t heel ect r oci r cui t ( pi c. 3) of t he machi ne, mus t cut of f t he el ect r i ci t y power and

ai r source fi r st .

Par t Si x: Ma c h i n e Mai nt ai n

1. The ma c hi n e s u r f a c e i s s t a i n l e s s s t e e l , whe n c l e a r t h e ma c h i n e , d on’t use sharp and hard

tools to scratch the surface.

2. Ca n u s e al cohol to clean the dirt on the surface of the machine.

3. Cy l i n d e r h a s been l ubr i cat ed i n t he factory, so no need di s as sembl y and

lubricate the cylinder again.

4. I t i s eas y t o cl ean t he pr oduct cyl i nder , SS t hr ee-wa y c o n t a c t a n d t h r e e -wa y di ver s i on val ve.

5. Change t he wor n s eal s t i mel y.

Par t Se ve n: Ma n u a l a n d S e m i a u t o ma t i c O p e r a t i o n

The ma n u a l / a u t o Sel ect or Swi t c h(pic.2) is setted for debugging or measure.When debugging the

new machi ne or change anot her pr oduct or change t he f i l l i ng r ange or af t er cl ear i ng t he machi ne,

it is better to debug i t by manual swi t ch. When f i ni s hed debuggi ng and t he machi ne f i l l wel l ,

thenyouchoose the aut o swi t ch. can swi t ch t he work model t o aut omat i c t o i mpr ove wor k ef f i ci ency,

no need t o t ur n of f t he machi ne f i r s t .

Par t Ei g ht : Op e r a t i o n o f Re s e t b u t t o n

Wh e n e l e c t r i c i t y p o w e r o f f s u d d e n l y o r a i r c y l i n e r c a n n o t r e t u r n b a c k d u e t o i m p r o p e r

oper at i on, pl ease pus h t hi s but t on.

Par t Ni ne : Op e r a t i o n o f Re e d s wi t c h

1. Fi xed t he r eed s wi t ch, us ual l y i t i s f i xed i n t he l ow back of t he ai r cyl i nder . I t

i s f i xed s i gnal swi t ch.

2. Moveabl e r eed s wi t ch, ususal l y i t i s f i xed i n t he hi gh f r ont of t he ai r cyl i nder ,

i t i s s i gnal swi t ch us ed t o adj us t t he f i l l i ng r ange.

Par t Te n: Na me o f e a c h pa r t

No.

Name

No.

Name

01

Filling Nozzle

04

Electricity Control

Box

02

Hopper

05

Product out Throttle

03

Product Cylinder

06

Product in Throttle

⧦状膏体示意⦍一

˙4 ˙

ht t p: / / www. r i gaocom E- ma i l : r i g a o @ma i l . wz p t t . z j . c n

日高包装机械

NO.

Name

No.

Name

07

Urgent stop reset

switch

08

Selector Switch

09

Swing air cylinder

10

Turn valve

⧦状膏体示意⦍二

Part Eleven: Electric Di a g r a m o f ma c h i n e

˙6 ˙

※ Part Twelve:Tr o u b l e s h o o t i n g

Problem

Analysis of Problem

Solution

Piston can not

Move front and

back

1.Check if turn on the air

pressure

The machine need the air

pressure

2.Chek if turn on the airpressure

valve

turn on the airpressure

valve

3.If air source and electricity

source is trun on

Turn on air source and

electricity source

4.Check if the air pressue is

enough

The air pressure needed is

4kg-6kg/c ㎡

5. .Check if diversion valve is

fixed properly

Fix it properly

6 Check if it is the O seal on

the pistion head with viscidity

to block the pistion

Change a new O seal

7. Check if the fixed reed switch

is moved

Fix it

Asymmetric

filling

Check the viscidity of your

product and the seals to see if

it leak

Slow down the product suck

and release speed.

Change the worn seals.

Check if there are enough

Produt in the hopper on your

Product tank.

Put enough product

Product leak

out from the

back of product

cylinder

Check the seals on the pistion

If have problem,change

new ones

If your product is too thin

Contact with our company

This manual suits for next models

6

Table of contents

Other IMC Adapter manuals