INDUSTRIAL SAFETY SOLUTIONS SafetyPro User manual

Getting Started with the SafetyPro™

Page 1 of 13

www.industrialsafetysolution.com - 1-877-762-9280

Thank you for choosing the

SafetyPro™

Industrial Labeling System!

SafetyPro Box Contents:

This box should contain:

1. (1) SafetyPro Labeling System

2. (1) US Cable

3. (1) Software CD

4. (1) QuickStart Guide

5. (1) Rollers & Guides Pack

Setu Ste s:

Follow these steps first:

1. Read all printed instructions

2. Unpack printer, remove packing

3. Load ribbon & vinyl (Page 2)

4. Setup software (Page 3)

5. Connect printer (Page 4)

FREE TECH SUPPORT

With the SafetyPro, you never have to feel stuck. Free technical support is just a

phone call away. Contact us at 1-877-762-9280 for setup help or any other questions

you may have.

Getting Started with the SafetyPro™

Page 2 of 13

www.industrialsafetysolution.com - 1-877-762-9280

Loading Vinyl & Ribbon

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Ste 1: Make sure the machine is turned off while

loading all materials. To open the machine, gently pull the

two light green cover lock tabs towards you. Lift the

chassis. Place the hood prop on setting #2. Your

printer should now resemble Figure 1.

Ste 2: Select a roll of vinyl supply and place the light

green plastic roller through it. Place the loaded roller

into the machine on the cradle. Place vinyl under the

Teflon bar, through the adjustable guides, over the

rubber platen and through the cutter. Adjust the green

guides so the right-hand guide lip is over the vinyl (this

guide contains a sensor that must be positioned over

the vinyl). Your printer should now resemble Figure 2.

Ste 3: Next, open the clear ribbon access cover. Install

a ribbon onto a plastic ribbon supply spindle. Install an

empty paper core on to the other plastic supply spindle

to serve as your rewind spindle. The ribbon spindle is

loaded on to the rear hub (Figure 3) with the flange side

in the right hub lock. The rewind spindle is loaded on to

the front hub.

When loaded correctly, the ribbon will unwind from the

back, down through the machine, under the print head

and back up to the rewind spindle (Figure 4). Secure the

loose ribbon to the empty core with tape. Make sure the

ribbon is free of wrinkles and is smooth. Gently turn the

rewind spindle toward back of the machine to tighten.

Ste 4: While gently lifting up on the chassis, release the

hood prop by pulling it towards you until it lays flat and

the machine can be closed. Close machine until it clicks

into place. The machine is now loaded properly and

should resemble Figure 5.

Getting Started with the SafetyPro™

Page 3 of 13

www.industrialsafetysolution.com - 1-877-762-9280

Installing Software & Drivers

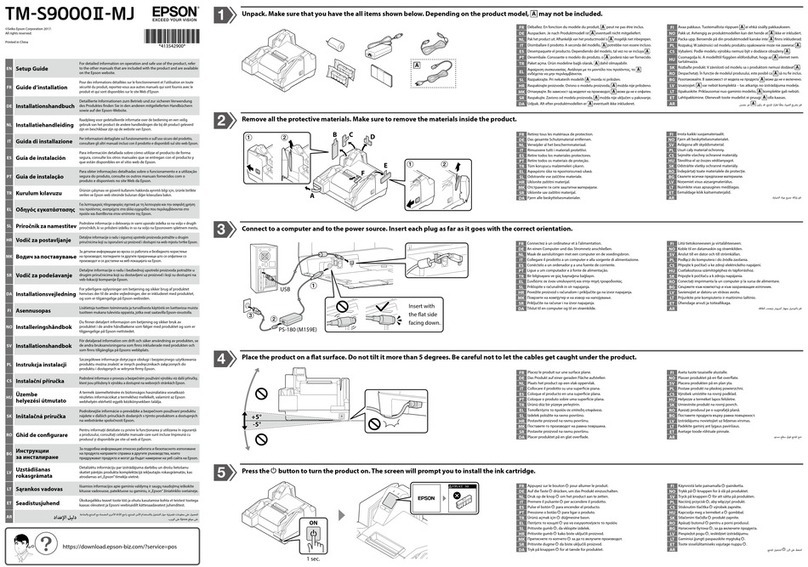

When the CD is inserted, the screen above will a ear

on your monitor. Click each o tion to install.

It is recommended

that you install ALL

of the software on

the CD. You should

install the software

BEFORE connecting

the rinter.

O tional Minimum Software Installation:

You may choose to install only the following

software, in order:

SafetyPro Drivers

FacilityWare Label Manager

If you choose this optional minimal installation, you

may add the Additional Software components at

any time.

Notes on USB vs. LPT Connections

USB (included)

The default, included connection for the

SafetyPro is US . With US connections,

Microsoft Windows can detect when the

printer is connected and powered on. The

“Add Printer Wizard” is started

automatically with US . Ensure the

software is installed and CD is still in the

drive before connecting and powering on

the SafetyPro when using US .

LPT (Parallel – not included)

You may optionally choose to use an LPT

(Parallel) connection with the SafetyPro.

When you use an LPT connection,

Microsoft Windows cannot detect the

printer. The “Add Printer Wizard” is not

started automatically, and you must

manually add the printer in the Printers &

Faxes section, or in the control panel

under Printers.

Getting Started with the SafetyPro™

Page 4 of 13

www.industrialsafetysolution.com - 1-877-762-9280

Connect & Power-on the SafetyPro

Make sure you have installed all of the software on the

CD before connecting and turning on your SafetyPro.

The CD should still be in the drive.

Connect &

Power on

the

SafetyPro

Printer

Microsoft

Windows

automatically

launches the

“Add Printer

Wizard”

Detailed Notes:

Once you have installed the Software CD, you may connect and power up your

SafetyPro printer. First, connect the US cable to your printer and computer, then plug

in the power cord and connect it to the printer. The power switch is on the back of the

printer, at the bottom, next to the power cord outlet.

When US -connected users switch on their SafetyPro for the first time, the “Add

Printer Wizard” will appear automatically on your monitor. With the CD still in the drive,

complete the wizard. LPT (Parallel) users will not see the wizard.

Once the “Add Printer Wizard” is complete, you should not see it again when turning

the printer off and back on.

If you see the New Hardware Wizard each time you power

on your computer contact your IT department, or contact 877-762-9280 for support.

Getting Started with the SafetyPro™

Page 5 of 13

www.industrialsafetysolution.com - 1-877-762-9280

SafetyPro Print Driver Settings

For continuous roll vinyl label stock (regular labeling

material, general ur ose labeling)

Getting Started with the SafetyPro™

Page 6 of 13

www.industrialsafetysolution.com - 1-877-762-9280

SafetyPro Print Driver Settings

For die-cut vinyl label stock (arc flash, NFPA RTK, ANSI,

Color stri e, and blank die-cut labels)

Getting Started with the SafetyPro™

Page 7 of 13

www.industrialsafetysolution.com - 1-877-762-9280

Using FacilityWare Label Manager

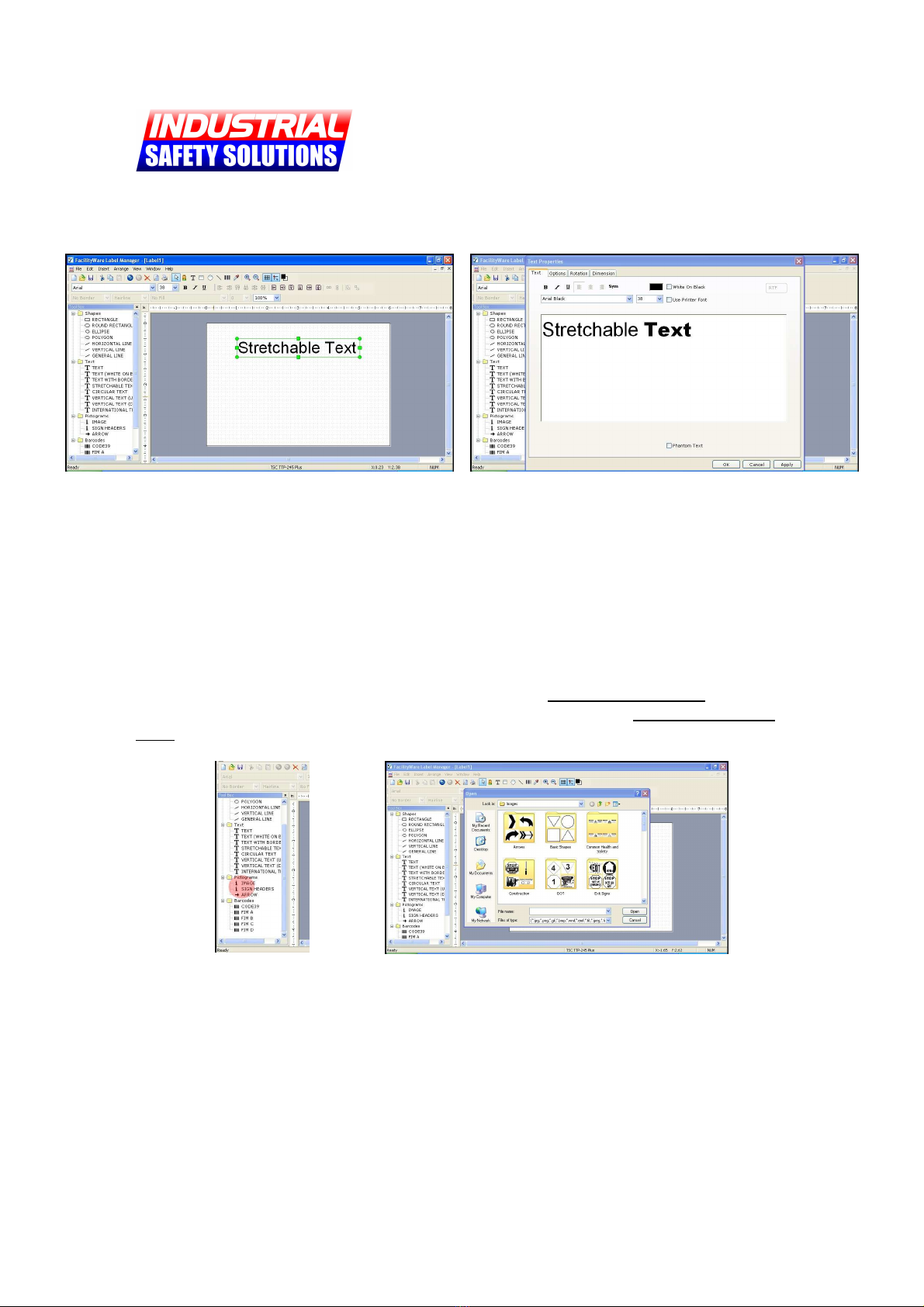

Figure 1: New Label

Figure 2: Custom Size

First, choose your label tem late…

When you start FacilityWare, you will be asked to select your template (Figure 1). You

can input your layout and loaded material type, then choose your label size from the

selections. If you need a custom size that is not on the list, you may click the

“Customize” button, and input your size manually (Figure 2).

If you want to use a pre-made template for Arc Flash, RTK, ANSI, or other standard

labels, click the “Templates” button on the bottom of the template setup screen (Figure

1). Choose your template from the list provided.

Figure 3: The Toolbox

Figure 4: Drag-and-Dro

“Drag-and-Dro ” makes label creation easy

The Tool ox (Figure 3) provides you with all of the available objects for creating your

label. To add any object from the Tool ox to your label, simply “Drag and Drop” it (See

Figure 4). Once the object is on your label, you can modify it as needed.

Getting Started with the SafetyPro™

Page 8 of 13

www.industrialsafetysolution.com - 1-877-762-9280

Using FacilityWare Label Manager

Figure 5: Stretchable Text Object

Figure 6: Text Object Pro erties

Adding Text

To add text to your label, locate the “Stretchable Text” object in the toolbox and “Drag-

and-Drop” it onto your label. Once added, the object will have green dots around the

edges, used for resizing (Figure 5). You may click and drag the object anywhere on your

label.

To edit the object, double-click it OR right-click and select “Properties.” The Object

Properties dialog will appear (Figure 6). You may enter multi le lines of text, and

manipulate font styles and sizes for any part of the text, as shown. Multi le fonts and

sizes may be used in a single object.

Figure 7: Image Objects

Figure 8: Select an Image

Adding Images

“Drag-and-Drop” any Image Object from the Pictogram section in the Tool ox (Figure

7). The image selection dialog will appear automatically (Figure 8). FacilityWare

includes thousands of labeling images, which you can use on virtually any type of safety

label imaginable. Choose one of these included images, or browse to your own image,

double click and it will append to your label blank.

Getting Started with the SafetyPro™

Page 9 of 13

www.industrialsafetysolution.com - 1-877-762-9280

Using FacilityWare Label Manager

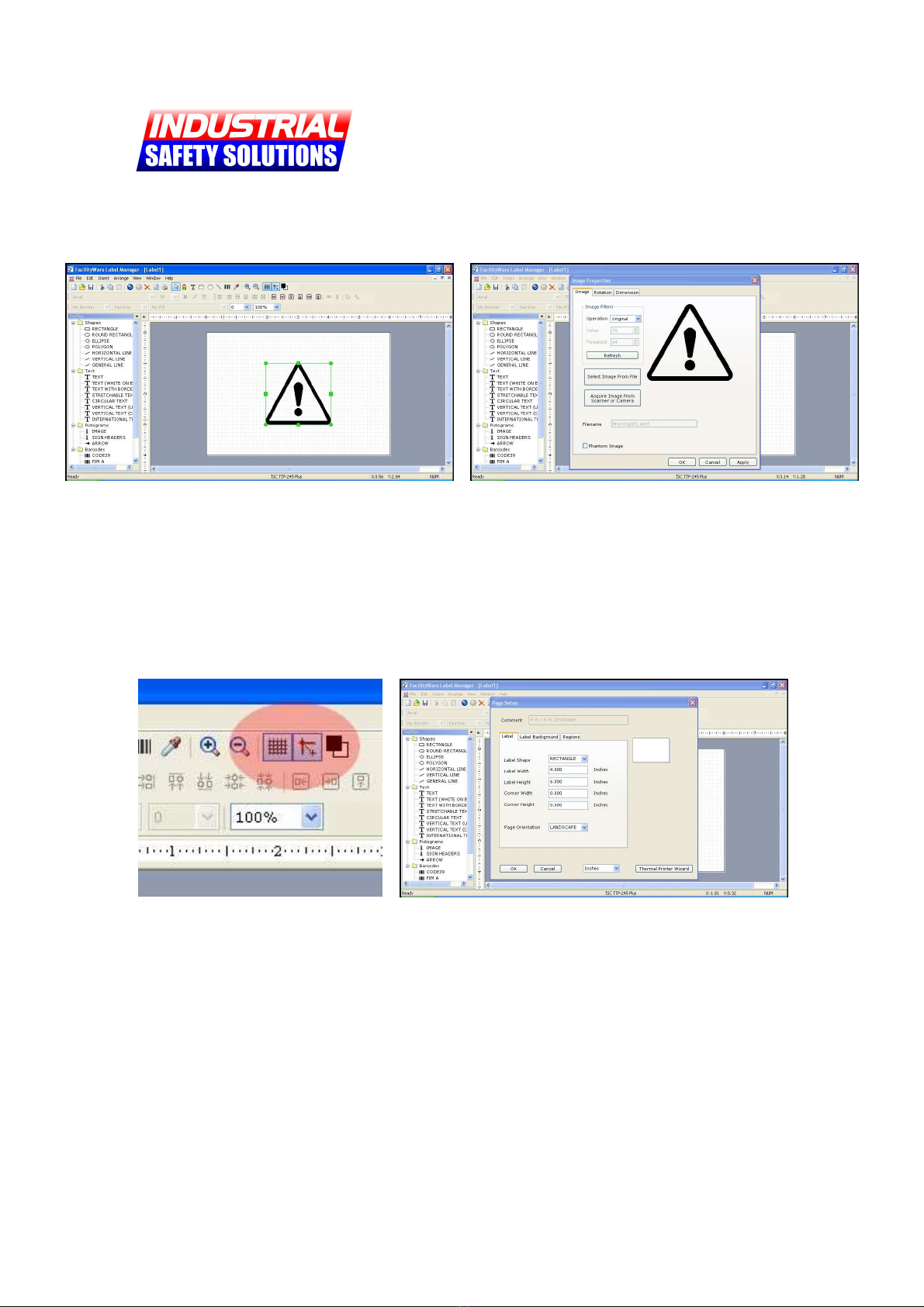

Figure 9: Image Object Selected

Figure 10: Image Object Pro erties

Adding Images (continued)

Once you have inserted an image object it will appear with green dots around it, used

for resizing (Figure 9). Move the image and size it as desired. For additional image

object options, such as rotation and color control, double-click the image OR right-click

and select “Properties.” If you are using a color image, make sure to convert it to black-

and-white for label printing.

Figure 11: Grid O tions

Figure 12: Label Setu

Grid O tions and Label Setu

FacilityWare is designed to let you control your label creation experience. Some

customers may want to disable the “Snap-to-grid” feature, which can be done quickly

and easily using the toolbar at the top of the software (Figure 11).

If you decided you need a different label size after you have already started with your

label creation, you can select the File menu at the top, then choose Label Setup (Figure

12). Adjust your size as needed.

Getting Started with the SafetyPro™

Page 10 of 13

www.industrialsafetysolution.com - 1-877-762-9280

Arc Flash Label Printing

Arc flash labeling is com lex, and cannot be covered in

a Getting Started guide. Consider the o tions below,

and call us at 1-877-762-9280 for more hel .

Using FacilityWare

PROS: Very easy, no actual

arc calculation knowledge

necessary, can be done by

anyone. Professional look.

CONS: Does not handle

calculations. Not suitable

for printing from large sets

of data.

NOTES: You can use pre-

made templates in

FacilityWare to create

professional, easy-to-read

arc flash labels. Some

templates are included;

click on “Templates” when

starting a new document.

Using SKM

PROS: SKM is a complete

arc flash solution, and

includes everything from

calculation to print.

Industry accepted.

CONS: Requires electrical

engineering knowledge.

NOTES: SKM is an industry

leader in arc flash

calculations and label

creation. SKM works

directly with the SafetyPro,

and support is provided

directly from SKM.

Electrical contractors often

choose this option.

Using AF Label Creator

PROS: Easy to use, can

import from Excel (CSV),

fast, Professional look.

CONS: Does not handle

calculations. Fixed label

layout.

NOTES: Our ISS Arc Flash

Label Creator is designed

as an alternative for

electrical contractors who

already have their arc flash

calculations completed and

in a raw data form (CSV).

The label layout is industry

standard.

We can hel you with any of these Arc Flash

labeling o tions.

Please contact us for details.

Getting Started with the SafetyPro™

Page 11 of 13

www.industrialsafetysolution.com - 1-877-762-9280

ISS Arc Flash Label Creator

Create, rint and store standard 4 x 6 arc flash labels

in seconds. Im ort large label batches instantly from

Microsoft Excel CSV

Getting Started with AF Label Creator

Using the ISS Arc Flash Label Creator is

simple. First, choose a header. For die-

cut materials without a pre-printed

header, choose Danger, Caution, or

Warning. For labels with an existing

header, select “None.”

Once your header is selected, fill in your

arc flash calculation results in the

appropriate fields. Add checkmarks for

your required PPE, and any other

information you want to include.

efore printing, be sure to enter an

“Equipment ID,” identifying what the label

is to be used to mark. You may now print

or save your label.

Im orting from CSV

ISS Arc Flash Label Creator can run batch print jobs from a CSV spreadsheet. An

example spreadsheet is included with the software, and can be loaded into Microsoft

Excel to demonstrate the file format. A text document explaining the file format can

also be found in the program’s main directory.

Getting Started with the SafetyPro™

Page 12 of 13

www.industrialsafetysolution.com - 1-877-762-9280

ISS RTK Label Creator

Print from a database of thousands of re-defined

NFPA chemical labels in seconds

Figure 1

Figure 2

Selecting a Chemical (Figure 1)

In RTK Label Creator, you can order the list of

chemicals by CAS number or alphabetically. Using

the "Search" menu, choose either of these sort

orders. The default sort order is alphabetical.

Once you have sorted the chemical list, choose a

chemical from the drop-down on the upper right-

hand corner of the software. Click the chemical to

load the hazard information. All of the information

will appear on the screen. Review it for accuracy

against your chemical manufacturers MSDS sheet

before continuing.

Select Quantity and Print (Figure 2)

Once you select a chemical, click the print icon to

print the label. Select the label size that matches

your loaded supply, then enter a quantity and click

OK to print. e sure you have the proper RTK label

stock loaded and aligned. Use the properties

button to setup your printer for the correct stock

size (refer to the print driver settings page for die-

cut materials).

Getting Started with the SafetyPro™

Page 13 of 13

www.industrialsafetysolution.com - 1-877-762-9280

Purchasing Form – Fax or Mail

Credit Card Information

Credit Card Type: □Visa □MasterCard □American Express □Discover

Credit Card Acct #: CCV:

Credit Card Expiration Date:

Name as it Appears on Credit Card:

Payment Amount (USD): $

Cardholder Signature: Date:

Notes:

Bill To

Contact

Name

Contact

Phone

Company

Name

Street Address:

City: State: Zip:

Notes:

Ship To (if different)

Contact

Name

Contact

Phone

Company

Name

Street Address:

City: State: Zip:

Notes:

Order Information

Line Item Qty Price

Totals:

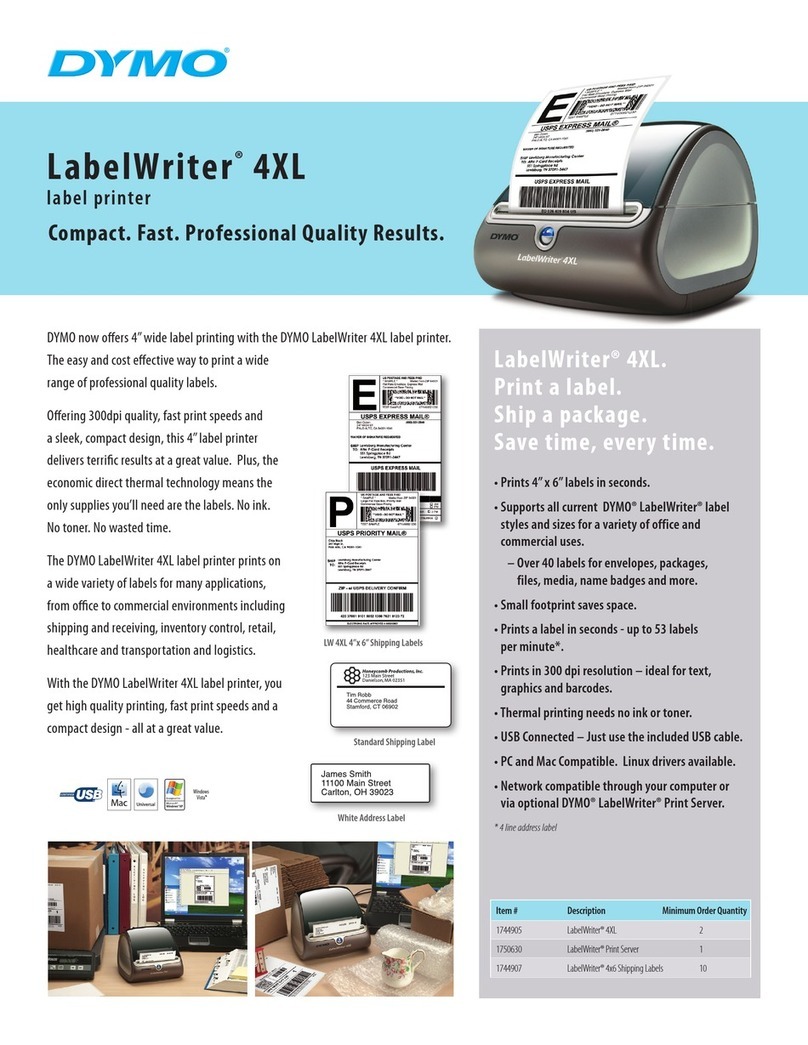

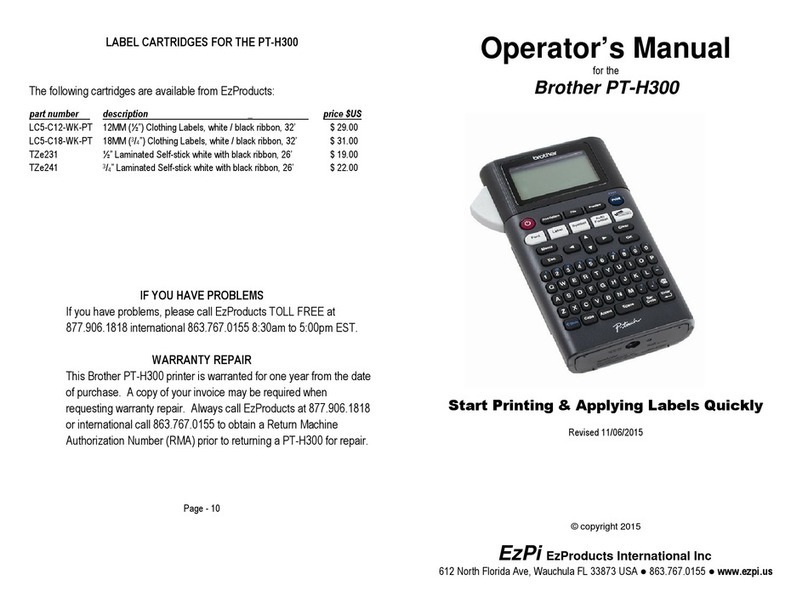

Popular Label Maker manuals by other brands

Brother

Brother P-Touch PT-H300 Operator's manual

London Electronics

London Electronics PORTI-P40 Operation manual

Dymo

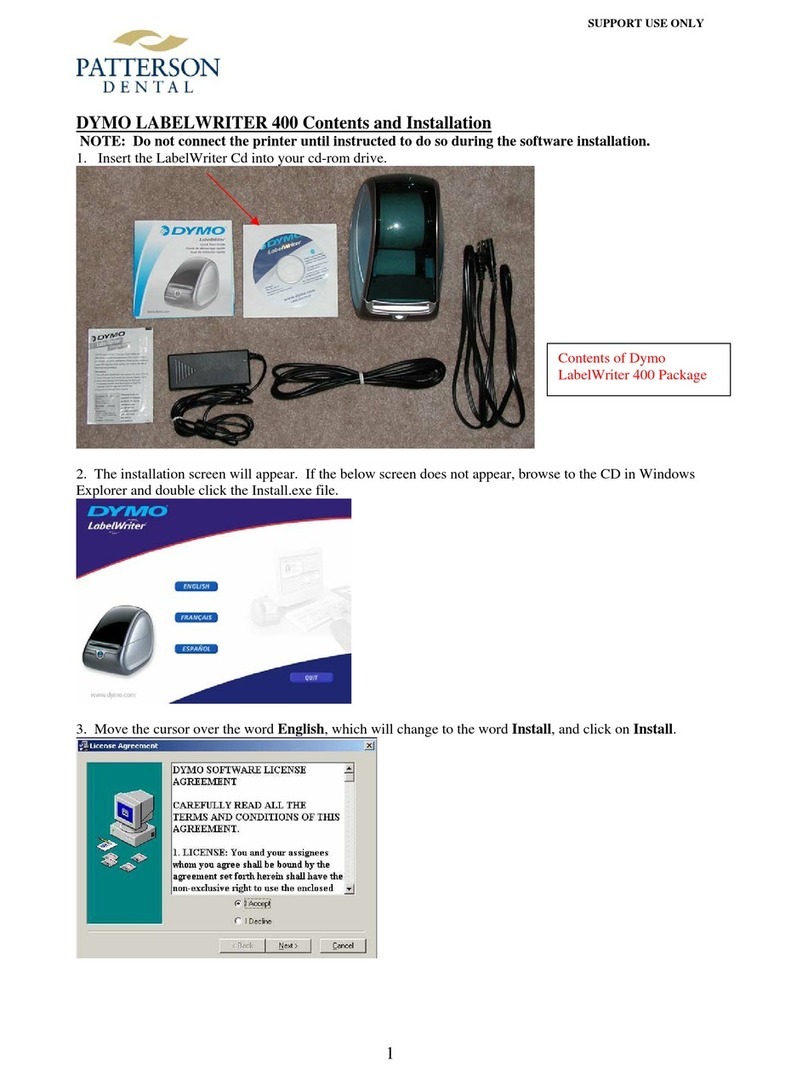

Dymo LabelWriter 400 Duo Guide Contents and Installation

Epson

Epson ColorWorks CW-C6000 Series user guide

Dymo

Dymo LabelWriter DUO quick start

Carl Valentin

Carl Valentin Compa II Serie Quick reference guide

Brady

Brady BradyPrinter i5100 user manual

BIXOLON

BIXOLON XT3-40 Series user manual

BIXOLON

BIXOLON SLP-TX400R Programming manual

Brother

Brother PT 1010 - P-Touch 1010 B/W Thermal Transfer... Guía del usuario

Custom Audio Electronics

Custom Audio Electronics KPM203 user manual

Epson

Epson LabelWorks LW-300 user guide