Preface

- 2 -

Contents

Preface ........................................................................................................................................ 1

Version History ........................................................................................................................... 1

Safety Precautions ..................................................................................................................... 4

Safety Disclaimer................................................................................................................. 4

Details of Safety Precautions.............................................................................................. 4

1 Product Information ............................................................................................................... 5

1.1 Nameplate and Model................................................................................................... 5

1.2 Component Description................................................................................................ 6

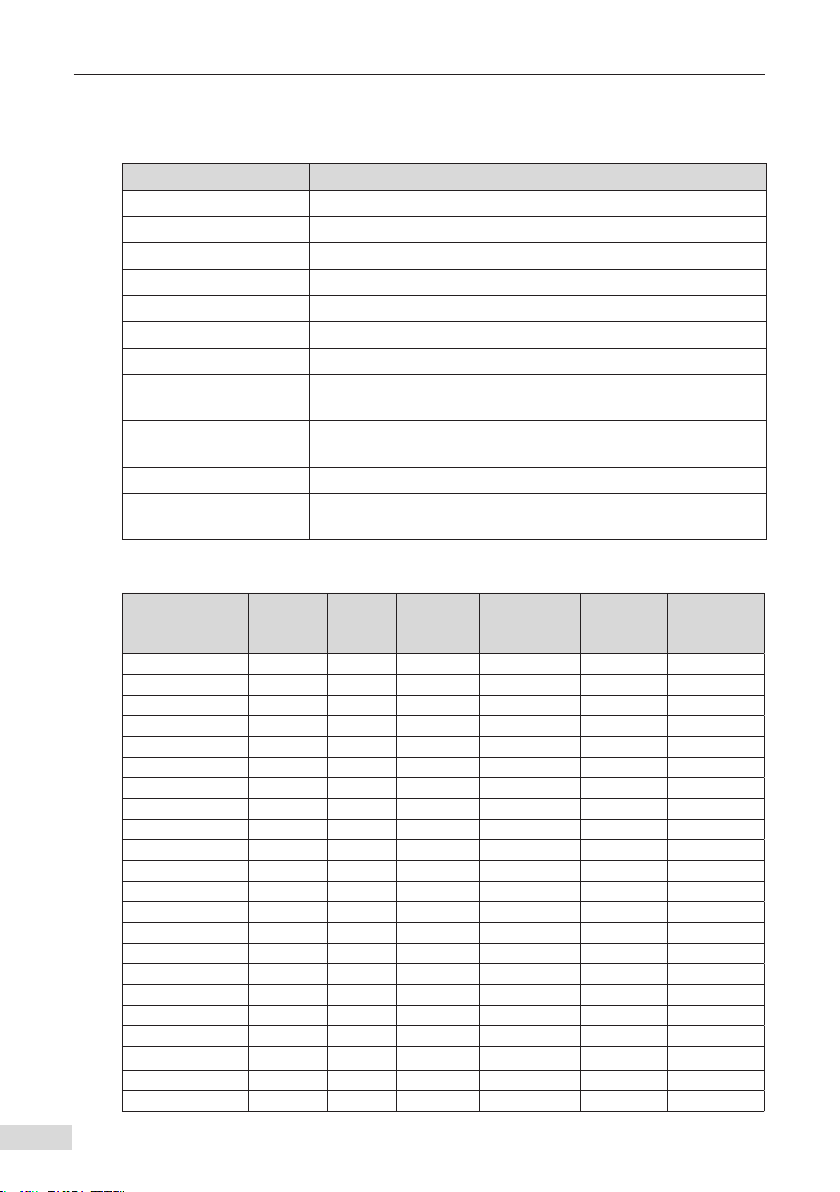

1.3 Specications................................................................................................................. 7

1.3.1 Mechanical Characteristics.................................................................................... 7

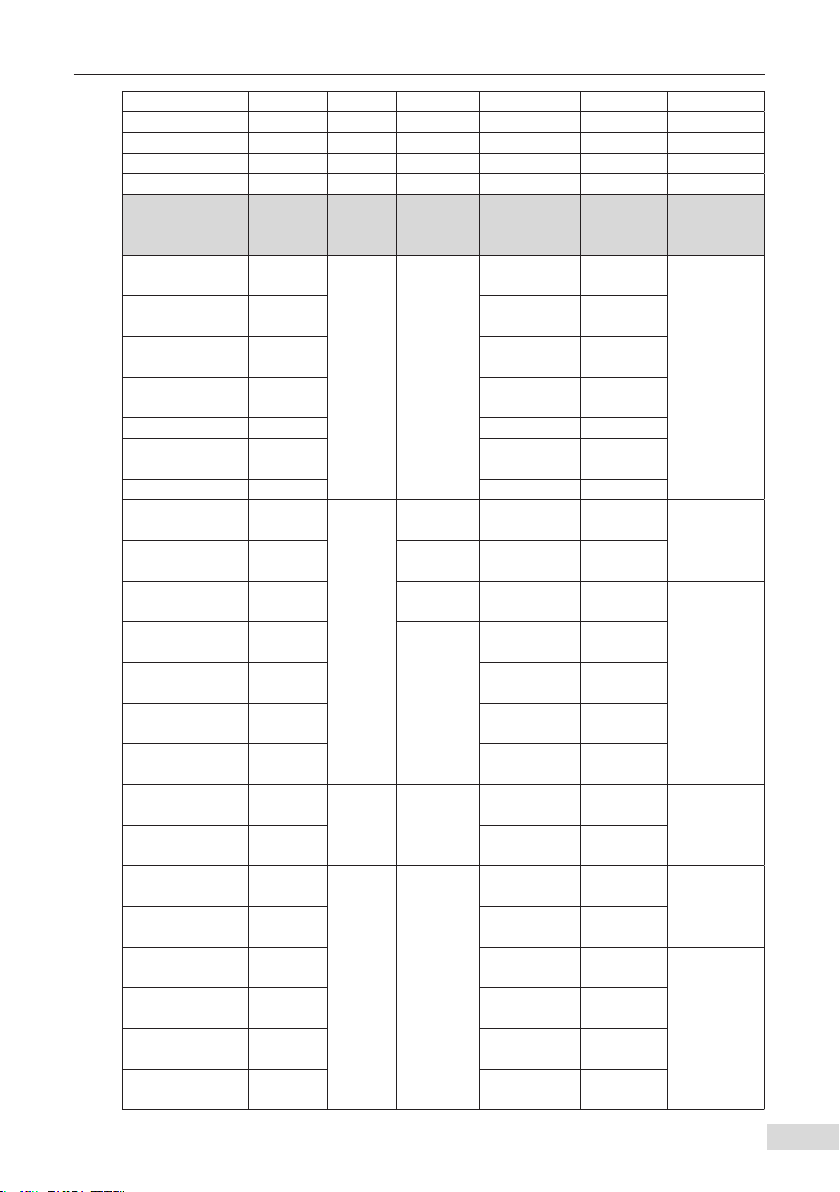

1.3.2 Ratings ................................................................................................................... 7

1.3.3 Overload Characteristics....................................................................................... 9

1.3.4 Radial/Axial Allowable Load ................................................................................ 10

1.3.5 Electrical Specications of Motor Brake ............................................................. 11

1.3.6 Torque/Speed Characteristics............................................................................. 12

1.3.7 Derating Characteristics ...................................................................................... 16

1.3.8 Temperature Curve of the Oil Sealing.................................................................. 17

1.4 Cables........................................................................................................................... 17

1.4.1 IS620/IS810........................................................................................................... 17

1.4.2 SV820N ................................................................................................................. 20

1.4.3 SV660P/N.............................................................................................................. 22

1.5 Connector Kit............................................................................................................... 24

2 Installation and Wiring.......................................................................................................... 25

2.1 Installation ................................................................................................................... 25

2.2 Wiring............................................................................................................................ 26

2.2.1 Wiring of Power Cables ........................................................................................ 26

2.2.2 Wiring of Absolute Encoder.................................................................................. 33

3 Mounting Dimension Diagrams............................................................................................ 41

3.1 Flange Frame Size: 40.................................................................................................. 41

3.2 Flange Frame Size: 60.................................................................................................. 42

3.3 Flange Frame Size: 80.................................................................................................. 44

3.4 Flange Frame Size: 100................................................................................................ 45

3.5 Flange Frame Size: 130................................................................................................ 46