Westerbeke L-25 User manual

Other Westerbeke Engine manuals

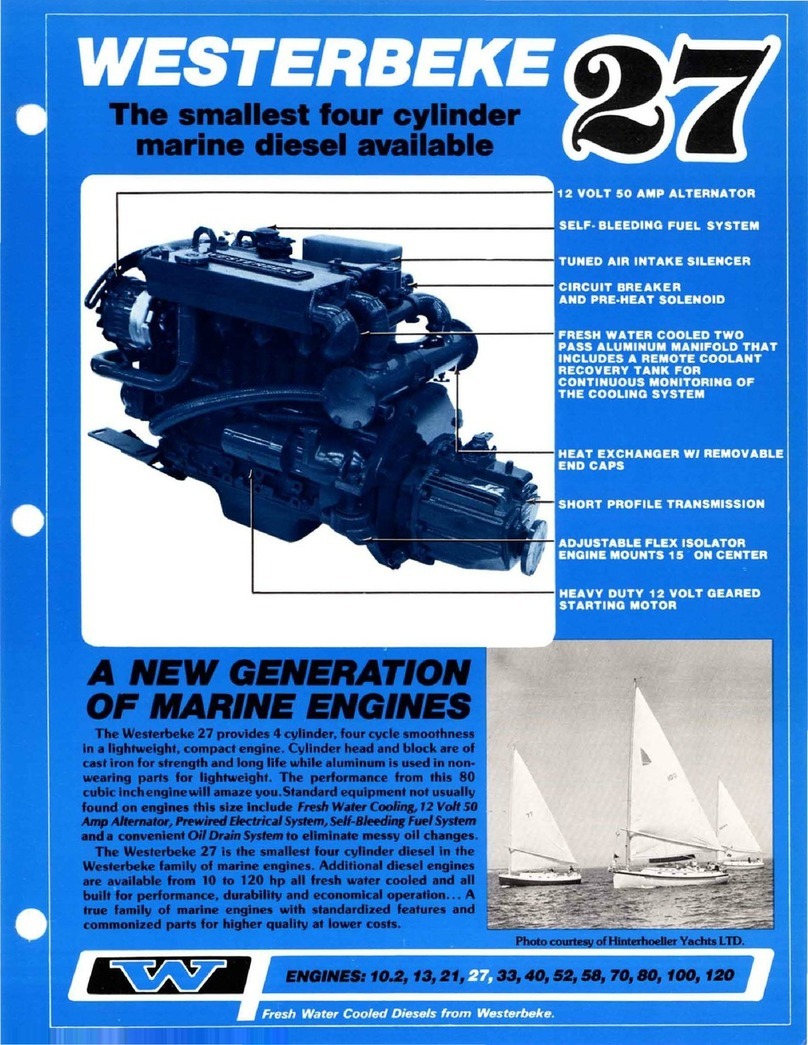

Westerbeke

Westerbeke WPDS-20 User manual

Westerbeke

Westerbeke Universal M-50 User manual

Westerbeke

Westerbeke FOUR-60 User manual

Westerbeke

Westerbeke 12C- TWO User manual

Westerbeke

Westerbeke W-13 Manual

Westerbeke

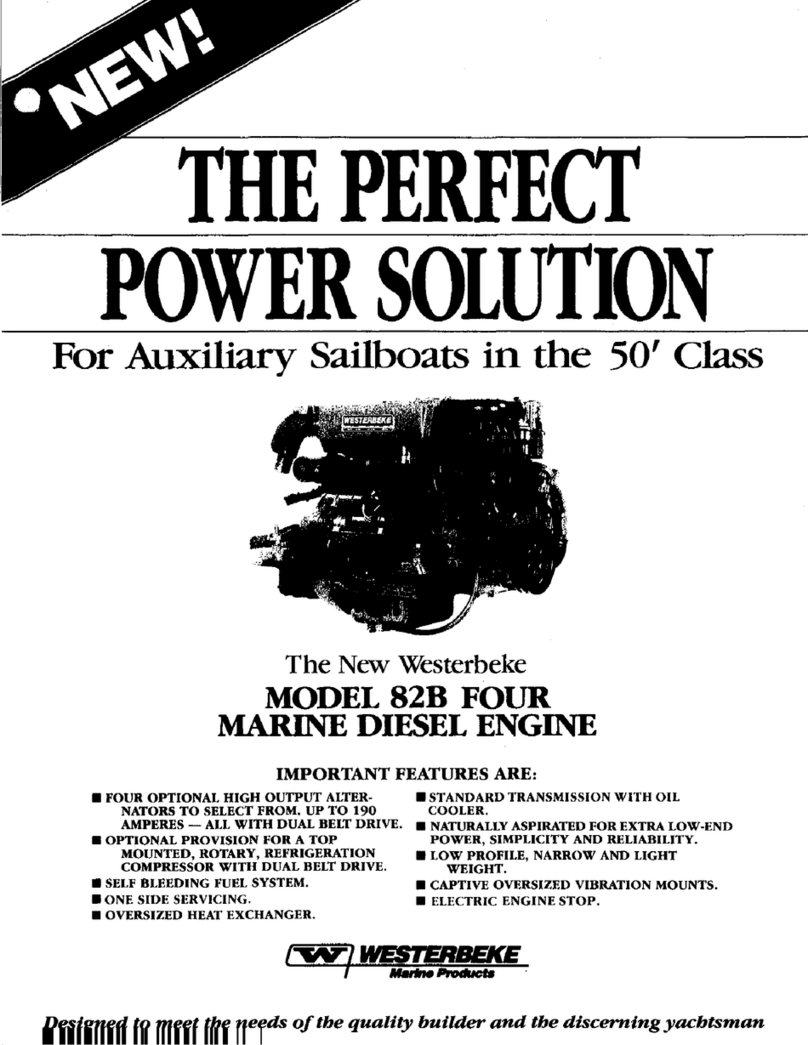

Westerbeke 82B FOUR User manual

Westerbeke

Westerbeke 12C- TWO User manual

Westerbeke

Westerbeke 63B FOUR User manual

Westerbeke

Westerbeke 14088 User manual

Westerbeke

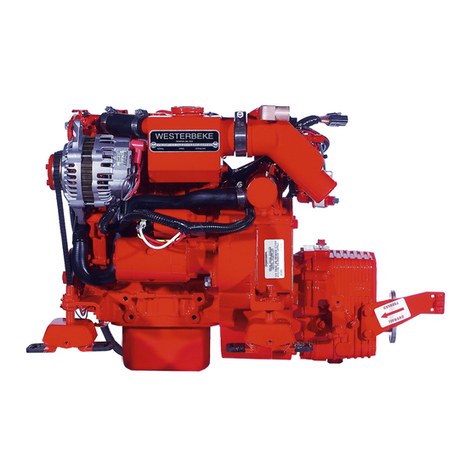

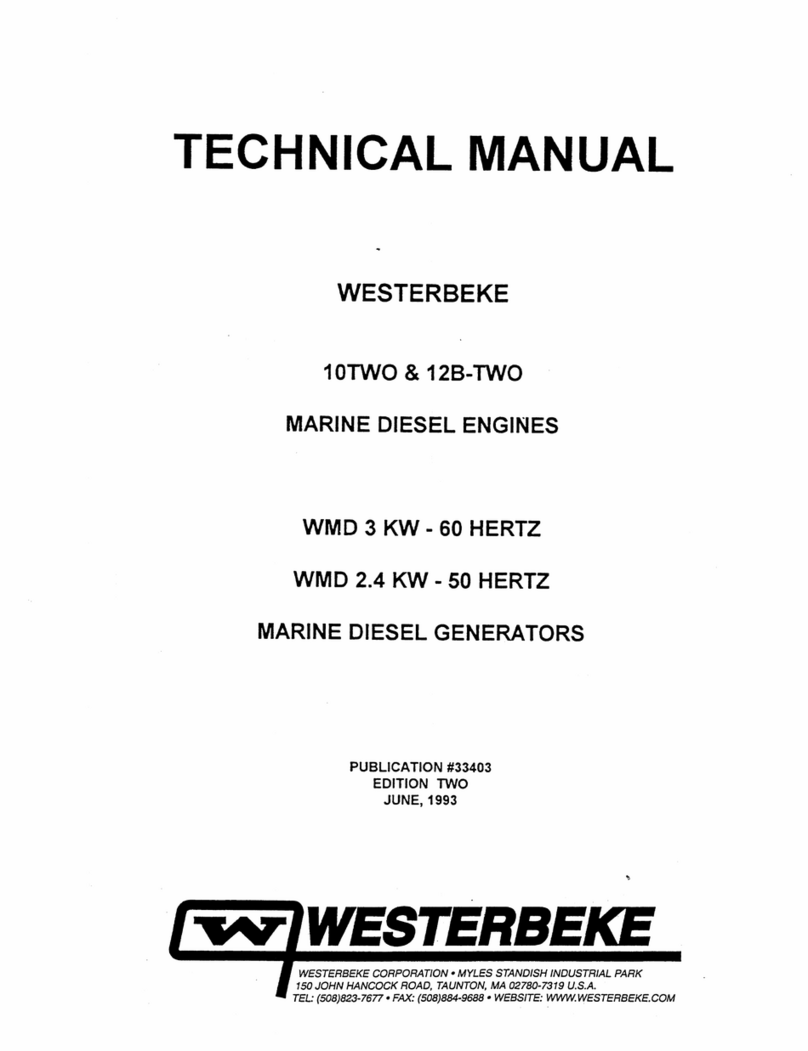

Westerbeke 10TWO User manual

Westerbeke

Westerbeke 44 A FOUR-35C THREE User manual

Westerbeke

Westerbeke 55B-FOUR User manual

Westerbeke

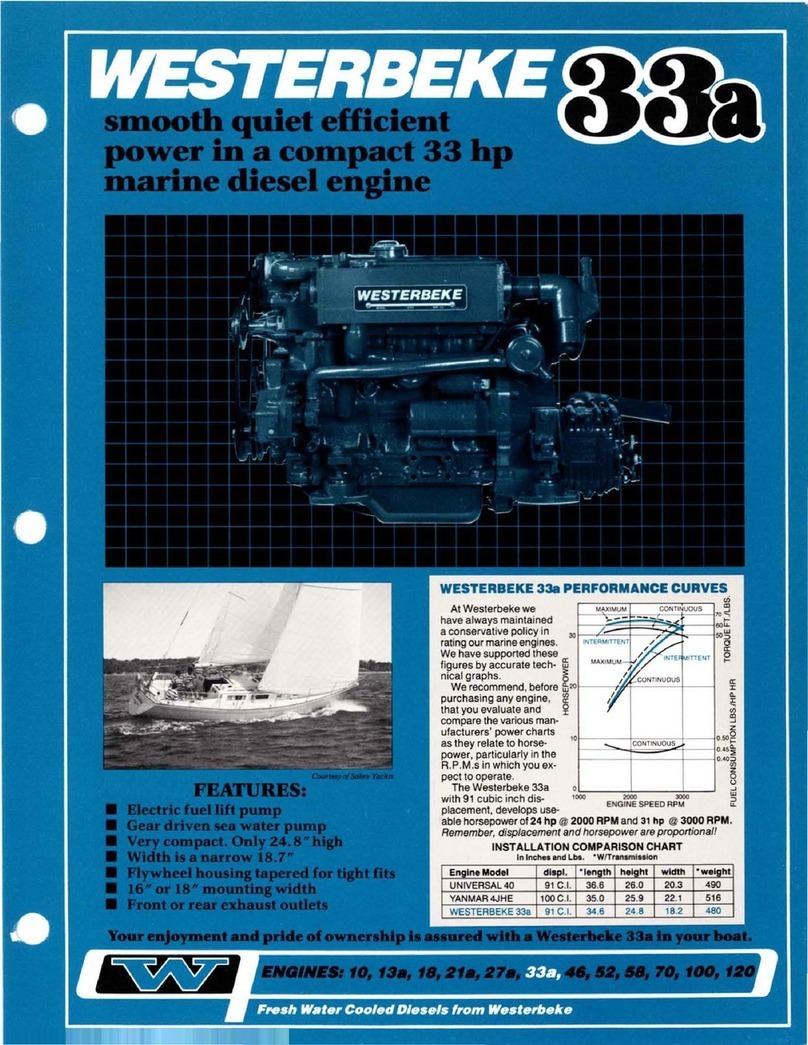

Westerbeke 33a User manual

Westerbeke

Westerbeke 44A FOUR - 35C THREE User manual

Westerbeke

Westerbeke 60 User manual

Westerbeke

Westerbeke 20B TWO User manual

Westerbeke

Westerbeke W-46 User manual

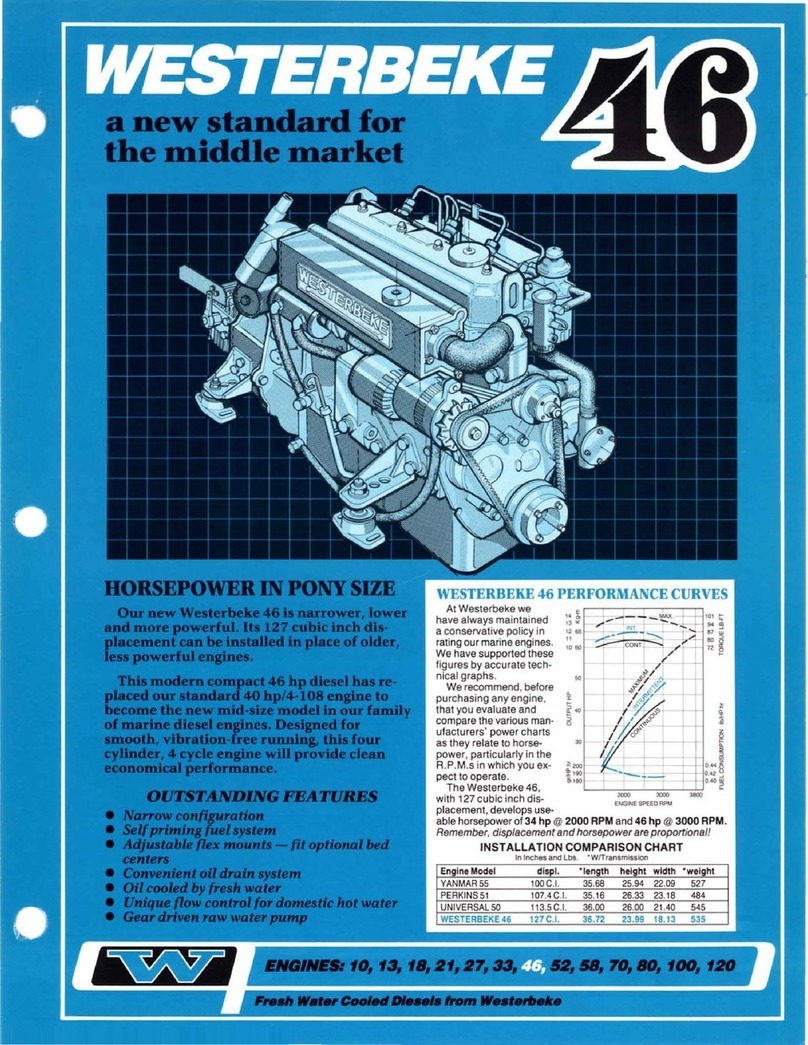

Westerbeke

Westerbeke W-13 User manual

Westerbeke

Westerbeke 10.0 KW-60Hz SBEG User manual

Westerbeke

Westerbeke 30B THREE User manual