Instron 2716 Series User manual

100 and 150kN Wedge Grips (Cat. nos. 2716 / 2736)

Operating Instructions M10-14402-EN Revision B

The difference is measurable

®

Electromagnetic Compatibility

Where applicable, this equipment is designed to comply with International Electromagnetic

Compatibility (EMC) standards.

To ensure reproduction of this EMC performance, connect this equipment to a low impedance

ground connection. Typical suitable connections are a ground spike or the steel frame of a

building.

Proprietary Rights Notice

This document and the information that it contains are the property of Illinois Tool Works Inc.

(ITW). Rights to duplicate or otherwise copy this document and rights to disclose the document

and the information that it contains to others and the right to use the information contained

therein may be acquired only by written permission signed by a duly authorized officer of ITW.

Trademarks

Instron®is a registered trademark of Illinois Tool Works Inc. (ITW). Other names, logos, icons

and marks identifying Instron products and services referenced herein are trademarks of ITW

and may not be used without the prior written permission of ITW.

Other product and company names listed are trademarks or trade names of their respective

companies.

Original Instructions

Copyright © 2006 Illinois Tool Works Inc. All rights reserved. All of the specifications shown

in this document are subject to change without notice.

Worldwide Headquarters

Instron

825 University Avenue

Norwood, MA 02062-2643

United States of America

European Headquarters

Instron

Coronation Road

High Wycombe, Bucks HP12 3SY

United Kingdom

Industrial Products Group

Instron

900 Liberty Street

Grove City, PA 16127

United States of America

3

Preliminary Pages

Product Support: www.instron.com

General Safety Precautions

Materials testing systems are potentially hazardous.

Materials testing involves inherent hazards from high forces, rapid motions, and

stored energy. You must be aware of all moving and operating components in

the testing system that are potentially hazardous, particularly force actuators or

a moving crosshead.

Carefully read all relevant manuals and observe all Warnings and Cautions. The

term Warning is used where a hazard may lead to injury or death. The term

Caution is used where a hazard may lead to damage to equipment or to loss of

data.

Instron products, to the best of its knowledge, comply with various national and

international safety standards, in as much as they apply to materials and

structural testing. We certify that our products comply with all relevant EU

directives (CE mark).

Because of the wide range of applications with which our instruments are used,

and over which we have no control, additional protection devices and operating

procedures may be necessary due to specific accident prevention regulations,

safety regulations, further EEA directives or locally valid regulations. The extent

of our delivery regarding protective devices is defined in your initial sales

quotation. We are thus free of liability in this respect.

At your request, we will gladly provide advice and quotations for additional

safety devices such as protective shielding, warning signs or methods of

restricting access to the equipment.

The following pages detail various general warnings that you must heed at all

times while using materials testing equipment. You will find more specific

Warnings and Cautions in the text whenever a potential hazard exists.

Your best safety precautions are to gain a thorough understanding of the

equipment by reading your instruction manuals and to always use good

judgement.

It is our strong recommendation that you should carry out your own product

safety risk assessment.

Preliminary Pages

4M10-14402-EN

Warnings

Hazard - Press the Emergency Stop button whenever you consider that an

unsafe condition exists.

The Emergency Stop button removes hydraulic power or electrical drive from the

testing system and brings the hazardous elements of the system to a stop as

quickly as possible. It does not isolate the system from electrical power, other

means are provided to disconnect the electrical supply. Whenever you consider

that safety may be compromised, stop the test using the Emergency Stop

button. Investigate and resolve the situation that caused the use of the

Emergency Stop button before you reset it.

Flying Debris Hazard - Make sure that test specimens are installed correctly

in grips or fixtures in order to eliminate stresses that can cause breakage of

grip jaws or fixture components.

Incorrect installation of test specimens creates stresses in grip jaws or fixture

components that can result in breakage of these components. The high

energies involved can cause the broken parts to be projected forcefully some

distance from the test area. Install specimens in the center of the grip jaws in

line with the load path. Insert specimens into the jaws by at least the amount

recommended in your grip documentation. This amount can vary between 66%

to 100% insertion depth; refer to supplied instructions for your specific grips.

Use any centering and alignment devices provided.

Hazard - Protect electrical cables from damage and inadvertent

disconnection.

The loss of controlling and feedback signals that can result from a disconnected

or damaged cable causes an open loop condition that may drive the actuator or

crosshead rapidly to its extremes of motion. Protect all electrical cables,

particularly transducer cables, from damage. Never route cables across the

floor without protection, nor suspend cables overhead under excessive strain.

Use padding to avoid chafing where cables are routed around corners or

through wall openings.

5

Preliminary Pages

Product Support: www.instron.com

High/Low Temperature Hazard - Wear protective clothing when handling

equipment at extremes of temperature.

Materials testing is often carried out at non-ambient temperatures using ovens,

furnaces or cryogenic chambers. Extreme temperature means an operating

temperature exceeding 60 °C (140 °F) or below 0 °C (32 °F). You must use

protective clothing, such as gloves, when handling equipment at these

temperatures. Display a warning notice concerning low or high temperature

operation whenever temperature control equipment is in use. You should note

that the hazard from extreme temperature can extend beyond the immediate

area of the test.

Crush Hazard - Take care when installing or removing a specimen,

assembly, structure, or load string component.

Installation or removal of a specimen, assembly, structure, or load string

component involves working inside the hazard area between the grips or

fixtures. When working in this area, ensure that other personnel cannot operate

any of the system controls. Keep clear of the jaws of a grip or fixture at all times.

Keep clear of the hazard area between the grips or fixtures during actuator or

crosshead movement. Ensure that all actuator or crosshead movements

necessary for installation or removal are slow and, where possible, at a low

force setting.

Hazard - Do not place a testing system off-line from computer control

without first ensuring that no actuator or crosshead movement will occur

upon transfer to manual control.

The actuator or crosshead will immediately respond to manual control settings

when the system is placed off-line from computer control. Before transferring to

manual control, make sure that the control settings are such that unexpected

actuator or crosshead movement cannot occur.

Robotic Motion Hazard - Keep clear of the operating envelope of a robotic

device unless the device is de-activated.

The robot in an automated testing system presents a hazard because its

movements are hard to predict. The robot can go instantly from a waiting state

to high speed operation in several axes of motion. During system operation,

keep away from the operating envelope of the robot. De-activate the robot

before entering the envelope for any purpose, such as reloading the specimen

magazine.

Warnings

Preliminary Pages

6M10-14402-EN

Hazard - Set the appropriate limits before performing loop tuning or running

waveforms or tests.

Operational limits are included within your testing system to suspend motion or

shut off the system when upper and/or lower bounds of actuator or crosshead

travel, or force or strain, are reached during testing. Correct setting of

operational limits by the operator, prior to testing, will reduce the risk of damage

to test article and system and associated hazard to the operator.

Electrical Hazard - Disconnect the electrical power supply before removing

the covers to electrical equipment.

Disconnect equipment from the electrical power supply before removing any

electrical safety covers or replacing fuses. Do not reconnect the power source

while the covers are removed. Refit covers as soon as possible.

Rotating Machinery Hazard - Disconnect power supplies before removing

the covers to rotating machinery.

Disconnect equipment from all power supplies before removing any cover which

gives access to rotating machinery. Do not reconnect any power supply while

the covers are removed unless you are specifically instructed to do so in the

manual. If the equipment needs to be operated to perform maintenance tasks

with the covers removed, ensure that all loose clothing, long hair, etc. is tied

back. Refit covers as soon as possible.

Hazard - Shut down the hydraulic power supply and discharge hydraulic

pressure before disconnection of any hydraulic fluid coupling.

Do not disconnect any hydraulic coupling without first shutting down the

hydraulic power supply and discharging stored pressure to zero. Tie down or

otherwise secure all pressurized hoses to prevent movement during system

operation and to prevent the hose from whipping about in the event of a

rupture.

Hazard - Shut off the supply of compressed gas and discharge residual gas

pressure before you disconnect any compressed gas coupling.

Do not release gas connections without first disconnecting the gas supply and

discharging any residual pressure to zero.

Warnings

7

Preliminary Pages

Product Support: www.instron.com

Explosion Hazard - Wear eye protection and use protective shields or

screens whenever any possibility exists of a hazard from the failure of a

specimen, assembly or structure under test.

Wear eye protection and use protective shields or screens whenever a risk of

injury to operators and observers exists from the failure of a test specimen,

assembly or structure, particularly where explosive disintegration may occur.

Due to the wide range of specimen materials, assemblies or structures that may

be tested, any hazard resulting from the failure of a test specimen, assembly or

structure is entirely the responsibility of the owner and the user of the

equipment.

Hazard - Ensure components of the load string are correctly pre-loaded to

minimize the risk of fatigue failure.

Dynamic systems, especially where load reversals through zero are occurring,

are at risk of fatigue cracks developing if components of the load string are not

correctly pre-loaded to one another. Apply the specified torque to all load string

fasteners and the correct setting to wedge washers or spiral washers. Visually

inspect highly stressed components such as grips and threaded adapters prior

to every fatigue test for signs of wear or fatigue damage.

Warnings

Preliminary Pages

8M10-14402-EN

9

Preliminary Pages

Product Support: www.instron.com

Table of Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Functional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2: Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Grip Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Series 2716 Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Series 2736 Grips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Jaw faces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 3: Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Attachment Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installing the Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Replacing Jaw faces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 4: Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installing a Specimen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Removing a Specimen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 5: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning and Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Preliminary Pages

10 M10-14402-EN

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Shear Pin Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 6: Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Ancillary Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

11

Product Support: www.instron.com

Chapter 1

Introduction

This chapter introduces you to the low capacity (24.5 kN to 147 kN [5000 lb to 30000

lb]) Series 2716 and 2736 wedge action grips and describes the grip components.

Illustrations and text detail the grip components and their function.

•Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

•Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Purpose

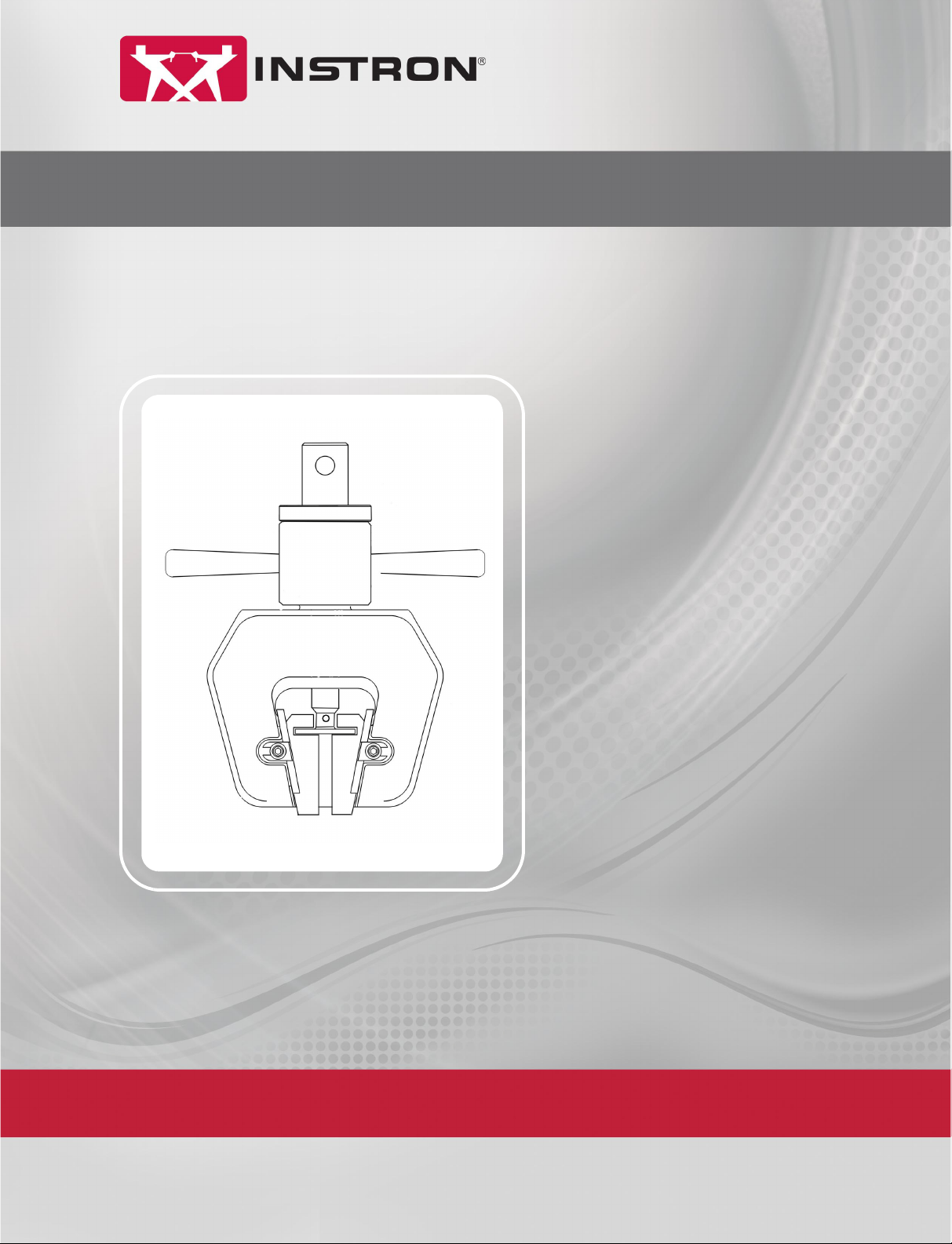

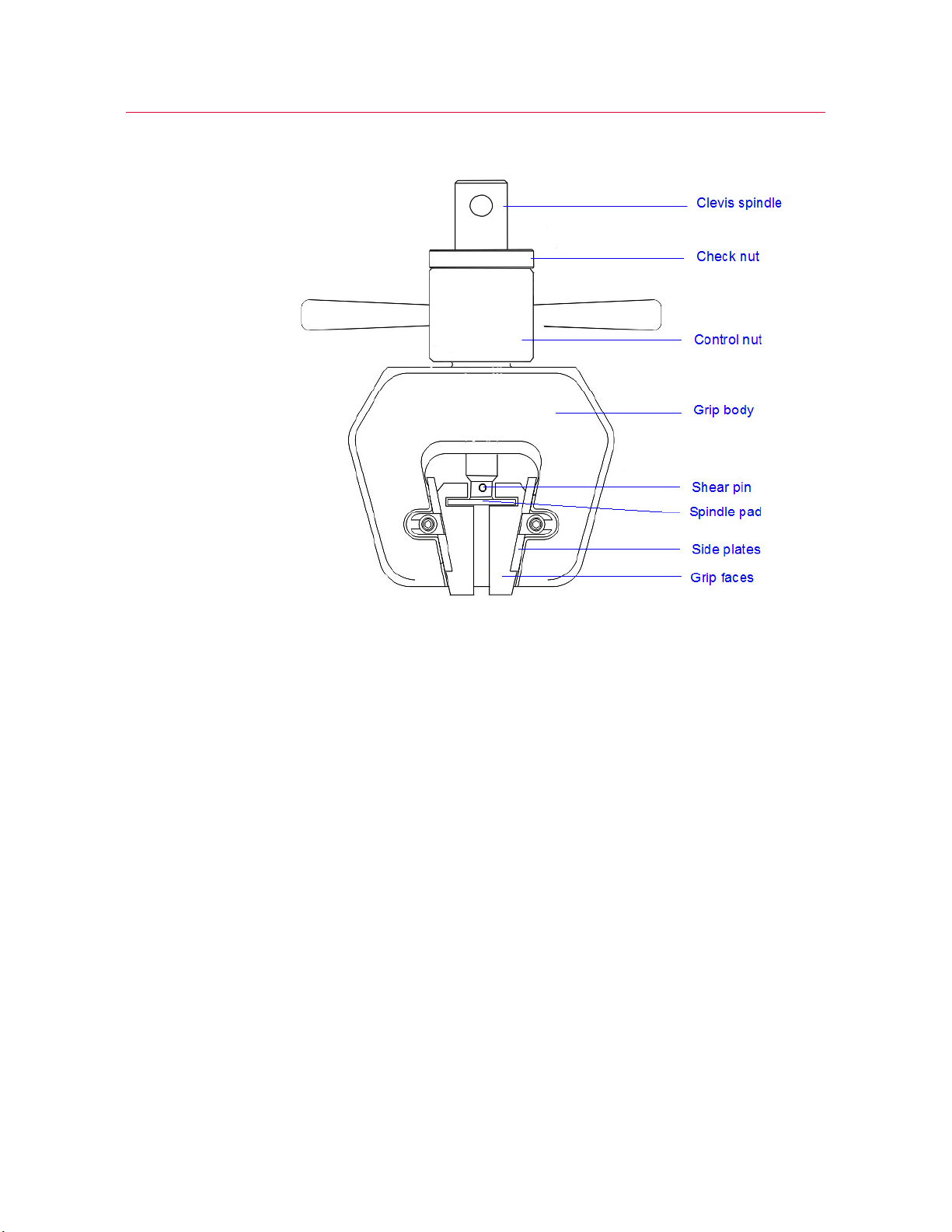

Instron Series 2716 and 2736 wedge action grips hold a test specimen between a

stationary load frame member and a force producing crosshead or actuator. Figure 1

and Figure 2 illustrates the grips and their components.

Chapter: Introduction

12 M10-14402-EN

Figure 1. Typical Wedge Grip (Front)

13

Purpose

Product Support: www.instron.com

Figure 2. Typical Wedge Grip (Rear)

The grips cover a wide range of common applications in materials testing. The two series

are similar, with the principal difference being that the series 2736 grips are rated for

high temperature use and configured with handles that facilitate their use in high-

temperature cabinets.

The grips are for static tensile testing only. The wedge action design lets the jaw faces

tighten onto a specimen without altering the vertical position of the faces in relation to

the specimen, letting you install a test specimen without exerting a tensile load on it

while tightening the grips. A compressive test load eliminates any gripping force and

causes the specimen to slip from the grips.

The open front design of the grip lets you change the jaw faces to accommodate flat,

round or different size specimens.

Chapter: Introduction

14 M10-14402-EN

Description

Components

The major grip components are the body, control mechanism, and jaw faces.

Body

The machined alloy-steel body has a vertical center bore with an integral threaded stud

extending away from the body. A control nut threads on the stud and a spindle passes

through the bore.

The grip body has a machined open cavity. Each side of the cavity tapers toward the

open end of the body. The jaw faces have a matching taper such that as the faces slide

toward the open end of the cavity, they are forced together and thus provide a gripping

force on a specimen.

Side plates, screwed to the front of the grip body, retain the jaw faces within the cavity.

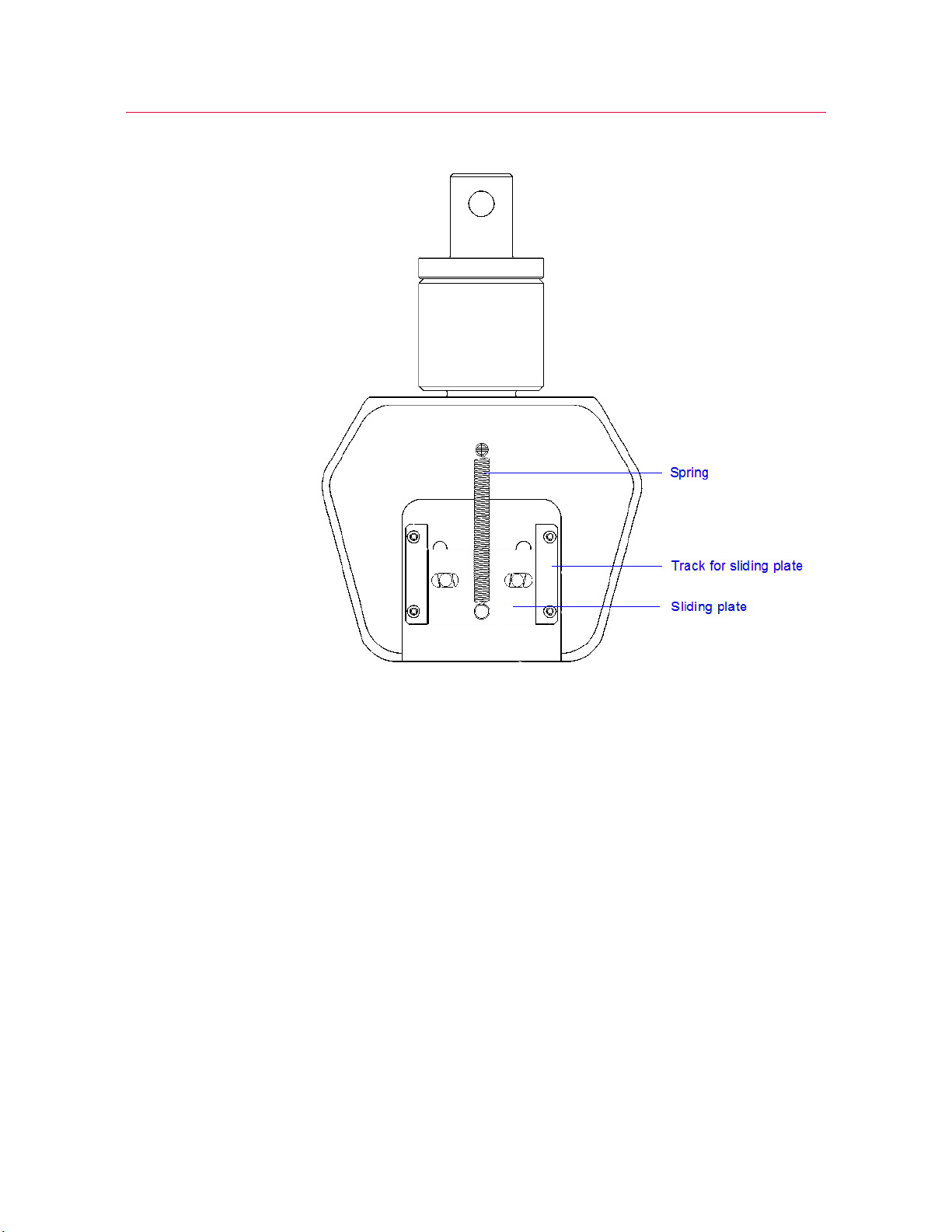

On the rear of the body, a spring-loaded plate slides in tracks screwed to the body. Pins

in the grip jaws extend through slots in the plate. The spring force on the plate, and

transmitted to the jaw pins, pushes the grip jaws against the tapered sides of the cavity

and also provides a constant retraction force on the grip jaws.

Control Mechanism

The control mechanism consists of a control nut and spindle. The control nut is a short

steel cylinder with a center bore and internal threads. The nut threads onto the body

threads. Handles on the control nut let you easily tighten and loosen the grips.

The spindle is a steel shaft with a one end either threaded or machined to accept a

clevis pin, The other end is machined for a shear pin which secures a flat spindle pad.

The threaded end passes through the control nut. The spindle pad slots into the base of

the jaw faces. Rotation of the control nut moves the grip body while the jaw faces are

held stationary. As the grip body moves, the tapers in the cavity move the grip jaws

laterally to grip or release the specimen without exerting a longitudinal (tensile or

compressive) force on the specimen.

Faces

Various jaw faces are interchangeable in each grip model size, to accommodate a range

of flat or round specimen sizes. There are four jaw faces in each set; a left and right face

for each upper and lower grip.

15

Description

Product Support: www.instron.com

The faces are made of hardened steel and are serrated for maximum gripping

effectiveness. Serrations are either 16 or 25 teeth per inch (tpi). The 16 tpi faces are

preferable for use with most metals since they provide greater penetration into the

specimen and longer wear. The 25 tpi faces are ideal for small diameter, thin, very hard,

or penetration sensitive specimens.

Functional

Closed

When you turn the handles to close the grip on a specimen, the screw action of the

control nut and body threads move the body away from the test specimen and push the

spindle end against the jaw faces. The position of the faces remain vertically fixed,

relative to the specimen, because the body is moving away from the specimen. The anti-

rotation pins prevent the grip from rotating as you tighten the control nut. The angle of

the jaw faces and the body wedges force the faces inward on the specimen until the

face serration bite into the specimen. The gripping force increases during a test as the

system applies more tensile force to the specimen.

Open

When you turn the control handles to open the grip, the screw action of the control nut

moves the body toward the test specimen. The slide plate, under tension from the

spring, applies a force to the grip jaw pins to move the grip jaws away from the

specimen.

Chapter: Introduction

16 M10-14402-EN

17

Product Support: www.instron.com

Chapter 2

Specifications

This chapter details the grip specifications and includes a dimensional drawing of the

grips.

•Grip Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

•Jaw faces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Grip Specifications

Series 2716 Grips

Table 1 on page 17 details the specifications for the 2716 series of grips.

Table 1. 2716 Series Specifications

Cat. No.

Load

Capacity/

kN (lb)

Temperature

Range/C (F)

Face

Width/mm

(in.) Mount1Weight2

/kg (lb)

Overall

Width3/

mm (in.)

Overall

Length3/

mm (in.)

2716-

002

100

(22,500)

-73 to 250

(-100 to 480)

25.4 (1.0) Type DM40.0

(88.2)

144

(5.67)

254

(10.0)

2716-

003

100

(22,500)

-73 to 250

(-100 to 480)

50.8 (2.0) Type DM60.0

(132.3)

168

(6.63)

254

(10.0)

2716-

008

150

(33,700)

-73 to 250

(-100 to 480)

50.8 (2.0) M48 x 2

Male

Thread

60.0

(132.3)

178 (7.0) 340

(13.5)

1. Refer to Chapter 3- Installation for attachment interface information.

2. Weights shown are total approximate shipping weight per grip pair (less faces)

3. Dimensions shown are approximate overall width and length per grip (less control nut handles and jaw

faces).

Chapter: Specifications

18 M10-14402-EN

Series 2736 Grips

Table 2 on page 18 details the specifications for the 2736 series of grips.

Jaw faces

Jaw faces are available for testing flat or round specimens. Use flat faces for flat

specimens and vee or round groove faces for round specimens. This section details the

various jaw faces available.

Caution

Do not use serrated jaw faces to test specimens with a hardness value greater than

40 Rockwell C.

When testing extremely hard specimens, the jaw face serrations may not adequately

penetrate the specimen surface. Further, hard specimens will cause accelerated wear

of the serrations.

Table 3 on page 19 lists the available jaw faces:

Table 2. 2736 Series Specifications

Cat. No.

Load

Capacity/

kN (lb)

Temperature

Range/C (F)

Face

Width/mm

(in.) Mount1Weight2/

kg (lb)

Overall

Width3/

mm (in.)

Overall

Length3/

mm (in.)

2736-

004

100

(22,500)

-73 to 315

(-100 to 600)

25.4 (1.0) Type DM40.0

(88.2)

144

(5.67)

254

(10.0)

2736-

005

100

(22,500)

-73 to 315

(-100 to 600)

50.8 (2.0) Type DM60.0

(132.3)

168

(6.63)

254

(10.0)

1. Refer to Chapter 3- Installation for attachment interface information.

2. Weights shown are total approximate shipping weight per grip pair (less faces)

3. Dimensions shown are approximate overall width and length per grip (less control nut handles and jaw

faces).

19

Jaw faces

Product Support: www.instron.com

Table 3. Jaw face compatibility

Cat. No. Face Type

Serrations per

in. Specimen Size/mm (in.) Use with grips

2703-001 Flat 16 0 to 6.4 (0 to 1/4) 2716-002 or 2736-004

2703-002 Flat 16 6.3 to 12.7 (1/4 to 1/2) 2716-002 or 2736-004

2703-006 Flat 25 0 to 6.4 (0 to 1/4) 2716-002 or 2736-004

2703-007 Flat 25 6.4 to 12.7 (1/4 to 1/2) 2716-002 or 2736-004

2703-004 Vee 16 7 to 12.7 (9/32 to 1/2) 2716-002 or 2736-004

2703-008 Vee 25 3.5 to 8 (1/8 to 5/16) 2716-002 or 2736-004

2703-009 Vee 25 7 to 12.7 (9/32 to 1/2) 2716-002 or 2736-004

2703-010 Vee 25 12.7 to 19 (1/2 to 3/4) 2716-002 or 2736-004

2703-070 Round 16 12.7 to 15.8 (1/2 to 5/8) 2716-002 or 2736-004

2703-071 Round 16 15.8 to 19 (5.8 to 3/4) 2716-002 or 2736-004

2703-011 Flat 16 0 to 6.4 (0 to 1/4) 2716-003, 2716-008, or

2736-005

2703-012 Flat 16 6.4 to 12.7 (1/4 to 1/2) 2716-003, 2716-008, or

2736-005

2703-013 Vee 25 3.5 to 8 (1/8 to 5/16) 2716-003, 2716-008, or

2736-005

2703-014 Vee 25 7 to 12.7 (9/32 to 1/2) 2716-003, 2716-008, or

2736-005

2703-015 Vee 25 12.7 to 19 (1/2 to 3/4) 2716-003, 2716-008, or

2736-005

2703-072 Round 16 12.7 to 15.8 (1/2 to 5/8) 2716-003, 2716-008, or

2736-005

2703-073 Round 16 15.8 to 19 (5.8 to 3/4) 2716-003, 2716-008, or

2736-005

Chapter: Specifications

20 M10-14402-EN

This manual suits for next models

6

Table of contents

Other Instron Power Tools manuals

Popular Power Tools manuals by other brands

GRAVEDA

GRAVEDA GRASPRESSO GP4-20 instruction manual

Dynabrade

Dynabrade Dynisher 50730 Important operating, maintenance and safety instructions

SW Stahl PROFI Tools

SW Stahl PROFI Tools 26131L instruction manual

Hi-Force

Hi-Force HTW Series Operating instructions manual

Desoutter

Desoutter PT025-L4500-S10S user manual

AFSA

AFSA 1258 manual

Chicago Electric

Chicago Electric 40039 Assembly and operating instructions

Delta Regis

Delta Regis ESB6-RA30 Operation manual

Yokota

Yokota TKA800-C manual

Warn

Warn VANTAGE 4000 Service instructions manual

Narex

Narex ASR 600-3MTB BASIC Original operating manual

Würth

Würth 1952 003 133 Translation of the original operating instructions