InterDiamant ID701 User manual

2

SUMMARY

GUARANTEE ....................................................................................................................................................... 3

DESCRIPTION ..................................................................................................................................................... 3

GENERAL NOTICE ............................................................................................................................................... 3

NOTICE FOR USE ................................................................................................................................................ 4

ASSEMBLY AND PREPARATION FOR USE ........................................................................................................... 4

STARTING AND UTILIZATION ............................................................................................................................. 4

MAINTENANCE .................................................................................................................................................. 5

DIAMOND DISC REPLACEMENT ......................................................................................................................... 5

TECHNICAL FEATURES ....................................................................................................................................... 5

MARKS AND CERTIFICATIONS ............................................................................................................................ 6

ELECTRICAL SCHEME MONOPHASE 220 V- 50 HZ ............................................................................................. 7

SPARE PARTS LIST .............................................................................................................................................. 8

3

(GB) OPERATING INSTRUCTIONS

Carefully read the instructions contained in this manual; they give important explanations concerning the safety

and the correct use of the machine. Always keep this manual for any further consultations.

GUARANTEE

The machine described in this manual is covered by a 12-month warranty from the date of delivery (the date of

receipt of the goods declared on the documents accompanying the machine during transport is considered); The

warranty is limited to those parts which, at the incontestable discretion of the manufacturer, have defects and / or

defects in construction and the operations necessary to prevent improper or improper operation of the machine

whose causes are traceable to an original defect of the same.

Components electrical equipment and parts subject to normal wear and tear due to use (e.g. blade, inserts, etc.) are

not covered by the warranty. Parts damaged in transit, for improper and / or incorrect use, and / or not in accordance

with these instructions, installation or maintenance by the purchaser, negligently, due to failure to carry out tests and

checks Mentioned in this manual by the inability to use it due to use not in accordance with the intended use and

explicitly declared by the manufacturing company are not covered by the warranty.

The warranty is valid only in respect of the original purchaser and does not in any way replace the machine. The

guarantee is void if the same has undergone alterations, modifications, and / or repairs by persons not expressly

authorized by the manufacturing company. The manufacturer shall not be liable for any direct or indirect damage

caused to persons, things or animals resulting from machine failure which is not attributable to birth defects or forced

suspension of use of the latter.

At the expiration of the guarantee period, each intervention requested will be carried out by charging the client with

the cost of the work, travel, food, accommodation, cost of replaced parts and possible transportation. In the event

that this is a significant intervention, the manufacturing company will provide the applicant in advance with the

approximate total cost that, unless there are unforeseen circumstances, should result.

Any dispute shall be judged by the competent judicial authority of the court of Piacenza.

The contents of this manual can be modified with no advanced notice, in order to add any technical improvement. It

is forbidden to reproduce it without our prior authorization

DESCRIPTION

Electrical sawing machine, ideal for cutting the building material: bricks, marbles, granites, coating tiles, concrete

products, excluding metal alloys and wood . It uses a diamond saw blade for wet cutting , suitable for the above

mentioned materials.

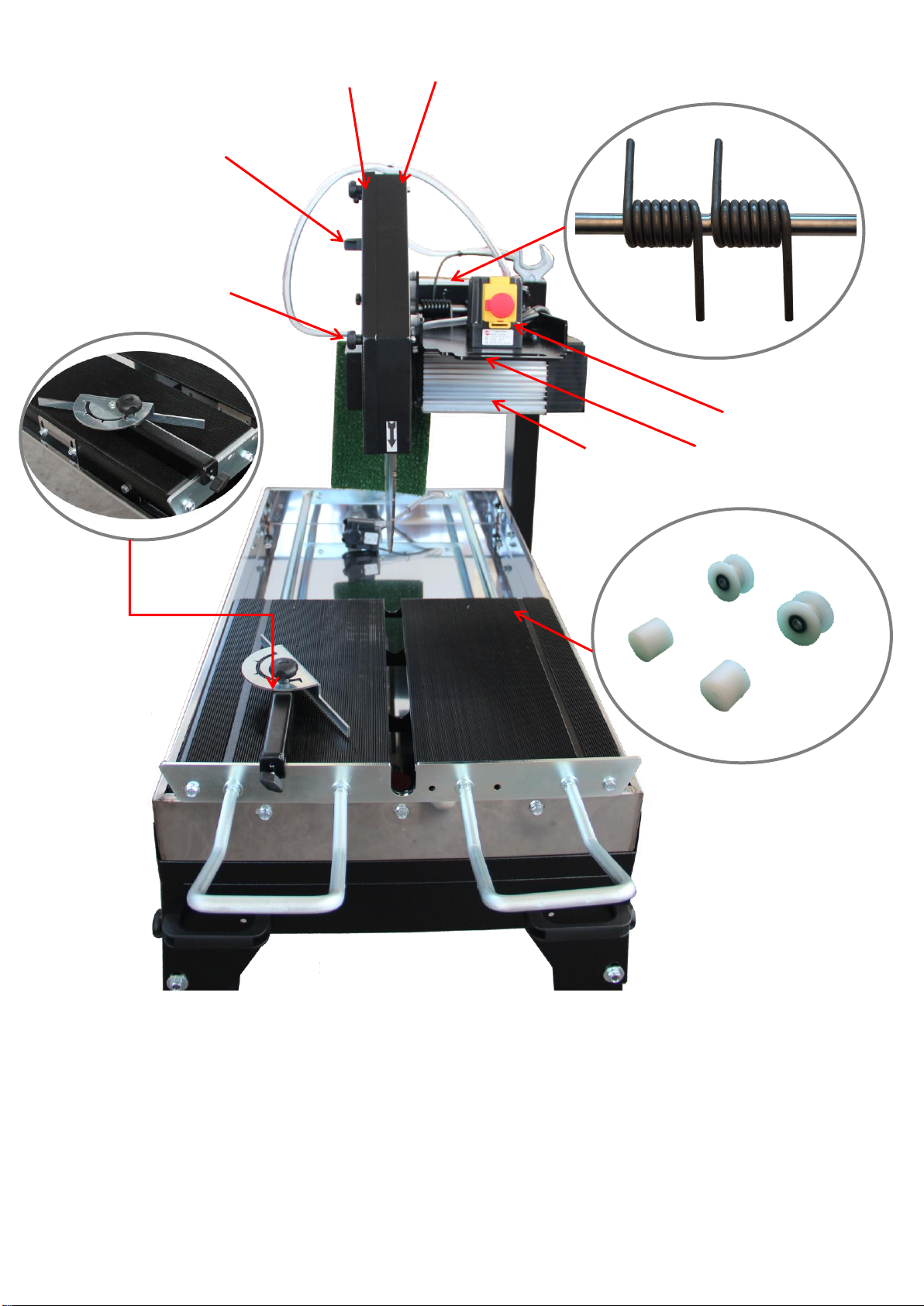

The saw machine is equipped with:

- Head motor, adjustable height for all the series

- Sliding trolley on nylon wheels equipped with sealing bearings

- Adjustable electro-galvanized slide guides

- Adjustable square for diagonal cut

- Blade covering protection (aluminium/painted iron) and painted iron/stainless steel basin to contain the

water

- Water re-circulation pump , with filter

- Motor equipped with thermical protection

- Minimum tension switch

GENERAL NOTICE

-The feeding of the machine shall be done according to the manufacturer's instructions. We decline any

responsibility for any connection carried out differently form the indications given by the manufacturer.

-The electrical equipment of the machine assures protection to the operator from electric shocks deriving from

direct contacts

-In order to protect the operator from electric shocks deriving from indirect contacts, the connection to the

source of power shall be provided with all necessary protections, according to the regulations actually in force

concerning the matter.

4

-Before connecting the machine, verify that the data concerning tension and frequency indicated on the label of

the machine correspond to those of the supply mains

-Be sure that all possible adapter and patch cords used for the connection of the machine are in conformity

with the safety regulations in force.

-Disconnect the feeding outlet before starting any maintenance, cleaning, water filling or replacement

operation.

-Keep the machine in a safe and dry place, out of children's reach.

-Do not manipulate the machine. In case of breakdown and/or bad functioning, address to a qualified and

authorised technical assistance or customer service.

-It is absolutely forbidden to use tools, which are not in conformity with those indicated or are suitable for

other materials (for ex. discs with widia teeth for wood, aluminium, etc.)

-The machine shall be destined only to the purpose it was built for. Any other use is to be considered

illegitimate and dangerous.

-Disconnect the feeding plug when the machine is not functioning.

NOTICE FOR USE

-We recommend that qualified personnel only shall use the machine, in places out of children's reach and away

from third persons, in order to avoid any possible and unintentional contact.

-Wear suitable clothes: do not wear large and unfastened clothes that could be drawn by the blade.

-Protect long hair by the suitable net

-Wear individual protection devices, such as ear-casings, gloves, eyeglasses, etc.

-Operate in dry places, protected from precipitations.

-Avoid any unsafe or unstable position.

-Not suitable materials cause irreparable damage to the tool

-If the diamond disc is cracked, damaged or worn, immediately replace it.

ASSEMBLY AND PREPARATION FOR USE

-Remove the machine from the packing.

-Rotate the legs in vertical position and fix them to the relevant leg holder using knobs

-Position the machine considering that the bearing surface shall be stable and perfectly plane

-Mount the diamond disc as indicated in the chapter: "Diamond disc replacement"

-Release the head by unscrewing lightly the nut or handle

-In order to get a diagonal cutting, apply the square to the trolley rule

-Fill the stainless steel water tank with water in such a way that the re-circulation pump is completely dipped.

STARTING AND UTILIZATION

Warning! before utilizing the machine you shall always:

-be sure that the nut fixing the disc between the flanges is well-tightened in order to assure a disk locking

-carry out the filling of the water basin in order to avoid irreparable damages to the pump which starts when a

machine starting occurs

-wear protections, ear-casings, gloves, eyeglasses, etc.

After preparing the machine to a normal running, you can proceed as follows:

-connect the machine to the supply mains

-mark off the material be cut

-position the piece towards the trolley head bar

-start the machine pressing the green starting push-button

-be sure that the disc rotates and the water wets the disc

-hold fast the material to be cut by a hand, by the other hand you shall bring the motor head towards the

piece to be cut (here, motor revolutions shall not have an important slowing down)

Warning! Hands shall not be positioned on the trajectory of the disc

5

While utilizing, the re-circulation pump shall always be dipped, if it is not the case, you shall add water into the basin.

In case of temporary power outage, the switch automatically disconnects contacts, in order to avoid a dangerous

starting on a power return. To re-start the machine, you shall press the green starting push-button.

At the end of the work, you shall press the red stop switch and disconnect the power supply.

Warning: do not loosen the bolts, so that a machine adjustment cannot be jeopardized.

MAINTENANCE

In order to keep the machine in perfect efficiency we suggest to carry out the following operations , after use:

-disconnect the power supply plug

-take away the cap from the basin in order to let the dirty water go out , carefully rinse to eliminate the

residuals.

-fill the basin with clean water and after connecting start the machine for at least one minute inn order to

clean up the pump. Then empty the basin again.

Periodically:

-remove the residuals accumulated in the blade-cover protection.

-Remove the residuals and clean the machine to prevent rust.

DIAMOND DISC REPLACEMENT

1) Disconnect the power supply plug.

2) Unscrew the fixing wing-nuts of the blade-cover protection

3) Unscrew the flange locking nut inserting a pin, in contrast, on the motor shaft

Attention: left threading.

4) Extract the saw blade and replace it considering that the rotation direction of the tools corresponds to the one

indicated on the blade covering protection

5) Assemble the flange again , lock the nut and mount the blade covering protection.

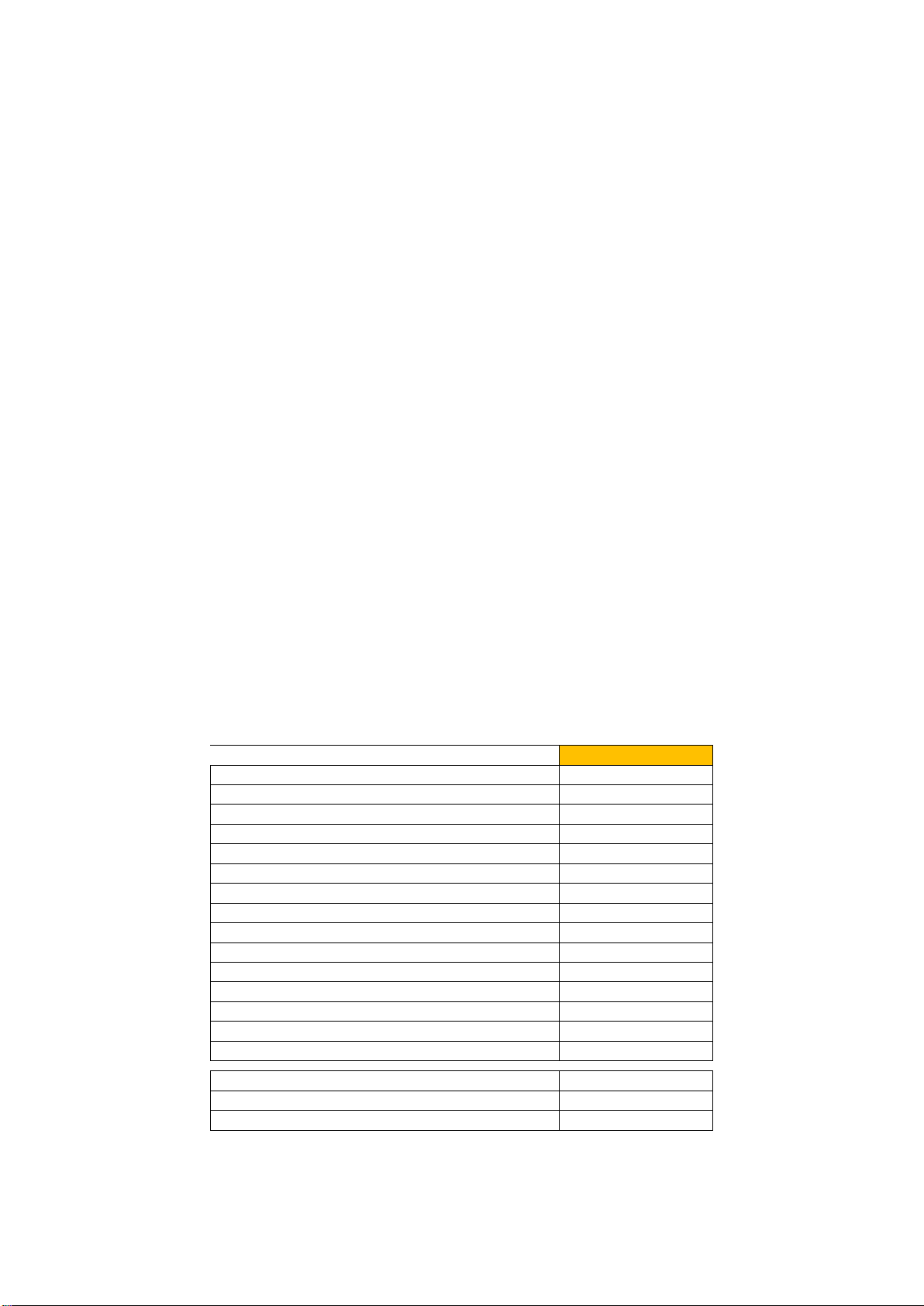

TECHNICAL FEATURES

ID701

BLADE DIAMETER (mm)

700

BLADE HOLE (mm)

30,0

CUTTING HEIGHT (mm)

260

MAX. CUTTING LENGHT (mm)

500

ELECTRIC PUMP PROTECTION

IP54

POWER ( WATT-P1 )

P1 3,0 kW

TENSION AND FREQUENCY ( V-Hz )

230 V/380V-50 Hz

RPM

1400

INSULATION CLASS

F

PROTECTION

IP68

CAPACITOR

45 µF

WORKTOP DIMENSIONS (mm)

500X450

MACHINE DIMENSIONS (mm)

600x1200x1400

WEIGHT (Kg )

70

MIN. TENSION SWITCH

YES

Acoustic pression level in the atmosphere

db (a) 89,8

Acustic power level

db (a) 105,1

Acustic pressure level at the driving place

db (a) 95,6

db (A) = 89.8

db (A) = 105.1

db (A) = 5.6

6

MARKS AND CERTIFICATIONS

The following model has submitted to the CE examination, according to EEC 2006/42.

The above mentioned certification is stated on the plate with CE mark on the machine and described on the

declaration which accompanies this manual.

7

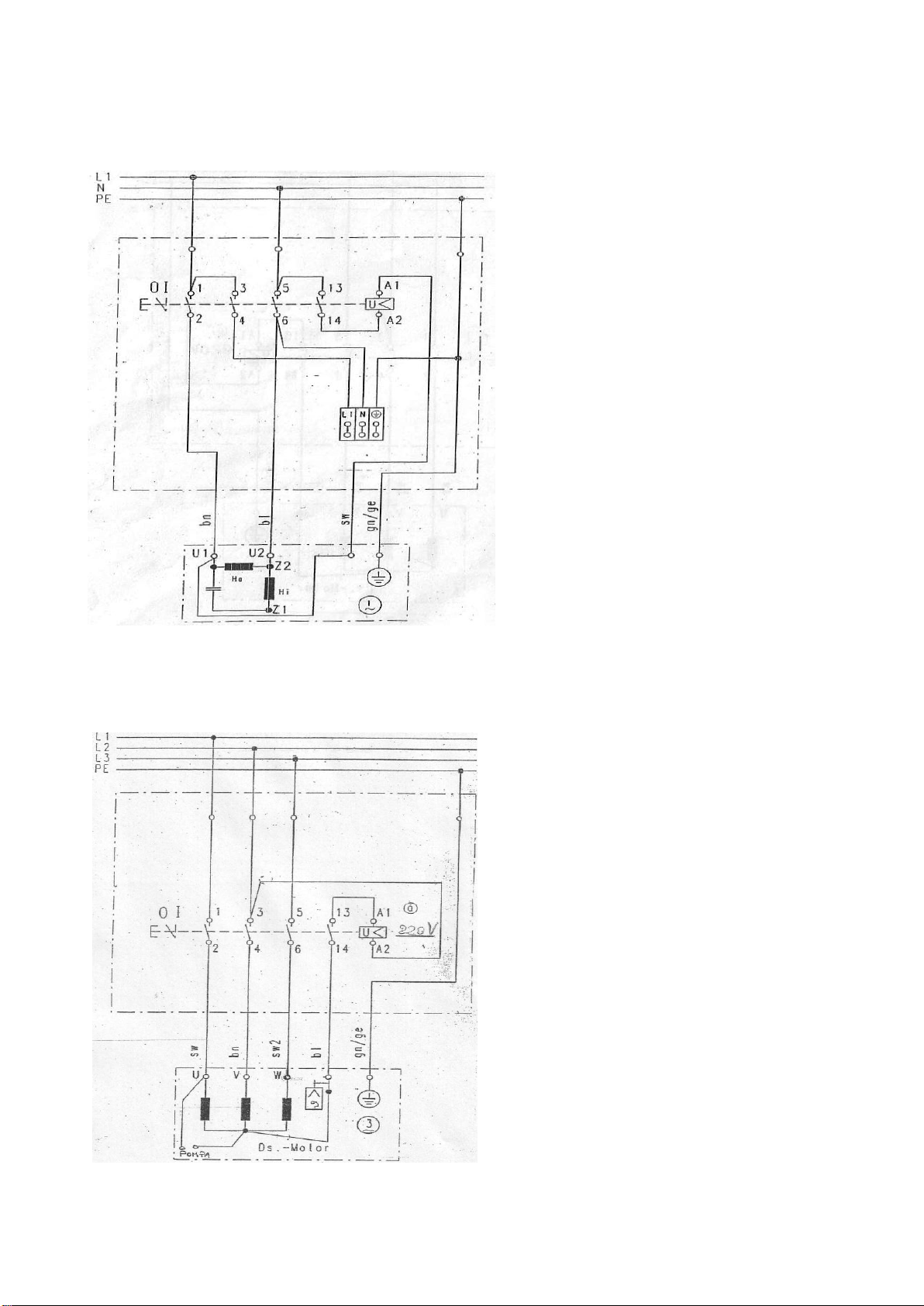

ELECTRICAL SCHEME MONOPHASE 230 V- 50 HZ

ELECTRICAL SCHEME THREE PHASE 380 V- 50 HZ

8

SPARE PARTS LIST

1

2

2

3

5

4

7

6

9

10

11

8

12

9

13

14

15

17

16

18

19

10

24

26

25

29

30

31

33

34

32

27

28

20

21

22

23

11

POSITION

DESCRIPTION

1

LEGS

2

TRANSPORT HANDLES

3

LEGS KNOB

4

FRAME

5

WATER TANK

6

WORKTOP HANDLES

7

COMPLETE WORKTOP

8

MUDFLAP

9

COMPLETE BLADE COVER D. 700 MM

10

WATER PIPE

11

WATER TAP

12

HUBCAP

13

WORKTOP GUIDES SUPPORT

14

WATER PUMP

15

WORKTOP GUIDE

16

WORKTOP BLOCK

17

RUBBER CAP

18

PIECES HOLDER GUIDE

19

COMPLETE GONIOMETER

20

EXTERNAL BLADE COVER

21

INTERNAL BLADE COVER

22

BLADE COVER HANDLE

23

BLADE COVER KNOB

24

ENGINE 3,0 KW 230V/380V-50Hz

25

MOTOR HOLDER

26

SWITCH WITH EMERGENCY STOP

27

SPRINGS

28

SPRING REBAR

29

WORKTOP WHEEL WITH BEARING

30

WORKTOP WHEEL

31

GONIOMETER PART 1

32

GONIOMETER PART 1 KNOB

33

GONIOMETER PART 2

34

GONIOMETER PART 2 KNOB

12

DICHIARAZIONE CE DI CONFORMITA’

(LINGUA ORIGINALE) ai sensi dell’Allegato II A della Direttiva 2006/42/CE

Noi,

Beta Diamond Tools s.r.l.. - Via dell’Industria 60 - 29100 Piacenza

dichiariamo sotto la nostra esclusiva responsabilità che il prodotto:

We, hereby declare on our own responsability that the product:

Nous, déclarons sous notre seule responsabilité que le produit

SB700IX

è conforme alle disposizioni della

is compliens to the norm :

est conforme aux suivantes dispositions :

-Direttiva Macchine 2006/42/CE

è conforme anche alle disposizioni delle seguenti direttive:

-Direttiva Compatibilità Elettromagnetica 2004/108/CE

Persona giuridica, stabilita nella Comunità Europea, autorizzata a costituire il fascicolo tecnico:

Beta Diamond Tools s.r.l.. - Via dell’Industria 60 - 29122 Piacenza

Piacenza, 01.06.2017 Beta Diamond Tools srl

L’amministratore

Table of contents

Other InterDiamant Saw manuals

Popular Saw manuals by other brands

GreenWorks

GreenWorks 20182 owner's manual

Central Machinery

Central Machinery 93012 Assembly and operating instructions

Ryobi

Ryobi P530 Operator's manual

Scheppach

Scheppach HM80L Translation from original manual

Huvema

Huvema HU 2613 VBS Super Operation manual

General International

General International 90-290 Setup & operation manual