Interface Devices OB-30 Instruction manual

O2 Booster Manual M99-1002-F November 2019

OB-30 OXYGEN BOOSTER

INSTALLATION, OPERATION

& MAINTENANCE MANUAL

INTERFACE DEVICES, INC. 230 Depot Road, Milford, CT 06460

Ph: (203) 878-4648, Fax: (203) 882-0885, E-mail: [email protected]

www.interfacedevices.com

Safety instructions specifically pertaining to this unit appear throughout this

manual:

Warning: denotes practices, which if not carefully followed, could result in property

damage, SERIOUS personal injury and /or DEATH

IN ADDITION TO READING THIS MANUAL, IT SHOULD BE MANDATORY FOR ALL

USERS TO VIEW THE OB-30 TRAINING VIDEO AT:

OB30training.com

OB-30 Serial Number:___________________

This manual covers specifications and information for models dating from 2005

and the latest design model from 2013. Please take note of the items pertinent to

the model vintage being used.

Save the original packaging in which the OB-30 was received to be used for

returning the unit for recertification.

Note “oxygen” & the chemical symbol “O2” are used interchangeably throughout

this manual.

IMPORTANT! FILE THIS MANUAL IN A SAFE PLACE FOR FUTURE SERVICE & PARTS NEEDS

ALWAYS REFERENCE THE SERIAL NUMBER FOR SERVICE & PARTS REQUESTS

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

2

STATEMENT OF WARRANTY

INTERFACE DEVICES, INC. (hereafter, the factory) warrants its products to be free from

defects in material and workmanship under normal use and service for a period of one (1)

year from date of shipment from the factory. Any defect discovered after the warranty period

has expired will be deemed to be outside the above coverage. No goods claimed to be

under warranty shall be accepted for return unless authorized by the factory beforehand.

Upon discovery of a defect (other than freight damage) or a shortage of an item received in

the original factory container, the purchaser shall, within (10) calendar days, deliver notice of

the defect or shortage. Damaged freight claims must be placed with the freight carrier and

will not be honored by the factory. If, after due investigation of a claim of defect or for

shortages is found valid, the factory, at it’s sole discretion, may discharge it’s entire

obligations to the purchaser by either repair or replacement of the defective product or

component and for shortages by furnishing a replacement of the missing quantity (FOB,

factory).

This express warranty supersedes and is in lieu of all other remedies and warranties,

including the implied warranties of merchantability and fitness for a particular purpose, and

liability for negligence.

IN NO EVENT SHALL THE FACTORY BE LIABLE TO THE CUSTOMER OR ANY OTHER

PERSON OR ORGANIZATION FOR ANY INDIRECT, INCIDENTAL, CONSEQUENTIAL,

SPECIAL, OR EXEMPLARY LOSSES, EXPENSES, OR DAMAGES ARISING OUT OF OR

RELATED TO ITS PRODUCTS, INCLUDING WITHOUT LIMITATION, ANY DAMAGES

FOR DIMINUTION OF MARKET VALUE, LOSS OF USE, LOSS OF PROFITS OR OTHER

FINANCIAL OR ECONOMIC LOSS, OR FOR ANY INTERRUPTION IN CUSTOMER’S

BUSINESS OCCASIONED BY ITS INABILITY TO USE THE PRODUCTS FOR ANY

REASON WHATSOEVER, EVEN IF THE CUSTOMER HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES OR LOSSES. THE FACTORY SHALL NOT BE

LIABLE FOR ANY DAMAGES CLAIMED BY THE CUSTOMER OR ANY OTHER PERSON

OR ENTITY WHETHER BASED ON CONTRACT OR IN TORT.

**WARNING**

There is an inherent risk associated with pressurized oxygen systems. Failure to follow

the manual’s instructions or other safety procedures increases the risk of an ignition

source being introduced into the oxygen flow stream that could result in a fire,

explosion, property damage, serious personal injury or death. In addition to following

the OB-30 manual instructions, remember to take appropriate safety measures with all

components in the oxygen system. In no event shall Interface Devices, Inc. be held

liable for any property damage, injury or death in the event the OB-30 booster is NOT

installed, operated or maintained in strict accordance with this manual and other

published oxygen service guidelines.

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

3

Table of Contents

1.0 General Description………………………………………………. 4

2.0 Specifications / Features ................................................................. 6

2.1 High Pressure Oxygen Booster

Component Description................................................................... 6

Non-Booster Component Pictures………………………………...7

3.0 Preparation for use.......................................................................... 8

3.1 Safety Instructions........................................................................... 8

3.2 General Safety Instructions............................................................ 8

3.3 Installation ..................................................................................... 10

4.0 Operation ....................................................................................... 11

4.1 Preparation for Operation............................................................ 11

4.2 Charging The Aircraft Oxygen System....................................... 11

4.3 Disconnecting from Aircraft......................................................... 12

5.0 Maintenance................................................................................... 12

5.1 Precautions & Procedures............................................................ 13

5.2 Preventative Maintenance Schedule………………………….... 13

5.3 Spool Lubrication Guideline ........................................................ 14

5.4 Storage ........................................................................................... 14

5.5 Recertification................................................................................ 15

6.0 Oxygen System Specification Information.................................... 16

7.0 Trouble Shooting.............................................................................. 17

8.0 Table 1 – Temperature Correction……………… ........................ 18

Drawings.............................................................................................19-28

Appendix A (Coalescing Filter) ............................................................. 29

Appendix B (Excess Flow Valve)………………………………………36

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

4

1.0 General Description

80 psi drive pressure produces 2,200 psi oxygen pressure

Shop air or nitrogen powered for use in and around the hanger

Designed for Safety:

Oxygen wetted components are principally brass – one of the best materials for oxygen

service surpassing materials such as stainless steel for ignition resistance in a pure

oxygen environment

All oxygen wetted parts have been cleaned per Spec. ARP 1176

Other materials are optimized for oxygen service including a Monel™ shaft for 2013

models and in 2005 model recertified units

Features:

No inlet valve. Air regulator or lubricator required

A coalescing drive filter is supplied and should be installed as near as possible to the

drive inlet

Dual 10 micron filters are included for the oxygen in and oxygen out ports

Integral cut-in and cut-out pressure switches. Pump will not run if oxygen

inlet pressure is below 250 psi or oxygen outlet pressure is above 2,400 psi

Polymeric seals and bearings for long life and high efficiency

Sparkless operation

To preclude drive supply from contaminating oxygen, twin rod seals are supplied with

a vent to atmosphere that minimizes the likelihood of drive media/oxygen migration

Integral air regulator with pump on/off air toggle switch

May be nitrogen-powered for remote operation

Excessive flow shut-off valve is supplied loose to mitigate risk/damage in the unlikely

event of an ignition incident or opening of the oxygen bottle too quickly. This valve is

supplied with newer models, available for retrofit for older models or units returned for

recertification

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

5

** Warning **

To Avoid Serious Injury, Property Damage or Death

1. Never operate the OB-30 unattended

2. Always have a properly rated and charged fire

extinguisher close at hand

3. Routinely check the drive filter and replace the

element in accordance with recommended

maintenance practices. (See paragraph 3.2.4 and

Apendix A).

4. Do not use on LOW PRESSURE aircraft systems.

This is an UNREGULATED OXYGEN

SOURCE equal to supply bottle pressure.

The use of a supply bottle pressure regulator is

required with this unit.

5. Do not use to boost air or any gas other than oxygen.

6. Do not exceed 2,200 PSIG inlet pressure.

7. All components used in the oxygen system shall be

clean, dry and free of all contamination per

specification SAE ARP1176.

8. Servicing and/or maintenance of oxygen systems shall

be done by trained and qualified personnel using

approved procedures.

9. All components in conjunction with the OB-30 booster

shall comply with NFPA – 53 “Recommended

Practice on Materials, Equipment, and Systems Used

in Oxygen-Enriched Atmospheres” - 2011 Edition

and SAE Spec. ARP 1532, “Aircraft Oxygen System

Lines, Fabrication, Test and Installation.”

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

6

2.0 Specifications / Features

Dimensions: 14” long (2005)/15” long (2013), 9.4” high and 8.9” wide.

Weight: 42 lbs (2005)/ 45 lbs (2013) complete.

Input & output hoses required: stainless steel/Teflon® -4 JIC rated to 3,000 psi.

Booster output rating = 2,200 psig.

Oxygen booster ratio: 30:1.

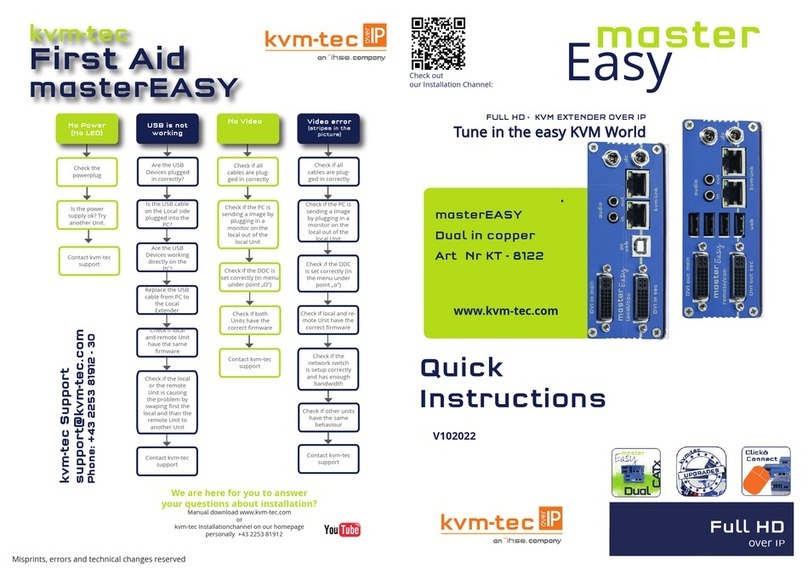

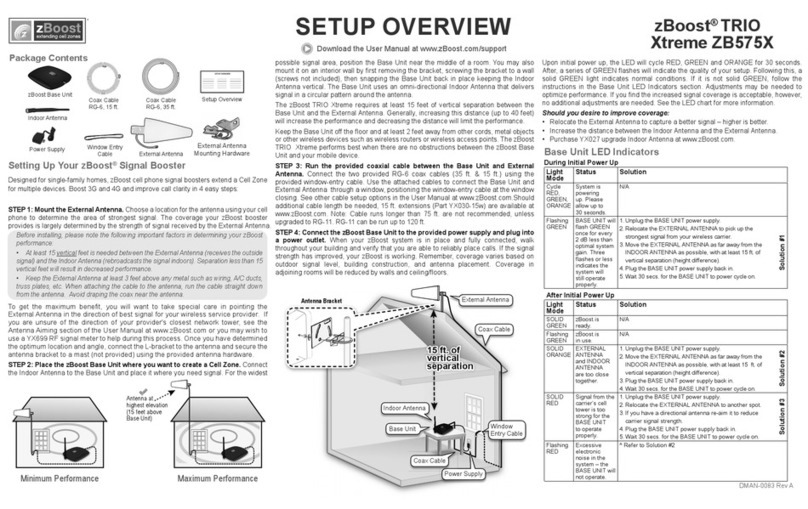

2.1 Component Description (Refer to Fig. 1a. for component location.)

1. Air or nitrogen inlet port (1/2 NPT).

2. Air regulator & gauge.

3. Booster On/Off air toggle switch.

4. Oxygen out port –4 JIC fitting 2,200 psig max.

5. Oxygen in port –4 JIC fitting 2,200 psig max.

6. Oxygen in (supercharge) pressure gauge.

7. Oxygen out pressure gauge.

8. Cut in/cut out pressure switches (factory preset).

9. Air vent filter.

10. Coalescing inlet filter, shipped loose. See Appendix A.

11. Excessive flow shut off valve, shipped loose. See Appendix B. Not included with

2005 models but available for models returned for recertification or as a retrofit.

12. Drive pressure relief valve.

Figure1a.

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

7

Coalescing Inlet Filter

Excessive Flow Valve (Included with 2013 Models.

Factory Recommended for Retrofit on 2005 Models)

ID/Date Label for Coalescing Filter.

To be Applied Prior to Installation

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

8

3.0 The OB-30 Preparation for Use

3.1 Safety Instructions

3.1.1 Information presented in this manual and on various labels, tags and plates on the unit plus other

system components pertains to equipment design, installation, operation, maintenance and

troubleshooting which must be read, understood and followed for safe and effective use of this

equipment. Also, refer to the OB-30 Training Video at http://OB30training.com.

3.1.2 The operation, maintenance, and trouble shooting of the OB-30 oxygen booster require practices

and procedures that ensure personal operator safety and the safety of others. Therefore, this

equipment is to be operated and maintained only by qualified persons in accordance with this

manual and all applicable local codes.

3.1.3 Any air compressor used to drive the booster must only supply clean, dry and filtered air. The OB-

30 comes with a coalescing filter that reduces the risk of water or compressor oil being introduced

to the booster, but a separate filter and dryer should be installed at the exit of the compressor.

Safety instructions specifically pertaining to this unit appear throughout this manual

highlighted by the signal word **Warning** to denote a potential hazard.

Warning: denotes practices, which if not carefully followed, could result in property damage,

SERIOUS personal injury and /or DEATH

3.1.4 Read through this entire manual prior to oxygen booster operation. All personnel using the OB-30

booster must understand and follow this manual and be fully trained in handling pure oxygen under

pressure. Users are encouraged to call Interface Devices, Inc. to discuss any operating or testing

requirements. All operators of the OB-30 must be familiar with high-pressure oxygen service per

the NFPA-53 publication: “Oxygen System Recommended Practices and Materials” and SAE

Specification ARP 1532

3.2 General Safety Precautions

** Warning **

It is mandatory that this instruction manual be read, understood

and followed by all persons operating this high-pressure oxygen

booster.

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

9

3.2.1 Gasses under pressure are a potential hazard in the form of stored energy. Accidents can occur

when this energy is improperly handled. Be sure that all equipment used is compatible and

designed to control the pressures encountered.

3.2.2 Oxygen flowing at a high velocity in a system can propel particles with such force that the impact

friction can raise the particles temperature to a possible ignition point. It is therefore imperative that

the components in the oxygen system be cleaned per SAE ARP1176 or equivalent specification at

all times and instructions for initializing oxygen flow be closely followed. An excessive oxygen

flow valve is available that will stop the flow of oxygen when above safe conditions. In the event

the valve stops the O2flow, depressurize the entire system to reset the valve and begin safe

operation with less flow.

3.2.3 Oxygen is a gas that promotes combustion; especially at high pressures. It is chemically stable, and

non-flammable but will, combined with other elements support combustion especially at elevated

pressures.

It is important to understand that combustion of materials such as oil can occur in oxygen rich

atmospheres resulting in ignition of materials including metals such as stainless steel.

3.2.4 The coalescing inlet filter and the vent filter need to be inspected prior to each use. The coalescing

filter element must be changed when the red indicator on the filter is on, contaminants are suspected

to be present or at least once per year, whichever occurs first. The vent filter must be changed

annually or immediately if contamination is present or even if the filter is thought to have been

compromised.

3.2.5 The use of oxygen approved lubrication in an oxygen system should be kept to a minimum. The

OB-30 requires regular lubrication of the air spool with Christo-Lube MCG-111 certified for

oxygen environments. An air line lubricator is not to be used. No lubricant shall be applied in any

area that will come into direct contact with oxygen during normal use.

** Warning **

Hydrocarbon based lubricants cannot be used. Only lubricants compatible with high pressure

oxygen systems shall be used. Only oxygen approved lubricants such as Christo-Lube MCG-

111 can be used

** Warning **

High oxygen concentrations can accelerate the combustion of most materials

including most metals up to and including explosion or serious fire.

** Warning **

High oxygen concentrations can accelerate the combustion of flammable

materials up to and including explosion. Familiarity with the excessive flow valve

mounted to the bottle for proper operation and maintenance is imperative.

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

10

3.3 Installation

3.3.1 Although the oxygen booster is inspected prior to shipping, it could be damaged during shipping.

Therefore, it should be carefully unpacked and placed on a clean level surface for inspection.

3.3.2 The OB-30 booster is shipped with special, high strength packaging. This packaging needs to be

saved for future use such as when returned for recertification.

3.3.3 The bottom of the booster is furnished with three ¼-20 by ½” deep tapped holes for mounting to a

bracket or cart.

3.3.4 Customer installed parts (oxygen components must be in accordance with NFPA-53).

a. Two stainless steel/PTFE –4 hoses rated to 3,000 psi working pressure

b. Aircraft pressurization attachment fitting

c. Coalescing inlet air filter rated to 125 psi at 40 SCFM (shipped loose)

d. 2013 models include an excessive flow valve (shipped loose)

e. 2005 models should be retrofitted with an excess flow valve cleaned and approved for

oxygen service from the factory or other source

f. Oxygen shut-off valve (mounted away from the booster)

3.3.5 Install the coalescing filter as near as possible to the booster inlet.

3.3.6 Install the excessive flow valve immediately after the regulator on the oxygen bottle.

3.3.7 Remove protective caps from “O2IN” and “O2OUT” fittings.

3.3.8 With oxygen supply regulator closed, connect both -4 hoses to the oxygen in and out fittings on the

booster.

3.3.9 Attach aircraft pressurization fitting to the far end of the -4 hose coming from the oxygen out hose.

3.3.10 Check all components for integrity and contamination. If all is well and thoroughly checked

to be in compliance, the OB-30 is ready for use.

** Warning **

The customer supplied oxygen supply must be complete with shutoff valves,

pressure gauges, pressure regulators and Stratoflex® -4 hose. All components

must be rated for 3,000 psi working pressure, cleaned for oxygen service and

c

onform to

N

FPA-

5

3

g

ui

d

el

i

ne

s

** Warning **

Always inspect unit before use. Damaged, contaminated or oily equipment must

never be used.

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

11

4.0 Operation

4.1 Preparation for Operation

4.1.1 Be sure all valves and controls are in the closed or “failsafe” position.

4.1.2 Decrease item 2 (figure 1a, page 6) inlet pressure regulator to minimum pressure setting.

4.1.3 Inspect all connections for contaminants before installation and tightening. Inspect and

replace any suspect components. Be sure all oxygen components are clean per SAE

specifications and comply with NFPA-53 publication: “Oxygen System Recommended

Practices and Materials”and SAE Specification ARP 1532.

4.1.4 Connect the output of the gas supply bottle to the gas inlet connection of the oxygen booster

(See figure 1a, page 6).

4.1.5 Decrease the gas supply bottle or shop supply air/gas regulator to the minimum pressure

setting.

4.1.6 Connect the O2fill line loosely to the aircraft and purge line by SLOWLY cracking open gas

supply bottle shutoff valve and adjusting the supply bottle pressure to a low flow setting.

4.1.7 Tighten the O2fill line connection at the aircraft.

4.1.8 The OB-30 booster is ready to charge an aircraft O2System.

4.2 Charging the Aircraft Oxygen System

4.2.1 After the oxygen booster has been properly connected, slowly open the O2supply bottle shut

on/off valve. Adjust the gas supply bottle pressure regulator to the required aircraft O2system

pressure. Wait until the bottle pressure and the aircraft system pressure are equal. If the flow of

oxygen ceases, the flow valve has probably been triggered. Depressurize the system to reset

the valve and reopen the oxygen supply at a lower flow.

4.2.2 Note: If the bottle pressure is lower than the required aircraft oxygen system pressure,

be careful not to over adjust the supply bottle pressure regulator once the maximum

** Warning **

Be sure fill line is secured prior to purging the unit. This will prevent the hose

from whipping about if too much O2is allowed to flow through the unit.

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

12

supply bottle pressure has been achieved. Increasing the oxygen pressure regulator

beyond this point will not increase output, and may damage the regulator spring.

4.2.3 Adjust the booster’s air pressure regulator to attain a pressure slightly lower than the final

required O2pressure (divide this oxygen pressure by 30 to find the initially required regulated

air pressure setting). Example: 2,200 psi final pressure minus 100 psi equals 2,100 psi, divided

by 30 equals 70 psi regulated air pressure.

Note: If the ambient temperature at the time of oxygen system recharging is above or

below 70 degrees Fahrenheit, refer to Table 1 to determine the correct final pressure.

4.2.4 Turn on the booster’s “pump run” toggle switch to “on” to further pressurize aircraft oxygen

system. Note: Because the oxygen booster pump operates at a theoretical ratio, actual boosted

oxygen pressures may vary slightly due to different physical conditions. The oxygen outlet

pressure gauge will show the aircraft system pressure developed by the oxygen booster. When

the set pressure that has been achieved (i.e.: booster stops pumping), increase the pressure of

the air regulator to obtain the required final aircraft system pressure. Turn off the booster’s air

toggle switch when the booster has stopped running.

4.3 Disconnecting the Oxygen Booster from the Aircraft

4.3.1 Close the oxygen bottle shut off valve.

4.3.2 Decrease both the air inlet pressure regulator and the oxygen supply bottle pressure regulator

to their respective minimum settings.

4.3.3 Disconnect booster’s air (or nitrogen) supply line.

4.3.4 Slowly loosen, bleed down, and disconnect oxygen hose at the aircraft. Disconnect the O2

supply hose from the bottle

4.3.5 Cap both all exposed hose connections to prevent contamination.

5.0 Maintenance

** Warning **

Maintenance must be undertaken by qualified personnel only.

The operation, maintenance and troubleshooting of the oxygen booster system

requires practices and procedures which ensure personal operator safety and the

safety of others. Therefore, this equipment is to be operated and maintained only

by qualified persons in accordance with this manual and all applicable codes.

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

13

5.1 Precautions and Procedures

5.1.1 All maintenance performed on the OB-30 oxygen booster shall be conducted in accordance with all

applicable codes governing the handling, operation, installation and trouble shooting for high-

pressure O2operation. Maintenance is to only be done by qualified persons.

5.1.2 All personnel must be familiar with the warnings associated with high-pressure O2 systems as

outlined in sections 3.1 and 3.2 of this manual prior to performing any maintenance on this unit.

5.1.3 The oxygen pressure gauges on this unit are supplied for reference purposes. Calibrated and

certified gauges should be used for determining final pressure to the aircraft, which are

available from the factory at time of purchase or upon request during recertification.

5.2 Preventative Maintenance Schedule

Item Usage Task Action Required

General Inspect all components prior to

every use for contaminants or

damaged/suspect components

Return the booster for recertification

if the booster or other components

have been suspected to have been

compromised or after 1500 hours of

operation or after 2 years, whichever

comes first

Reciprocating Circuit

(See paragraph 5.3.1

below for instructions)

Ensure the drive section and

reciprocation circuit are clean and

lubricated with oxygen approved

Christo-Lube MCG-111

Lubricate the spool section every 6

months using ONLY lubricant

approved for oxygen service such as

Christo-Lube MCG-111

Vent Filter Inspect prior to every use to ensure

cleanliness Replace the vent filter annually or

immediately if it appears to be

contaminated

Coalescing Drive Filter Inspect prior to every use to ensure

cleanliness. Verify the filter

indicator is green and not red

Replace the filter element annually,

when the filter indicator turns red or

immediately if it appears to be

contaminated

Other System

Components Inspect prior to every use to check

for contaminants and ensure

cleanliness

Replace any component that may

have been compromised in any way.

Consult the manufacturer of the

component for additional

instructions

The exterior of the OB-

30 is dirty or

contaminated in any

way

Do not use the booster Return for factory recertification

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

14

5.3 Spool Lubrication Guideline

5.3.1 Provided the booster is not due for recertification, this section offers tips on lubricating the

spool. If the booster is beyond the two-year time frame for required certification or

compromised in any way the booster must be returned for service and recertification. As part

of this process, the factory will tend to spool section lubrication.

To lubricate the spool section of the booster, refer to drawing number P33-1003 or P33-1004

in this manual. Remove the 2 cap screws securing item 9, Retainer Cap and item 15, Spool

Cap. Extract item 6, Spool by pushing it from the Retainer Cap end using your pinkie finger

or a blunt, soft small diameter tool. CAREFULLY remove the Bushings, O-rings and all

Cages and Tee Seals, items 4 and 5, one at a time. You may need a pick type tool, which

should be made from a soft material such as brass.

Clean all the extracted parts with a parts cleanser approved for pure oxygen wetted

components and wipe clean. Apply Christo-Lube MCG-111 synthetic oxygen approved

lubricant to the spool, cages and tee seals. Snugly install the retainer cap and then, one part at

a time, put the assembly back in the spool cavity including O-rings, Bushings, Tee Seals and

Cages. Ensure the Spool is free to move. Install the Spool Cap and tighten the cap screws on

both the Spool Cap and Retainer Cap.

Note: Oxygen compatible synthetic Christo Lube MCG-111 is available from the factory in 2

oz. tubes.

5.4 Storage

5.4.1 Store the unit away from any aircraft in a clean, dry and secure area when not in use. Be sure

all hoses are capped and the unit is covered with a lint free covering for the duration of unit

storage to ensure complete O2system cleanliness for future aircraft system recharging

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

15

5.5 Recertification

5.5.1 The OB-30 must be inspected prior to each use. If, after conducting the OB-30 inspection, it is

believed it may have been compromised with suspect components or sub-optimal operational

or maintenance practices it must be returned for a complete inspection, cleaning and

recertification. Recertification is also required for any OB-30 that has been in service for 1500

hours or two years since its last factory certification, whichever occurs first. OB-30 boosters

being returned for recertification can only be sent to:

Interface Devices, Inc.

230 Depot Rd.

Milford, CT 06460 USA

The OB-30 is heavy for its size, so purpose built packaging is used to ship the booster. BE

SURE TO SAVE THE ORIGINAL BOX/PACKAGING as this was designed specifically to

transport the OB-30 booster for return to IDI when recertification is required. Contact IDI

prior to returning the booster to obtain a Return Merchandise Authorization (RMA). Be sure to

have the OB-30 serial number. The company, contact name, phone number & e-mail address

MUST be included with the booster being returned.

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

16

6.0 Oxygen System Specification Information

For more information about the specifics of the OB-30 booster, contact:

Interface Devices, Inc.

230 Depot Rd.

Milford, CT 06460 USA

Tel+1 203-878-4648

OB-30 Training Presentation: http://ob30training.com

For more information concerning specific SAE Aircraft Oxygen Equipment Specification, contact:

Society of Automotive Engineers

400 Commonwealth Drive

Warrendale , PA 15096-0001 USA

Tel: +1 724 776 4841

For more information concerning specific Oxygen System Recommended Practices and Materials

contact: National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471 USA

Tel: +1 617 770-3000

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

17

7.0 Trouble Shooting

Troubleshooting Chart

Symptom Probable Cause Remedy

Pump will not cycle

(Only regulated

oxygen Pressure at

out put.)

No air supply to pump

Pump regulator set too

low

Four way air

reciprocating valve

spool stuck at mid

position

Look for and fix

Increase setting

Disconnect/ reconnect air supply (resets air spool to end position)

If spool still sticks, manually push spool to far end with probe through

hole in “spool stop cap”. If stuck or requires excessive force,

disassemble air valve assembly. Inspect for contamination or

mechanical bind. Repair or replace, lubricate seals with Christo-Lube

MCG-111 lubricant or other oxygen approved lubricant. Refer to the

OB-30 Exploded Assembly Drawing in this manual

Pump makes one

cycle then stops

Faulty “2 way air valve”

(Broken, leaks or

contaminated)

Repair or replace

Pump cycles

constantly when dead

headed (discharge of

the unit is plugged

preventing output

flow of oxygen)

External leak at pump or

downstream high-

pressure circuit

Contaminated or stuck

open check valve

cartridge

Internal leak in pump

Look for and correct

Clean or replace

Check all dynamic and static seals and gaskets

No O2flow to booster

from the bottle

Excessive flow valve

has closed (where

applicable)

Reset valve by depressurizing the entire system per manufacturer’s

instructions.

For further assistance, call Interface Devices, Inc. at 203-878-4648.

** Warning **

Troubleshooting can only be undertaken by qualified personnel trained in

servicing oxygen equipment only.

INTERFACE DEVICES, INC.

OB-30 OXYGEN BOOSTER

18

8.0 Table 1

Temperature/Pressure Correction

At Temperature

Degrees F Fill to Working Pressure

x Figure Below

110° 1.1000

105° 1.0875

100° 1.0750

95° 1.0625

90° 1.0500

85° 1.0375

80° 1.0250

75° 1.0125

70° 1.0000

65° 0.9875

60° 0.9750

55° 0.9625

50° 0.9500

45° 0.9375

40° 0.9250

Example: Ambient Temp. = 90° F, Working pressure is 1800 PSIG

Charge Pressure = 1800 PSIG * 1.0500 = 1890 PSIG

Table of contents