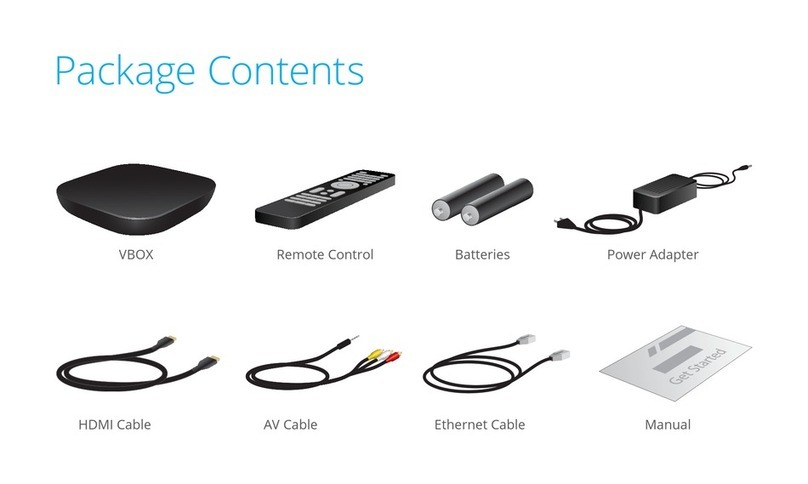

International Tapetronics Corporation 770 Series User manual

www.SteamPoweredRadio.Com

•

TECHNICAL

MANUAL

(890-0024-000)

770 SERIES

REEL-TO-REEL

REPRODUCER

/

25

Hz

DETECTOR

tnTERnATIOnAL

TAPETROnlCS

CORPORATIOn

2425

SOUTH

MAIN

STREET •

BLOOMINGTON,

ILLINOIS

61701

OCopyri

ght

1981

lnternaUonal Tapetronics Corporati

on

.

Made under

one

or

more

of

the following

pa

tents:

3,

800.3233,

801

. 043 3, 801,3293,833,925 3. 865.719

other patents pending

www.SteamPoweredRadio.Com

0381

DM

PREFACE

THE ITC

lNSTRUCT

IO

N

MA

N

UAL

Int

ernational Tapetronics Corporation Manuals

are

wr

itten

with

the intent

of

assisting the reader-user

toward a better understanding

of

I

TC

equipment

Most

instruction manuals are seldom read except

at

the time

of

crisis when equipment malfunction is suspected.

When thishappens,

the

manual is usuallymissing,

or

at

best,difficult

to

locate.PLEASE

FIND

A

CON

V

ENLE

NT

SPOT

TO

KEEP

TH

IS

MANUAL

We

at

ITC

have tried

to

produce a useable manual.

But,beinghuman, wearesubject

to

the

frailties ofbehav,

ior

.Therefore, should you discover any

errors

or

omis-

sions,

or

should you wish

to

contribute

any recommen-

dations.please sendus

your

comments.

We

will

bemost

appreciative.

www.SteamPoweredRadio.Com

0381 DM

ITC's 770

SERIES

REEL

-TO.REEL

REPRODUCER

has

been

designed for

broadcasters

.Itis ideallysuited

for

use

in

program

automation

systems.

The

770SERIES is:

• designed

to

meet

or

exceed

the

NAB (National

Asso

ciation

of

Broadcasters)

standards

for reel-to-

reel

tape

reproducers;

• available

in

a variety

of

co

nfigurations including,

.

•.

.

one

or

tw

o track,

mono

or

stereo

capab

ilit

ies

and

. . . . ta

pe

speeds

of

3·3/4,

7-1

/2,

and

15

IPS;

•

constructed

with a heavy

1/2

inch (12.7mm) thick

aluminum tool plate

deck

for stability;

• equipped with a unique, high quality, profession

al

head

assembly;

• utilizing two induction

torque

motors

for supply

and

t

ake

up

reel handling

and

a D.

C.

servo

capstan

motor

for

tape

drive:

and

• designed for simplicity

and

serviceability of

mechan

-

ical

and

elect

ron

ic

com

ponents

.

The 770 Series

reproducer

is designed for long life,

durability,

and

ease

of

service

• low maintenance, positive action differential disc

brakes

design:

•

strong

,

cast

stainlesssteel turntable;

• long

life

control switches

and

an

il'l9enious switch

support;

• multispeed D.C.

servo

capstan

mo

tor;

• automatic

cue

lever

and

ta

pe

lift

er;

and

• unique magnetic playback head.

iii

www.SteamPoweredRadio.Com

TAB

LE

OF CO

NT

ENTS

PREFACE

....

.........

.......

..

.....................

.

...

....

..

.

.....

.. i

TABLE

OF

CONTENTS

.. .

....

.

...................

.

....

..

....

.

.....

. .·.V

ILLUSTRATIONS

.....

.

.......

..

......

.

...

....

..

•.

................

.

..

IX

SECTION

I.

INTRODUCTION

A.

Tape

Tr

an

spo

rt . . . . . . . . . . . . . •. . . . . . . . .. . . . . . . . . . . • •. . .. . . . . . . . . . . l·l

B. H

ead

Assembly

...................

.

..

. •

....

.

...........

.

....

.•

...

1-1

C.

Ele

ct

ronics

...........

. , .. ••. . . . . . . . . . . . . . . . . . . . . . . . • . • . . . . . . . . ..

1-1

D. Specifications

.....

.

....

. .

..

.........

. •

..

,. .

....

..

.....

.

....

.

.....

1-1

1.

Power

2. Wind Time

3. Motors

4. T

ape

Speeds

5.

Tape

Width

and

Tra

c

ks

6. Reel Sizes

7. Flutter (NAB Weighted)

8. Audio

Output

9. Distortion (Amplifier)

10

. Signal-to-Noise Ratio

11.

Crosstalk

12.

Equalization

13.

Fr

equency

R

espo

nse

14.

H

eadp

hone

Output

15.

Ambi

ent

Operating T

emperature

16.

Remote Control

17.

Br

akes

18, External

Connectors

19.

Dimensions

20. Weight

E.

Warranty

......

. . .

...

...

..

.....

.

....

.

.....

.

..

. .

•.

.....

.

.....

.

...

1-2

F. Options

and

Accessories . . •. . . . .

..

........

.

..

.

...

. .

...•

.•

.

...

.

....

1-2

SECTION

II

. INSTALLATION

A.

Unpacking

and

Handling

........

.

...........................

.

.....

2-1

8.

Installation in Ra

ck

.

....

.

..........................

.

..

•.

...

.

....

.. 2-1

C.

Optional Console Housing

...

..

...

...

.

....

. ,

.....

.

...........

..

....

2-1

D.

Connecting Audio Lines

...

.

...

..

...............

.

...

...

......

•

.....

2-1

E.

Connecting R

emote

Controls

...

,

....

,

.....

.

.......

.

..........

.

....

2-2

F. Initial

Checks

Before Operation

..............

..

, .

....

,

•.

.

..........

2-2

G.

Functional

Checkout

.

••

.

....

•.

...

..

.........................

. .

..

. 2-2

SEC

TION

Ill

. OPERAT

IN

G INSTRUC

TIONS

A.

Threading

the

T

ape

...

..

...

.

....

.

..

.....

....

••

.

..

....

.

...........

.

3-1

B.

Controls and Indic

ators

.

..

..

....

..

.

......................

....

.

.•

, . 3-1

1.

Start

Switch

2.

Stop

Switch

3.

Fast

Rewind and Fast Forward

4. Reel Size Switch

5. Power

6. Speed

7.

Cue

Lever

8. LED

Ind

icator

9. Limited Range Front Panel Level Controls

V

www.SteamPoweredRadio.Com

SECTION

IV

. SETUP,

ALIGNMENT

.

AND

CALIBRATION

A. Mechanical

Adjustment

-

Tran

sport

....................

• •

...

.........

4-1

1.

Reel

Motors

Torqu

e

Adjustment

..

...........

.

....

..

.

............

4-1

2.

Torque

Boost

Adjustment

..........

....

...

•

..........

..........

4•2

3.

Supply

Tension

Arm

D

amping

Adjustment

. .

............

•. •.

.....

.

4-2

4.

Pressure

Roller P

ressure

Adjustment

. .

•.

...

. .

.....

..

...

.

.........

4-2

5.

Solenoid

Air Damping

...............

...........

••

....

. •

...

.....

4-3

6.

Reel

Turntabl

e Height

..

...

•

........

.........

....

.

..........

.

...

4-3

a)

Measuring

Turntable

Heights

b) Adjusting

Turntable

H

eights

7.

Br

ake

Tension

Ad

jus

t

ment

....

. .

.........

...

..

. •

•.

..•.........

. . 4.4

a) Initial

Brake

A

djustment

b) Final B

ra

ke

Adjustment

8. H

ead

Height

and

Zenith

..

. .

..

•.

...

.

.........

..

.....

.•...

. . •

••

..

4-5

a)

H

ead

Assembly

Lock

Screw

b) C

oar

se

Height

c)

Coarse

Zenith

d)

Fine

Height

and

Zenith

9.

Capstan

Motor

Speed

M

easure

m

ent

and

Ad

just

ment

s

..............

4-6

a) 3.75

ips

b)

7.5 ips

c) 15

ips

B.

Ele

ct

rical .

.....

•.

......

..

..

•

............

...

.

....

...

....

..........

4•6

1.

Reproduce

H

ead

Azimuth

and

Phasing

...

.•

........

...

...........

4-6

2.

Reproduce

Amplifier Equalization

.......

.

......

•..

....

• .

....

.•

...

4-8

3.

Reprodu

ce

Amplifier Level

....

.....

. •

...

.......

.................

4-8

4. Infrared

Tape

Sensor

...

.

...................

.....

....

.

.......

.

..

4-8

5.

Capstan

Motor

Speed

Change

...............

.

...................

4-9

SECTION V. ROUTrNE MAINTENANCE

A.

General

....

•

....

•.

.....

•

....

.

.................

. .

..

.

........

.....

5-1

B.

Main

tenance

Tools

and

Aids . .

...

....

.

...

. •

..

................

.

.....

5-1

C.

Ma

int

enance

Sc

h

edule

............

..

..........

..

...

.

.............

. 5-2

D.

Spare

Parts

....

. . . . .

..

.•

...

.•.

...

.•

........

..

..................

..

5-2

E.

Parts

/

Equipment

Return

Poli

cy

.....

••..

. .

....

••

..

.

..

.........

.

.....

5.3

SECTION VI. THEORY

OF

OPERATION

A.

Power

Supplies

. . . .

..

. .

.........

..

..............

...

..

..•......

...

6-1

1.

Solenoid

and

B

rake

2. 24 Volt DC

Supply

3. 5 Volt

DC

Supp

ly

8.

Tr

ansport

Logic

Control

.......................•.......

•

.....

••.

..

6-1

1.

Stop

Ci

rcuitry

2.

Fast

Wind

Circuitry

3.

Start

Circuitry

4.

External

Connect

io

ns

C.

Program

R

eproduce

Amplifier . .

..

.........................

...

......

6-2

D.

Optional

Motion

Sense

/

Start

M

emory

.....•...........

.

..

.

...

..

...

..

6-2

SECTION

VII

.

MECHANICAL

DRAWlNGS

AND

PARTS LIST

A

Deck,

Front

.

.....

•

...

.

......................

.

.........

.......

. . . 7-1

1.

Turn

table

and

reel

retainer

.....

, . . .

..

.

..

..

. .

.....

.

......

.

.....

..

7-2

2. H

ead

Cover

......

.

.....

...

.

....

.......

.

..

.

..

.

........

....

.•

..

.

7-2

3. H

ead

Mounting

Block .

..

. .

...

....

..

.•

....

.

......

.............

. . 7.3

4.

Tape

Guide

.............

.

..................

..

,

........

.

..

• . .

..

7-3

5.

Capstan

Motor

........

..

...

•..

....

...

. ,, ,

...........

...

.......

7-4

vi

www.SteamPoweredRadio.Com

B.

Deck,

Rear

...........

......

.

..

..

.•

..

....

..

.....

.......

.....

.

..

. . 7-5

1.

Dashpot,

Foil

Sense

Po

st

......

.....

......

..

...

.•.

..........

•.

..

7-6

2.

Pr

essur

e Roller Solenoid M

echanism

, .

...

.............

. .

....

.

•.

..

7-7

3.

To

r

que

Mot

or

/

Brake

Assembly

.....

..

,

.....

. . , . ,

................

7,8

4.

Swi

tchca

rd

. .

....

.

....

•.

....

. .

....

.

.........

. ,

.....

.

....

.•

..

..

7-9

5.

Pow

er

Transformer

.......

..

. .

....

•

...

.

....

..

•..

..

..

.

..

...

.

...

7•

10

6. Motion

Sense

...

, . . ,

..

.

................

....

•

..

.

..

•.

. ,

....

,

...

7

-1

1

SECTION

VIII

. E

LECTRICAL

ORA

WING

S

AND

PARTS

LIST

A.

Mother

Board

1.

Component

Loading

an

d Overlay

.................

•.

, . . .

•.

.....

. . 8-1

2. Schematic

..

.

..........

.....

..

....

, , . ,

...

.

.......

......

. .

...

. . 8-2

3.

Pa

rts

List .

...

.....

.

.....

•.

...

......

.

.........

.••.

...

.

........

. 8·3

8. P

ower

Cage

Wiring

Chart

...

•.

..

..

,

...

.

............•...........

..

. 8-5

C . Re

prod

uce

Amplifier

1.

Component

Loading

and

Overlay .

...................

.••

...

. . •.

..

8-6

2.

Schematic

...

........

. .

.......

...

..

.

•.

•.

..

.

..........

.......

..

8-7

3.

Parts

List .

••

. .

..

•. . . .

.••

....

..

.....

....

.

..........

.•

.....

•.

. . . 8·8

D. Switch

car

d

1.

Component

Loading

and

Over

lay

............

....

. . , •

..

.

...

•.

...

8-10

2.

Schemati

c

............

....

.

.....

. , , .

.•

........

..

....

........

. 8•

ll

3. Pa

rts

List •

........

.

.......•

. . .

...

...

......

.

.....

.

....

.••.

.

..

. 8-

12

E. Motion

Sense

1.

Component

Loading

and

Overlay

....

..

......

.•

...•

•

....

..•

.....

8-13

2. Schematic

.....

...

.......

•

..

..

•

•....

.

.......

..

.

....

.....

...

.•

8-

14

3.

Parts

List

....

....

.

.......................

••

, . , . . .

.......

.

..

. . 8•

15

SECTION

IX

. 25 Hz

DETECTOR

(OPTIONAL)

A. Introduction . . , •

....

,

....

....

.........................

..

. . , . . . . , . 9-1

1.

Gener

al D

esc

ription

..

.

...

....

.

....

..

, , ,

.•

,

...

.

..............

..

9-1

2. Specifications

..

. .

..

...

.

......

•

..

...

.

.....

. , . . .

...

,

•..

....

•

....

9-

1

a)

Input l

mpedence

b) Sensitivity

c) Bandwidth

d) D

etecto

r Enable

e)

Power

f)

Temperature

R

ange

g)

Rejection

h)

E.

O.M

. Relay

B.

In

sta

llation •

...

••

....

.•

....

..

........

....

..

...

..

...

.....

•..

. .

..

.•

9-1

l.

Unpacking

and

Handling

2.

Audio

Connectio

ns

3.

Control

Connections

4. Mounting the

Dete

c

tor

(Field

In

stallation)

C.

Principles

of

Electrical

Operation

. , .

..............

..

...

..

.......

..

..

9-2

I. Det

ecto

r Circuit

2. External Output-Relay

Dr

iver

and

Control

Circuit

3. End

of

Tone

Stop

Circuit

4. Delayed

Stop

Circuit

D.

Setup,

Alignment,

and

Calibra

ti

on

..

..

.

....

. . . ,

..•

....

•

•...

. .

.......

9-3

I.

B

oost

Adjust

2.

Detector

Sensitivity

Ad

just

3.

Stop

Delay Adju

st

4.

Detector

Freq

uen

cy

Tr

im

E. Mechanical Drawing and

Part

s

Li

st .

.....

.

....

....

..••

....

•.

....

. . • . 9-4

vii

www.SteamPoweredRadio.Com

Figure

2-1

Figure 2-2

Figure 2-3

Figure3-1

Figure 3-2

Figure 3.3

Figure 4-1

Figure 4-2

Figure 4-3

Figure 4-4

Figure 4-5

Figure 4-6

Figure 4-7

Figure 4-8

Figure 4-9

Figure 4-10

Figure 4-11

Figure 4-12

Figure 4-13

Figure 4-14

Figure 4-15

Figure 4-16

Figure 4-

17

Figure 4-18

Figure 4-19

Figure 4-20

Figure 4-21

Figure 4-22

Figure5-1

Figure5-2

Figure 5-3

Figure

7-1

Fig

ure

7-2

Figure 7-3

Figure 7

-4

Figure 7-5

Figure 7-6

Fi

gure

7-7

Figure 7-8

Figure 7-9

Figure

7-

10

Figure 7-11

Figure 7-12

Figure 7-13

ILLUSTRATIONS

De

ck

Dimensions

..................................

.

Connection

of

Audio Lines

.....................•.....

Sample Remote Control Schematic

..................

.

Tape

Loading

Path

...........

.....•....•.......•...

Front

View

of

the

Reproducer

..

.................•....

R

ear

View

of

Reproducer

......

•

....

•..

..

•••..

..•....

Reel Motors

Torque

Adjustment

..

..

.................

.

Motor

Torque

Adjustment

Po

ints •

...

.•

...

.•

.....

•.

...

Torque

Setting

Chart

..

..

..............

.

........

...

.

Torque

Boost Adjustment

•.

.

•....•..•

....

..

....

.

....

Pressure

Roller

Pressure

Adjustment

.................

.

Adjusting

the

Solenoid Plunger .

........

..•.....••....

Proper

Height

of

the

Reel turntable

..................

.

The

Split Collar

Gauge

.................

•

•.

.........

.

Inserting

the

Split Collar

Gauge

.....................

.

Brake

Assembly a

nd

Adjustment Points

..•..

........

••

Slip

Torque

Adjustment

..........................

..

.

Brake Slip

Torque

Chart

...........................

.

Head

Height

and

Zenith Adjustment

Po

ints

....

•...

....

Height Adjustme

nt.

...

..

..

..

....

.

.................

..

Zenith Adjustment

.........................

•.

.......

Tape

He

ight Position

............

..

....

.

.....

...

....

.

Adju

stment

Points for

Capstan

Mot

or

Speed

....

....

. . .

Phasing .

•.

...

.....

•

.....

,

....

.•.

.

......

..

.•.......

Phasing .

...

............

......•..

....

..

..

.•......

..

Phasing

......

.

...............

.

......

.

....

...

.....

.

Phasing

..

....

..........

.

...

..•..

.

.•......

•

.......

.

Reproduce

Amplifier

Controls

.......................

.

Lubricating

the

Servo

Capstan

Motor

..

. •

....

•

•.•.....

Maintenance

Schedule

.....................

.

.......

.

MaintenanceTools a

nd

Aids .

.•.

.

..•.....

•

..

....

••.

..

Deck

Mechanical Assemblies -

Fr

ont

........

.....

....

.

Reel

Turnt

able

and

Retainer •

...

.

....

.

...............

Head

Cover

..•

...

.•..

..

••.

...•.....

.•.

...

..•.

...

..

Head

Block

..............

.

....

...

.........

....

....

.

Tape

Guide

.......

...

..•

•..

...

•

.....••....

......

.

••

Capstan

Motor

..

................................

. . .

Deck

Mechanical Assemblies •

Rear

.

...

•..............

Dashpot

and

Foil

Sense

.....

...

...

.....

...........

. .

Pressure

Roller Solenoid Mechanism

.................

.

Torque

Motor

and

Brake

Assembly

..........

........

.

Switchcard Assembly

..........•......•..........

, . .

Power

Transformer

.

..

...

..

....

.

...........

..

......

.

Motion

Sense

. .

...

..

....

.

.................

..

....

••.

Page

2-1

2-2

2-2

3-1

3-1

3-2

4-1

4-1

4-1

4-2

4-2

4-3

4-3

4-3

4-4

4-4

4-5

4.5

4-5

4-5

4-6

4-6

4-6

4-7

4

.7

4-7

4.7

4-8

5-1

5-1

5-2

7-1

7-2

7-2

7.3

7.3

7.4

7-5

7-6

7-7

7-8

7-9

7-

10

7-

11

ix

www.SteamPoweredRadio.Com

)(

Figure 8 I

Figure 8-2

Figure 8

-3

Figure 8-4

f=igure 8·5

figure

8-6

figure

8·7

Figure 8-8

Figure 8-9

Figure 9-1

Figure 9-2

Figure 9-3

Figure 9-4

Figure 9-5

ILLUSTRATIONS

(continued)

Mother

Board

Component

Loading

and

Overlay

.......

.

Mother

Board

Schematic

.

....

.

...........

. . . . •

...

,

..

Power

Supply

Cage

Wiring

layout

...

....

.....

.

......

.

Reproduce

Amplifier

Component

loading

and

Overlay

..

Reprodu

ce

Amplifier

Schematic

.

..

..

.

...............

.

Switc

hcard

Component

L

oading

and

Overlay . . . . . •

..

.

Switchcard

Schematic

. . • .

..

.•

...

..

,

................

.

Motion

Sense

Component

Loading

and

Overlay .

.•.....

Moti

on

Sense

Schemat

1c . . . . . . . . .

...

. . . . .•

..

•.....

.

25 Hz

Remote

Control

Schematic

......

.•

..

....••.

....

25

Hz

Dete

ctor

R

ear

View

..

.

........

.

.......

.•..

...

,

25

Hz

Detector

Mechanical

Parts

..

...

.•.

...

. .

..

......

25 Hz

Detector

Component

Loading

and

Overlay .

.....

.

25 Hz

Detector

Schematic

. . .

......

.

..

.....

.•..

......

Page

g.J

8·2

8-5

8-6

8-7

8-

10

8-

11

8-

13

8

14

94

9A

9.5

9-6

9.7

www.SteamPoweredRadio.Com

SECTION I- INTRODUCTION

-A.

TAPETRANSPO

RT

The I

TC

770 reproduceris constructed

of

heavy 1/2

inch

(]2.7mm)

thick

aluminum tool plate. The tool plate

is stress-relieved, and is resistant

to

thermal variations.

Theprecision milled toolplatealuminum

deck

providesa

stable reference

for

each critical assembly, resulting in

improved tape handlingand phase stability.

Individual

motors

areused in thetapedrivesystem.A

DC

Servo

motor

is used

for

capstan drive. This direct

drive system. along

with

its electronic control system

providesaccuratespeed control

with

minimumwowand

flutter Heat generation is substantially

lower

than hys•

teresis syn

ch

ronousmotors.

The

two reel

driv

e

motors

are

four pole, 1800

RP

M, induction motors. These

motors

have permanently lubricated ball bearings, and

develop adequate

torque

to

provide positive control

of

the tape reels

An air damped solenoidoperates thetape lifterscind

pressure rollerassembly.

The

use

of

air

damping, and a

TEFLON

® covered plunger

in

this solenoid result

in

quiet operation and minimum maintenance.

The transport incorporatesa tape liftersystemoper•

aled

by the pressure roller solenoid which allows both

manual andautomatic operation.

The

tape is automati•

cally liftedaway from thehead(s) duringeither fast wind

mode.

To

monitor

recordedinformationwhile in thefast

windmodes, theautomaticpositioning

or

the liftersmay

be overridden by pushing the

CUE

lever toward the

heads. The lifters

will

remain in this position until the

START

/

PLAY

mode is entered,

or

the

CUE

lever is

manually returned to

its

original position.

Disc

type

brakes

with

a one-way clutch provide a

differential between the take

up

and supplyreels. Differ-

ential action is essential to provide

smooth

a

nd

even

braking action.

The

disc brakes

are

designed

for

min·

im

ummaintenance.However,

if

a touch-

up

isnecessary,

the adjustment is simple

to

makeand easily accessible.

B. HEAD ASSE

MB

LV

The

ITC

770 SERIES reproducer is equipped with a

unique, high quality professional head assembly. The

head is mounted in a machined aluminum bracket

designed toprovidesimpleand highlyaccurateazimuth,

height, and zenith adjustments.

Theazimuthpivot

point

islocated

dire

ctlybehind the

center

of

the head in both

1he

vertical and horizontal

plane.

This

fealure permitsazimuthadjustment

without

disturbing the zenith

or

height adjustments, and can be

locked into position after adjustment. The head mount-

ing arrangement permits convenient head replacement

when it is required.

As an aid to head maintenance and tape marking/

editing, the entire head assembly is housed beneath a

hinged, springloaded "

Oip

-

top"

co

ver. Thedesign

of

this

0381

DM

coverallows

it

to

beeasily opened

or

closed andremain

in either position.

C.

ELECTRONICS

The electronics

of

the 770 Series reel-

to

-reel repro•

ducer

providesimplicity andserviceability. Bulky wiring

iseliminatedbythe mother-daughterboardconstruction

with modular cables and connectors.

All assemblies, including motors, brakes, solenoids,

and P.C. boards, plug

in

for easy serviceability and

replacement in the field. All normal maintenanceadjust-

ments

are

accessible from the front panel. The equaliza.

tion and programlevel calibrations are exposed byrem·

oval

of

the switch

dre

ss

panel. Limited range level

controls, designed

to

give an 8dB boost

or

a 4dB cut in

audiolevel, are locatedon the front panel. A headphone

jack is provided

for

program monitoring

pur

poses.

All

electrornc logicis either

J.C.

, transistor,

or

simple

relay type. Active components and relays are socket-

mounted on the printed circuit boards.

O. S

PE

C

IFI

C

AT

I

ONS

I. Power:

105

to 130 volts

AC

,

60

Hz,

160

watts maximum

2. Wind Tim

e:

Less than 60 seconds for

2500

feet

of

tape.

Less than 90 seconds for 3600 feet

of

tape.

3. Motors:

Capstan •

Direct

drive

DC

servo control with

electrolyzed shaft. Reels T

wo

capacitor-start

induction torque motors.

4. Tape Speeds

7-1/2 and

15

1ps

(19

and

38

cm

/sec)

or

3-3

/4 and 7-1/2 ips (9.5 and

19

cm

/sec)

Speedaccuracy±0.2%

or

lessmeasured with

1.5

mil (0.038 mm) tape.

5.

Tape

Width and Trac

ks

:

1/4 inch (6.3 mm) tape, 1.0 mil (0.025 mm)

base

minimum.

Full

Tr

ack • mono

1/2

track -mono

or

stereo

1/ 4 track • stereo

6. Reel Siz.es:

NAB

or

EIA

with

a hub diameter

of

1.

75

inch

(44.45 mm)

or

greater. Maximum reel nange

diameter

of

10.5

inches (266.7 n'lm). Selectable

tape tension for small

or

large reels. Reels

of

dissimilar sizes, i.e. 7inches(177.8mm) and

10

.5

inches(266.7 mm), should not be used together.

7. Flutter (

NAB

We

ighted):

3-3

/4 ips0.10

'½,

or less

7-1/2 ips 0.07%

or

less

15

ips 0.05%

or

less

I,1

www.SteamPoweredRadio.Com

8.

Au

di

o

Output

:

With transformer(s) . . . +24d8 m before clipping

mt

o 600

ohm

load, balanced.

Wi

thout

tr

ansformer(s)

..

. +18d8m before clip-

ping into 600

ohm

load, unbalanced.

9. Di

sto

rtion (Amplifi

er)

:

0.5%

rms total harmonic distortion. maximum

at

t 18dBm

output

level at 1 kHz with output trans-

former(s). +16d8m

wi

thout

output

transformer(s).

10. Signal

-To-Noise

Ratio:

1

-2

52dB measured from a 700

Hz

tone,

recorded

at

185

nWb/m, with reprodu

ce

amplifier adjusted

for

+8dBm output, to tape recorded with bias but

no signal. Measurement

is

unweighted noise with

a bandwidth of 20 to 20,000 H

z.

11

.

Crosstalk

:

55dB or better with a 185nWb/ m 1 kHz tone

on

adjacent track.

12. Equa

li

za

t

io

n:

NAB with high

fr

equency adjustment for 3-3/

4,

7-1/2 end

15

ips. Automatically switched

wi

th

sp

eed

switch

be

tween low

and

high

speed

equal-

izers.

13. Freq

ue

n

cy

R

es

pon

se

:

3-3/4 ips

(+2

dB -3.5dB) 25 to 35 H

z;

±2dB 35

to

8,000 Hz.

7 1/ 2 ips (+2dB -

3d

B) 25

to

35 Hz; ±2d8

35 lo 15,000 Hz.

15 ips (+2d8 -3.SdB)

25

to 35 Hz; ±2dB

35 to 18,000 Hz

14. He

adphon

e

Outpu

t:

24 mV into 8

ohms

(wi

th AT-0001 output trans-

fo

rmer

s)

58

mV

into 8 ohms (without AT-0001 o

utp

ut

transformer

s)

IS. Ambie

nt

Op

erati

ng

Te

mp

eratu

re

:

40

° to 130°F (5° to 55°C)

16

. Re

mot

e

Cont

rol:

Start,

Sto

p, Rewind, Forwa

rd

,Speed Sel

ec

t, Foil

Sense and Mode Indi

ca

tors.

17.

Br

a

kes

:

M

ec

ha

ni

ca

l disc with one-way clutch.

10

-1

/ 2 inch (266.7 mm) rnetal r

ee

ls stop time

adjusta

bl

e from 2-1/ 2 s

ec

o

nd

s

to

10 sec

ond

s.

18.

Exte

rn

al

Con

n

ec

tors:

Latching type Beau Ser

ie

s 3300, mating

pl

ugs

furnished.

19

.

Dim

e

nsions

:

19 in

ches

(48

2.

6

mm

)

wi

de

1-1/4 inch

(31.75 mm) overhang on

ea

ch side wi

th

10

-1/2 inch (266.7 mm) reels.

14

in

ch

es

(355.6 mm) high, 2-1/4

in

c

hes

(57

.

15

mm) overhang on

top

with

10

-1/2

in

ch (266.7 mm) reels.

7-7/8" (197.6 mm)

de

ep, in

cl

uding mating

pl

ugs.

20. Weight:

Unpacked •44 pounds

(19

.96 kg)

E.

WARRANTY

International

Tape

tronics Corporation (ITC) war A

ra

n

ts

to Purchaser thal the equipment sold

1s

free oi W

defectsofworkmanship

or

mate

r

ial

nnd

con

for

ms

tothe

specifications referr

ed

to

or

set

out herein. This war

ranty, applying only to the original user. extends from

date

ofshipment for a periodoftwoyears. No claimshall

be maintained hereunder unless written notice is re-

ceived bySeller within thirty days

afte1

the discovery of

the facts giving rise

to

the

claim. The sole

or

exclusive

liability ofSeller for breachofwarrantyshall beto refund

the

purchase

price of the item sold,

or

al its option, 10

replace

or

repair the item

or

part

conce

rned FOB its

factory,

or

such

other

place

as

ti

may

designate ITC's

liability shall arise only

1f

Purchaser causes the defective

pa

rt

or

item

to

be

delivered to ITC for inspection upon

ITC's request

at

Purchaser's expense. This warranty

shall n

ot

be

effective

if

the alleged defect is

due

to

mal

-

treatment, exposure, excessive moisture

or

any

other

use of

the

equipment other than the use for whi

ch

the

manufacturer prescribed.

No warranties expressed

or

implied shall

be

app

l

ica

-

ble to

any

equipmentsold hereunder, and the foregoing

shall

co

nstitute t

he

Buyer'ssole right and remedy under

theagreementsin this paragraph

co

ntained. In no event

shall International Tapelronics

Co

rporation have any

liability for

co

nsequential damages.

or

f

or

loss, damage,

or

expense

directly

or

indirectly arising from the use of

the

products,

or

any

inability

to

use them either

separ

-

ately

or

in combination

with

other equipment

or

mate-

rials,

or

from any

othe

r

cause.

IT

C's

warranty is given solely

to

the original user and

only

to

the extentabovedescribed. Nodealer

or

agent

is

au

thorized to make any

other

or

addition

al

guaranty

or

warranty.

F.

OP

T

lONS

AND

A

CCE

S

SO

RIE

S

833-0

01

8

-2

00 25 Hz DE

TE

CTO

R

86

4-

0016,000 REMOTE CONTROL FOR

REPRODUC

ER

S

864-00

17-

000 REMOTE C

ONT

R

OL

FOR

RECORDER/ REPRODU

CE

RS

864-0014-

0)0

CONSOLE CABINET

864-0015-000 ADD-

ON

STACKING K

IT

(USE

WITH

CONSOL

E C

AB

INET)

281-0014-012 FILLER PANEL, 1-3/4H

(44

.45 mm)

USE WITH CONSOLE CABI

NET

830-0022

-02

l HEAD & TURNTABLE HEI

GHT

GAUGE

830-0036-

001

DI

SC

BRAKE ADJUSTMENT

GAUGE

831

-007

5-

003

REPR

ODUCER TEST EXTENDER

831-0119-003 RECORDER TEST

EX

T

EN

D

ER

These i

tems

are available for yo

ur

IT

C Model 770

unit. Plea

se

c

all

fo

r

co

mplete infonnation.

03

81

OM

-

www.SteamPoweredRadio.Com

SECTION

II

-

INSTALLATION

A. UNPACKING

AND

HANDLING

Carefully remove

the

ITC 770 Series reel-to-reel

reproducerfrom the shipping

carton

and

inspect the unit

for damage.

All

pa

cking material

mu

st

be

retained

if

a

claim for shipping damageis

to

be

filed.

If

shipping

damage

ls found,

contac

t International

Tapetronicsimmediatelyfor assistancein

filing

a claim.It

is suggested

that

packing material

be

retained for any

further shipment of

the

unit.

B. INSTALLATION

IN

RACK

770

Series

reel-to-reel machines

are

supplied

in

a 19

inch (482.6mm) mounting configuration. Adequate ven-

tilation isessential. Vertical spacingbetween reel-

to

-reel

machines

and

ot

her

equipmentshould

be

from

1-3

/4 inch

(44.45 mm)

to

3-1/2 inc

he

s

(88.9

mm).

The

spacing

depends

on

the

temperatu

re

inside

the

closed rack.

Please refer

to

Fig

ure

2-1

fo

r

deck

size

and

reel over-

hang dimensions.

The reel is in

close

prox

im

ity

to

the

deck

plate.

For

this reason it may

be

necessary, in

some

applications,

to

space

out

the

770 Series

deck

in

the

rack

installation. A

simple inexpensive 1/ 4 inch (6.35 mm)

spacer

can

be

made

byusing a

10

-32

socket

head

screw

and

a l/ 16inch

(1.58 mm)

flat

washer

.

Four

of

these

spacers

may

be

mounted

in

the

rack

panel

ne

ar

the

lo

cation of

the

four

mounting slots.

C. OPTIONAL CONSOLE

HOUSING

The

optional console housing for

the

770 Series is

shippedseparately,

and

requires minor assembly upon

receipt.

After Temoving

the

console from

the

packing mate·

rial, install

the

four c

asters

in

the

bottom

of

the

console

legs.

Set

the

co

nso

le

upright,

and

rotate

the

tr

ansport

deck

table

to

its

ve

rtical position by pressing

the

release

button

located

on

the

front

upper

right

hand

sideof

the

console cabinet. This

will

allow the table

to

rotate

and

lock in various planes. With

the

aid of a

noth

er

person,

ca

refullyslide

the

transport

mechanisminto

the

mount-

ing

area

.

NOTE: When handling

the

tra

nspo

rt

,

be

careful not

to

damage delicate items

su

ch

as

motors

and

brakes,

After the transport is properly located, carefully

rotate

the

table

back

to its horizontal position.

Se

c

ure

the

assembly with

the

enclosed

rack

mounting

screws

and

washers.

Included with the consoleis a 1-3/

4"

(44.45 mm) filler

panel. Thispanelshould

be

mounted

toward

the

top

end

of

the

transport

deck

assemblyin

order

to

fill

the

va

c

ant

space

.

0381 DM

/

10

1/

21

•

RH

LS

/

(266.7m"')R£ElS

-t-

-

--

:;:::,--

!.......

I•

I•

(~5S.60m

m)

l

l/

4 I•

(

82

. 5Smm)

g

~

@

◊

@o

()

~o

@o

oO

0

19

10

--=7

(482

.

60mm)

I

114

1ft

pl

.

7Smml

2.

"32

71•

(S9

. 10

mm

)

6 7181•

(1H

.6 2

Mm

)

L

72

5

/n,

.

(197

.

64

mm)

Fi

g

ur

e 2-1

D. C

ONNECTING

AUDIO

LINES

A six pin unwir

ed

plug is provided with

ea

ch 770

Series

reproducer

. This is

used

to c

onnect

the audio

output.

Refer

to

Figure

2-2

for

proper

connectionof

the

audio lines.

Care

should

be

taken

to

insure

proper

con-

nections of

each

chan

nel

on

stereo

machines. It is

recommended

that

two

conductor

shielded cables be

u

sed

for

outp

ut

connections.

2-1

www.SteamPoweredRadio.Com

TO

Jl02

~

- - - - - - - - - - - - - - - - -

HIGH

5 I \

3 I ' LOW

CHA

,.,Nt

l I

------------

-

---

HIGH

l'-

-'--

-

-------

~

LO

W

------------

-

----

6

PIN

PLUG

Figure 2-2

E.

CONNECTING

REMOTE

CONTROLS

R

emote

contro

l functions

are

provided

through

con

-

nector

Jl0l

for START,

STOP,

REWIND,

FORWARD.

and

associated

lamp

circuits

(24volt,40 ma.).

Ali

switch

-

ing runctions

require

a single pole, normally

open,

momentary

contact

switch.

A IS

conducto

r plug is supplied with

the

machine

for

wiring

th

e

remote

functions. Figure 2-3

shows

a sample

remote

control

schematic.

2-2

..I._

STOP

SW

ITCH

READY

LAMP

7

_I_

START

SWITCH

I I

f--------v

8

13

15

PIN

PLUG

RUN

L.AMP

REWI

ND LA.MP

FAST

_I_

FORWARD

SWIT

CH

FAST

FORWARD

LAMP

Figure

2·3

F. INI

TIAL

CH

ECKS BEFORE OPERATION

Check

all

motors

and

rotating

parts

before

operat

ing

th

e 770

Series

machine.

The

caps

t

an

motor

and

pressure

roller

shou

ld

rotate

freely.

The

two

reelturntablesshould

rotate

wi

th

some

resistance

due

to

the

action

of

the

brakes

beingengaged. Be

certa

in

that

P.C

.

cards,

relays,

and

ribbon

cable

connectors

are

properly

seated.

Insure

that

the

line

frequency

and

voltageare

correct,

117 volts

±10%,

60

Hz.

before plugging in

the

power

cord.

G.

FUNCT

IO

NAL

CH

ECKOUT

1.

Plug

the

unitin

and

turn

the

ON

/

OFF

switch

to

the

ON

position.

Th

e

capstan

motor

should

rotate

clockwise

as

viewed from

th

e front.

2.

Push

REWIND, FORWARD,

STOP

,

and

RUN.

Nothing

should

happen

.

3.

Bl

ock

the

lig

ht

path

m

the

tape

sensor

with

the

reel

size

switch in

the

large

re

el position.

All

operatio

ns

are

to

be

viewed from

the

front of

th

e deck.

a)

Push

FORWARD

(blue) -

Th

e t

ake

-

up

motor

should

run

at

full

speed

counterclockwise.

The

supply

motor

shou

ld

run

slowlyclockwise. B

oth

brake

solenoidsshould activate

and

release

the

brakes.

b) P

ush

REWI

ND

(white) -

Th

e supply

motor

should

run

at

full

speed

clockwise.

Th

e

lake-up

motor

should

run

slowlycounterclockwise. Both

brake

solenoids should activate

and

release t

he

brakes

.

c)

Push

STOP

(yellow) . Reel

motors

should

stop

.

Brake

solenoids

should

deac

tivate

and

apply

the

brakes.

d)

Push

RUN (gr

een)

Pr

essure

roller should

engage. T

ake

-

up

motor

should

turn

counter

-

clockwise. Rewind

motor

should

turn

clockwise

after

th

e

boost

interval. Br

ake

solenoids

should

activate

and

release

the

brakes

.

e)

Fr

om

the

rewind

or

forward modes,

push

STOP.

There

should

be

approximately 1-1/2

se

c

ond

delay

be

f

ore

t

he

run

mode

can

be

en

t

ered

.

NOTE

:

If

motion

sense

has

been

installed,

th

e

run

mode

can

be

entered

at

any

timefrom a

fast

mode.

0381

OM

www.SteamPoweredRadio.Com

SECTION

III

. OPERATING INSTRUCTIONS

A. T

HR

EADING THETAPE

The

ITC 770 Series reel-to-reel

reprodu

ce

r is

de

-

signed toallow

tape

threadingwithout opening

or

closing

any

doors

or

interferring

components.

Please refer

to

Figure 3-1 for a diagram of

the

tape

loading

path

. If

the

tape has

been

lo

aded

correc

tly

the

ready

indicator LED

on

the

front panel

will

illuminate.

Figure 3-1

0

l•P!

!HO

WH

t.0•0f'O ~RO•tRLI

G)

0 ° 0 0

I

B. C

ONTRO

LS

AND

INDICATORS

Refer

to

Figure 3-2 for a front view of

the

reproducer.

All

of

the

variousswitching functions

are

shown.

1.

The

ST

ART SWITCH ·

The

start

switch

will

not

function

if

t

he

tape

has

not

been

l

oaded

properly,

i.e.

across

the

tape

sensing LED

photo

-transistor

located to

the

left

of

the

magnetic

heads

.

Activating

the

ST

ART

SWITCH

pu

ts

the

trans

-

port

in

the

run

mode

at

the

selected speed. When

the

start

switchis pressed,

full

torque

is momentar-

ily

applied

to

the forward reel motor causing

the

tape

to

moveinstantly.

The

durationof this

"torque

boost"

may

be

adjusted

at

the

r

ea

r of

the

machine.

See

Figure 3-3.

Normally,

the

start

switch

ca

nnot

be

activated

when

the

machine is

in

the

fast forward

or

rewind

mode

of operation. An optional motion

se

n

se

cir-

cuitry isavailable

to

allowfor this typeofswitching.

A built-in

start

mode

delaycircuitpreventsentering

the

start

mode

for approximately

one

se

c

ond

after

coming

out

of

the

f

ast

forward

or

fast rewind

mode

of operation.

D 0

ll

MITtl> R•NGE ·

•Eve,

<XlNTROl.S

I

SCRE'NS(4)

CUE

lE\/

CA

-

M

A.

NUAt.. 1A.PE

Llflt~

OE<Ul

/

S10

P

Sl

,ART

sw,,c..

s

w

rrc

i

◄

\

'

LLO

TAPE

LOAO(O ,.

o,e•

1()11

0381

OM

0£MO\/

L

tO~

ACCESS

tO

ELECT~ONIC

AOJUS"l'ME•

IS

_/

SHEO

HfGH/1-QW

I

Figure

3·2

f~)t

rO"l,.RI)

~WIT(;H

www.SteamPoweredRadio.Com

2.

The

STOP

SWITCH

can

be

activated

whene

ver

tape

is

loaded

on

the

machines.

Stop

will

terminate

all

other

operating

modes

of

the

machine

.

3.

Th

e FAST REWIND

and

FAST FORWARD

modes

may

be

ente

red

from

any

other

operating

mode

except

when

a

stop

signal is

present.

P~CSS\Hll

AO

LLtA

$0ll

M

OIO

LI

JtOWEft

--......-r

ffll.tNsrou,tft

Figure 3-3

n D

M

OTION

St~st

to,t10•

•

\.

>

4.

The

REELSIZE

SWITCH

is

used

to

select

the

tape

tension

for

different size reel

hubs.

When

using

the

4-1/ 2 inch (114.3

mm)

NAB

hub

the

switch

must

be

in

the

largereelposition.

When

using

the

2-1/ 2inch

(63.5mm)EIA

hub

the switchshould

bein

the

small

reel position.

For

best

tape

handling. intermixing

of

different reel sizes is

not

recomm

ended.

H

two

different

size

reel

hubs

have

to

be

used

simultaneously,

the

following

procedures

should

be

used

to

minimize

tape

handling

damage

:

•

To

stop

ou1

of

either

fast wind

mode

activate

the

opposite

fast wind

mode

switch

until

the

tape

motion

has

ceas

ed,

and

then activate rhe

stop

switch

immediately

lo

set

the

me

chanical

brakes.

5.

The

POWER

switch either appli

es

or

remove

s

power

to

th

e machine. A

6.

The

SPEED

swi1

ch

con

trols the

speed

of

the

cap

• W

st

an

motor

and

provides

any

necessary

equaliza

tion switching, High

and

Low positions

are

pro

v1ded for 3-

3/4

-7-1/2 JPS,

or

7-1/2

15

JP

S

operation.

7.

The

CUE

LEVER provides a

means

for manual

control

of

the

tap

e lifters. N

or

mally,

the

tape

lifters

are

engaged

in

the

stop

mode

and

the

high

speed

mode

. Pushing

the

cue

le

ver

upward in

these

modes

disengages

the

tape

lifters

and

permits

tape

cueing.

Pushing

the

cue

lever

downward re-en-

gages

the

tape

lifters. Entering

the

start

mode

alwaysdisengages

the

tape

lifters

and

returns

them

to

the

automatic

mode

of

operation

.

8.

A

red

LED indi

ca

tor

is found

on

the

l

ower

right-

hand

corner

of

the

770Series.

It

is a visual md1cator

that

the

tape

1s

loaded properly

and

that

a

stop

command

is not

present.

9. Limited

range

fr

o

nt

panel level

co

ntrols

may

be

used

to

vary

the

program

output

levelaproximately

+8

or

-

4d8

from

the

calibrated (vertical) position.

0381

DM

www.SteamPoweredRadio.Com

SECTION

IV

.

SETUP,

ALIGNMENT,

AND

CALIBRATION

A.

MECHAN

I

CAL

ADJUSTMENT-TRANSPORT

1. REEL

MOTORS

TORQUE

ADJUSTMENT

Reel

motor

torque

in

the

770 may

be

measured

by

usinga small spring

scale

ca

pableofmeasuring

up

to

one

pound

or

250

grams

.

Use

an

empty r (177.8 mm)reel

with 2

¼H

(57.15mm)

hub

,

and

tightly tiea 4 foot (121.92

cm) section of twine

around

the

cente

r

hub

of the reel.

Loop several

turns

of twine

around

the

reel

hub

and

con

ne

ct

the

free

end

of

the

twine

to

your spring

scale

.

See

Figure 4-

1.

It

should

be

noted

that

either

torque

motor

may

be

used for

se

tting

the

proper

tension.

These

motors

a

re

con

nected

in

series during

the

run

mode

of operation.

Therefore, their torques

will

be

essentially

the

same.

Power resistors

used

to adjust

torque

settings

on

the

770Series are accessible by removing the stainlesssteel

cover located directly

on

top of

the

electronics housing

on

the

back

of

the

770

Series

deck.

CAUT

ION: RE-

M

OVE

POWER

CORD

FROM

SOC

KET BEFORE

ADJUSTING RESISTORS.

While the

torques

are

being

measured

,

the

reel motor

not beingused

should

be

heldstationary

and

not

allowed

to

rotate.

If

rotationis permittedt

he

final

torque

setting

will

be

affected,

t,;<:RU5E

TORO\IE

Rf28

S

MA

LL A

ElL

T

AP

E

ADJUST

* MOTOR

REEL

SIZE

SWITCH

L

ARGE

SMALL

LARGE

RI

H ~ 1

30

LARGE REEL _ HOL O U CK

/

TAPE

ADJ/

TOROU(

•o~

usr

I

Figur

e4-2

TORQUE

ADJUST

ADJUSTING

TORQUE

RESISTOR

SET

TING

Rl34

6

.0

oz

. - I

70

g

R 12 8

3.0

oz. -

85

g

R

13

0 1.

0oz

. -

28g

To

adjust the reel

motors

torque

properly, first adjust

the

largereel

torque

with

the

reel sizeswitch, S105in

the

large reel position.

Once

this adjustment has

been

made

transfer

the

reel size switch, S105,

to

the

small reel

position

and

adjust the smallreel

torque

.

See

Figure4-2.

R

ef

er to Figure 4-3 for

the

proper

torque

settings.

ff

USE

2 1/ 4 "

DIAMETER

RE

EL

HUB

.

0381

OM

HEAVY TWINE

SPRING SCALE'

REWIND TOROUE

MOT

OR

ASSEMBLY

0

7•

REELS

2 114'

OI

AMEl

ER

HUB

/

Figure

4-1

Figure 4-3

HE

AVY

TWINE

SPRING

SC

AL

E~ '

FOR

WA

RD

TOROUE

MOTOR

A

SSE

MBLY

www.SteamPoweredRadio.Com

•

2.

TORQUE

BOOST

ADJUSTMENT

The

torqul.:!

boost

time

Is

controlled

by

potentiometer

Rl

19,

and

1s

locdted on the

mother

board. This

pot

en-

tiometeris accessible from the

mar

panel

of

the

electron-

ic::;

housing

on

the

770 Series

deck.

See

Figure 4.4.

AdJUtitmenl

1s

made

with

a nat blade scre

wd

river. First

attach

two

large reels

lo

the mac.hinc

and

thread them

prop<>tly

.

M~ke

cet

ta1n

the reel size switch

1s

in

the large

reel

po:,1tI0I1

Then. fast wmd the tape

until

almost the

entire

lc>ngth

b

on

the

forward

take

up

reel. N

ext.

repeatedly :,tart

and

stop the machine Adjust

Rl

19

\1

otqul"

boos, adJu::.tment)so

thc1t

tape maintains

proper

wr,1p

on

tlw

headand

exhibits

minimum

bounce.Several

adjustments

may

be

necessary

to

obtain

opt

imum

per

form,it1l

,,

.

to'kfi~u•t

"0llt"

~Ot f:HU0

l I

Figure

4-4

3. SUPPLY TENSI

ON

ARM

DAMPING

ADJUSTMENT

4-2

a)

With

aninsulated nat bladescrewdriver,adjust the

supply tension arm airpot (See Figure4-

17)

so that

thetension

arm

exhibitsa s

mooth

,gentlereturn

to

the upward most position. Roughly speaking,

it

should takeapproximatelyone second

for

the

arm

to

return

when pulled

down

to

its

lowermostposi•

tion.

After

pulling the

arm

down.

allow a moment

for

the

airpot

to

stabilize before releasing the ten-

sion arm.

b)

With

almost the entire length

of

tape wrapped

on

the forward take-upreel. repeatedly

start

and

stop

the

machine and observe the

amount

of

tape

"bo

un

ce'' present.

c) Adjust

the

airpot

until

the tapedoes

not

lose con•

tact

with the heads. Please

note

that

the

airpot

has

an effective range

of

approximately one

quarter

of

a

turn

.Therefore,

make

this

adjustmentcautiously

as

a small adjustment change can have major

impact

in

controlling

the

tape

"bounce"

.

4. PRESSURE ROLLER PRESSURE ADJUST-

MENT

Th

isadjustment will normally be re

quir

edonly aher

pressure roller replacemen

t.

but

for

optimtrm azimuth

andphasestability,a

nd

!ap

edriveability, pressureroller

pressure should be checked periodically

a) Attach a strong piece ol twme aro

un

d

tht

rollc-r

shaft and the

other

end

to

aspring

seal<>

capable

of

measuring up

to

10

po

unds (4.536 k

g)

Se<>

Figure

4.5,

SPRING

SCALE

TWINE

PRESSURE

ROLLER

CAPSTAN

Figure 4•5

b)

Blocl~ the

opto

-sensor with a piece

of

non-trans-

parent adhesive tape such

as

masking tape and

place the machine

into

the

RUN

mode. Begin pull-

mgonthesprmgscale handle

in

theopposite direc

tion

the

solenoidispulling

until

the pressure

roller

is disengaged

from

thecapstan.

c)

Theinstant

the

pressurerollerleaves thecapstanis

the

point

at

which themeasurement must

be

taken.

The

pulling

for

ce

at

this pointshould be between 6

and 7 pounds.

d)

If

adjustment isrequired, loosen theclevis

lock

nut

and rotate the solenoid plunger

as

follows: (See

Figure

4-6).

•

To

increase pressure. rotate the plunger

to

penetratedeeperintothesolenoid.

Do

notallow

the plunger

to

"bottom

out''

to

the seat

of

the

solenoid.

•

To

decrease pressure, rotate the plunger

for

less penetration into the solenoid.

NOTE

:

If

the above procedures

do

not

appear

to

work.

back the plunger 7 turns

out

of

the

solenoid andrepeat Step d .

0381

DM

www.SteamPoweredRadio.Com

•

e)

Once

adjustment

is

co

rr

ect,

retighten

the

clevis

locknut.

5.

SOLENO

ID

A

IR

DAM

PING

It is

desirable

to

have

the

pressure

roller

descend

as

quickly

as

possible

to

help

control

tape

bounce,

and

fa

c

ilit

ate

rapid

starts.

At

the

same

ti

me

,

some

damping

action

must

be

maintained

to

minimize

the

mechanical

noise

level

of

the

pressure

roller

assembly.

Th

e

pressure

roller

damping

is

adjusted

by

means

of

an

air

release

valve

on

the

r

ear

of

the

pressure

roller/

tape

lifter solenoid, F

igure

4-

6.

To

make

this

adjustme

nt

,

repeatedly

start

and

stop

the

ma

chine

while

rotating

the

air

r

elease

valve

counterclockwise

until

the

pressure

ro

ller

asse

mbly

begins

to

make

a

"s

l

apping"

noise

.

At

that

point, slowly

rotate

the

valve

clockwise

until

the

"slapping"

noise

disappears

.

Leave

the

solenoid

air

release

valve

at

this

setting

.

Fig

u

..-e

4-6

SMOfH

lf•D

Figure

4-7

0381

DM

•1H

OA

MP

AO,IU

l,llNG

SC~£

#

PFl'tSSUR( R:0'-LE,.

'4sfi,<>,o

OAcVOl

""41

~u,

11\.A1 Oft O

IU

H

t'I

Al

S S'Ufllf

~Ct

/ o•

n"

.,.._

••,

ocew

At

this

point

verify

the

Torque

Boost

Adjustment

,

"Item

IV

-2"

and

,

if

necessary,

fine-tune

the

Supply

Ten-

sion

Arm

Damping

Adjustment

"

Item

JV

-3.

''

Proper

operation

can

be

verified

by

repeatedly

stopping

and

starting

the

ma

c

hine

with varying

amounts

of

tape

loaded

on

the

forward

take

-

up

reel.

6. REEL T

URNTABLE

HEI

GHT

Reel

turntable

heights

should

rarely

require

adjust

-

ment.

H

owever,

adjustments

will

be

required

when

torque

motor

maintenance

is

performed

,

and

other

parts

have

been

replaced

or

adjus

t

ed.

Turntable

height

ad

-

justment

may

also

be

required

to

adjust

the

ma

c

hines'

ability

to

wind

tape

in

the

center

of

the

reel

during

normal

run

modes.

a)

MEASURING TURNTABLE HEIGHTS

Use

the

sho

rt

end

of

lTCgaug

e

830-0022

-

021

to

measure

the

proper

height

of

the

r

eel

turnta

b

le

.

R

efer

to

figure

4-7.

NOTE

:

ITC

gauge

830

-

0022

-0

21

is a

dual

-

purpo

se

fixture,

used

to

measure

head

height

on

one

end

,

and

used

to

measure

the

770

reel

turntable

height

on

the

othe

r

end.

Be

sure

to

use

the

"

short

"

end

of

the

gauge

when

measuring

770 reel