Inverter NN-T591WB User manual

Other Inverter Microwave Oven manuals

Popular Microwave Oven manuals by other brands

Conrad Electronic

Conrad Electronic 2372935 operating instructions

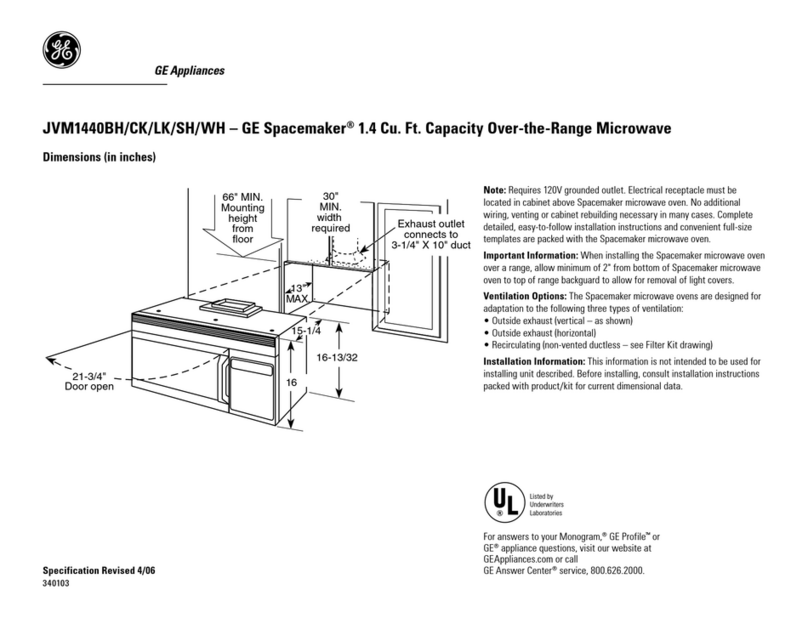

GE

GE Spacemaker JVM1440BH datasheet

DAEWOO ELECTRONICS

DAEWOO ELECTRONICS KOR-6L8K5S83 Operating instructions & cook book

DAEWOO ELECTRONICS

DAEWOO ELECTRONICS KOR-1N5A9S Operating instructions & cook book

Daewoo

Daewoo KQG-6617G Operating instructions & cook book

Samsung

Samsung M1779 Owner's instructions