18-4

18. BF200D • BF225D • BF250D iST®

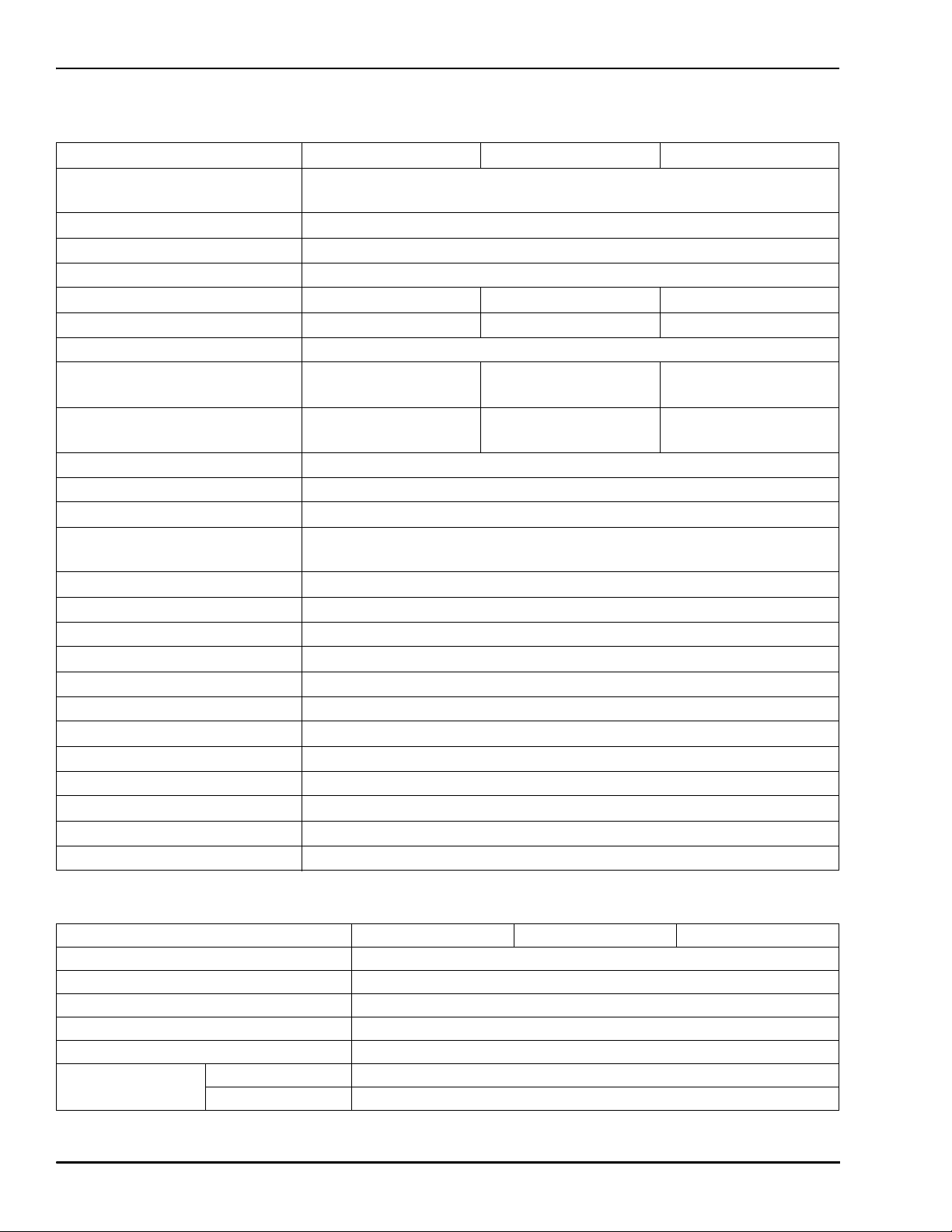

SPECIFICATIONS

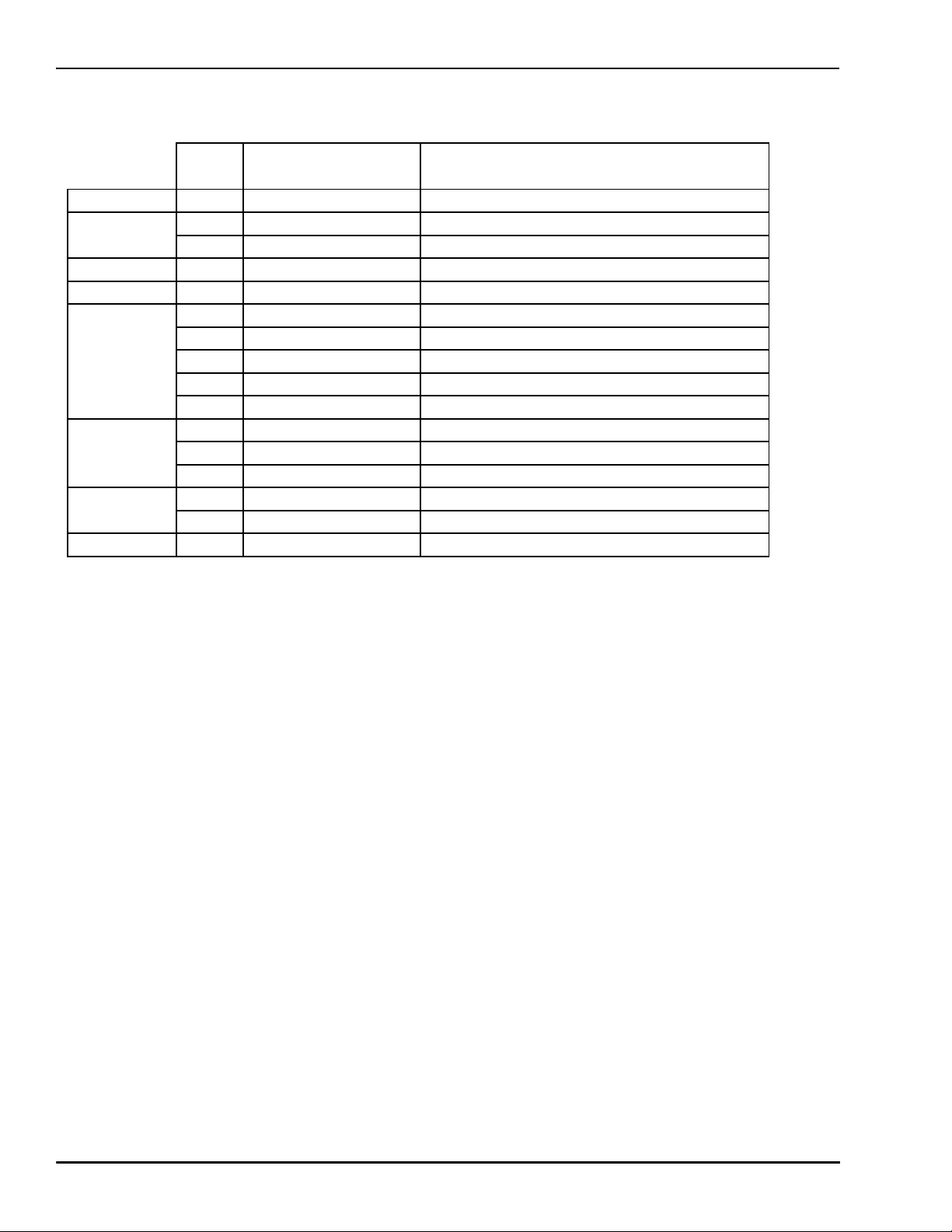

ENGINE

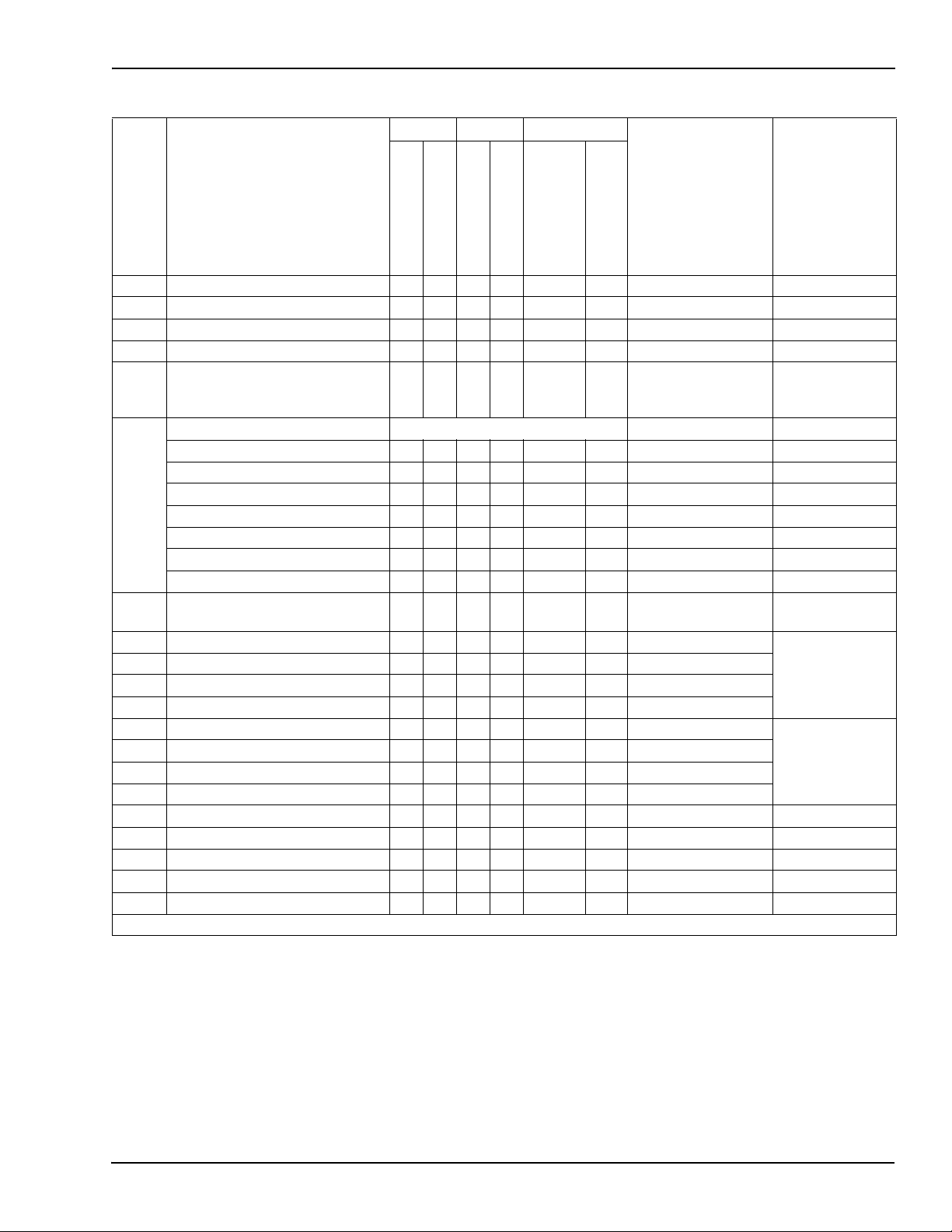

LOWER UNIT

Model BF200D BF225D BF250D

Type Water-cooled, 4-stroke, SOHC,

60° V6, VTEC

Displacement 3,583 cc (218.6 cu in)

Bore x stroke 89 x 96 mm (3.5 x 3.78 in)

Full throttle range 5,000 - 6,000 rpm

Rated horsepower 200 hp @ 5,500 rpm 225 hp @ 5,500 rpm 250 hp @ 5,800 rpm

Maximum torque @ 4,000 rpm 229 lbf-ft 232 lbf-ft 236 lbf-ft

Compression ratio 10.0:1

Fuel consumption ratio

(at rated power) 320 g/kW•h 300 g/kW•h 320 g/kW•h

Fuel consumption ratio

(at continuous max. power) 320 g/kW•h 300 g/kW•h 320 g/kW•h

Cooling system Forced water circulation by impeller pump with thermostat

Ignition system Full-transistorized battery

Ignition timing 0° at 650 rpm BTDC

Spark plug ZFR6K-11E (NGK) - standard

IZFR6F 11 (NGK) - optional

Fuel supply system Programmed fuel injection

Fuel injection system Electronic control

Fuel injection nozzle Multi-point type

Lubrication system Pressure lubrication by trochoid pump

Oil capacity 8.8 L (9.3 qt)

Recommended oil Honda Marine genuine engine oil SAE 10W-30, FC-W™

Starter system Electric starter

Battery system 1040 MCA (800 CCA, 110 AH) minimum (engine only)

Stopping system Primary circuit ground

Fuel used Unleaded gasoline (minimum 86 pump octane)

Fuel pump Electromagnetic type

Exhaust system Underwater type

Model BF200D BF225D BF250D

Clutch Dog clutch (forward-neutral-reverse)

Gear ratio 2.00:1 (24/12)

Reduction type Spiral bevel gear

Gear case oil capacity 1.47 L (1.55 qt)

Recommended gear case oil Marine SAE 90, API service designation GL4

Propeller rotation

(viewed from rear)

Clockwise LDA, UDA, XDA, types

Counterclockwise UCDA, XCDA types