TABLE OF CONTENTS

600B SERIES MAINTENANCE MANUAL

TABLE OF CONTENTS JULY 2016 - V1.0

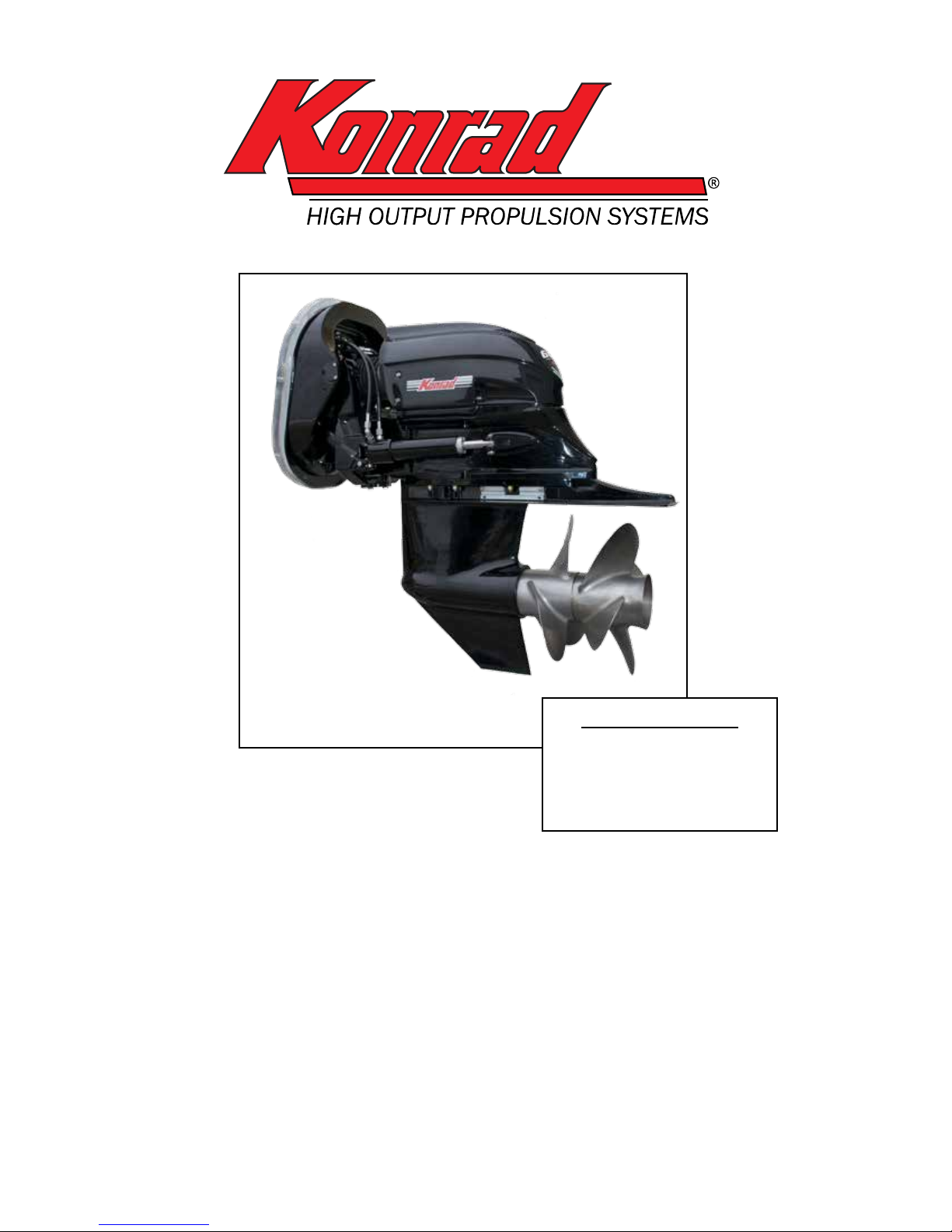

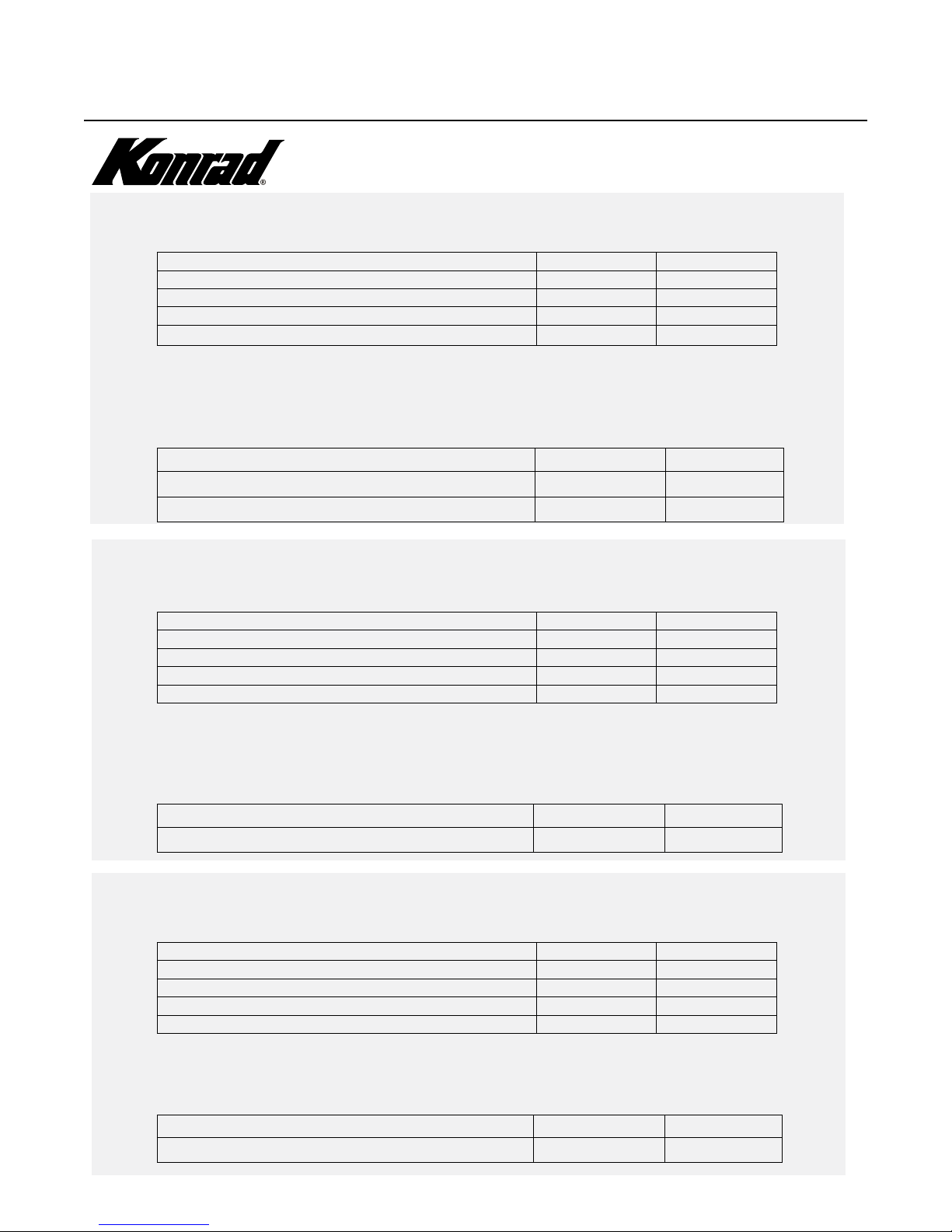

1 - KONRAD 600B SERIES STERNDRIVES

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Break-In Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specications for Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sterndrive Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specied Gear Oil and Lubricants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sterndrive Removal

A. 620B/680B all dates and 660B build dates January 26, 2016 or after. . . . . . . .

B. 660B build dates before January 26, 2016. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sterndrive Installation

C. 620B/680B all dates and 660B build dates January 26, 2016 or after. . . . . . . .

D. 660B build dates before January 26, 2016 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 - KONRAD 600B SERIES GENERAL MAINTENANCE

Sterndrive Gear Lube

Filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Fluids

Trim/Lift Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller and Hardware

Model 620B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 660B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1

2

2

3

4

5

6

7

11

9

14

18

19

20

21

22

23

23

23

24

25

25

25