5/3/2019 3

Glossary

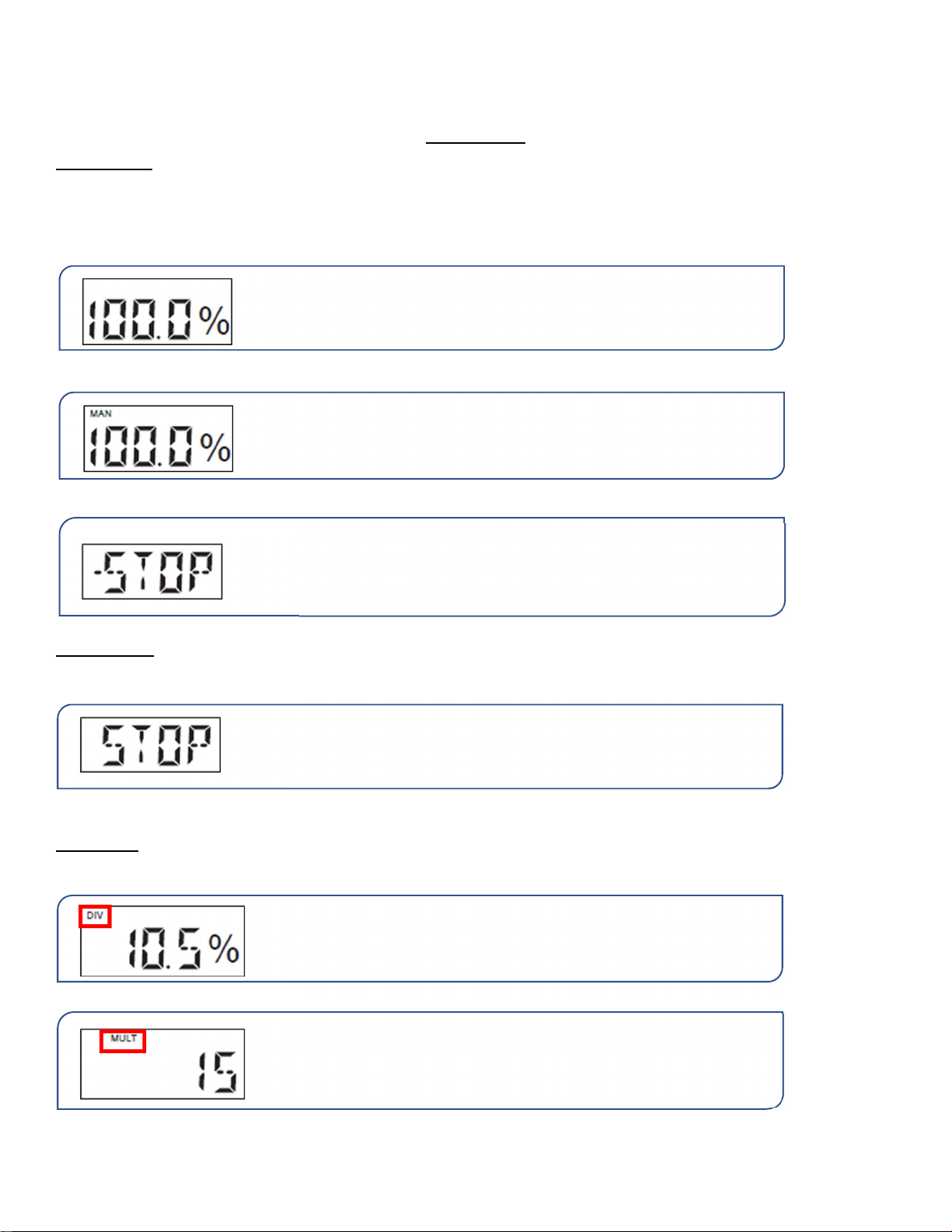

WAIT MODE – the state where the chemical pump will not inject chemical.

While in this MODE, other MODES can be navigated to and settings can be changed.

When the pump is in WAIT MODE, the ON LED will light ORANGE.

.

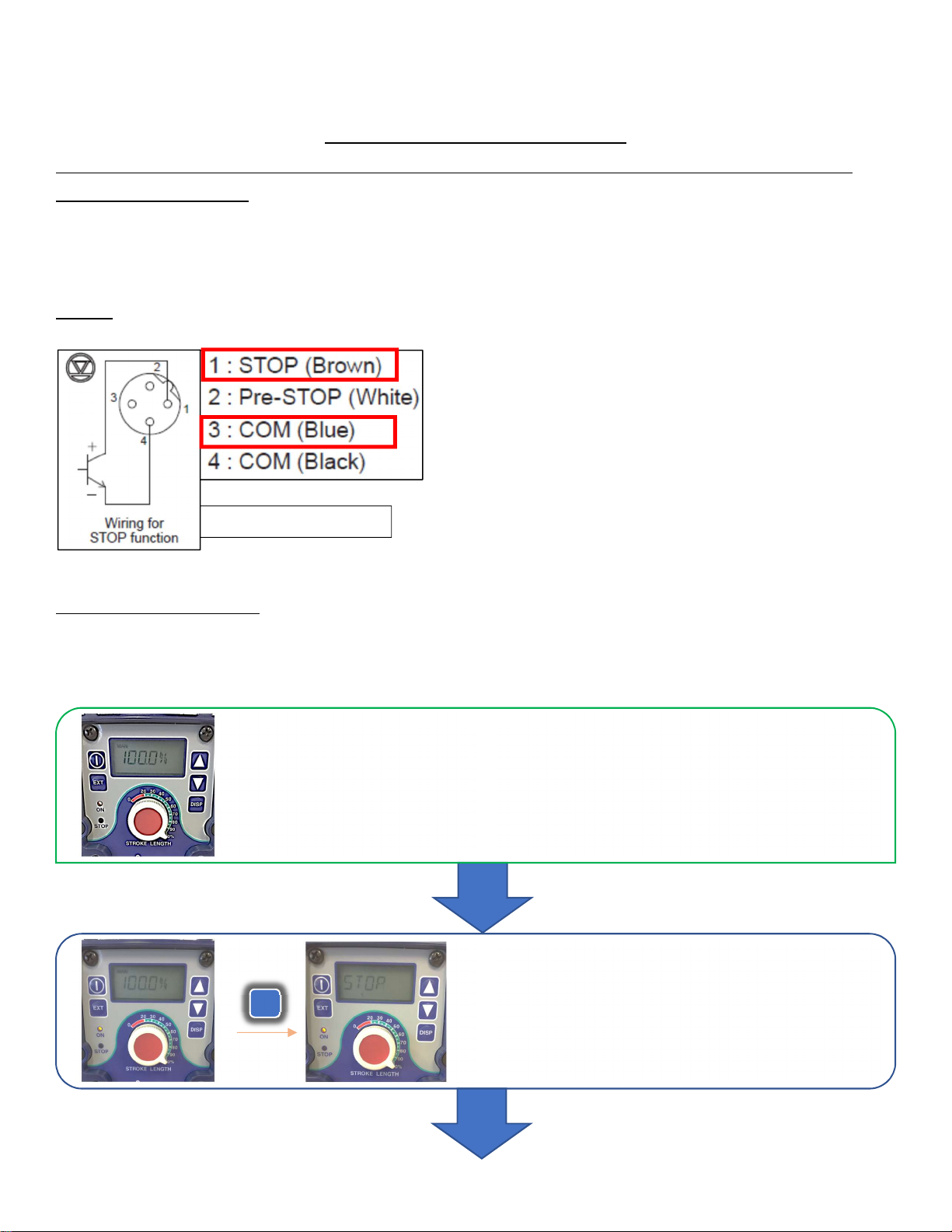

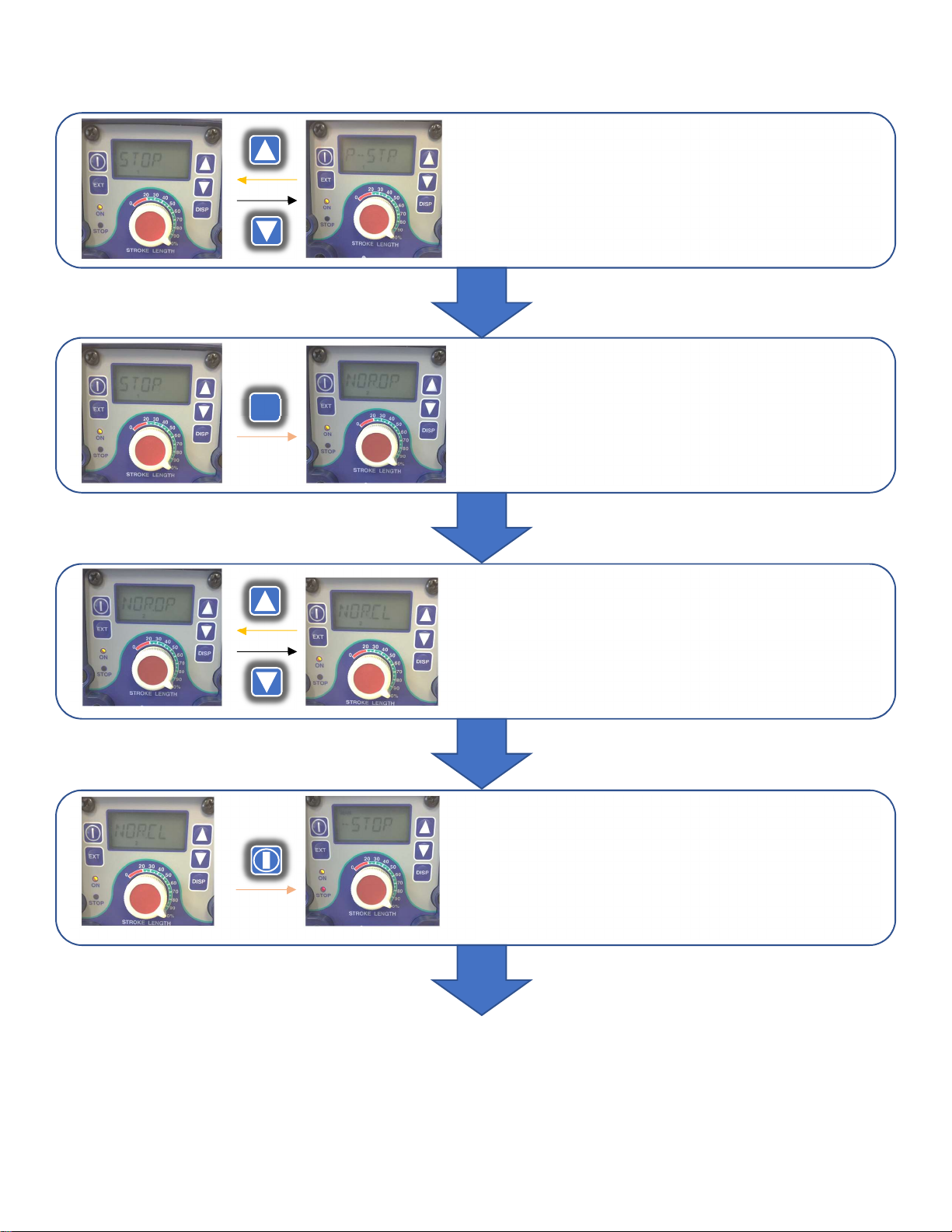

START/STOP – the chemical pump will Start or Stop after receiving a signal based on if the pump is set to be NO

(normally open) or NC (normally closed).

EXT MODE – the mode where the pump injects based off of an external signal. For Miura, this mode receives the pulse

signals from the CPI-MI or WP2.

If the pump is set to EXT MULT, a [MULT] will show on the display.

The value on the display will depend on the set multiplier value.

The EWN-Y pump in WAIT MODE; the ON LED is ORANGE.

*100% is an example

While wired/set to START/STOP,

this will be displayed while the

pump is in WAIT MODE and is stopped. The ON LED will be Orange.

*It could be stopped due to receiving a signal or from not receiving

a signal, depending on if the pump is set to NO or NC.

The EWN-R pump in WAIT MODE; the ON LED is ORANGE.

*100% is an example

STOP is displayed when the pump has stopped, either by lack of

signal or due to a signal being received.

If the pump is set to EXT DIV, a [DIV] will show on the display. The

value on the display depends on the set dividing value.