GENERAL INFORMATION

To ensure safe and reliable operation, please carefully read this service and installation manual in its entirety before

installing and / or using this product. Reasonable care and safe methods in according with sound plumbing practices

should be strictly adhered to. Before installation, refer to and understand all relevant local plumbing and electrical codes.

DO NOT THROW AWAY THIS MANUAL. Keep it in a safe place so that you may refer to it for periodic service and

maintenance.

Always disconnect the power before servicing this product. Failure to do so may result in

serious injury or death. Consult with a qualied electrician if you are unsure of the power

source or cannot determine whether power has been properly disconnected

• Risk of electric Shock. Always disconnect power before servicing the pump.

• Electrical Connections and wiring for a pump installation should only be made by qualied personnel.

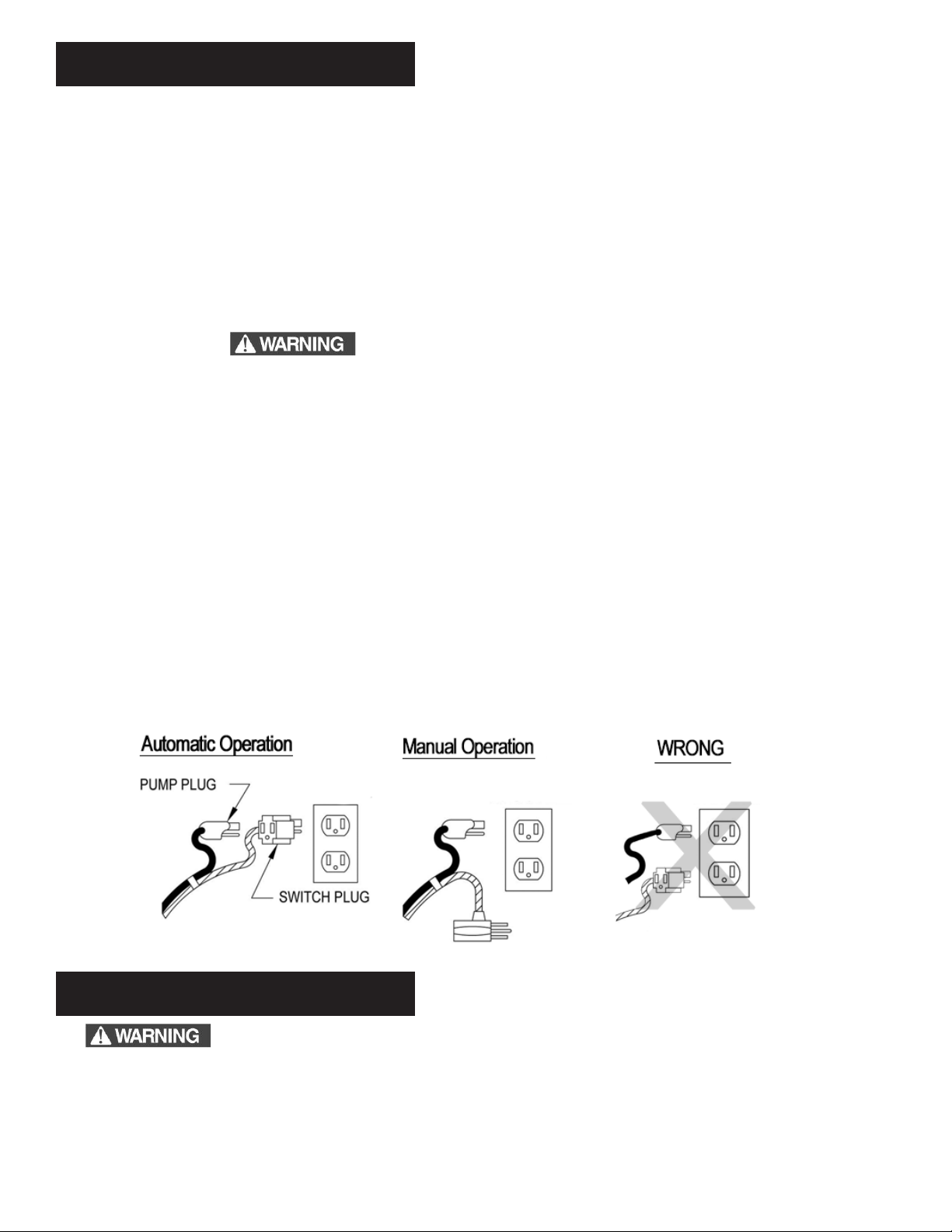

• This equipment is only for use on 115 volt and is equipped with an approved 3-conductor cord and 3-prong,

grounding-type plug. To reduce the risk of electric shock, be certain that it is connected to a properly grounded,

grounding type receptacle.

• DO NOT bypass grounding wires or remove the ground prong from the plug.

• DO NOT use an extension cord.

• NEVER plug this pump into an outlet while standing on a wet surface.

• NEVER lift this product by the electrical power cord.

• NEVER attempt to open or service this pump while it is connected to an electrical power supply.

• DO NOT pump gasoline or any ammable liquid with this pump. Explosion, re or serious injury or death may

result from pumping gasoline or any ammable liquid with this product.

• DO NOT pump chemicals or corrosive liquids with this pump

• To reduce risk of electircal shock, fully read and understand the operating and installation instructions

accompanying this pump BEFORE attempting to install or operate this pump.

• Know the pump application, limitations, and potential hazards.

• Release all pressure within system before servicing any component.

• Drain all water from system before servicing.

• Secure discharge line before starting pump. An unsecured discharge line will whip, possibly causing personal

injury and/or property damage.

• Check hoses for weak or worn condition before each use, making certain that all connections are secure.

• Periodically inspect sump, pump and system components.

• Keep free of debris and foreign objects. Perform routine maintenance as required.

• Provide means of pressure relief for pumps whose discharge line can be shut-off or obstructed.

Personal Safety:

• Wear safety glasses at all times when working with pumps.

• Keep work area clean, uncluttered and properly lighted – replace all unused tools and equipment.

• Keep visitors at a safe distance from work area.

• Make workshop child-proof – with padlocks, master switches, and by removing starter keys.

• When wiring an electrically driven pump, follow all electrical and safety codes that apply.

• DO NOT use this pump in water over 150° F

• DO NOT modify the pump in any way.

• DO NOT remove any tags from the pump or the electrical cords. Removal of these tags may void your warranty.

SAFETY INFORMATION